This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’re curious how thread is made? Let me give you the scoop!

You’re curious how thread is made? Let me give you the scoop!

First, raw materials like silk from silkworm cocoons, cotton from plants, or polyester from petroleum are processed.

For silk, cocoons are harvested, combed into tops, twisted into rovings, and spun into single threads.

Cotton fibers undergo cleaning, combing, rolling into bands, and twisting into rovings before spinning.

polyester chips are extruded into tow, stretched, cut, and combined into twisted bands that wind onto cones.

After dyeing, threads receive a finishing twist for strength and liveliness.

Intrigued? There’s more to unravel if you keep exploring!

Table Of Contents

Key Takeaways

- Crafting thread is a labor of love, transforming humble materials like silkworm cocoons, cotton plants, and petroleum chips into silky smooth strands through intricate processes of combing, twisting, and dyeing. It’s like watching a caterpillar spin its cocoon, each step unfolding a tiny miracle.

- Getting the perfect thread is a delicate balancing act, akin to a tightrope walker nailing every step. Too loose a twist, and your thread loses its mojo; too tight, and it’ll be as limp as overcooked spaghetti. But when you hit that sweet spot? Magic happens, baby!

- Behind every vibrant hue adorning your threads lies a masterful symphony of computer-controlled color mixing, dye bath wizardry, and drying finesse. It’s like watching a painter craft a masterpiece, one carefully blended stroke at a time.

- Thread production might seem like a straightforward gig, but oh boy, the safety measures and quality control will make your head spin faster than a cotton gin on steroids. From hazmat suits to eagle-eyed inspections, these folks don’t mess around when it comes to keeping you and your threads top-notch.

How is Thread Made?

How is thread made? Thread is produced by twisting fibers from natural sources like silk from silkworms or cotton plants, or synthetic materials like polyester made from petroleum. These fibers go through processes of cleaning, combing, rolling into roving, spinning into singles, dyeing, twisting, and finishing treatments.

Raw Materials for Thread

You’re about to explore the raw materials that form the foundation of thread production. The main sources are silkworms and mulberry leaves for silk, cotton plants for cotton, and petroleum for synthetic polyester.

Silk: Silkworms and Mulberry Leaves

The silkworm’s diet consists solely of mulberry leaves, rich in nutrients that allow it to spin a resilient cocoon. You witness an awe-inspiring process:

- Silkworms munching tirelessly on mulberry leaves

- Cocoons harvested with utmost precision

- Fibers unraveled, forming lustrous silk threads

- Threads ideal for delicate garments and exquisite embroidery

Silk epitomizes nature’s engineering marvel, transforming humble leaves into luxurious fibers. Bask in this intricate journey from leaf to lustrous thread.

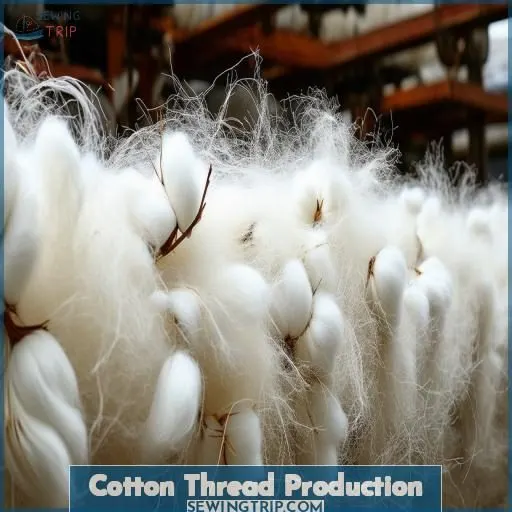

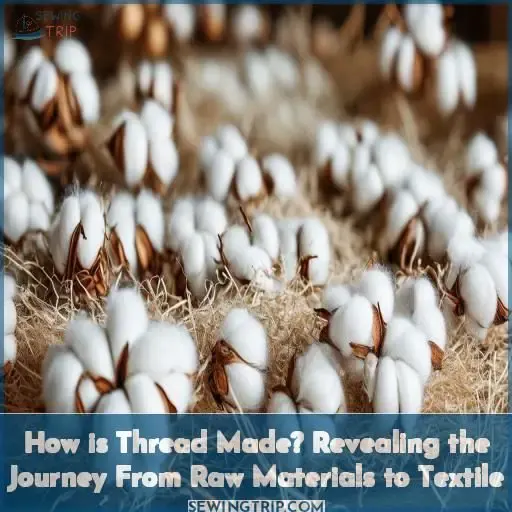

Cotton: Cotton Plants

Cotton threads originate from cotton plants grown in fields. You’ll find these fluffy white fibers wrapped around cotton plant seeds. After picking, the fibers undergo cleaning, combing, and rolling into bands called "roving." The roving is then twisted and spun into cotton thread for sewing and weaving.

| Process | Description |

|---|---|

| Growing | Cotton plants cultivated in fields |

| Harvesting | Cotton fibers picked from plants |

| Ginning | Fibers separated from cotton seeds |

Polyester: Petroleum

- Extrusion into long, thin strands

- Stretching to increase strength

- Cutting to remove weak fibers

- Combining bands and twisting

- Final stretching and winding onto cones

With polyester’s durability and versatility, this thread finds its way into all kinds of apparel and sewing projects.

