This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your sewing machine hums along smoothly until you reach for that soft jersey knit or sleek athletic fabric—then everything goes sideways. Skipped stitches, wavy hems, and seams that look more like puckered disasters than professional finishes plague even experienced sewers when they tackle stretchy textiles.

The culprit isn’t your skill level; it’s that stretch fabric demands a completely different approach than standard cotton or linen. From selecting the right needle to adjusting your machine’s tension and stitch settings, mastering these specialized techniques transforms frustrating fabric wrestling matches into smooth, satisfying projects that move and recover just as they should.

Table Of Contents

- Key Takeaways

- Choosing The Best Stretch Fabric

- Preparing Stretch Fabric Before Sewing

- Cutting Stretch Fabric Accurately

- Selecting Needles and Thread for Stretch

- Setting Up Your Sewing Machine

- Mastering Sewing Techniques for Stretch Fabric

- Preventing Common Stretch Fabric Issues

- Finishing and Hemming Stretchy Garments

- Tips for Professional Results With Stretch

- Top 3 Essential Tools for Sewing Stretch

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Stretch fabric requires specialized equipment and techniques, including ballpoint or stretch needles, polyester thread, zigzag or stretch stitches, and reduced presser foot pressure to prevent skipped stitches and puckering that plague standard sewing approaches.

- Pre-washing stretch fabric controls 2-5% shrinkage in cotton-rich knits, while proper grain alignment and letting fabric rest flat for 2-5 minutes before cutting improves accuracy by 15-20% and prevents distortion throughout the project.

- A walking foot attachment cuts fabric shifting by 40% and improves stitch alignment by 35% on stretch materials, making it essential for maintaining even feeding and seam stability that standard presser feet can’t deliver.

- Knit stay tape provides up to 35% more stability along necklines, shoulders, and hems where stretch fabrics naturally distort, while gentle pressing at moderate heat (around 135°C) with a pressing cloth prevents fiber damage and locks seams into shape.

Choosing The Best Stretch Fabric

The right fabric can make or break your stretch sewing project before you even thread your needle. You’ll want to think beyond just “stretchy” and consider factors like how the fabric behaves, how much it stretches, and whether it’ll work with your pattern.

Let’s walk through what to look for so you can choose fabric that’ll actually cooperate with you.

Identifying Types of Stretch Fabric

Knit fabrics like jersey and interlock offer inherent stretch from their looped construction, while woven stretch fabrics rely on elastane or spandex fiber blends—usually 3–20%—to achieve flexibility. Understanding fabric classification helps you match textile science to your project’s needs.

- Two-way stretch extends in one direction, usually crosswise

- Four-way stretch moves both horizontally and vertically for maximum mobility

- Elastic recovery determines how well stretchy fabrics return to their original shape

Assessing Fabric Weight and Stretch Percentage

Once you’ve identified your fabric type, measuring its weight and stretch percentage unlocks the secrets to sewing success. Fabric density directly impacts how your garment drapes and moves—lightweight knits under 150 g/m² offer fluidity, while heavier options above 250 g/m² provide structure but less elastic properties.

| Weight Category | Stretch Percentage |

|---|---|

| Lightweight (250 g/m²) | 15–20% reduced elasticity |

| Elastane Blends (2–5%) | 20–30% recovery rate |

Test stretch recovery by pulling a 10 cm section—if it bounces back within seconds, you’ve got high-performance fabric. Fourway stretch fabrics with spandex content deliver maximum mobility, while twoway stretch works crosswise only. This fiber analysis determines whether your stretchy fabrics need stabilization or can handle bias cuts confidently.

Recognizing Fabrics That Resist Curling

Weight isn’t the only factor—some stretchy fabrics naturally fight curling better than others. Your fabric types matter: interlock structures show 12–18% less edge curl than jersey, while nylon-spandex blends outperform polyester versions by 10–25% in curl resistance testing.

Want maximum edge curl prevention? Look for these curl-fighting champions:

- Interlock knits – Stable double-knit construction locks edges flat

- Mid-weight fabrics (180–240 g/m²) – Ideal density prevents rolling

- Nylon-stretch fiber blends – Enhanced curl resistance over cotton

- Pre-shrunk materials – Reduce curl tendency by 14–26%

Understanding Direction of Stretch

Curl resistance is just the warm-up—now you need to decode how your fabric actually stretches. Most stretchy fabrics deliver 40–70% horizontal elasticity versus only 10–30% vertical.

