This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

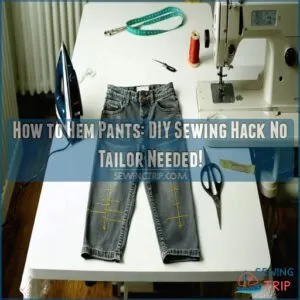

That first crooked hemline you sew will teach you more than any YouTube tutorial—mostly that eyeballing measurements never works. New sewers often skip the preparation steps, diving straight into stitching only to end up with wavy, uneven hems that scream “homemade” in all the wrong ways.

The truth is, professional-looking hems aren’t about perfect stitching technique—they’re about the work you do before your needle ever touches fabric. Prewashing, pressing, and measuring might feel tedious, but these sewing hem tips for beginners transform shaky first attempts into clean, durable finishes.

Once you understand which hem type matches your fabric and how your tools actually work, you’ll stop dreading hemming projects and start seeing them as the satisfying final touch they should be.

Table Of Contents

- Key Takeaways

- Essential Tips for Preparing Fabric for Hemming

- Tools Every Beginner Needs for Hemming

- How to Sew Basic Hem Types

- Mastering Blind Hem Techniques

- Hemming Tips for Machine and Hand Stitching

- How to Manage Different Fabrics for Hems

- Creative and Decorative Hem Ideas

- Common Hemming Mistakes and How to Avoid Them

- Step-by-Step Hemming for Beginners

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Professional-looking hems depend more on preparation—prewashing fabric, pressing folds, and accurate measuring with a hem gauge—than on fancy stitching techniques.

- Matching your hem type to your fabric matters: single fold for casual wovens, double fold for clean durable edges, narrow rolled for delicate materials, and blind hem for invisible finishes.

- Different fabrics demand different approaches—stabilize knits before stitching, use heavy-duty needles for denim, and support sheers with tissue paper or stabilizer underneath.

- Most hemming mistakes trace back to skipping the iron, eyeballing measurements instead of using proper tools, or mismatching thread weight and needle size to your fabric.

Essential Tips for Preparing Fabric for Hemming

Before you sew a single stitch, a little prep work makes all the difference between a hem that lasts and one that puckers, shifts, or ends up uneven.

Mastering advanced techniques for garment sewing starts with proper fabric prep—marking grain lines, stabilizing edges, and pre-washing when needed.

Getting your fabric ready isn’t complicated, but skipping these steps is where most beginners run into trouble. Here’s what to do before you even thread your needle.

Prewashing Fabric to Prevent Shrinkage

Before you cut a single thread, prewashing fabric is the step that saves your hem later. Cotton can shrink anywhere from 2 to 5 percent in that first wash — linen even more, up to 7 percent. Skip fabric prep, and your freshly hemmed pants could end up shorter than expected after one trip through the laundry.

The fix is simple. Run your fabric through the same wash cycle you’d use on the finished garment. Warm water with mild detergent works for most fabric types. For colorfast testing on dark or bright materials, wash a small swatch first to catch any dye bleed early.

Smart fabric preparation methods now mean hems that hold their shape for good. For more details on how necessary steps like prewashing can influence both fabric longevity and overall website functionality, visit this resource.

Pressing The Hem for Precise Folding

Once your fabric is prewashed, pressing the hem is where folding precision actually happens. Think of it as setting the stage before the performance.

Good heat control starts with testing your iron on a scrap — synthetics can scorch fast. These fabric prep steps shape everything that follows:

- Lift and place the iron rather than sliding to avoid stretching

- Press after each fold for a locked, flat edge

- Use a pressing cloth on delicate fabrics to prevent shine

Solid pressing techniques make your stitches follow a clean, straight path every time. For a deeper dive into the differences between pressing and ironing techniques, check out expert guidance to boost your sewing results.

Using Hem Gauges for Accurate Measurements

Once your hem is pressed flat, a hem gauge takes the guesswork completely out of measuring. This small six-inch tool — a go-to for sewing beginners — has a sliding marker you set to your exact hem width, anywhere from ¼ to 1 inch. Place it flush against the fold, press, and move along the edge. That’s accurate folding made simple.

