This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Sewing a button on a jacket with lining can be a meticulous task, but with the right approach, you’ll master it in no time.

Sewing a button on a jacket with lining can be a meticulous task, but with the right approach, you’ll master it in no time.

You’ll need to select the appropriate thread and needle, mark the button placement accurately, and create a sturdy anchor. Forming a shank is crucial for ease of buttoning, and securing the button properly ensures longevity.

Reinforce the button’s strength, attach the lining carefully, and apply finishing touches for a professional look. Remember, attention to detail and patience are your allies in achieving a durable and neat result.

Yes, you can sew a button on a jacket with lining. Start by threading a needle with double-thread, then stitch through the button and fabric, using a toothpick for spacing, and finish by wrapping the thread around the stitches to create a shank.

Table Of Contents

Key Takeaways

- Use a thread that matches the jacket fabric and lining for a neat finish, and select a needle appropriate for the fabric weight and texture to ensure durability.

- When sewing a button, create a shank to allow space between the button and fabric, securing the button with strong thread and multiple stitches for added strength.

- Attach the lining by cutting it to mirror the jacket shape, pinning it in place carefully, and sewing it with a slipstitch for a seamless look, reinforcing the attachment as necessary.

- Ensure the finished jacket’s durability and integrity by double-checking button alignment, shank robustness, secure lining attachment, and providing care instructions, alongside regular inspections for early signs of wear.

Preparing the Jacket and Materials

Before you start sewing a button on your jacket with lining, it’s crucial to select the right materials and tools for the job.

You’ll need a suitable thread that matches or complements your jacket, a needle that can handle the fabric, and the correct type of button.

Gathering these items beforehand ensures a smooth process and a professional-looking result.

This preparation step is foundational, setting the stage for a successful sewing project that not only looks good but is also durable.

Selecting the Right Thread and Needle

To ensure your jacket’s button is as secure as it’s stylish, you’ll need to select the right thread and needle. The thread size and type should be compatible with the fabric of your jacket and its lining.

Opt for a thread that’s strong yet matches the colors of your jacket and lining fabric to keep the repair discreet. The needle type should be appropriate for the fabric’s weight and texture, ensuring it can pierce through the layers without causing damage.

- Choose a thread that’s strong enough to handle the wear and tear of a jacket, like polyester or a polyester-cotton blend.

- Pick a needle that’s the right size for your fabric, ensuring it’s neither too large (which could damage the fabric) nor too small (which could break under the strain).

- Match the thread color to your jacket and lining for a seamless look; neutrals can be a versatile choice.

- Consider the type of lining fabric when selecting your needle type; a sharper needle may be needed for heavier or more tightly woven fabrics.

Gathering Buttons and Other Sewing Tools

Once you’ve selected the appropriate thread and needle for your jacket’s fabric, it’s time to gather the rest of your sewing tools.

You’ll need buttons that match the jacket’s style and are compatible with the fabric. Consider button types that complement the jacket’s color and design, and ensure you have thread colors that blend or contrast as desired.

Needle sizes should be chosen based on the fabric’s weight and the button’s holes. Keep extra buttons and thread chains for future button replacements, ensuring your jacket remains functional and stylish for years to come.

Marking Button Placement

Marking button placement is a crucial step in ensuring your jacket’s functionality and aesthetic appeal. Begin by identifying your garment’s pressure points, such as the bust, belly, or hips, which may strain the fabric.

Use these points as a guide for positioning your buttons, ensuring they align with areas that require support to prevent gaping. For a balanced look, measure the distance between the top and bottom buttons and divide this by the number of spaces between buttons to determine even spacing.

Consider the garment’s closure line, typically the center front or back, to align buttons and buttonholes accurately.

When marking, use pins or chalk for precision, keeping in mind the fabric’s characteristics and the final appearance you desire. For jackets, especially, pay attention to the sleeve, collar, cuff, and center front, ensuring buttons are positioned to enhance the garment’s structure and style.

Remember, the goal is to achieve a seamless blend of form and function, where each button not only serves a purpose but also contributes to the garment’s overall beauty and utility.

Sewing the Button

When it comes to sewing a button on a jacket with lining, the process involves a few key steps to ensure durability and ease of use.

First, you’ll need to create an initial anchor for the button, which involves securing the thread to the fabric so the button stays in place during use.

Next, forming a shank is crucial, especially for jackets, as it provides the necessary space between the button and the fabric, allowing the buttonhole to fit over the button easily. This step is particularly important for thicker fabrics or jackets where ease of buttoning and unbuttoning is essential for comfort and functionality.

