This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ll find Roman shades in high-end homes for good reason—they offer clean lines, light control, and architectural elegance that off-the-shelf options rarely match. But custom workroom prices can hit $300-500 per window, putting designer-quality treatments out of reach for most budgets.

Learning how to sew Roman shades yourself changes that equation entirely, giving you full control over fabric, fit, and function for a fraction of the cost. The construction requires precision measuring and careful assembly, but the technique itself is straightforward once you understand the core components: fabric panels, dowel rods, plastic rings, and a simple cord system. With the right materials and a methodical approach, you can create professional-grade shades that transform your windows and save you hundreds of dollars per room.

Table Of Contents

Key Takeaways

- Custom roman shades cost $300-500 per window from workrooms, but DIY construction cuts that expense dramatically while giving you complete control over fabric selection, light filtration, and finished dimensions.

- Accurate measurement separates successful projects from frustrating failures—you’ll need to choose between inside-mount (sits within the frame) or outside-mount (attaches to the wall), then measure width at three points and height at three points, using the narrowest width and longest height.

- Fabric weight matters more than aesthetics alone—choose drapery-weight cotton or linen between 150-250 GSM that won’t stretch or sag, avoiding quilting cottons, stretchy knits, and heavy velvets that sabotage smooth operation.

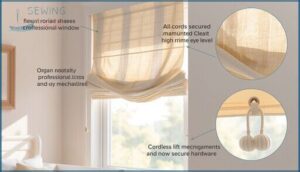

- Threading plastic rings in vertical columns 8-12 inches apart over dowel pockets creates the folding mechanism, but cord safety isn’t optional—install cleats at least 64 inches high or choose cordless systems entirely to prevent strangulation hazards.

Measuring and Planning Roman Shades

Getting your measurements right from the start will save you hours of frustration and wasted fabric later.

If your pattern doesn’t fit quite right, knowing how to adjust and modify sewing patterns can help you customize the design to match your unique proportions.

Precise measurements at the start prevent hours of frustration and wasted fabric later

You’ll need to decide whether your shade mounts inside the window frame or outside on the wall, then take careful measurements that account for how the fabric will behave when sewn. Here’s how to measure, plan, and calculate everything you need before you cut a single piece of fabric.

Once your measurements are ready, you’ll want to cut your fabric precisely so the finished shade hangs evenly and looks polished.

Inside Window Frame Vs. Outside Mount

Before you cut fabric or thread your sewing machine, you need to decide how your roman shades will mount. This choice affects frame depth requirements, light gaps, aesthetic styles, and window proportions throughout your shade installation project.

If you’re unsure which machine features matter most for shade-making, explore what features to look for in a sewing machine to find one that handles heavy fabrics and long seams with ease.

- Inside mount sits within the window frame, creating a custom look while exposing decorative trim

- Outside mount attaches to the wall above, making windows appear larger and blocking more light

- Frame depth determines which mounting option works—shallow casings under 1 inch usually require outside mounting board placement. For a detailed comparison of these methods, see .

Accurate Window Measurement Steps

Once you’ve chosen your mounting method, grab a steel tape measure—cloth tapes stretch and throw off your numbers.

For even better results, try one of these creative sewing tool hacks like clipping your tape to the table edge so it stays put while you measure.

Measure width at the top, middle, and bottom of your window frame, recording each to the nearest 1/8 inch. Then measure height on the left, center, and right. Use the narrowest width and longest height to guarantee your roman shades fit perfectly without binding.

For those who want to guarantee precision, refer to these accurate measurement guidelines to avoid common fitting mistakes.

Calculating Fabric and Lining Dimensions

Now that you have your window measurements, turn those numbers into fabric yardage. Start with your finished width and add seam allowances, then factor in pattern repeats and fold calculations to determine lining dimensions and stack heights.