Silk Thread Production

To begin silk thread production, you’ll first harvest the cocoons created by silkworms after they feed on mulberry leaves and secrete their fiber-forming liquid. Next, these cocoons undergo a washing process to soften the fibers, preparing them for the subsequent combing stage where the cocoons are untangled and formed into a "combed top" material.

Harvesting and Washing Cocoons

You’ve harvested the cocoons – now let’s wash them. Gently immerse them in hot water baths to soften and remove the sericin protein gum, a key step in silk thread production. Check the cocoon quality, ensuring silkworms were raised on nutrient-rich mulberry leaves for strong fibers.

| Cocoon Quality | Silkworm Health | Mulberry Nutrition |

|---|---|---|

| Uniform shape | Active metabolism | High protein |

| Dense & compact | Free of diseases | Balanced nutrients |

| Undamaged silk | Optimum temperature | Pesticide-free |

Combing Cocoons Into Combed Top

Once the cocoons are washed, you’ll comb them to produce a "combed top" – tufts of long, parallel silk fibers. This combing process maintains consistent quality and prepares the fibers for spinning. Proper combing techniques, refined over centuries, maximize the combed top’s cleanliness, strength, and uniformity – critical for high-quality silk thread production.

Twisting Combed Top Into Roving

After combing the cocoons into a soft ‘combed top’, you’ll twist it into a ‘roving’. This involves:

- Drafting the combed top to the desired thickness

- Applying a precise twisting technique

- Maintaining consistent roving quality and elasticity

- Ensuring the right amount of twist for ideal silk thread strength

A well-twisted roving is essential for producing high-quality silk thread in the next stage.

Spinning Roving Into Single Thread

You then spin the roving into single silk threads, carefully controlling the spinning process and roving thickness for ideal thread strength. The roving passes through twisting guides that insert a tight "S" twist, consolidating the fibers and enhancing the thread’s durability. With utmost precision, you monitor the fiber quality and twist direction to produce lustrous, high-tenacity silk threads.

Cotton Thread Production

For cotton thread production, the first step is to thoroughly clean and comb the cotton fibers, removing any debris or impurities. Next, these fibers are rolled into narrower bands, which are then twisted together to form the "roving" – a thicker, rope-like bundle of fibers that serves as the precursor to the thread itself.

Cleaning and Combing Cotton Fibers

After the silk thread production, you’ll focus on cotton. First, the harvested cotton fibers undergo thorough cleaning to remove impurities like:

- Leaf debris

- Dirt particles

- Other contaminants

Next, the fibers are combed and carded to align their staple length and smooth any tangles. This prepares the cotton for the next important step.

Rolling Fibers Into Narrower Bands

After the fibers are cleaned and combed, you’ll roll them into narrower bands for added strength. Precisely controlling the band width and tension is critical to producing a strong, uniform thread. The narrower bands help reinforce the fibers, allowing them to withstand the twisting process that lies ahead.

Twisting Bands Into Roving

With the narrower cotton bands ready, you’ll twist them into "roving" – the precursor to thread. This process follows these steps:

- Gather the bands

- Apply controlled twist

- Maintain uniform thickness

- Monitor roving quality

Twisting transforms the loose bands into a cohesive, strong roving suitable for spinning into durable cotton thread. Careful fiber preparation and quality control are essential for satisfactory roving properties.

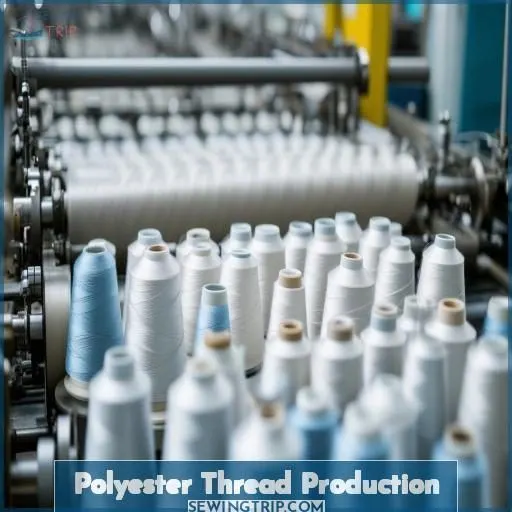

Polyester Thread Production

To produce polyester thread, you start by extruding petroleum chips into long, continuous strands called polyester tow. These tow strands are then stretched and cut to remove any weak fibers, leaving only the strongest bands which are combined and twisted together before being stretched again and wound onto cones.

