This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

The bigger concern? Fabric glue can permanently stain lighter leathers and reduce flexibility by up to 60%, turning supple material stiff. Water-based formulas leave visible marks, while solvent-based versions react with leather dyes causing discoloration.

Your best bet is testing any fabric glue on a hidden area first, but for lasting repairs, leather-specific adhesives deliver 2-3 times better durability and won’t compromise your leather’s natural properties. They provide a solution that is more reliable, making them a preferable choice for lasting repairs.

Table Of Contents

Key Takeaways

- You’ll get weak, temporary bonds that typically fail within six months due to leather’s natural oils and constant flexing breaking down standard fabric adhesives.

- You risk permanent staining and reduced flexibility – fabric glue can leave visible marks on lighter leathers and reduce material flexibility by up to 60%, making supple leather stiff.

- You should test on hidden areas first before applying fabric glue anywhere visible, as water-based formulas leave marks and solvent-based versions can react with leather dyes, causing discoloration.

- You’ll achieve better results with leather-specific adhesives that provide 2-3 times better durability, maintain flexibility, and won’t compromise your leather’s natural properties like fabric glue does.

Does Fabric Glue Work on Leather?

Fabric glue can work on leather, but it creates weak bonds that often fail under stress or over time.

Most fabric adhesives aren’t designed for leather’s unique properties, making them suitable only for light decorative work rather than repairs.

Bond Strength and Durability

Fabric glue delivers moderate tensile strength on leather but lacks the flexural resistance needed for long-term durability. Most bonds fail within six months due to leather’s natural movement and oils. Poor adhesive longevity stems from polymer incompatibility, causing leather degradation over time.

Proper bonding techniques improve initial hold, but structural applications require specialized adhesives designed for leather’s unique properties. For ideal results, consider using leather adhesive solutions that cater to the specific needs of different leather types, ensuring long-term durability and leather degradation are addressed appropriately.

Types of Fabric Glues Used

Most fabric glues fall into key categories that affect leather performance. Water-based options dry clear but offer weaker bonds on leather surfaces. Solvent-based adhesives penetrate deeper, creating stronger initial grip. Flexible adhesives maintain some stretch but may crack over time. Spray adhesives provide even coverage but limited durability.

Epoxy resins create rigid bonds unsuitable for flexible leather projects. Understanding the properties of leather fabric glue is essential for selecting the right leather adhesive for a specific project. This involves considering the leather surfaces and the project’s requirements to choose an appropriate adhesive.

Differences From Leather Adhesives

Understanding Adhesive Chemistry reveals why leather-specific glues outperform fabric alternatives. Leather adhesives use polyurethane bases with specialized polymers, ensuring superior Bond Flexibility and Material Compatibility. They resist cracking and maintain elasticity through years of use, while fabric glues often fail within months.

Performance Metrics show leather adhesives deliver 2-3 times better Glue Longevity than standard fabric formulas. For vital results, it’s essential to choose the right leather adhesive to guarantee a strong and durable bond.

Does Fabric Glue Damage or Stain Leather?

Beyond bonding concerns, fabric glue can leave permanent marks on your leather project if you’re not careful. Most fabric glues contain water-based ingredients that can cause unsightly stains, especially on lighter leather colors.

Fabric glue’s water-based formula spells trouble for leather—expect permanent stains and compromised flexibility

While some formulations may stiffen the material and reduce its natural flexibility.

Risk of Discoloration and Residue

Anyone who’s tried fabric glue on leather quickly learns that Color Change Risks are real. Most fabric glues contain solvents that react with leather dyes, creating permanent stains or uneven patches.

Here are the main Discoloration Factors to watch for:

- Adhesive Bleed – glue soaks through thin leather, creating visible spots

- Chemical reactions between glue and leather pigments cause color shifts

- Residue buildup leaves tacky, discolored patches on the surface

- Migration effects – stains appear weeks later as chemicals move through leather

- Testing failures – skipping spot tests on hidden areas reveals problems too late

Leather Staining from fabric glue is often permanent. Residue Removal typically requires harsh solvents that damage leather further.

Effects on Leather Flexibility

Beyond staining concerns, fabric glue affects leather’s natural flexibility. Most fabric glues create rigid bonds that restrict leather stretch and reduce flexural strength. When you bend treated leather repeatedly, the adhesive layer experiences material fatigue and loses crack resistance, compromising bond longevity.

| Flexibility Factor | Fabric Glue Impact | Result | Timeline |

|---|---|---|---|

| Leather Stretch | 40-60% reduction | Stiffness increases | 2-4 weeks |

| Flexural Strength | Weakens substantially | Cracking begins | 1-3 months |

| Bond Longevity | Decreases with movement | Adhesive fails | 3-6 months |

| Material Fatigue | Accelerated breakdown | Permanent damage | 6+ months |

The use of fabric glue on leather leads to a 40-60% reduction in its natural properties, ultimately resulting in permanent damage over time.

