This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Making a sewing table transforms your creative space from cramped and cluttered to organized and efficient. When you’re hunched over a standard desk with your machine wobbling and supplies scattered everywhere, sewing becomes a chore instead of a joy. A custom table solves this by giving you a sturdy, spacious surface that fits your machine perfectly and keeps everything within arm’s reach.

You don’t need a workshop full of professional equipment or sophisticated carpentry skills to build one yourself. With basic tools, affordable materials like melamine plywood, and a solid plan, you can create a sewing station customized to your exact needs—whether that’s extra storage for fabric, a flush-mount machine opening, or simply more elbow room to spread out your projects.

Table Of Contents

Key Takeaways

- Building your own sewing table gives you complete control over dimensions, storage, and machine placement, transforming cramped workspaces into organized creative stations that fit your exact needs.

- You can create a professional-quality table using basic tools like a cordless drill and circular saw, along with affordable materials like melamine plywood, without needing advanced carpentry skills.

- Proper planning before construction—measuring your machine’s footprint, determining ideal height based on your elbow measurement, and mapping out storage needs—prevents costly mistakes and ensures ergonomic comfort.

- Essential customizations like drop-in machine openings, pocket hole joinery for hidden fasteners, and strategic cable management elevate a basic frame into a polished workspace that handles years of heavy use.

Planning Your DIY Sewing Table

Before you cut a single board or pick up a drill, you need a solid game plan. The right sewing table starts with understanding exactly how you’ll use it, how much space you’re working with, and what features will make your sewing life easier.

If you’re planning to work on larger quilts, investing in a spacious quilting table gives you the room to manage bulky fabric without cramping your workflow.

Let’s walk through the key decisions that’ll shape your entire build.

Assessing Your Sewing Needs

Your sewing habits shape every choice you make when building a DIY sewing table. Before you sketch sewing table plans or measure your sewing space, answer these three questions:

- What do you sew most? Garment work, quilting, or bag making each demands different machine requirements and storage solutions.

- How often do you sew? Daily sewists need a permanent sewing station, while occasional crafters might want a foldable sewing desk.

- What feels uncomfortable now? Shoulder strain or crowded fabric points to ergonomic needs you can’t ignore.

For machine quilting, it’s especially important to think about to guarantee your workspace accommodates your quilting needs.

Choosing The Right Table Size

Once you know what you sew, the next big decision is figuring out what fits your room without cramping your style. Table size guidelines depend on the projects you tackle most, and workspace optimization starts with honest measurements. A 30 by 50-inch DIY sewing table accommodates garment work comfortably, while quilters often opt for 36 by 72 inches to support wider fabric yardage.

| Project Type | Recommended Size | Why It Works |

|---|---|---|

| Small garments, bags | 30″ × 50″ | Compact, fits tight corners |

| Quilting, home decor | 36″ × 72″ | Spreads fabric flat, less shifting |

| Mixed projects | 3′ × 6′ | Balances space and function |

| Tiny spaces | 24″ × 48″ | Foldable sewing desk option |

If your room measures around 10 by 12 feet, a 3 by 6-foot sewing machine table placed against one wall leaves walking clearance and room for storage solutions like rolling carts. Wider tables, near 48 inches, keep 54-inch home decor fabric from hanging off the edge but can dominate small rooms quickly. When floor space is tight, consider a narrower homemade sewing table around 36 inches wide, paired with a separate fold-out cutting surface. This way, you gain ergonomic considerations without sacrificing movement or adding clutter. For affordable options, you can repurpose cabinets and melamine, as detailed in. Remember, your sewing table plans should reflect how you actually move around your workspace, not just what looks impressive online.

Determining Ideal Table Height

After you nail down the right footprint, ergonomic height becomes your next checkpoint. Most sewists find comfort zones between 28 and 30 inches for a seated homemade sewing table, matching your bent elbow measurement.

Stand with relaxed shoulders, measure from elbow to floor, and you’ve got your baseline for sewing posture. Table adjustability helps you fine-tune your DIY sewing table as projects shift, keeping wrists level and shoulders happy through long sessions.