Here’s how to nail the math:

- Add 0.5–1 inch to inside-mount width for movement clearance

- Calculate cut length by adding 6–8 inches to your drop

- Divide total width by fabric width to find how many panels you’ll need

- Multiply pattern repeat size by rounded-up repeats for patterned fabric

Your lining should be 1–1.5 inches narrower than face fabric so edges wrap cleanly around the sides.

Choosing Materials and Fabric for Roman Shades

The fabric you choose shapes how your roman shade looks, feels, and performs over time.

Weight, texture, and light filtration all play a role in whether your finished shade hangs beautifully or sags after a few weeks.

Here’s what you need to know to pick the right materials and avoid common mistakes.

Selecting Suitable Fabrics and Linings

Your fabric selection sets the foundation for everything else. Start with durable, drapery-weight cotton or linen in decorative fabrics that resist stretching—quilting cottons won’t hold up.

For extra structure and stability, consider adding interfacing to your fabric before you start cutting or sewing.

For lining materials, standard sateen adds privacy and protects your face fabric from sun, while thermal or blackout options boost insulation. When planning pattern layout and color coordination, consider how texture choices affect the finished drape and whether you need interlining for extra body.

Determining Fabric Translucency and Weight

Light transmission through your roman shade depends on fabric density and weave structure. Hold medium-weight cottons—around 150 to 250 GSM—against a sunny window to check translucency before sewing.

Tighter weaves block more daylight, boosting shade opacity and privacy. Darker decorative fabric absorbs visible light better than pale hues. Pair your face cloth with the right lining to reach your target light control for each room.

Avoiding Unsuitable Fabric Types

Certain materials sabotage your roman shade project from the start, no matter how precisely you sew. Fabric selection demands attention to durability, maintenance, and textile science to keep folds crisp and cords running smoothly for years.

- Stretchy knits and jersey sag between dowels, growing uneven after repeated raising and lowering

- Heavy upholstery velvet overloads basic cord systems and stacks into thick piles that block light

- Moisture-sensitive silk spots permanently in bathrooms, where fabric safety and shade maintenance matter most

Step-by-Step Sewing and Assembly Guide

Now that you’ve chosen your materials and taken your measurements, it’s time to bring your roman shade to life.

This step-by-step assembly guide walks you through the entire construction process, from cutting your first piece of fabric to threading the final cord. You’ll learn exactly how to create crisp folds, secure your mounting board, and guarantee safe, smooth operation every time you raise or lower your finished shade.

Cutting Fabric and Lining to Size

Before you make the first cut, take a moment to square your face panel—align the selvages and check the grain alignment so your shade hangs true.

For fabric cutting, add about 3 inches to your finished width and 5 inches to the drop. Lining sizing runs simpler: cut it roughly 1 inch narrower than your target width, keeping pattern matching and trimming allowance in mind throughout.

Sewing Sides and Creating Rod Pockets

Once you’ve squared your panels, you’re ready to join them. Pin your fabric and lining right sides together along the vertical edges, allowing a 1/2-inch seam allowance on each side—this keeps your finished shade close to the planned width while securing the layers firmly. After sewing, turn the shade right side out and press those side seams crisply.

Here’s where rod pocket construction comes in: – Mark horizontal lines across the lining at 8 to 12-inch intervals using a ruler and level so each rod pocket stays parallel to your window frame. – Fold the lining up about 1/2 to 3/4 inch at each marked line and stitch a straight seam to form narrow channels for your dowels. – Cut dowels roughly 1/2 to 1 inch shorter than the finished shade width so they slide easily into the rod pockets without pushing against your side seams.

These folding techniques guarantee your roman shades stack neatly when raised, and proper dowel placement prevents sagging between folds.

Attaching Plastic Rings and Dowels

Once your rod pockets are finished, you’ll hand sew plastic rings to the lining about 1 inch in from each side edge and every 8 to 12 inches horizontally across, aligning each row over a dowel pocket.

Use strong polyester thread and stitch through both layers so cord tension pulls evenly during shade operation.

Slide wooden dowel rods into the pockets, keeping them centered and 1/2 to 1 inch shorter than your fabric width for smooth fabric folding when the roman shades rise.

