This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your first swimsuit will teach you everything the fabric guides don’t. That perfect tropical print loses its snap after three pool sessions. The buttery-soft blend that felt luxurious in your hands puckers at every seam. The “four-way stretch” that promised to move with you sags in all the wrong places by mid-swim.

Fabric selection for sewing swimwear isn’t about choosing what looks pretty on the bolt—it’s about understanding how spandex content, fiber composition, and recovery rates determine whether your handmade suit stays sleek or becomes a saggy disaster.

The difference between a swimsuit that performs and one that fails comes down to knowing which technical specifications actually matter when fabric meets chlorine, salt, and constant stretch.

Table Of Contents

- Key Takeaways

- Key Qualities of Swimwear Fabrics

- Top Fabric Types for Sewing Swimwear

- Choosing Fabric Based on Swimwear Purpose

- Understanding Fabric Weight and Thickness

- Tips for Sewing Stretch Swimwear Fabrics

- Where to Buy Quality Swimwear Fabrics

- Caring for Swimwear Fabrics

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Spandex content and fiber composition—not aesthetics—decide whether your handmade suit holds its shape or sags by mid-swim, so prioritize recovery rate and chlorine resistance above everything else.

- Polyester-spandex blends outlast nylon in chlorinated pools, while nylon-spandex wins on softness and comfort, making your end use the real deciding factor.

- The right sewing tools—stretch needles, zigzag stitches, and a serger—are non-negotiable; wrong technique on stretch fabric ruins seams no matter how good the material is.

- Rinse in cold water immediately after every swim, skip the dryer, and store in a cool dark place—because even the best fabric breaks down fast without proper care.

Key Qualities of Swimwear Fabrics

Not all fabrics can handle the unique demands of swimwear. You need materials that won’t sag after a few laps, fade in the sun, or turn into a soggy mess.

Let’s break down the essential qualities your swim fabric must have to perform when it counts.

Understanding fabric types and their unique properties will help you choose a swimwear material that balances stretch, durability, and quick-drying performance.

Stretch and Recovery

Fabric elasticity is your secret weapon against the dreaded swimsuit sag. When you’re picking materials, focus on recovery rates—spandex blends bounce back to their original shape in 5 to 10 seconds. Test your stretch swimwear fabric by pulling it. Real 4way stretch gives you freedom without the bag.

Choose spandex blends that recover their shape in 5 to 10 seconds—real four-way stretch prevents swimsuit sag and gives you freedom of movement

- Higher spandex content accelerates fiber memory in critical zones

- Stretch gradients across panels support movement while preserving fit

- Use a stretch needle during sewing techniques for stretchy fabrics to prevent damage

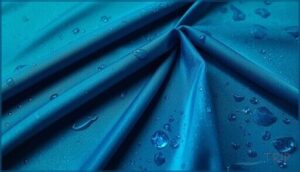

Chlorine and Salt Resistance

Pool exposure breaks down fabrics fast—chlorine and salt don’t play nice with cheap materials. That’s where chlorine-resistant formulations shine. Polyester-spandex blends hold their shape after 1,000 hours of simulated pool testing, while nylon needs stabilized polymers to fight hydrolysis.

Fabric finishes with hydrophobic coatings create a barrier against chemical damage and salt buildup.

| Fabric Type | Chlorine Resistance | Salt Damage Risk |

|---|---|---|

| Polyester-Spandex | High (Rating 4-5) | Low |

| Nylon-Spandex | Moderate to High | Moderate |

| Standard Nylon | Low to Moderate | High |

| Coated Blends | Very High | Very Low |

Chemical resistance relies on tight molecular structures that block ion diffusion. Swimwear fabric selection should prioritize fabrics with ceramic or fluorinated finishes—they slow chlorine penetration and minimize mineral deposits. For fabric selection for swimwear that lasts, look for ratings above 4 on colorfastness scales.

Chlorine testing separates weekend suits from competition gear. Learn more about the importance of rigorous fabric safety testing when choosing swimwear materials.