Planning for Storage and Organization

Once your height feels right, storage transforms chaos into creative flow. Deep drawers measuring at least 8 inches handle fabric rolls, while shallow 3-inch compartments corral bobbins and needles perfectly.

Mount pegboards for scissors and rulers, add adjustable shelves spaced 10 to 12 inches apart, and install cable management clips underneath—your DIY Sewing Table becomes a haven where every notion has its home.

Selecting Materials and Tools

Getting the right materials and tools makes all the difference when you’re building a sewing table that’ll actually last. You don’t need fancy equipment or expensive lumber to create something solid and functional.

Let’s walk through what you’ll need to gather before you start cutting and assembling.

Choosing Durable Table Top Materials

Your sewing table top is the workhorse of your DIY sewing table, so material selection matters. You want surface durability that manages daily wear resistance and moisture tolerance without constant upkeep.

Here are three solid table top finishes for your woodworking projects:

- Melamine plywood – Smooth, scratch-resistant, and budget-friendly for most sewing table plans

- High-pressure laminate over MDF – Outstanding durability with easy-clean surfaces

- Butcher block – Refinishable hardwood that gets better with age

Picking a Support Structure (Legs, Frames)

Your frame choice makes or breaks your DIY sewing table, so let’s talk leg materials and frame styles. Wooden legs in oak or maple resist dents and support heavy machines, while metal frames handle higher loads with less flex—key for stability features.

Most DIY furniture projects need frames rated around 150 to 200 pounds. Adding H-style bracing or adjustable heights gives you rock-solid support for any woodworking project.

Sourcing Budget-Friendly Supplies

You can slash costs on your DIY sewing table by hunting discount lumber at Home Depot’s cull section—damaged plywood drops 30 to 70 percent.

Repurposed materials like old IKEA tables or secondhand Kallax units work beautifully.

Budget hardware from bulk boxes and affordable finishes such as water-based polyurethane keep your DIY furniture projects under budget while delivering pro results.

Gathering Essential Tools

You’ll need five categories of woodworking equipment to build a solid DIY sewing table. Start with measuring tools like a tape measure and combination square, then grab cutting gear—circular saw, jigsaw, and miter saw.

Add a cordless drill and pocket hole jig for joining, plus a random orbital sander for finishing. Don’t skip safety gear: goggles, dust mask, and hearing protection keep DIY furniture making safe.

Measuring and Designing The Table

Getting your measurements right from the start saves you from headaches later. You’ll want to account for your sewing machine’s size, plan how it sits in the table, and map out where everything else goes.

Let’s walk through the key steps to design a table that actually works for your setup.

Measuring Your Sewing Machine Footprint

Before you cut a single board for your DIY sewing table, grab a tape measure and get the exact footprint of your sewing machine. This step gives you control over table dimensions and ensures your sewing space works perfectly. Here’s what to measure:

- Length from the handwheel to the opposite end—most machines run 15 to 20 inches

- Width from front to back at the base, usually 6 to 8 inches

- Clearance needs behind for power cords—add at least 2 inches

- Height from table surface to the top of the spool pin

Add about 2 inches to width and depth for breathing room around your sewing desk, and you’ll have the perfect ergonomic design for comfortable, productive sewing table plans.

Designing a Drop-in or Flush Mount

A drop-in sewing table lets your machine sit perfectly flush with the workspace, giving you complete control over large projects. Start by marking cutout sizes about 0.25 inch larger than your machine base.

Set drop depth by measuring from sewing bed to base—usually around 3 inches. Install support ledges underneath using 0.75-inch cleats, and plan insert panels plus access openings for easy cord routing and maintenance.

Creating a Functional Layout

Once you’ve designed your drop-in, map out a functional layout that makes sewing feel seamless. Group your machine, cutting surface, and pressing station in a U or L shape so you’re only two to three steps from each task.

Position the needle about 6 to 8 inches from the front edge, leaving at least 18 inches of open space to the left for fabric management. Plan task lighting 24 inches above the needle and route power cables along the underside to keep walkways clear.