Extruding Petroleum Chips Into Polyester Tow

To start making polyester thread, you’ll extrude petroleum chips into polyester tow. This involves melting the chips and forcing the molten substance through tiny holes to create continuous polyester filaments with a circular cross-section. The filaments are extruded with chemical compositions precisely engineered for tenacity, elongation, and heat resistance properties suited for high-quality threads.

| Property | Importance |

|---|---|

| Tenacity | High strength |

| Elongation | Stretchiness |

| Heat Resistance | Thermal stability |

| Circular Cross-Section | Smooth texture |

| Chemical Composition | Custom performance |

Stretching and Cutting Tow to Remove Weak Fibers

You then stretch and cut the polyester tow to remove weak fibers, ensuring:

- Maximum strength

- Enhanced elasticity

- Optimized durability

- Consistent quality

This essential step guarantees the fibers meet stringent standards, paving the way for combining and twisting the strongest bands into high-performance polyester thread.

Combining Strong Bands and Twisting

After removing the weak fibers, you’ll combine the strong polyester bands and twist them together. This twisting process is essential for ensuring the thread’s strength and durability. Different twisting techniques, like varying the twist level, can impact the yarn’s quality and properties like control, strength, and liveliness.

Stretching and Winding Fibers Onto Cones

You stretch the strong polyester fiber bands to their limit and adjust machine tensions to ideal levels. The winding techniques and cone sizes are essential – too loose and it’ll tangle, too tight and fibers will break. With precise winding at ideal tensions onto sturdy cones, you’ve mastered stretching and winding polyester fibers into high-quality thread.

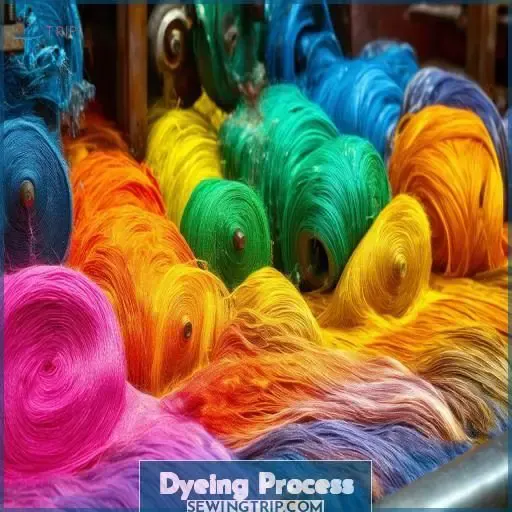

Dyeing Process

You’ll learn about the intricate dyeing process that transforms plain threads into vibrant works of art. After manufacturing, threads undergo computer-controlled dye mixing, ensuring precise color formulation; then, they’re immersed in massive dye vats and dried to lock in the brilliant hues.

Computer-controlled Dye Mixing

You’ll employ a computer-controlled dye mixing system that precisely calculates dye concentrations for exact color matching. This guarantees exceptional mixing accuracy and batch uniformity, confirming that the dyes meet the highest quality standards. With advanced technology, you can achieve vibrant, uniform coloring customized to customer demands.

Immersing Threads in Dye Vats

With precise computer-controlled color mixing, you’ll immerse the threads into massive dye vats, ensuring every fiber absorbs the desired hue. This careful dyeing process enables unparalleled accuracy, producing vibrant, consistent colors that’ll make your creations truly stand out.

Drying Dyed Threads

After immersion in the dye vats, you’ll carefully thread the dyed strands through specialized drying equipment. With precisely controlled temperatures, airflow, and drying times, each batch is meticulously dried to perfection. Safety is paramount too – ventilation systems remove harmful fumes while ensuring suitable working conditions for your skilled team.