Preparing and Installing The Mounting Board

Your mounting board acts as the backbone of your roman shades, so wood selection matters—choose kiln-dried pine cut to your finished width.

Wrap the board with leftover fabric, stapling on the back side, then attach your shade panel by stapling from center to edges.

Plan bracket placement about 2 inches from each end, and predrill screw installation points to prevent splitting.

Threading Cords and Ensuring Smooth Operation

With your mounting board set, thread braided nylon cord through each ring column, starting at the bottom and working up.

Tie a secure double knot at the lowest ring, then run the cord straight through all rings above, across the pulley systems at the headrail, and into the chord lock.

Balance each cord so the shade lifts evenly—smooth operation depends on proper cord tensioning and alignment with those wooden dowel rods inside.

Safety Tips for Cord Management

Cord safety isn’t optional when sewing roman shades—exposed cords create window hazards and strangulation prevention starts in the design phase.

Install cord cleats at least 64 inches high, keeping excess cord wrapped and taut. Better yet, choose cordless systems for child protection, especially in nurseries and playrooms.

If you use a pulley and chord lock, secure all plastic rings firmly and keep operating cords shorter than 8 inches.

Top 5 Essential Products for Sewing Roman Shades

You’ve got your fabric cut and your sewing plan ready, but the right hardware makes all the difference between a shade that works smoothly and one that frustrates you every time you touch it.

The products you choose for rings, cords, and mounting components directly affect how easily your shade raises and lowers, plus how long it lasts. Here are five essential items that’ll help you build a roman shade you can operate with confidence for years to come.

1. Boao Roman Blind Curtain Rings

You’ll find Boao Roman Blind Curtain Rings in bulk packs of 100 transparent plastic pieces, giving you enough Roman shade rings for several window projects. These curtain accessories feature a 16 mm inner diameter that fits standard lift cords smoothly, and their clear plastic finish stays invisible against light fabrics.

When sewing Roman shades, attach these rings in vertical columns over each dowel pocket—spacing them 8 to 12 inches apart ensures your blind lifts evenly. The sturdy plastic construction prevents rust in humid rooms while maintaining consistent cord management throughout daily use.

| Best For | DIYers and home sewers making custom Roman shades who need affordable, rust-proof hardware in bulk quantities. |

|---|---|

| Material | Plastic |

| Color | Transparent |

| Weight | 0.64 ounces |

| Use Case | Roman shade rings |

| Quantity | 100 pieces |

| Primary Application | Roman blinds |

| Additional Features |

|

- 100-piece pack gives you enough rings for multiple shades or several vertical cord columns on wide windows

- Clear plastic design blends into light fabrics and won’t rust in kitchens or bathrooms like metal rings

- 16 mm inner diameter fits standard lift cords with room for knots, preventing jams when raising the shade

- Some customers report packages arriving open or missing pieces due to quality control issues

- Plastic construction may not hold up as well as metal rings for heavy-duty or commercial projects

- Limited to specific uses like Roman shades and light display purposes rather than versatile applications

2. Stainless Steel Screw Eye Rings

After you’ve attached those plastic rings to your Roman shade fabric, you’ll anchor stainless steel screw eye rings into your wooden mounting board to guide each lift cord upward.

These 1/2-inch screw eyes resist rust near humid windows, and their non-magnetic stainless construction outlasts zinc-plated hardware that flakes over time.