Sketching and Planning Dimensions

With your functional layout mapped, grab graph paper to create scale drawings that capture every measurement. Sketch your DIY sewing table footprint—usually 60 by 30 inches—then mark height, leg length, and top thickness so nothing gets lost in translation.

- Label each board dimension directly on your sewing table plans

- Use 1 inch equals 1 foot scale for accurate space planning

- Note tolerances like “cut to ± 1/16 inch” for precision

Cutting and Preparing Components

Now it’s time to turn your measurements into real pieces you can work with. This stage is where precision meets power tools, and getting your cuts right the first time saves you headaches down the road.

Let’s walk through the key prep steps that’ll set you up for a smooth assembly later on.

Marking and Cutting Table Top Openings

Once your table top design is ready, trace your sewing machine’s outline directly onto the surface—add about a quarter-inch wiggle room all around. Drill starter holes at each corner, then guide your jigsaw along the pencil lines with steady hands.

This opening size technique keeps cutting table projects snug but workable. Woodworking pros often cut slightly inside the line first, then fine-tune for that perfect drop-in fit.

Sanding Edges for Safety

After cutting your machine opening, run 120-grit sandpaper along every sharp corner—this splinter prevention step keeps fabric and arms safe during long sewing sessions. Proper edge smoothing transforms rough plywood into touchable surfaces.

Here’s your safety checklist:

- Wear an N95 mask—sanding techniques create fine dust that irritates lungs

- Use 150-grit next for smoother edges

- Check with bare hands for remaining rough spots

Smart woodworking means protecting yourself while building furniture-making projects.

Preparing Supports and Shelves

Sturdy storage starts with choosing your materials—grab three-quarter inch plywood or MDF for fixed shelves since they won’t sag under fabric stacks. Cut shelf depth between ten and sixteen inches so you keep legroom clear.

For bracket installation, use L-shaped metal brackets screwed into your table frame. This shelf design creates rock-solid storage solutions that’ll last through countless DIY furniture plans.

Prepping Materials for Assembly

Before you build your DIY sewing table, organize every component using painter’s tape labels so legs and rails match perfectly. Group screws and bolts in zip bags by step—tool organization saves hours during woodworking projects for beginners.

Stage prepped boards near your work area in assembly order, and keep your drill and clamps within reach. Smart material selection and assembly planning turn DIY furniture plans into smooth home improvement projects.

Assembling The Sewing Table

Now it’s time to bring all those cut pieces together and build your sewing table!

This is where you’ll construct the frame, secure the top, and make sure everything sits level and sturdy. Follow these steps to assemble a table that’ll hold up to years of creative projects.

Building The Table Frame or Base

A solid frame is the backbone of any DIY Sewing Table. Start with 2×4 kiln dried pine for your leg design and side rails—affordable yet strong enough to handle a heavy machine.

Use pocket hole screws or corner brackets for joint techniques that lock the base construction together. Add a center stretcher to boost table stability and prevent wobble when you’re sewing at full speed.

Attaching The Table Top Securely

Securing your tabletop properly keeps your DIY Sewing Table steady for years. Drive screws every 6 inches through the apron into the underside—predrill pilot holes to avoid splits.

For solid wood, use table top fasteners like figure 8 plates to allow wood movement without cracking. Tight screw attachment points near your machine reduce vibration control issues.

Choose hardware selection that matches your tabletop thickness for a rock-solid workspace following your DIY Furniture Plans.

Installing Machine Platform or Drop-In

Your drop-in sewing table reaches its full potential once you align the machine platform flush with the tabletop. Cut the opening about 0.25 to 0.5 inch larger than your sewing machine base for easy removal.

Mount the platform using adjustable pins with washer stacks at five support points, letting you fine-tune height adjustment until the bed sits perfectly level—no catching fabric mid-seam.

Ensuring Stability and Levelness

A rocking table ruins every stitch. After assembling your DIY sewing table, stability checks become your best friend.

Here’s how to lock in rock-solid performance:

- Thread adjustable leveling feet under each leg to compensate for uneven floors and eliminate wobble

- Add cross braces between legs to stop side-to-side racking during high-speed sewing

- Check weight distribution by placing your machine near the front edge without tipping

- Install rubber pads under legs for vibration control

- Use a bubble level across the top to confirm flatness within 3 millimeters

These tweaks transform a basic drop-in sewing table into furniture that manages heavy machines without complaint!