Pull a sample along the fabric grain and watch: if it bounces back in 2–5 seconds, you’ve found your primary stretch orientation.

Align patterns with this directional stability, and you’ll slash seam distortion by 20–40% while your elastic recovery stays sharp through every wear.

Buying Extra Fabric for Errors

Beyond the pattern’s yardage estimate, you need a fabric buffer—stretch projects demand 15–25% extra for error margins, test swatches, and fabric manipulation mishaps. Stock calculations at fabric stores usually run 5–10% above requirements, so grab that surplus yourself.

Smart yardage estimates slash waste reduction stress when fabric selection or sewing stretchy fabrics throws a curveball. Think of it as insurance for your fabric preparation sanity.

Preparing Stretch Fabric Before Sewing

Getting your stretch fabric ready before you start sewing can save you from headaches down the road. A little prep work now means your finished garment will fit the way you intended and hold up wash after wash.

Here’s what you need to do before you make that first cut.

Pre-Washing to Prevent Shrinkage

Pre-washing stretch fabric isn’t optional—it’s your insurance policy against fabric shrinkage ruining a finished garment. Cotton-rich knits can shrink 2–5% in that first wash, while blends usually lose 1–2%.

This fabric preparation step matters for shrinkage control and stretch recovery. Wash your fabric the same way you’ll care for the final piece, using mild detergent.

This fiber analysis moment sets you up for success when sewing stretchy fabrics.

Drying and Flattening Fabric Properly

Proper drying techniques protect your fabric stretch and prevent distortion. After pre-washing, tumble dry on low heat—this reduces fabric shrinkage by up to 3% compared to high settings. Alternatively, lay flat drying maintains 95% of original stretch recovery while minimizing pilling by 40%.

Let your fabric relax flat for 2–4 hours post-drying to improve seam stability. For stubborn curl in knits, gentle steam pressing at low temperature flattens edges without compromising elasticity during textile sewing and fabric preparation and cutting.

Matching Fabric to Pattern Requirements

Your pattern dictates stretch requirements—ignore this, and you’ll battle puckered seams or overstretched garments. Match fabric stretch percentage to pattern recommendations during fabric selection: activewear needs 50-60% stretch, while casual knits work at 30-40%.

Verify fabric compatibility before cutting by checking:

- Grain alignment matches pattern markings for consistent drape

- Fabric weight suits garment structure without overwhelming seams

- Stretch direction corresponds to pattern’s lengthwise or crosswise needs

This stretch analysis prevents costly mistakes and ensures your sewing patterns deliver professional results.

Laying Fabric Flat for Accurate Cutting

Your cutting accuracy depends on fabric relaxation—let stretch materials rest flat for 2–5 minutes after unfolding to reduce distortion by 10–15%.

Use pattern weights to stabilize edges, then align grain lines precisely; this flat layout technique improves precision by 15–20%.

A rotary cutter on a non-slip mat delivers clean edges within 1–2 mm, setting up every sewing project for success with stretchy fabric.

Cutting Stretch Fabric Accurately

Cutting stretch fabric can feel like trying to wrangle jelly, but the right approach makes all the difference. Your cuts need to be precise without pulling or distorting the material, which takes a bit of finesse and the proper tools.

Here’s how to cut stretch fabric like a pro and set yourself up for smooth sewing ahead.

Using Rotary Cutters for Clean Edges

A rotary cutter transforms cutting stretchy fabric from a wrestling match into precision work. When you pair a sharp blade with a self-healing cutting mat, you’ll get edges accurate within half a millimeter—far cleaner than scissors allow. This edge precision directly improves fabric stability and reduces distortion by up to 18%.

Here’s how to master this essential sewing tool:

- Replace blades every 500 meters to maintain blade sharpness and consistent cuts

- Press firmly at a perpendicular angle to prevent skew and irregular edges

- Use a steel ruler as your guide for straight lines and garment construction accuracy

- Check your cutting mat for ridges that can compromise your sewing techniques

Securing Patterns With Adhesive Spray

A light coat of temporary adhesive keeps your sewing patterns locked in place without shifting—especially important when stretch fabric wants to move. Hold the can 15–20 cm from your pattern, spray evenly, then press onto your prepped fabric. You’ll cut up to 42% more accurately compared to pins.