UV Protection and Colorfastness

Sun exposure demands fabrics that won’t quit on you—UV blocking and color fading resistance separate weekend suits from serious gear. Fabrics with UPF 40+ ratings shield your skin 40 times better than bare exposure, while chemical UV absorbers maintain color integrity through hundreds of sessions.

Smart swimwear fabric selection balances UV 50 protection with chlorine resistant treatments:

- Polyester fabrics maintain vibrant colors under relentless sun exposure

- Dark colors absorb more UV light than pastels for enhanced sun protection

- UV stabilizers prevent spandex degradation and preserve fabric treatment longevity

Quick Drying and Comfort

You want swimwear that sheds water fast and keeps you comfortable poolside. Moisture-wicking polyester spandex blends pull dampness away from your skin for fast evaporation—microfiber varieties dry within 5 to 15 minutes after immersion.

Breathable fabrics with soft texture maintain thermal regulation to prevent clamminess, while stretchy fabric properties guarantee quick recovery without cling or sag.

Top Fabric Types for Sewing Swimwear

Choosing the right fabric is where your swimwear vision starts to take shape. The material you pick determines how your suit performs in water, how it feels against your skin, and how long it’ll last.

Let’s break down the main fabric types you’ll work with so you can make the best choice for your project.

If you’re planning to make your own bedding, this step-by-step tutorial on sewing bed sheets walks you through choosing the right fabric weight and construction method.

Nylon-Spandex Blends

When you’re sewing swimwear that won’t quit on you, nylon spandex blends are your go-to fabric. Here’s why this duo dominates swimwear fabric selection:

- Elasticity that bounces back fast – with 25 to 35 percent elastane content (often branded as Lycra), recovery happens in under five seconds

- Abrasion resistance – balanced nylon prevents pilling during active wear

- Excellent hand feel – smooth microfiber weaves reduce skin irritation

- Multi-directional stretch – comfortable motion across warp and weft directions

The outstanding durability and comfort of swimwear are attributed to the fabric’s.

Polyester-Spandex Blends

Polyester spandex blends combine durability and dependable stretch, making them an economical workhorse for athletic swimwear. The fabric composition typically consists of 85 to 90 percent polyester and 10 to 15 percent spandex, ensuring elastic recovery that maintains shape even after repeated wear.

These blend ratios strike a balance between performance and affordability, rendering polyester blends ideal for competition suits and high-elasticity activewear. In such applications, sewing techniques for stretch fabrics demand reliable fabric selection, which polyester spandex blends consistently provide.

Neoprene and Specialty Fabrics

Neoprene types break the mold when you need insulation and structure beyond traditional swimwear fabric. This foam insulation material, often laminated fabrics with nylon facing, delivers 20 to 30 percent stretch while trapping warmth in cold water.

NeopreneScuba variants and specialty textures like ribbed knits add visual punch to athletic pieces, giving you bold fabric selection choices that perform under pressure.

Recycled and Sustainable Options

Recycled fibers like ECONYL and REPREVE are flipping the swimwear game with eco-friendly materials that cut virgin petroleum use by up to 60 percent per yard while matching standard performance.

- Recycled polyester blends maintain stretch and colorfastness through sustainable production with lower carbon footprints

- Regenerated nylon from fishing nets delivers chlorine resistance in a circular economy model

- rPET spandex mixes offer identical recovery at reduced environmental cost

Green manufacturing meets your design vision without compromise.

Choosing Fabric Based on Swimwear Purpose

The fabric you choose should match how you’ll actually use your swimwear. A suit built for racing laps needs different properties than one designed for beach volleyball or poolside lounging.

Let’s break down the key considerations that’ll help you select the right fabric for your specific needs.

Competitive Vs. Recreational Use

Think of your swimsuit fabric choice like picking gear for a specific mission. Competitive swimwear demands high-performance metrics through chlorine-resistant nylon spandex blends that maintain compression during races, while recreational fabric choice for swimwear prioritizes athlete comfort and freedom.

Event specificity drives textile materials selection—race suits need durability under intense training, but casual pieces balance swimwear customization with all-day wearability at the pool.