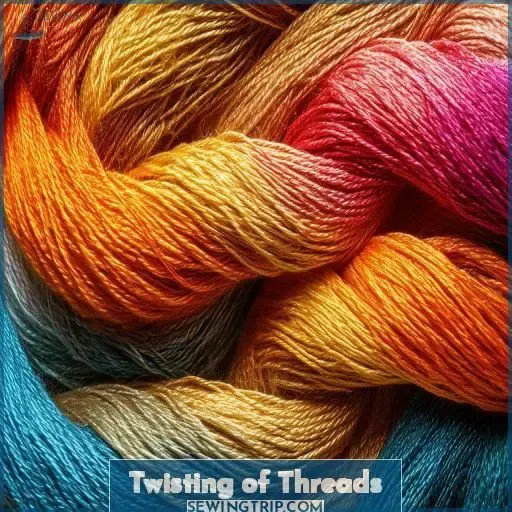

Twisting of Threads

You’ll discover that twisting thread is an essential process involving two key steps – the singling twist and the finishing twist. The singling twist provides a consolidating force by twisting the fibers in the "S" direction, while the finishing twist balances this by inserting a twist in the opposite "Z" direction, ultimately affecting the thread’s control, strength, and liveliness.

Singling Twist: Consolidating Force, S Direction

You’ll first apply a singling twist – a consolidating force in the "S" direction. This cements the fibers into a cohesive thread, boosting strength and durability. Twisting enhances fiber consolidation for textile longevity while optimizing machine efficiency. The "S" twist direction strategically prepares the thread for its finishing counterpart.

Finishing Twist: Balances Singling Twist, Z Direction

After the singling twist consolidates the fibers, you insert a finishing twist in the opposite "Z" direction. This finishing twist balances and strengthens the thread, ensuring it maintains its structural integrity during use. The degree of insertion affects the thread’s strength and appearance.

Twist Level: Affects Thread Control, Strength, Liveliness

Along with the balancing finishing twist, the twist level itself vitally affects your thread’s performance. It’s like finding that sweet spot – too loose and your thread will lack control, but too tight restricts its liveliness. The ideal twist level guarantees:

- Optimal elasticity for stretch and recovery

- Consistent durability to withstand wear and tear

- Uniform texture for a professional, branded look

- Smooth handling for effortless stitching and sewing

Nailing the twist is key to unleashing your thread’s full potential.

Wet Processing

You’ll want to pay close attention to the mercerising process, which strengthens and lustres cotton threads by treating them with caustic soda. Proper lubrication is also essential; it reduces friction and needle cooling, typically applied after dyeing.

Mercerising: Strengthens and Lustres Cotton Threads

To enhance cotton threads’ strength and luster, you’ll undergo the mercerizing process. This involves treating the threads with caustic soda, which swells and straightens the fibers, increasing their dye absorption and colorfastness. The result? Cotton threads with a soft, lustrous appearance and superior durability for sewing and embroidery projects.

Lubrication: Reduces Friction and Needle Cooling

In the wet processing stage, effective lubrication techniques are vital for reducing friction and employing needle cooling methods. Lubricants, applied post-dyeing, minimize heat and wear during sewing, enhancing thread performance. Industrial thread lubrication guarantees smoother operation, while friction reduction strategies and commercial lubrication practices optimize efficiency, extending the lifespan of both threads and needles (Source).

Finishing

Proceeding from wet processing, the next crucial step in thread production is finishing. Guaranteeing efficient winding is paramount.

The threads are meticulously wound onto supports such as cones or tubes to precisely determine thread length .

Maintaining consistent tension control during winding is essential to prevent thread damage and to ensure uniformity (Source).

The winding speed must be carefully adjusted to balance throughput and quality, maximizing both .

Diverse support types cater to various needs, whether for high efficiency or specific applications.

Thread Types

Threads can be classified based on their origins: animal (silk), plant (cotton), synthetic (nylon, polyester), and specialized types like metallic, upholstery, and invisible. You also have combinations such as a core of one fiber wrapped with another, each offering unique properties for various applications.

Animal: Silk

You’ve just learned about finishing; let’s delve into animal-derived silk. Silkworm care is crucial for high cocoon quality, particularly their diet of mulberry leaves. Innovative techniques in silk production enhance thread quality, while precise silk dyeing guarantees vibrant colors. Balancing traditional methods with modern advancements guarantees the finest silk threads for diverse applications.

Plant: Cotton

Shifting from silk, let’s examine cotton, a versatile thread widely utilized. Cotton cultivation commences with planting seeds and nurturing growth.

- Harvesting: Cotton is picked from plants.

- Ginning: Separate fibers from.

- Baling: Press and package cotton for transport.

- Spinning: Twist fibers into thread for sewing purposes.

This results in strong, stretch-resistant threads ideal for various applications.

Synthetic: Nylon, Polyester

Synthetic fibers like nylon and polyester revolutionize modern thread production. Nylon production involves melt spinning, creating a durable, elastic thread . Polyester production, derived from petroleum, results in strong, heat-resistant fibers (Source). Both types deliver exceptional thread strength, making them ideal for various commercial and industrial applications .