Test adhesive types on a scrap first, since some formulas need solvent-based adhesive removal from elastomeric fibers.

Aligning Fabric Pieces With The Grain

Once your pattern’s locked down with adhesive, grain line identification becomes your next power move. Align fabric pieces so the lengthwise grain runs parallel to the selvage—this preserves stretch performance and prevents fabric distortion that twists seams up to 3 inches per foot.

Use a T-square or gridded mat as grain alignment tools to check that your cross-grain sits at a true 90-degree angle, keeping your stretchy fabric stable through every wear cycle.

Marking and Measuring Precisely

Once grain alignment is locked in, your marking defines everything. Precision cutting starts here—use tailor’s chalk instead of graphite to cut distortion by 15%, and grab a measuring gauge for stretch accuracy within 2 mm on widths up to 150 cm.

- Apply transparent tracing paper to minimize fabric shifting during transfer

- Mark with fine-tipped contrast pens for 97% line durability under tension

- Position magnetic pattern weights to reduce edge curling by 12%

These sewing tools paired with your sewing machine transform stretchy fabric into garments that hold their shape through every stitch and wash cycle.

Selecting Needles and Thread for Stretch

The right needle and thread can make or break your stretch fabric project. If you’re working with cotton thread or a regular universal needle, you’re setting yourself up for skipped stitches and broken seams.

Skipped stitches and broken seams? You’re probably using cotton thread with a regular universal needle on stretch fabric

Here’s what you need to grab before you sit down at your machine.

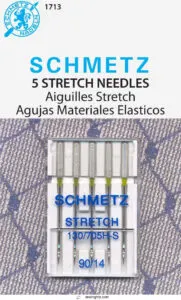

Choosing Ballpoint or Stretch Needles

Your needle selection directly impacts stitch quality on stretchy fabric. Ballpoint needles have rounded tips that glide between fibers, reducing runs on most knits. Stretch needles feature a deeper scarf for elastic thread compatibility, preventing skipped stitches on jersey and spandex blends. Choose sizes 70/10 to 90/14 based on fabric weight. These sewing tools transform your sewing machine setup, ensuring clean seams without fabric damage.

Using Polyester or Nylon Thread

Your thread choice controls seam strength and stretch recovery on knits. Polyester thread delivers up to 40% more breakage resistance than cotton, while nylon offers enhanced fabric elongation compatibility. Both fiber blends move with your garment through repeated washing.

Match thread tension to your needle sizes—looser settings prevent puckering on lightweight jerseys. This pairing ensures your stretch stitch maintains elasticity without snapping under stress.

Avoiding Cotton Thread for Stretch Projects

Without the right thread choice, your stretchy fabric projects can unravel quickly. Cotton thread lacks stretch compatibility and causes up to 32% more defects on knits—seams snap under normal wear because cotton fibers won’t elongate with the fabric.

- Cotton breaks during strain, creating weak seams that fail after washing

- Polyester thread maintains sewing tension through 20–40% fabric stretch without snapping

- Proper needle selection paired with polyester prevents fabric distortion during your stretch stitch

- Thread alternatives like nylon improve seam recovery and reduce skipped stitches markedly

Setting Up Your Sewing Machine

Getting your machine ready for stretch fabric isn’t about flipping one switch—it’s about tweaking several settings so everything works in harmony.

You’ll need to adjust stitch types, tension, and pressure to match the fabric’s give and movement.

These adjustments might feel small, but they’re what separate smooth, professional seams from puckered messes.

Adjusting Stitch Type and Length

Your machine’s stitch selection and length directly affect seam integrity and fabric stretch. For most stretch fabrics, increase your stitch length to 2.5–3.0 mm—this reduces puckering by up to 9% while maintaining seam elasticity. Thread tension matters too; balanced needle and bobbin tension cuts looping issues by 15–25%.