Support and Coverage Needs

Your body deserves fabric that works as hard as you do. Bust support hinges on strategic nylon spandex placement in cups and side panels—power mesh torso control smooths without restricting movement.

Swimwear linings add coverage options while fit adjustments through multi-panel construction distribute tension evenly.

Swimwear fabrics with targeted elastane content maintain shape after repeated wear, so textile materials choice directly impacts how confidently you move.

Style Preferences: Solid Vs. Printed

Solid colors refine your silhouette and hide chlorine wear less than prints, while patterns let you play with visual appeal through strategic print placement. Color psychology drives mood—dark solids slim, bright prints energize. Your swimwear design should match your vibe:

- Solids minimize pattern matching when sewing

- Prints disguise minor fabric flaws

- Dark tones visually slim the torso

- Bright patterns draw focus strategically

- Sublimation inks resist cracking during fabric care and maintenance

Understanding Fabric Weight and Thickness

Fabric weight and thickness aren’t just technical specs—they directly impact how your swimsuit performs in the water and feels on your body. The right weight depends on what you’re making, from sleek racing suits to supportive swimwear that holds its shape.

Let’s break down the key considerations so you can choose fabric that delivers the performance and comfort you’re after.

Optimal Weight for Performance

Performance swimwear fabrics typically range from 180 to 260 GSM (grams per square meter), balancing power-to-weight demands with endurance efficiency. Heavier fabrics—around 240–260 GSM—offer excellent body composition support and compression, enhancing lean muscle definition. Lighter weights dry faster and reduce drag. Textile science for swimwear shows that ideal fabric characteristics improve weight management without sacrificing durability or stretch recovery.

| Fabric Weight (GSM) | Best For |

|---|---|

| 180–200 | Recreational suits, quick-dry needs |

| 210–230 | Training suits, daily lap swimming |

| 240–260 | Competition, maximum compression |

| 270+ | Specialized athletic performance wear |

Lining Fabric Considerations

Lining Material acts as your swimsuit’s inner layer—the unsung hero that keeps you comfortable from first dive to final lap. The right swim lining fabric transforms a scratchy suit into second-skin luxury.

- Nylon Spandex blends offer exceptional stretch and recovery for active movement

- Lycra content maintains shape while allowing fabric breathability during extended wear

- Smooth surfaces reduce friction and boost comfort factors against skin

- Quality seam finishing prevents irritation at stress points

- Proper fabric care preserves lining integrity through countless swims

Power Mesh for Added Support

When your lining needs backup, power mesh steps in. This lightweight four-way stretch fabric adds support without bulk—think of it as invisible armor for your torso.

Mesh panel construction targets problem zones while the open grid keeps you cool. Pair it with a stretch needle and you’ll get smooth elastic integration.

Power mesh benefits go beyond swimwear fabrics—it’s your secret weapon for contouring comfort.

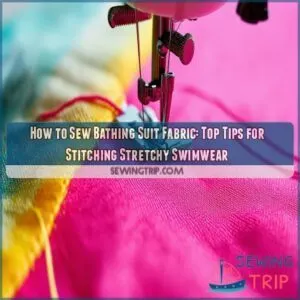

Tips for Sewing Stretch Swimwear Fabrics

Sewing with stretch swimwear fabrics isn’t like working with cotton or denim—these materials fight back if you’re not prepared. You’ll need the right tools and techniques to keep your seams smooth, your fabric from warping, and your finished piece looking professional.

Here’s what you need to know before you fire up that machine.

Needle and Thread Selection

Your needle sizes matter more than you think. Ball point needles or stretch needles in sizes 70-90 glide through spandex without snagging, while polyester thread withstands chlorine and UV exposure better than cotton.

Match your needle size to fabric weight for proper fabric compatibility, and adjust thread tension to prevent puckering.

Test sewing techniques on scraps first—this simple step prevents wasted yardage and perfects your stretch stitches.