Hem gauge calibration and consistent fabric alignment ensure every section matches, with no eyeballing required.

| Technique | Hem Gauge Use | Result |

|---|---|---|

| Measuring Techniques | Set slider to target width | Uniform hem depth |

| Fabric Alignment | Flush against folded edge | No skewed or crooked hems |

| Curved Hems | Mark points at intervals | Smooth, even curve |

| Hem Width Control | Check after pressing | Fold stays accurate |

| Sewing Hem Tips | Test on scrap first | Confidence before the real thing |

A measuring tape helps navigate curves where rigid tools struggle. Together, these hemming techniques elevate your sewing results to a genuinely professional level.

Tools Every Beginner Needs for Hemming

Getting your tools sorted before you start hemming makes everything so much easier. You don’t need a whole sewing room worth of equipment — just a few key pieces that do the heavy lifting.

Here’s what every beginner should have on hand.

Hem Gauges and Measuring Tapes

Two small tools can make or break your entire hemming project: a hem gauge and a measuring tape. Hem gauge basics start with a 6-inch ruler featuring a movable slider — set it to any depth between ⅛ and 2 inches for consistent folds every time.

Pair that with a flexible 60-inch measuring tape for accurate hemming around curves. Look for measuring tape tips like dual metric and imperial markings for easy sewing measurements. Together, these sewing basics eliminate guesswork completely.

Pressing Tools Like Hot Rulers

Hot rulers are game-changers for sewing hems for beginners. These heat-resistant tools handle direct iron contact, letting you measure and press your hem in one pass along your ironing board — no constant repositioning needed.

The non-slip surface keeps fabric handling steady, while built-in grid lines guide precise hem measurement from ⅛ inch upward.

As a pressing technique, start low on temperature, glide smoothly, and you’ll get crisp, professional creases. Matching thread to these ironing accessories just seals the deal.

Sewing Machine Attachments for Hems

The right sewing machine attachments make all the difference. Swap in the correct hem feet and your sewing machine practically does the work for you — no manual folding, no guesswork.

Pairing the right foot with pre-washed fabric that won’t shift gives you consistently clean, professional hems every time.

- Blind hem foot – Perfect for blind hemming on dress pants or skirts

- Rolled hem foot – Curls raw edges into a clean 2–4mm fold

- Edge joining foot – Keeps fabric aligned for even, parallel stitching

- Adjustable hemmer – Shifts width from 2mm to 20mm across fabric weights

Pair these hemming tools with proper sewing machine maintenance and matching thread, and you’ll get nearly invisible results every time.

How to Sew Basic Hem Types

There’s no single hem that works for every project, and that’s actually a good thing — it means you can match your technique to the fabric and finish you need. Getting comfortable with just a few basic hem types will take you a long way.

Here are the three every beginner should learn first.

Single Fold Hem Techniques

One fold, one stitch line — that’s really all a singlefold hem asks of you. These fabric fold techniques work beautifully on casual woven garments where hem depth control matters but speed counts too.

Fold your fabric inward once, anywhere from ¼ to 1 inch depending on your project, press that crease firmly, and pin it in place. Your edge stitching methods here are simple: stitch close to the folded edge finishing, and you’re done.

Double Fold Hem for Clean Edges

A double fold hem is your best friend for clean hems that actually last. The trick is simple: fold the raw edge in about ½ inch, press, then fold again roughly 1½ inches. That second fold is your hem allowance doing its job — burying the raw edge completely.

Sewing hem tips that make every double fold hem shine:

- Choose stable wovens like cotton for ideal fabric selection

- Press firmly between each fold for sharp, reliable creases

- Set stitch quality around 2.0–2.5 mm for lightweight fabrics

- Topstitch close to the inner edge, catching both layers

- Backstitch at both ends to lock edge finishing securely

Narrow Rolled Hem for Lightweight Fabrics

Chiffon, organza, silk — these are the fabrics where a narrow rolled hem truly shines. This lightweight finish trims the edge down to just 1/16–1/8 inch, so there’s barely anything there.

For rolled hem tips that actually work, set your stitch length to 1.0–1.5 mm and grab a rolled hem foot — hem foot usage here is everything. Match your thread, and the hem practically disappears.

Mastering Blind Hem Techniques

The blind hem is the secret behind those polished, store-bought finishes that make clothing look professionally made.

Once you know the steps, it’s surprisingly approachable—even for beginners. Here’s what you need to get it right.