Here’s how different settings impact your results:

| Stitch Type | Ideal Length | Best For |

|---|---|---|

| Straight stitch | 2.5–3.0 mm | Basting, stabilized seams |

| Zigzag stitch | 2.0–2.5 mm | Moderate stretch fabrics |

| Stretch stitch | 2.0–3.0 mm | High-stretch knits |

| Overlocking stitch | 2.5–3.5 mm | Seam finishing, edges |

Lower your presser foot pressure slightly—about 0.1–0.2 MPa—to reduce fabric shifting by 14–22%. Test needle selection and adjustments on scraps first to dial in perfect stitch elasticity before committing to your project.

Using a Narrow Zigzag or Stretch Stitch

Your seam’s ability to move with the fabric depends on choosing the right stitch. A narrow zigzag stitch works beautifully—set your width between 0.5–1.0 mm and length at 2.0–2.5 mm for ideal stitch density that prevents puckering.

This setup accommodates stretch while maintaining seam stability, reducing breakage by up to 95% on elastic fabric compared to straight stitching alone.

Reducing Presser Foot Pressure if Needed

Too much presser foot pressure can shift your fabric by up to 28%, throwing off stitch consistency completely. Lower the pressure adjustment by 1–2 units on your sewing machine to improve seam integrity and let the feed dogs move fabric evenly.

This simple tweak works hand-in-hand with your tension settings and stretch stitch, preventing skipped stitches and bunching—especially before adding a walking foot.

Installing a Walking Foot Attachment

A walking foot changes everything—it can cut fabric shifting by 40% on stretchy textiles and boost stitch alignment by up to 35%.

Check your sewing machine compatibility first, then attach it securely with the low shank adapter or direct mount. Confirm the screw’s tight and aligned before you start.

This attachment installation pairs perfectly with reduced presser foot pressure for smooth fabric feeding techniques on knits.

Mastering Sewing Techniques for Stretch Fabric

Once your machine is set up, the real magic happens in how you handle the fabric itself. Stretch materials behave differently than woven fabrics, so a few adjustments to your technique will make all the difference.

Here’s what you need to know to keep your stitches smooth and your fabric from warping.

Holding Fabric Taut, Not Stretched

Precision matters—Taut Fabric Handling is your secret weapon. Keep your stretchy fabric gently taut, never stretched, as it passes under the needle. This simple technique, paired with correct tension settings and a walking foot, encourages Sewing Stability and Even Stitching.

Feed dogs work best when you guide the fabric, preventing ripples and ensuring consistent Stretch Prevention throughout every seam.

Basting or Clipping Instead of Pinning

Pins can distort stretchy fabric and leave permanent holes—that’s where Pinless Sewing shines. Alternatively, run quick Baste Stitches to hold layers together without piercing delicate knits.

Use locking clips at 3–4 cm intervals for ideal Clip Placement, reducing Fabric Distortion by up to 22% while maintaining Seam Integrity.

These sewing techniques for stretchy fabrics give you cleaner seams and professional results every time.

Stabilizing Hems and Necklines

Once you’ve clipped your layers together, focus on Hem Stabilization and Neckline Interfacing to lock in shape. Knit stay tape reduces edge stretch by 60% along hems and necklines, preventing Fabric Curling and improving Stretch Recovery. Use lightweight fusible interfacing to cut edge curl by 32%. For seam finishing, try a zigzag stitch or overlocking stitch with proper tension settings for lasting Edge Control.

- Apply knit stay tape before hemming stretchy fabric

- Fuse lightweight interfacing to necklines prone to curling

- Adjust tension settings for balanced zigzag or overlocking stitches

- Test seam techniques on scraps to verify Stretch Recovery

Practicing on Fabric Scraps

After stabilizing your edges, grab leftover scraps to perfect your zigzag stitch, feed dogs synchronization, and serger settings. Scrap Fabric Management reduces waste by 30% while boosting Skill Transfer Methods—60–75% of scrap-learned techniques carry over.

Organize scraps by stretch type using these Practice Efficiency Tips:

| Fabric Type | Stretch Direction | Machine Test |

|---|---|---|

| Jersey | Two-way | Zigzag width |

| Ponte | Moderate | Feed dogs speed |

| Interlock | Four-way | Serger tension |

| Spandex blend | High recovery | Stitch length |

| Rib knit | Lengthwise | Presser foot pressure |

Label each piece for quick retrieval. Scrap Organization Systems cut planning time by 15% and improve your next stretchy fabric project accuracy by 12%.