Best Stitch Types for Stretch

Ditch regular straight stitches—they’ll snap the first time you take the plunge. A zigzag stitch creates stretch seams that move with four-way stretch fabrics, preventing fabric distortion while maintaining elastic recovery.

Triple straight stretch stitches offer seam reinforcement for high-stress areas, and flatlock stitches lie flat against the skin.

Master these sewing techniques for swimwear that performs as boldly as you do.

Avoiding Puckering and Distortion

Tension management saves your seams from looking like sad, rippled waves. Lower your upper thread tension and watch puckering disappear—balanced tension keeps swimwear fabric lying smooth instead of tunneling.

Master these sewing techniques for swimwear success:

- Fabric handling: Let feed dogs do the work; pulling stretches knit layers unevenly

- Needle selection: Ballpoint needles slide between fibers without creating runs

- Stitch length: Increase to 2.5–3.0 mm on four way stretch to prevent compression

Using a Serger for Professional Seams

A serger transforms swimwear construction from amateur to polished in one pass. Thread four cones of polyester or nylon stretch thread, balance your tension on scrap fabric first, and let the differential feed prevent wavy edges on curves.

Regular serger maintenance—cleaning blade areas and replacing worn cutters—keeps edge finishing crisp.

This overlock method joins seams while finishing raw edges simultaneously, essential for professional swimwear sewing.

Where to Buy Quality Swimwear Fabrics

Finding the right swimwear fabric can feel like a treasure hunt, but knowing where to shop makes all the difference. You’ll want suppliers who stock performance fabrics with proper stretch, recovery, and chlorine resistance—not just pretty prints that fall apart after three pool sessions.

Let’s break down your best options for sourcing quality swim fabrics that’ll hold up to your design vision.

Online Swim Fabric Retailers

Shopping online for swimwear fabric puts you in the driver’s seat with instant fabric availability checks and clear retailer comparisons. Most swim-focused shops like SwimOutlet and Swimsport UK deliver detailed specs on nylon-spandex and polyester blends, plus real-time stock levels.

Here’s what to expect:

- Free shipping thresholds around $50–$75 with tracking

- Return policies for unused yardage in original packaging

- Online reviews highlighting chlorine resistance and sustainable swimwear options

Local and Independent Fabric Stores

Your local independent fabric shop connects you to hands-on staff expertise that no online search can match. You’ll touch swimwear fabric samples, check stretch recovery in real time, and get sewing swimwear advice from clerks who know fiber composition analysis inside out. Many offer custom orders and local workshops where you build sustainable swimwear skills while earning store loyalty perks.

| What You Get | Why It Matters |

|---|---|

| Fabric sampling before purchase | Test chlorine resistance hands-on |

| Staff expertise on blends | Match fiber to your swimwear design tips |

| Custom orders for yardage | No compromise on project needs |

| Local workshops and meetups | Master techniques with community support |

| Store loyalty discounts | Reward repeat business with savings |

Evaluating Fabric Before Purchase

Before you buy, run a physical Fabric Testing session—stretch it to check recovery, hold it up to light for Weave Inspection, and verify Fabric Composition Analysis matches the label. Quality Swimwear fabric snaps back fast and resists puckering.

Compare your Color Matching needs against samples in natural light. Sustainable Fabric and Textured Swimwear Fabric varieties demand closer Texture Analysis since Material Sourcing affects how they handle chlorine and perform under stress.

Caring for Swimwear Fabrics

You’ve invested time and effort into sewing your swimwear, so don’t let poor care undo all that work. The fabrics you choose—whether nylon-spandex, polyester blends, or sustainable options—need specific handling to maintain their stretch, color, and performance.

Here’s how to keep your handmade swimwear looking fresh and fitting right for seasons to come.

Washing and Drying Guidelines

Always rinse your swimwear in cold water immediately after use to flush out chlorine and salt that attack chlorine-resistant fibers.

Hand wash with gentle detergents free of fabric softener—those additives break down water resistance and fabric composition.

Skip the dryer entirely. Use air drying tips: lay flat on a towel or hang from the center, never by straps, keeping swimwear manufacturing quality intact.