Customizing and Finishing Touches

Now that your table is built and sturdy, it’s time to make it truly yours. This is where you’ll add the storage, finishes, and personal touches that turn a basic frame into a customized workspace.

Let’s explore the options that’ll make your sewing table both beautiful and functional.

Adding Drawers, Shelves, or Bins

Drawer placement under your tabletop keeps scissors and bobbins within arm’s reach while you sew. Side-mounted bins on casters give you flexible storage that rolls away when you need more legroom.

Shelf design between the legs creates a stable platform for fabric stacks without stressing your work surface.

A well-planned ergonomic layout balances DIY sewing table storage with comfortable access to every tool you’ll use.

Painting, Staining, or Sealing The Surface

Once your storage is in place, you can transform raw wood into a polished work surface. Start with surface prep—sand using 120 then 220 grit and wipe clean.

Paint finish hides flaws, while stain options showcase natural grain. Seal everything with water-based polyurethane for scratch resistance.

Color selection sets your room’s mood, and proper sealant types protect against daily wear in DIY home improvement projects.

Installing Cable Management or Power Strips

Your sealed surface needs power, so mount a certified power strip underneath for electrical efficiency. Screw it near the back edge to keep plugs off the floor and cords within reach. Cable organization comes easy with plastic raceways along the table’s back—snap covers let you add wires later without hassle.

- Confirm your strip accommodates 15 amps to avoid overloading during power strip safety checks

- Run machine cords through a rear notch for clean cord management

- Clip cables every 8 to 12 inches under the table mounting surface

- Leave slack in power cords to reduce plug strain

Personalizing for Comfort and Style

Comfort meets function when you tailor your DIY sewing table to fit you. Add a cushioned wrist pad at the machine edge to support good sewing posture during long seams.

Clip a daylight LED lamp where it shines on the needle from your non-dominant side—these lighting options show true fabric colors.

Paint the frame in your favorite shade or mount a pegboard for decorative touches that make this custom furniture yours.

Top 5 Essential Tools for Building

You don’t need a fully stocked workshop to build a great sewing table. The right handful of tools will get you through every cut, join, and finish with confidence.

Here are five essentials that’ll make your build smoother and help you work like a pro.

1. General Tools 10 Inch Contour Gauge

Capturing the exact curve of a wall or molding can save you hours of frustration! That’s where the General Tools 10 Inch Contour Gauge shines. This handy tool uses thin sliding pins to copy irregular shapes up to 10 inches wide, so you can transfer wall profiles, baseboard curves, or corner details straight to your tabletop.

The pins lock in place once you’ve traced the shape, and the built-in ruler lets you mark dimensions directly. Its lightweight, rust-proof plastic construction makes it perfect for tight spots around your sewing table build.

| Best For | DIYers and woodworkers who need to transfer irregular shapes like moldings, corners, and wall profiles for precise cuts and fits. |

|---|---|

| Material | Plastic |

| Weight | 15.8 ounces |

| Primary Use | Shape duplication |

| Skill Level | DIY/Beginner |

| Durability | Sturdy plastic |

| Storage Feature | 4 back magnets |

| Additional Features |

|

- Captures complex curves and angles up to 10 inches wide with adjustable sliding pins

- Lightweight plastic design won’t rust and fits easily into tight spaces

- Built-in magnets and ruler make it simple to hold, measure, and mark dimensions on the spot

- End-caps can be too thick for certain applications like crown molding

- Pins don’t always stay perfectly aligned around the edges

- Metal fins are stiff and sharp enough to cause injury if you’re not careful

2. Craftsman Cordless Drill Driver Kit

A cordless drill driver is the beating heart of any DIY build, and the Craftsman V20 kit truly delivers. With a brushless motor, a sturdy half-inch chuck, and two-speed gearbox, you can switch easily from drilling pilot holes to driving screws through plywood or hardwood.