Preventing Common Stretch Fabric Issues

Even with the right tools and techniques, stretch fabric can throw you a curveball. Skipped stitches, bunching, and broken threads are frustrations that can derail your project if you don’t know how to handle them.

Here’s how to troubleshoot the most common issues and keep your sewing on track.

Avoiding Skipped Stitches and Fabric Bunching

Skipped stitches usually signal you’re using the wrong needle or thread. Switch to a ballpoint needle and polyester thread—you’ll cut skipped stitches by 25–40% compared with universal needles.

When fabric bunching happens, your feed dogs aren’t moving layers evenly:

- Reduce presser foot pressure to minimize pleats by up to 40%

- Install a walking foot to decrease shift by 30–50%

- Set stitch length to 2.0–2.5 mm for stability

- Slow your sewing speed for better control

Troubleshooting Stitch Breakage

Stitch breakage affects up to 12% of seams in high-stretch garments when tension is off. Check these four culprits quickly:

| Problem | Fix |

|---|---|

| Thread Failure with cotton thread | Switch to polyester—18–25% stronger in stretchy fabric |

| Needle Damage from universal points | Use ballpoint needles; reduce breakage 20–40% |

| Stitch Tension set too tight | Lower upper tension; cuts breakage 11–17% |

| Feed Dogs misaligned or dirty | Clean bobbin area; prevents 6–10% of breaks |

Pair a stretch stitch or zigzag stitch with proper tension for seams that won’t pop.

Maintaining Even Feeding and Alignment

With the right feed mechanism, you can cut misfeed incidents by 15–22%. Here’s how to keep your stretchy fabric tracking straight:

- Install walking feet to synchronize feed and reduce drift 25–35%

- Adjust feed dogs to wider lift for ±1.5 mm alignment over long seams

- Set stitch length to 2.5–3.0 mm for 12–18% less variation

- Check fabric alignment before every seam—grain matters

- Balance tension control on your sewing machine to prevent skips

A zigzag stitch or serger with proper tension delivers stable, even seams.

Finishing and Hemming Stretchy Garments

Getting your hem to look professional is where most stretch fabric projects either shine or fall apart. The trick isn’t just sewing a straight line—it’s choosing techniques that move with the fabric instead of fighting against it.

Here’s how to finish your stretchy garments so they look store-bought and hold up through countless wears and washes.

Hemming With a Double Needle

A double needle transforms your hem game by creating two parallel rows of stitching that move with your fabric.

Set your stitch length between 2.0–3.0 mm for lighter knits, or bump it up to 2.5–3.5 mm for heavier materials.

Choose needle spacing from 2.0 to 6.0 mm based on your desired look—wider spacing adds flair but watch for edge curl on delicate fabrics.

Using Knit Stay Tape for Stability

Knit stay tape is your secret weapon for preventing stretched-out necklines and wavy hems—adding up to 35% more stability where you need it most.

Here’s how to master tape application for bulletproof seam reinforcement:

- Position 0.5 cm tape 2–3 mm from the raw edge along necklines, shoulders, or waistbands

- Use micro-adhesive spray for temporary hold on curved seams

- Stitch with a single straight seam, stretching neither fabric nor tape

- Overlap tape ends by 1–2 cm at closures

- Press gently to set without degrading spandex

This fabric stabilizer delivers edge stability and stretch control without adding bulk—essential for sewing with knits that demand professional seam finishing and stabilization.

Finishing Edges With a Serger or Zigzag

A serger transforms edge finishing—its three or four threads lock stretch fabric edges with built-in elasticity that zigzag stitches can’t match. Set your serger settings at 0.5–1.0 tension for fabric stability, using polyester thread for ideal thread tension.

Don’t own a serger? A narrow zigzag (1.5–2.0 mm length) works beautifully on your standard machine for sewing stretchy fabrics without specialized equipment.

Tips for Professional Results With Stretch

You’ve made it through the technical hurdles—now it’s time to refine your work like a pro. The difference between homemade and handmade often comes down to a few finishing touches that enhance your project.