Preventing Fading and Loss of Stretch

Beyond washing, protect your color stability with UV resistance tactics: keep suits out of direct sun while drying. Navy and black show better dye fixation than bright yellows and reds under ultraviolet exposure.

Choose chlorine resistant polyester blends with four-way stretch LYCRA for stretch preservation—they hold pigment longer than nylon. Fabric treatment with UV stabilizers guards against fade in under thirty minutes of sun.

Storage Tips for Longevity

Once you’ve beaten fading, proper fabric storage determines whether your chlorine-resistant swimwear fabric holds up for seasons or falls apart. Store your materials in a cool, dark location where humidity control stays between 40 and 60 percent for moisture management and color preservation.

Follow these fiber protection guidelines:

- Use breathable cotton bags instead of plastic for storage

- Keep fabric away from sunlight and heat sources

- Avoid damp basements with fluctuating temperatures

- Maintain consistent climate control year-round

- Fold swimwear loosely to prevent permanent creasing

Frequently Asked Questions (FAQs)

What fabric to use for sewing a swimsuit?

Most swimwear fabrics contain 20 to 25 percent spandex blended with nylon or polyester. You’ll want stretch, chlorine resistance, and quick-drying properties.

Choose nylon-spandex blends for smooth comfort or polyester-spandex for enhanced colorfastness.

What is the best fabric for swimwear?

The best fabric for swimwear is nylon blends with spandex, offering elastic recovery, water resistance, and fabric durability.

These activewear fabrics feature breathability matters, ideal swimwear texture, and essential swimwear fabric properties for performance swim knit construction.

Which fabric for swimwear?

Wondering what sets championship suits apart from basic bikinis? Your ideal swimwear fabric depends on purpose—nylon blends for recreational comfort, polyester spandex for competitive performance, or eco-friendly recycled materials combining elastic recovery with water resistance and durability.

What sewing machine is best for bathing suits?

A dedicated serger with differential fabric feed manages stretch best, but any sewing machine with adjustable thread tension, ballpoint needles, automatic stitch settings, and variable sewing speed works for creating swimwear using reliable sewing patterns.

What is the best thread for sewing swimsuits?

You might think any strong thread works, but polyester thread outperforms the rest for sewing swimwear.

It stretches with Lycra, resists chlorine damage, and pairs perfectly with ballpoint needles for durable, flexible seams.

Which material would make the best swimwear?

Nylon-spandex blends deliver exceptional swimwear performance with 40 to 50 percent stretch, full recovery, chlorine resistance, and quick-drying comfort—making them the go-to fabric for both competitive swimmers and recreational enthusiasts.

Can you sew swimwear on a regular sewing machine?

Yes, you can sew swimwear on a regular sewing machine. Use a ballpoint needle, stretch stitch or zigzag, and adjust tension for four-way stretch swim knit fabrics to prevent puckering.

How do I prevent swimwear fabric fraying?

Think of raw edges like loose ends waiting to unravel your hard work.

Use a serger, stretch stitches, and quality polyester thread to lock every edge and keep your swimwear holding strong.

What fabrics work for reversible swimsuits?

For reversible durability, reach for nylon-spandex knit fabric with four-way stretch. It flips cleanly, resists seam bulk, and holds dual-sided print beautifully.

Spandex content around 15–20% keeps your swimwear fabric snug on both sides.

Can swimwear fabric handle heavy embellishments?

Sure, swimwear fabric can handle embellishments — but they fight back. Embellishment weight strains spandex stretch, knit fabric recovery suffers, and water durability drops fast. Smart garment construction and sewing placement keep things in check.

Conclusion

Cheap fabric unravels your vision; the right fabric builds it. Mastering fabric selection for sewing swimwear means understanding that every percentage of spandex, every fiber choice, every weight decision directly shapes how your finished suit performs in real water.

You’re not just sewing seams—you’re engineering something that moves with a body, resists chlorine, and holds its shape session after session.

Choose deliberately, cut confidently, and the swimsuit you create will outlast anything hanging on a rack.