Creating the Initial Anchor

After marking the button placement, you’re ready to create the initial anchor, which is crucial for the button’s stability.

Thread your needle with a length of thread that matches your jacket’s fabric, ideally around 18 to 24 inches, and double it for strength. Begin by pushing the needle from the inside of the jacket to the outside, right at the marked spot for your button.

Make a small stitch to form the anchor point, ensuring the knot placement is secure on the inside. The thread tension should be firm but not too tight to avoid puckering the fabric.

Use a needle size that’s appropriate for the fabric and buttonholes to prevent damage. As you stitch, consider the shank height, which will depend on the button type; for a traditional lining or quilted lining, a higher shank may be necessary to accommodate the thickness.

If you’re working with a removable lining, ensure your stitches only go through the lining and not the outer fabric.

For a Hong Kong seam finish or a sleeve lining, maintain the same attention to detail for a polished look. Repeat the process a few times to ensure anchor strength before moving on to attaching the button itself.

Forming a Shank for Ease of Use

After anchoring your button with a few stitches, it’s time to form a shank. This is crucial for ease of use, especially on thicker fabrics like those of a Sienna Maker Jacket.

To create a shank, wrap the coil thread around the base of the button, between it and the foundation fabric. Aim for a shank length that allows the button to sit above the fabric, making it easier to button up.

This technique is also useful for sewing on snap closing pockets or adding a welt inside pocket to a woven poly crepe garment. The shank provides space for the fabric of the garment to sit comfortably beneath the buttoned area, ensuring smooth closure along the shoulder seams.

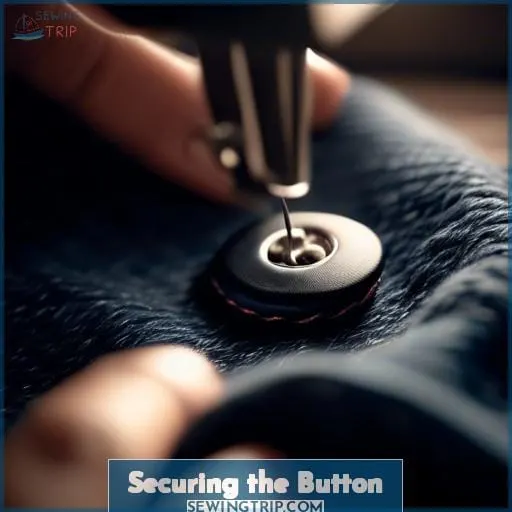

Securing the Button

Once you’ve positioned the button correctly, it’s time to secure it firmly to your jacket. Start by threading your needle with a strong polyester thread, which is less likely to disintegrate in the wash.

Choose a needle size that’s easy to handle and can pass through the buttonholes without straining the thread.

Begin by anchoring the button in place with a few small stitches, ensuring the thread is taut but not puckering the fabric. To create a shank, which provides space between the button and the fabric for ease of buttoning, wrap the thread around the stitches beneath the button several times.

The shank length should be sufficient to accommodate the fabric’s thickness, especially if you’re working with a wool jacket or a cuff facing.

Reinforce the button by passing the needle through the fabric and the buttonholes several more times. Each pass adds to the button’s strength, reducing the likelihood of it coming loose with wear. After you’ve achieved the desired reinforcement, finish by tying off the thread securely on the underside of the fabric to prevent unraveling.

Reinforcing Button Strength

Once you’ve secured the button to your jacket, it’s time to bolster its durability. The strength of a button is paramount, especially on lined jackets where the button fabric undergoes frequent tugging.

To reinforce button strength, consider the shank strength, which allows the button to withstand the pull and weight of the fabric. Shank buttons are ideal for this purpose as they provide extra space between the button and the fabric, reducing stress on the material.

Selecting the right thread choices is crucial. Opt for a strong polyester or nylon thread, which offers resilience and longevity. The needle size should correspond to the thread and fabric thickness; a larger needle may be necessary for heavier fabrics to ensure the thread passes through without causing damage.

For lining durability, ensure the button is sewn through the outer fabric and not just the lining. This prevents the lining from tearing away from the button over time. By taking these steps, you’ll ensure your button remains firmly in place, maintaining the jacket’s functionality and appearance.

Attaching Lining to Button Area

When attaching the lining to the button area of your jacket, precision is key. Begin by ensuring your lining fabric is cut to mirror the jacket’s shape, excluding any excess like collars or facings. Place the lining correctly over the area, aligning it with the edges and seams of the jacket.

If you’re using lining interfacing, apply it to the wrong side of the lining fabric before stitching to add structure and prevent stretching.