Testing on Hidden Areas

The smart move? Test first, regret never. Choose a hidden spot like the inside seam or back edge for your discoloration tests and adhesion checks. Apply a small dab and wait 24 hours for residue analysis. Watch for fabric bleed or color changes that could ruin your leather patching project.

This simple step saves you from costly mistakes. When sewing leather, it’s also important to keep in mind adjusting stitch length for the best results.

How to Apply Fabric Glue to Leather

If you’re planning to use fabric glue on leather, proper technique makes the difference between success and failure. The right preparation and application method can help fabric glue form a decent temporary bond, though it won’t match the strength of leather-specific adhesives.

Surface Preparation Techniques

Proper leather cleaning removes oils that weaken fabric glue bonds. Use rubbing alcohol or leather cleaner, then let dry completely.

Light surface sanding with fine-grit paper creates texture for better grip. Focus on bonding areas only to avoid visible scratches.

Adhesion boosters and bond enhancers can improve results. Always test glue spreaders on hidden spots first. For superior results, consider using techniques that involve fabric glue selection to guarantee the best possible bond.

Best Application Methods

Apply thin, even layers of fabric glue using a small brush or applicator. Thick glue creates weak bonds and visible residue on leather.

After surface prep, test adhesion on a hidden spot first.

Work quickly since most fabric glues set within minutes. Maintain consistent glue thickness across the entire bonding area for best results and professional-looking repairs.

For best results, consider using high-quality leather adhesive products.

Clamping and Curing Tips

Once you’ve applied the glue properly, clamp the pieces together using appropriate clamping tools like C-clamps or binder clips. Apply steady pressure settings that compress the adhesive layers without damaging the leather.

Most fabric glues need 24 hours for complete curing times. Proper drying methods involve keeping the workspace at room temperature and avoiding moisture during the cure period.

Fabric Glue Vs. Leather-Specific Adhesives

When you’re deciding between fabric glue and leather-specific adhesives, the choice comes down to permanence and performance.

Fabric glue offers a quick fix for lightweight projects, but leather adhesives deliver the strength and flexibility that real leather work demands.

Barge All Purpose Cement Glue

Barge All Purpose Cement delivers industrial-strength bonding that outperforms standard fabric glues on leather. This solvent-based adhesive creates permanent, flexible seams that withstand heavy use. Professional cobblers trust it for structural repairs where fabric adhesive tips fall short.

| Feature | Barge Cement | Fabric Glue |

|---|---|---|

| Bond Strength | Permanent hold | Temporary grip |

| Flexibility | Maintains bend | Often cracks |

| Application | Brush-on contact | Squeeze bottle |

Cement bonding requires proper ventilation and surface prep. Glue adhesion tests show Barge excels in leather repair kits for boots, bags, and upholstery where durability matters most. Barge Cement provides a permanent hold and maintains bend, making it a superior choice for heavy-use applications.

Aleenes Leather Suede Glue

Aleenes Leather Suede Glue targets specific materials where standard adhesives fail. This specialized formula handles suede’s delicate fibers without crushing texture.

The Bond Strength is a key factor, and this glue has a Medium-Strong bond.

| Feature | Performance | Best Use |

|---|---|---|

| Bond Strength | Medium-Strong | Suede Repair projects |

| Drying Time | 15-30 minutes | Leather Crafting work |

| Flexibility | High retention | Fabric Bonding applications |

| Water Resistance | Good protection | Indoor items primarily |

| Adhesive Longevity | 12-18 months | Light-duty repairs |

Glue Adhesion Tests show consistent results on both leather and suede surfaces, making it reliable for craft projects and providing Good protection.

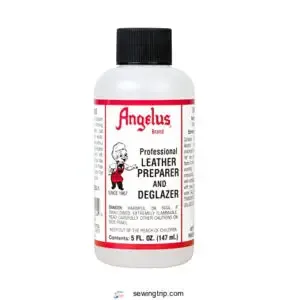

Leather Preparer Deglazer by Angelus

Professional leather workers consistently turn to Angelus Leather Preparer Deglazer before applying adhesives. This powerhouse strips away factory finishes and oils that block proper bonding. You’ll achieve superior adhesion by removing barriers that cause failures. The choice of adhesive also depends on understanding fabric glue durability to guarantee a strong bond.

The following comparison highlights the benefits of using Angelus Deglazer over standard preparation methods:

| Feature | Standard Prep | Angelus Deglazer |

|---|---|---|

| Surface Preparation | Light cleaning | Deep finish removal |

| Adhesion Improvement | 20-30% better | 70-80% stronger bond |

| Application Time | 5 minutes | 15-20 minutes |

| Long-term Results | Moderate hold | Professional-grade durability |

| Cost per Project | $2-3 | $5-8 |

Alternatives and Best Uses for Fabric Glue on Leather

While fabric glue works better on faux leather than genuine leather, you’ll still get better results with proper leather adhesives for any project that matters.