The built-in LED light brightens tricky spots under the table, while the lightweight design means less fatigue. Plus, the interchangeable V20 batteries work with any other V20 tools you’ll add to your growing workshop.

| Best For | DIYers and homeowners who need a reliable, versatile drill for everything from furniture assembly to light framing work. |

|---|---|

| Material | Metal |

| Weight | 6.3 lbs |

| Primary Use | Drilling and driving |

| Skill Level | Intermediate/Professional |

| Durability | Brushless motor |

| Storage Feature | Soft bag included |

| Additional Features |

|

- Brushless motor delivers serious power (350 unit watts out) and longer runtime than standard motors

- Two-speed gearbox (0-600/0-1,900 RPM) lets you dial in the right speed for delicate or heavy-duty tasks

- V20 battery system means you can share batteries across your entire Craftsman cordless tool collection

- Clutch and bit clamp can feel stiff out of the box, taking some break-in time

- LED light stays on whenever you pull the trigger—no manual off switch

- Only comes with a soft bag instead of a hard case, so you’ll need to be careful during transport

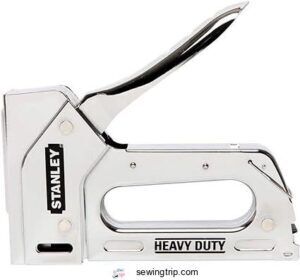

3. Stanley Heavy Duty Staple Gun

You’ll need a powerful staple gun to secure fabric, batting, or dust covers to your table’s wooden frame, and the Stanley TR110 has you covered. Its all-steel construction won’t bend or break when you’re driving staples into dense wood or plywood edges.

The bottom-load channel holds a full strip of T50 staples, so you won’t pause mid-project. With an integrated handle lock for safe storage and enough power to bite into solid backing, this tool makes upholstery work feel smooth.

| Best For | DIYers and home crafters who need a reliable staple gun for furniture upholstery, window screens, or decorative projects around the house. |

|---|---|

| Material | Alloy Steel |

| Weight | 2.12 pounds |

| Primary Use | Heavy-duty stapling |

| Skill Level | All levels |

| Durability | Heavy duty steel |

| Storage Feature | Compact design |

| Additional Features |

|

- Heavy-duty steel build that won’t flex or fail when driving staples into hardwood

- Holds 84 staples at once so you can work without constant reloading

- Side window lets you see when you’re running low on staples

- Takes a lot of hand strength to squeeze the trigger, which can be tough for some users

- Can cause hand fatigue during long projects

- Some quality control issues reported with defective units

4. Craftsman Mitre Saw Tool

Cutting accurate angles transforms a basic sewing table into a polished piece, and the Craftsman CMHT20600 mitre box delivers those clean cuts without power tools. Its cam-shaped pins lock into a honeycomb base, holding your trim steady while you saw 45-degree and 90-degree angles for corners and edges.

The built-in saw stop prevents you from slicing into the box itself, and molded storage bins keep pins organized. At 19.3 inches long, it manages small trim work beautifully—perfect for framing out storage cubbies or cutting decorative edging on your table.

| Best For | DIYers and hobbyists who need precise angle cuts for small woodworking projects like picture frames, trim work, or furniture modifications. |

|---|---|

| Material | Plastic |

| Weight | 0.01 ounces |

| Primary Use | Precision cutting |

| Skill Level | DIY/Small projects |

| Durability | Plastic construction |

| Storage Feature | Molded-in bins |

| Additional Features |

|

- Cam-lock pins and honeycomb base keep workpieces secure for accurate cuts at multiple angles (45°, 90°, 22.5°)

- Built-in saw stop protects the box from damage and extends its lifespan

- Compact size with smart storage bins makes it easy to keep organized and portable

- Plastic construction isn’t durable enough for heavy-duty or professional use

- Saw struggles with thicker materials and has limited cutting range at 45-degree angles

- Box can still be cut into if you’re not careful, despite the saw stop feature

5. Kreg Pocket Hole Jig

Pocket holes hide the screws that hold your table together, and the Kreg KPHJ320 jig guides every angled hole perfectly. You’ll drill into leg boards and aprons at a fixed angle, then fasten them with self-tapping screws that pull joints tight without clamps or complicated joinery.