Now, focus on the lining placement. Pin the lining in place, making sure it lies flat and smooth against the fabric. When you’re ready to sew, choose a lining stitching technique that will secure the lining without adding bulk.

A slipstitch is often used for a neat, invisible finish. If the button area is subject to strain, reinforce it with additional stitches or a small piece of interfacing on the lining side.

Finally, inspect your lining finishing. The lining shouldn’t pull or distort the jacket’s fabric, and the buttons should close easily without puckering. A well-attached lining not only conceals the inner workings of the jacket but also contributes to its overall comfort and durability.

Finishing Touches

After attaching the lining to the button area, it’s time to focus on the finishing touches that will elevate the durability and appearance of your jacket. First, double-check the button placement to ensure alignment with the buttonholes, guaranteeing a seamless closure.

For buttons with shanks, ensure the shank formation is robust, allowing the button to stand correctly and provide ease of use. When it comes to the lining attachment, confirm it’s securely in place, preventing any future detachment or wear at the seams.

Incorporate durability tips such as using a strong, matching thread for sewing buttons and reinforcing the area with extra stitches or a backing button if necessary. This will help withstand the frequent pulling and stress buttons often endure. Lastly, provide care instructions to maintain the jacket’s integrity over time.

Advise gentle cleaning methods and immediate repairs to loose buttons or torn lining to extend the jacket’s life. These final steps are crucial in crafting a well-made, durable jacket that looks professional and lasts longer.

Additional Tips for Durability

After ensuring your button is securely attached and the area is neat, consider these additional tips for reinforcing durability:

- Select the Right Thread: Choose a thread strength type that matches the fabric of your jacket. Polyester core with wrapped cotton offers durability with a soft finish.

- Consider Shank Length: For thicker fabrics, ensure the button shank length is adequate to accommodate the fabric, allowing the garment to drape nicely.

- Needle Size Matters: Use a needle size that’s appropriate for the thread and fabric button matchup. A needle that’s too large can create holes and weaken the fabric.

- Reinforce with Interfacing: If the fabric is delicate, consider adding interfacing behind the button area to prevent tearing and maintain shape.

These steps will help maintain the integrity of your jacket and ensure that the buttons stay in place through regular use.

Care and Maintenance

After reinforcing the strength of your buttons, it’s crucial to maintain the integrity of your work with proper care.

To ensure your buttons remain securely fastened and your jacket looks its best, consider these sewing tips and maintenance practices.

First, always check the fabric compatibility before washing; some materials may require special care or dry cleaning to prevent damage.

Regularly inspect button placement and thread tension to catch any early signs of wear or loosening.

If a button does start to wobble, address it promptly to avoid losing it altogether.

Frequently Asked Questions (FAQs)

How do you adjust the button placement if the jacket has been significantly altered in size or shape after the lining has been attached?

When significantly altering a jacket’s size or shape, reevaluate button placement to ensure balance and functionality. Measure from top to hem and side to side, ensuring buttons align with stress points and avoid belts.

Adjust for fabric overlap, maintaining a shank for movement.

What are the best practices for sewing buttons on jackets with different types of fabric linings, such as silk or heavy wool?

A stitch in time saves nine, especially when sewing buttons on jackets with linings of silk or heavy wool.

Use a matching, strong thread, like 100% polyester, for durability. For silk, be gentle to avoid puckering; for wool, ensure your needle can handle the fabric’s thickness.

Create a shank for ease of use and to accommodate the fabric’s drape. Always test on a scrap first to perfect your technique.

How can you ensure that the button on a lined jacket does not affect the drape or fit of the lining, especially in tailored or fitted jackets?

To prevent buttons from altering the drape or fit of a jacket’s lining, sew them on without pulling the thread too tight.

What techniques can be used to repair or reinforce the area around a button on a lined jacket if it becomes worn or torn from frequent use?

Despite concerns that a repair might alter the jacket’s look, reinforcing a worn button area can be done discreetly.

Place a small fabric patch behind the tear and sew over it to fortify the material.

How do you modify or replace buttons on a lined jacket to accommodate accessibility needs or to make the jacket easier to use for individuals with limited dexterity?

Replace traditional buttons with magnetic or Velcro closures to ease use for those with limited dexterity.

Consider larger, easy-to-handle toggles or snap fasteners for a secure, accessible alternative.

Conclusion

Mastering the art of sewing a button on a jacket with lining is a testament to your dedication to detail and craftsmanship. By carefully selecting your materials, marking the placement, and executing precise stitches, you’ve ensured your button isn’t only functional but also aesthetically pleasing.

Keep honing your technique, and you’ll find that knowing how to sew a button on a jacket with lining is a subtle, yet invaluable, sartorial skill.