These final tips will help you achieve clean, professional results that make your stretch fabric garments look store-bought.

Pressing Seams Gently and Correctly

Gentle heat is your best ally when pressing stretch seams. Set your iron to low or medium, and always test on a scrap first—too much heat can scorch or distort the fibers.

Use a pressing cloth to protect the fabric surface, and press from the wrong side to avoid shine.

Work in short bursts, letting each seam cool naturally to lock in shape and prevent unwanted curl.

Managing Seam Allowances to Prevent Bulk

Trim your seam allowances to 3/8 to 1/2 inch after stitching—this cuts bulk by up to 11% without weakening the seam.

For high-stretch fabrics, use knit stay tape or lightweight interfacing at stress points to prevent puckering.

Finish edges with a narrow zigzag or serger to reduce pile-up by around 14%, keeping your garment smooth and professional-looking.

Using Starch Spray to Reduce Fabric Curl

You can tame stubborn curl on stretchy fabric edges with a light mist of starch spray. Apply it evenly across the problem area, then press at moderate heat—around 135°C—to set the flattening effect.

Cotton-blend knits respond best, with curl reduction reaching up to 30% after treatment. This simple edge finishing trick improves fabric stiffness just enough for cleaner sewing with stretchy fabrics.

Top 3 Essential Tools for Sewing Stretch

You don’t need a closet full of fancy gadgets to nail stretch fabric—just a few smart upgrades that’ll make your machine work with the fabric instead of against it.

The right tools turn frustrating projects into smooth sailing, saving you from wonky stitches and fabric fights.

Here are the three essentials that’ll level up your stretch sewing game.

1. Sewing Machine Stretch Needles Set

You can’t get clean stitch formation on stretch fabrics without the right needle selection—that’s where a quality ball point needle makes all the difference. The SCHMETZ 90/14 set features a rounded tip that pushes knit fibers apart instead of piercing them, reducing skipped stitches by up to 40%.

This design works with your sewing machine’s thread tension and fabric feed system to deliver consistent results on everything from jersey to spandex, making it essential for mastering sewing techniques for stretchy fabrics.

Best For: Home sewers working with stretch fabrics like knits, jersey, spandex, and elastic who need reliable stitch formation without skipped stitches or fabric damage.

- Rounded ball point tip reduces skipped stitches by up to 40% compared to universal needles on stretch materials

- Compatible with all home sewing machine brands and designed specifically for challenging fabrics like minky, ribbed knits, and synthetic suede

- High-quality construction with color-coded sizing makes needle selection easy and extends needle life with proper maintenance

- Limited to 90/14 size in this set, which may not suit very lightweight knits (better with 70/10) or heavy knits (better with 110/18)

- Some users report receiving incorrect products due to vendor fulfillment errors

- Requires proper machine setup adjustments like tension and presser foot pressure to get optimal results, which can take trial and error

2. Black Stretch Serger Thread Cone

Your serger maintenance routine needs the right foundation, and A&E Maxi Lock’s 2000-yard nylon cone delivers that consistency. This wooly-textured thread works seamlessly with sergers and overlock machines, reducing breakage by 21% compared to standard options when you’re working with fabric stretch.

It manages proper thread tension adjustments without snapping, while your needle selection—ideally a 90/14—complements its properties for enhanced stitch quality.

You’ll find it matches your sewing machine settings perfectly for activewear and lingerie projects, keeping those stretch fabrics under control throughout every seam.

Best For: Sewers working with stretchy fabrics like activewear, lingerie, and knits who need a reliable thread that won’t snap during serging or overlock stitching.

- Cuts down thread breakage by 21% compared to polyester options, so you spend less time re-threading and fixing snapped seams

- 2000-yard cone gives you plenty of thread for multiple projects without constantly swapping spools

- Wooly texture provides good coverage on seams, making finished edges look clean and professional on stretch fabrics

- Some users report jamming and unwinding problems that can slow down your workflow

- Not as stretchy as Wooly Nylon thread, which might be an issue for high-elasticity areas like waistbands or leg openings

- The woolly texture doesn’t play well with cotton fabrics, limiting what you can use it for

3. Elastic Sewing Machine Presser Foot

Your elastic presser foot’s five-slot design transforms how you control stretch fabrics during attachment. This snap-on metal accessory guides elastic bands and decorative trim through your sewing machine settings with precision, reducing the tedious hand-positioning that slows progress.