It accommodates material from 1/2 inch to 1 1/2 inches thick, so you can build sturdy frames and attach cross braces under your tabletop. At $39.00, it’s compact, durable, and includes the drill guide and hex wrench you need to get started.

| Best For | DIYers and woodworkers who want to create strong, hidden joints in furniture projects without needing advanced skills or expensive tools. |

|---|---|

| Material | Glass-filled nylon |

| Weight | 1.4 pounds |

| Primary Use | Creating pocket joints |

| Skill Level | Beginner to experienced |

| Durability | Hardened steel |

| Storage Feature | Compact design |

| Additional Features |

|

- Creates rock-solid joints with hidden screws that give your projects a clean, professional look

- Adjustable guides work with materials from 1/2″ to 1 1/2″ thick, so you can tackle different frame sizes and thicknesses

- Compact design fits in tight spaces where bulky tools won’t reach, and at $39 it’s an affordable way to step up your joinery game

- You’ll need to clamp your workpiece down for accurate drilling, which adds an extra step to the process

- Kreg’s specialty screws cost more than standard screws, so consumables add up over time

- Takes some practice to dial in the perfect angle and depth, especially if you’re new to pocket hole joinery

Frequently Asked Questions (FAQs)

What is the best lighting for sewing tables?

Daylight LED bulbs in the 5000K to 6500K range give you the truest fabric colors, so your thread and prints don’t look off.

Pair overhead lighting with an adjustable task lamp for shadow-free stitching!

How do I soundproof the sewing table?

An ounce of prevention beats a pound of cure. Place a thick rubber mat under your machine to absorb vibration, then add soft pads under each table leg to keep noise from traveling through floors.

Can wheels be added for portability?

Locking swivel casters are your best bet—they let you roll the table wherever you need it, then lock both wheel and swivel so everything stays rock-solid while you work.

How to manage power cords and outlets?

Route cords along the back edge with adhesive clips so they don’t snag fabric.

Mount a surge protector under the table for easy access, and keep plugs on a dedicated circuit to avoid overloading.

What are ideal sewing chair considerations?

Your sewing chair should offer height adjustment so your forearms stay level with the table, plus a contoured backrest that bolsters your lower spine and a cushioned seat that won’t compress after long sessions.

How do I prevent my sewing table from wobbling?

Check every leg length first—just 2 to 3 millimeters of difference causes wobble. Tighten all screws and bolts where legs meet the frame, then add adjustable leveling feet or thin shims to stabilize it.

Can I use reclaimed wood for my table?

Reclaimed wood brings character, durability, and strength to your project. Just inspect each board carefully for hidden nails, treat for pests, sand smooth, and seal well before fabric touches it.

What weight capacity should my table support?

Your table should handle at least 60 to 80 pounds—enough for a typical home machine plus fabric and tools. If you’re using heavier equipment, aim for 100 pounds or more.

How do I protect the surface from pins and scissors?

You can place a self healing cutting mat on top to absorb blade pressure and pin pricks.

Clear vinyl covers also work great, blocking sharp tips while letting you see the surface underneath.

Should I add wheels or casters for mobility?

Wheels give you the freedom to rearrange your workspace in seconds. Just flip the caster locks down when you sew so the table stays put, then release and roll it away when you’re done.

Conclusion

The best sewing tables are the ones you build yourself—not because you’re a master carpenter, but because you know exactly what you need. Making a sewing table puts you in control of every detail, from the perfect height to the storage that actually makes sense for your space.

You’ve now got the blueprint to create a workspace that fits your creative flow, not the other way around. Time to grab those tools and get building!

- https://www.rebeccagracequilting.com/2013/01/what-height-my-sewing-table-ergonomics.html

- https://www.goldstartool.com/blog/choosing-the-perfect-sewing-table-factors-to-consider.htm

- https://www.naksewing.com/portfolio-of-stories-blog/best-sewing-machine-table-height

- https://www.quiltingboard.com/main-f1/sewing-table-size-pros-cons-configuration-t27484.html

- https://carriedawayquilting.com/2015/08/diy-cutting-table/