Pre-drill pilot holes before driving them in to prevent wood splitting, then position one screw eye directly above each vertical column of sewing rings—this alignment keeps your Roman shades lifting smoothly without tangled cords or uneven folds.

| Best For | DIYers building Roman shades or craft projects who need small, rust-resistant hardware to guide lift cords through wooden mounting boards near windows. |

|---|---|

| Material | Stainless Steel |

| Color | Silver |

| Weight | 0.639 ounces |

| Use Case | Screw eyes for anchoring |

| Quantity | 25 pieces |

| Primary Application | Crafts and frames |

| Additional Features |

|

- Solid stainless steel resists rust and corrosion in humid window areas without flaking or staining your fabric over time

- Pre-drilled pilot holes let you anchor these screw eyes into wood securely, and the smooth metal rings reduce friction on lift cords

- A 25-piece pack gives you enough hardware to outfit several Roman shades at once, so you’re set for multiple window projects

- The thin gauge steel can pull out of soft woods if you skip pilot holes or overtighten during installation

- At just 1/2 inch overall length, these screw eyes work only for lightweight shades—heavier fabrics need larger, longer-shanked hardware

- Small size means they’re easy to misplace during a project, and you’ll need to order extras if you’re tackling wide or tall windows

3. Rope King Mason Twine

Threading your lift cords with Rope King Mason Twine gives you size 18 nylon line that accommodates shade weight far beyond what’s needed—160 pounds of break strength versus a few ounces of fabric. This mason line resists rot, mildew, and abrasion while sliding smoothly through plastic rings and screw eyes, so your window treatment raises evenly every time.

You’ll find high-visibility colors helpful when managing multiple cords during assembly, while the twisted nylon properties keep knots secure without slipping through your cord management hardware.

| Best For | DIYers re-stringing Roman blinds who need affordable, durable cord that won’t stretch or fray through daily raising and lowering. |

|---|---|

| Material | Polyester |

| Color | Multiple Colors |

| Weight | Not specified |

| Use Case | Cord and line |

| Quantity | 1,000 feet |

| Primary Application | Tying and binding |

| Additional Features |

|

- 160-pound break strength handles shade weight easily while staying thin enough to glide through small rings and screw eyes

- Nylon resists rot, mildew, and moisture so cords last years even in humid kitchens and bathrooms

- High-visibility color options make threading multiple cords during assembly much easier to track

- Frays quickly when cut unless you apply heat to seal the ends immediately

- Slippery nylon surface can let knots loosen if you don’t tie them properly or use enough wraps

- Bright fluorescent colors show through on light fabrics if you prefer a more discreet look

4. Wooden Dowel Rods For Crafts

Crisp folds across your Roman shade depend on sturdy wooden dowel rods slipped into each rod pocket you sew. Craft dowels in 5/16 or 3/8 inch diameters provide the rigidity your fabric needs without adding bulk, while birch and poplar dowel material accepts paint or stain evenly if you want a custom finish.

Cut each piece about one inch shorter than your shade width so the wood dowels slide smoothly into pockets without pressing seams, and sand any rough edges before making Roman shades to protect your fabric from snags.

| Best For | DIYers building Roman shades or craft projects who need affordable, smooth dowels that are easy to cut and finish. |

|---|---|

| Material | Baltic Birch Wood |

| Color | Natural Wood |

| Weight | 8.8 ounces |

| Use Case | Dowel rods |

| Quantity | 1 piece |

| Primary Application | Woodworking projects |

| Additional Features |

|

- Pre-sanded Baltic birch saves prep time and prevents fabric snags in Roman shade pockets

- Multiple diameter options from 1/8 to 2 inches let you match rod thickness to your project weight

- Lightweight poplar and birch accept paint or stain evenly for a custom look

- Some pieces arrive with a greenish tint or bent shape due to quality control gaps

- The 1/4 inch diameter may be too thin for heavy-duty structural projects

- You’ll need to cut dowels yourself since most come in standard 12, 36, or 72 inch lengths

5. Clear Cord Safety Cleats

Secure lift cords with clear cord safety cleats once your Roman shade is fully assembled, placing these blind accessories at least 20 inches above floor level to prevent window hazards and protect children from strangulation risks.

The transparent plastic design blends with your window treatment while keeping fabric cords taut and organized, meeting current home security standards for child safety.