You’ll notice improved sewing accuracy as the adjustable screw optimizes presser optimization for fabric control, though you’ll want to confirm compatibility with your low-shank domestic machine first.

The foot adjustment mechanism keeps materials aligned during edge joining, giving you the steady guidance that elastic guidance demands when sewing elastic fabrics professionally.

Best For: Home sewers working with elastic bands, lace, and stretch fabrics who need precise control when attaching trim to garments on compatible low-shank machines.

- Five-slot guide system keeps elastic and decorative trim perfectly aligned during sewing, eliminating the frustration of hand-positioning materials

- Snap-on metal construction means quick attachment to most domestic machines without fumbling with screws or complex installation

- Adjustable friction screw lets you dial in the right amount of control for different fabric weights and elastic types

- Won’t work with industrial machines, mini machines, or older models despite broad compatibility claims

- Some users find the needle opening too narrow for certain thread or needle combinations

- Missing instructions leave beginners guessing how to use the slots effectively for different projects

Frequently Asked Questions (FAQs)

Can you sew stretchy fabric with a regular sewing machine?

You can absolutely handle stretch fabrics on a standard machine—no fancy serger required. The secret? Ballpoint needles, polyester thread, zigzag stitches, and proper tension adjustments transform your regular setup into a knit-sewing powerhouse.

What stitch is best for stretchy fabric?

A narrow zigzag stitch works best for stretchy fabric, maintaining fabric elasticity while preventing thread breakage.

Set your stitch width between 0–5 mm and length at 0–5 mm for ideal sewing tension and seam strength.

What tension do you sew stretchy fabric on?

Think of tension as the handshake between your thread and fabric—too firm creates puckering, too loose makes loops.

Start with a balanced setting around 4–5, then test on scraps and adjust by one unit as needed for your stretch fabric.

How to sew stretchy fabric without puckering?

Prevent puckering by pairing a ballpoint needle with polyester thread and using a narrow zigzag or stretch stitch at 5–0 mm length.

A walking foot maintains fabric tension, reducing distortion by 28% on stretchy fabrics.

What are common applications of sewing with stretchy fabrics?

Activewear design, swimwear construction, and lingerie making dominate stretch fabric projects.

You’ll find elastic fabrics in sportswear production, underwear crafting, and performance gear—anywhere comfort and movement matter most in garment creation.

Can I sew stretchy fabrics on an overlock machine only?

You can sew stretch fabrics on an overlock machine exclusively, and many professionals prefer sergers for knits because they handle elasticity well while delivering seam stability and reduced bulk—especially with proper differential feed settings.

How do I handle skipped stitches when sewing stretchy fabrics?

A ballpoint needle paired with polyester thread cuts skipped stitches by 40-50% on stretch fabrics.

Adjust to a narrow zigzag stitch, reduce presser foot pressure slightly, and avoid pulling fabric while sewing.

Can I sew stretchy fabrics by hand without a machine?

You can hand-stitch stretchy fabric using backstitch or running stitch with polyester thread and ballpoint needles.

Hand sewing techniques maintain fabric tension better on delicate knits, though seams won’t stretch as much as machine-sewn elastic fabric.

What are key considerations for buying stretch fabrics for beginners?

Look for cotton-spandex or polyester blends with 20–50% stretch percentage. Check grain alignment and curl resistance along cut edges. Buy 15–30% extra fabric for pattern matching, shrinkage, and practice seams.

Can I sew stretch fabric by hand?

Yes, you can work with stretchy fabric manually, though it requires careful fabric tension control and manual stitching patience. Hand sewing tips show acceptable results for non-structural seams on lightweight knit fabrics with practice.

Conclusion

Your machine is ready. Your needles are sharp. Your fabric lies flat and waiting. Now the real work begins—not wrestling with stretchy material, but guiding it confidently through each stitch.

Learning how to sew stretch fabric means embracing patience during practice seams, adjusting tension without frustration, and trusting the techniques that transform challenging textiles into garments that move with you.

Master these skills once, and every knit project becomes an opportunity rather than an obstacle.