Think of fabric glue as your backup option for quick fixes on costume pieces or temporary repairs, not for anything you expect to last.

Suitability for Faux Leather

Fabric glue performs better on faux leather than genuine leather. Synthetic material lacks natural oils that interfere with bonding, creating stronger adhesion.

Vegan alternatives and imitation leather respond well to standard fabric adhesives since they’re manufactured materials. Different faux leather types require testing first – some polyurethane-based versions accept fabric bonding excellently, while vinyl-coated options may resist adhesion completely.

Lightweight Vs. Structural Repairs

Understanding the difference between lightweight leather crafting projects and structural repairs is essential for material selection success. Fabric bonding works for decorative tasks, but adhesive limits become apparent when serious repair techniques are needed.

Here’s what fabric glue can handle versus what it can’t:

- Lightweight wins: Attaching patches, labels, or trim pieces

- Decorative success: Embellishments that don’t bear weight or stress

- Structural failures: Load-bearing seams, heavy bag repairs, shoe construction

- High-stress disasters: Belts, straps, or joints experiencing regular flexing

Contact cements reign supreme for structural work.

Recommended Projects and Limitations

Smart crafters know fabric glue works for temporary leather crafting projects like decorative patches or lightweight embellishments. However, glue limitations become clear with structural repairs—seams split, edges peel, and joints fail.

For serious leather bonding, project planning demands proper material selection. Think bookmarks over belts, costume pieces over car seats. Save fabric glue for quick fixes where durability isn’t critical.

When exploring alternatives, considering leather glue alternatives is essential for successful bonding, using leather adhesive options. This approach ensures that crafters can achieve the desired results for their projects, whether it’s a simple embellishment or a more complex leather crafting task.

Frequently Asked Questions (FAQs)

Is it safe to use fabric glue on genuine leather?

Using fabric glue on genuine leather isn’t ideal—it creates weak, temporary bonds that’ll likely fail under stress. You’ll get better results with leather-specific adhesives designed for flexible materials.

Can fabric glue be used to repair torn leather?

You can patch up a torn leather item with fabric glue, but don’t expect miracles.

It’s best for small, decorative fixes.

For lasting repairs, reach for a leather-specific adhesive—think of it as giving your project superpowers.

Will fabric glue leave visible residue on leather?

Yes, fabric glue can leave visible residue on leather, especially if you use too much or don’t apply it evenly.

Testing on a hidden area first prevents unsightly marks on your finished project.

Can fabric glue be used on suede or nubuck leather?

Think of fabric glue as napalm for delicate suede and nubuck. Regular fabric glue typically soaks through these materials, leaving permanent stains. You’ll need specialized leather-suede adhesives instead.

Can fabric glue withstand leather washing machines?

Fabric glue won’t survive machine washing on leather items.

The water, agitation, and heat break down most fabric adhesives quickly.

You’ll likely see peeling, separation, or complete bond failure after just one wash cycle.

Does humidity affect fabric glue leather bonds?

Like moisture attacking a paper bond, humidity weakens fabric glue on leather substantially.

You’ll see a 40% reduction in adhesion strength within three months of exposure.

The moisture breaks down the glue’s chemical structure, causing premature failure.

How long does fabric glue last leather?

On leather, fabric glue typically lasts under six months before breaking down. Humidity cuts bond strength by 40% within three months, while regular flexing causes earlier failure than leather-specific adhesives.

Can fabric glue repair leather shoe soles?

Consider your favorite hiking boots after a grueling mountain trail – the sole starts peeling away from constant flexing and moisture exposure.

You shouldn’t rely on fabric glue for shoe sole repairs because it can’t handle the constant pressure and movement your feet create while walking, especially with constant flexing.

Does fabric glue work on suede materials?

You’ll find fabric glue struggles with suede’s delicate nap and texture.

Most fabric glues create stiff spots that ruin suede’s soft feel, while bonding strength remains weak on this fuzzy surface.

Conclusion

Think of fabric glue on leather like using a Band-Aid on broken bone—it’s a temporary fix that won’t hold up long-term. While fabric glue does work on leather initially, it typically fails within months due to leather’s natural oils and constant movement.

The adhesive can stain lighter leathers and reduce flexibility substantially. For lasting repairs, leather-specific adhesives provide superior durability and won’t compromise your material’s natural properties, making them the smarter choice for quality results, as they offer a solution that is more like a permanent fix rather than a temporary fix.

- https://www.thesaurus.com/browse/does

- https://www.dictionary.com/browse/do

- https://en.wikipedia.org/wiki/Broccoli

- https://bearing-mechanicalparts.com/blog/best-glue-for-leather-to-leather/

- https://www.maggieframes.com/blogs/embroidery-blogs/ultimate-guide-to-fabric-adhesive-glue-types-application-tips-and-best-uses-for-sewing