Mount each cleat to a solid surface using pilot holes, then wrap excess cord length around the fixture for reliable cord management every time you raise or lower your shade.

| Best For | Parents and pet owners who want to keep blind cords safely secured and out of reach while maintaining a clean, nearly invisible look. |

|---|---|

| Material | Plastic |

| Color | Transparent |

| Weight | 0.81 ounces |

| Use Case | Cord safety cleats |

| Quantity | 4 pieces |

| Primary Application | Blind cord safety |

| Additional Features |

|

- Keeps cords organized at a safe height to prevent strangulation hazards for kids and pets

- Clear plastic design blends seamlessly with most window treatments and decor

- Easy DIY installation with included mounting hardware for walls or window frames

- Provided wall anchors may not hold well in drywall without hitting a stud

- Anchors are made of soft plastic that may not grip screws securely

- Best results require mounting to solid surfaces like studs or trim

Frequently Asked Questions (FAQs)

What is a roman shade?

Some folks think Roman Shade History began in dusty ancient Rome with wet cloths blocking sun—and they’re right.

Today’s Roman Shades are elegant Fabric Window Treatments folding accordion-style, offering exceptional Shade Operation and timeless Folding Styles.

How to choose a pattern for Roman Shades?

Choose patterns that match your window size—bold florals or geometric prints create room accentuation in larger spaces, while subtle fabric texture and small print repeats prevent overwhelming compact areas when sewing Roman shades.

How do you hang a roman shade on a window?

Window covering incidents cause over 200 child injuries annually, making proper cord management essential.

First, attach mounting brackets level inside the window frame or on the wall, then slide the headrail into place and secure excess cords with safety cleats.

How do you make Roman shades with mini blinds?

You can upcycle a deconstructed mini blind by removing slats, leaving the cord and lift system intact, then weaving roman shade fabric through the existing strings to create a custom shade design without complex sewing or shade installation.

Is it hard to sew Roman shades?

Sewing roman shades isn’t overly difficult, but it does require patience with fabric selection, precise measurements, and mastering basic sewing techniques—beginner tips and careful planning make the DIY complexity manageable for most home sewers.

How do you make professional looking Roman shades?

Professional finishing separates DIY projects from designer work.

Crisp folds depend on precise dowel spacing, even cord tension, and a well-trained pleat. Press every seam, align rings vertically, and secure cords with dedicated cleats for polished results.

How much fabric is needed for Roman shades?

You’ll generally need about 2 yards of fabric for standard-sized Roman shades—though honestly, measuring three times and cutting once saves you from that oops, too short curtain catastrophe.

Calculate yardage by adding 6 inches for hem allowances to your finished shade length.

How do you attach fabric to a roman blind?

You’ll attach your finished roman shade fabric to the mounting board using either hook-and-loop tape for easy removal or by wrapping and stapling the top edge directly onto the board’s back surface.

Can I make Roman shades without sewing experience?

You don’t need a single stitch to pull this off. No sew options using tension rods, adhesive hem tape, and DIY kits give beginners cordless designs that skip fabric choices requiring sewing machine expertise.

How long does a Roman shade project take?

A DIY Roman shade project timeline runs six to ten hours across a weekend for most home sewers, though your first attempt may stretch to twelve hours as you navigate measuring, sewing complexity, and installation time.

Conclusion

Picture your windows dressed in custom shades that fold with precision, filter light exactly as you envisioned, and cost a fraction of what designers charge.

Learning how to sew Roman shades puts that transformation within reach—you’ve got the measurements, materials list, and assembly roadmap laid out. Now it’s about dedicating a weekend to careful construction.

The rings, cords, and dowels become second nature once you’ve threaded your first shade, and every window after gets easier.

- https://fandrinteriors.com/how-to-measure-for-roman-shades-like-a-pro-learn-step-by-step/

- https://atcharlotteshouse.com/how-to-sew-roman-shades-like-a-professional/

- https://windowcoverings.org/revised-safety-standard-2022/

- https://www.willowbloomhomeblog.com/step-by-step-lined-roman-shades-one-room-challenge-week-3/

- https://www.spoonflower.com/