Specialized: Metallic, Upholstery, Invisible

You might’ve heard of metallic thread for glitzy embroidery, upholstery thread that lasts for heavy-duty applications, or nearly invisible thread for seamless stitching. These specialty threads open new domains in textile innovation. From metallic gleam to industrial strength, they merge form and function, pushing the boundaries of the thread market with eye-catching flair and rock-solid durability.

Combinations: Core of One Fiber, Outer Wrap of Another

You’ll find that thread combinations with a core of one fiber and an outer wrap of another offer unbeatable versatility. Here’s what you need to know:

- Core provides strength and durability

- Wrap adds desirable surface properties

- Silk core with cotton wrap is a classic combo

- Polyester core with nylon wrap offers stretch and resilience

These innovative combinations allow threads to harness the best qualities of different materials, showcasing the ingenuity of textile engineers.

Thread History

You’re familiar with thread’s ancient origins, like hand-spinning plant fibers and animal hide strips for clothing and other textiles. But the Industrial Revolution brought machine manufacturing for greater efficiency, along with modern materials like silk, cotton, and polyester that revolutionized thread production.

Ancient Origins: Hand-spinning Plant Fibers and Animal Hide Strips

In ancient times, you hand-spun plant fibers like flax or animal hide strips into thread for weaving textiles. Mastering spinning techniques gave you control over thread quality. These humble origins evolved as materials like cotton and silk grew popular, paving the way for textile innovations that met humanity’s evolving needs.

Industrial Revolution: Machine Manufacturing for Efficiency

The Industrial Revolution transformed thread production with machinery, increasing productivity and quality control. You gained:

- Spinning machines for faster, consistent spinning

- Power looms for efficient weaving

- Quality testing methods for uniform threads

- New spinning materials like cotton and worsted wool

Improved manufacturing fueled economic growth, creating skilled jobs and meeting consumer demand for quality textiles.

Modern Materials: Silk, Cotton, Polyester

After mechanization transformed thread manufacturing during the Industrial Revolution, modern materials like silk from silkworm cocoons, cotton from plant fibers, and petroleum-derived polyester enabled higher production volumes. Advanced dyeing techniques yielded vibrant colors, while intricate twisting processes enhanced thread strength and texture for diverse applications.

Frequently Asked Questions (FAQs)

What are the steps of making thread?

You start by spinning fibers into yarn and then twisting those yarns together to form thread. Different materials like cotton, silk, or polyester go through unique processes of spinning, twisting, and treating to create various thread types.

What is thread usually made of?

Like a spider spinning its web from silk, thread is typically crafted from natural fibers like cotton or silk, or synthetic materials like polyester or nylon. Each source requires diligent processing to transform raw materials into durable, dyeable strands.

How was thread created?

You create thread by twisting fibers together. Silk threads come from cocoons, cotton from plants. Synthetics like polyester start as petroleum chips, extruded into fibers. Each fiber type undergoes spinning, twisting, and dyeing processes.

How is natural thread made?

To make natural thread, you first harvest fibers from plants like cotton or silk cocoons. Then you comb, stretch, twist, and bundle those fibers into strong, compact threads ready for dyeing and weaving.

How are thread colors developed and tested?

Like a painter’s canvas, thread hues blossom through expert dyeing. From computer-controlled mixing to immersive dye baths, we test each vibrant shade to guarantee rich, lasting color for your sewing masterpieces.

What recycling methods exist for textile waste?

You can recycle textile waste through mechanical recycling, chemical recycling, or thermal recycling. Each method has its advantages and drawbacks, so choosing the right approach depends on the type of waste material and desired end product.

How is thread quality ensured during production?

Just like the diligent silkworm, quality control is woven throughout thread production – from fiber selection to twisting, dyeing, and careful winding onto spools.

What safety measures protect thread factory workers?

Workers wear personal protective equipment like masks, gloves, and protective clothing. Proper ventilation, machine guarding, and training on hazard awareness guarantee a safe working environment.

How are thread production costs minimized sustainably?

To sustainably minimize thread production costs, you’ll recycle materials, optimize energy use, and closely monitor quality and waste. Smart inventory management and skilled labor training are also key cost-saving strategies.

Conclusion

So, now you know how mundane thread undergoes an intricate, multi-step transformation from raw materials before gracing your favorite textiles. From glistening silk harvested by hand to high-tech polyester spun from oil, every strand of thread represents a carefully orchestrated production journey. Mastering the nuances of how thread is made affords newfound appreciation for this oft-overlooked fiber.