Setting Up The Blind Hem Stitch

Most sewing machines include a blind hem stitch that alternates straight stitches with a single zigzag bite — and getting it right comes down to a few smart adjustments. Start by selecting the blind hem symbol, then focus on stitch width adjustment, setting it between 2.0 and 2.5 mm so the bite barely catches one or two threads. Thread tension control matters too — loosen it slightly to around 3 or 4.

These hemming techniques work best when you test on scrap fabric first, fine-tuning in small 0.5 mm steps until your hem stitch optimization delivers that clean, nearly invisible result.

Proper Use of a Blind Hem Foot

With your blind hem settings locked in, it’s time to let the foot do the heavy lifting. The blind hem foot‘s anatomy is simple but clever — a central guiding ridge keeps stitch alignment precise, so only a thread or two gets caught.

Here’s why proper setup pays off:

- Fabric guidance stays consistent, preventing frustrating puckers

- Tension adjustment errors show less when the foot sits flat

- Hemming techniques feel smooth once everything clicks into place

Always remove pins before they reach your sewing machine foot — broken needles are a hard lesson. For sewing for beginners, snap on your blind hem foot, press your fold crisp, and let that guide ridge do the steering.

Achieving an Invisible Hem Look

Once your blind hem foot has guided those tiny stitches into place, thread color matching becomes your secret weapon. Even one shade off catches the eye under indoor lighting—so hold your spool directly against the fabric before you commit.

| Fabric Type | Best Thread Choice |

|---|---|

| Lightweight silk | Fine polyester, exact match |

| Denim | Cotton-poly blend, close match |

| Knits | Stretch polyester, tone match |

| Delicate lace | Hand-stitch, invisible thread |

Keep stitch length control tight—around 2.0 mm—so each bite catches just one or two threads. Fabric grain alignment matters here too; stitching off-grain creates subtle puckers that no amount of pressing fixes. Press from the wrong side afterward, and those invisible stitches practically disappear.

This hemming guide approach works beautifully for sewing for beginners ready to level up their invisible hem game.

Hemming Tips for Machine and Hand Stitching

Whether you’re using a machine or sewing by hand, the stitching method you choose makes a real difference in how your hem holds up. Both approaches have their strengths, and knowing a few key tricks keeps things running smoothly.

Here’s what you need to know to stitch clean, lasting hems either way.

Machine Straight Stitches for Durable Hems

Your sewing machine’s straight stitch is the backbone of durable hemming methods. Set stitch tension carefully and adjust stitch length — 2.0–2.5 mm for lightweight fabric selection, up to 3.0–4.0 mm for denim hem reinforcement.

Match your thread choice to fabric weight, and control your sewing speed for even results. Pair needle size to fabric, and these sewing techniques will keep your hems looking sharp wash after wash.

Hand Stitching With Slip or Running Stitches

When your machine isn’t the right tool for the job, hand stitching steps in beautifully. The slip stitch is your best friend for invisible hems — you’re only catching one or two threads every 6–12 mm, so barely anything shows on the right side. Running stitch works well for lightweight fabrics, leaving a clean dashed line.

- Use fine sharps sewing needles for neat, snag-free stitch tension

- Keep your stitch length consistent — 1–2 mm for slip stitch tips, 2–3 mm for running stitch

- Single-strand thread improves hand sewing control and reduces bulk

Avoiding Tangled Threads During Hand Sewing

Thread management is the unsung hero of knot-free sewing. Keep your thread under 60 centimeters — longer strands tangle almost inevitably. Thread the needle from the freshly cut spool end so the natural twist works with you, not against you.

A quick pass through beeswax makes hand sewing feel smooth. Match your thread tension by holding the strand loosely, pausing every few stitches to untwist.

Your sewing needles should suit the fabric weight — sharp, fresh, and snag-free.

How to Manage Different Fabrics for Hems

Not every fabric plays by the same rules, and that’s where a lot of beginners hit a wall. Knits stretch, denim fights back, and sheer fabrics can feel like you’re trying to hem a cloud.

Here’s how to handle each one without losing your mind.

Hemming Knit Fabrics Without Stretching

Knit fabric is basically fabric that wants to stretch — which makes hemming it a genuine challenge. Start with knit stabilizers like fusible interfacing strips (about 1–1.5 cm wide) pressed along the raw edge before folding. A walking foot keeps both layers moving evenly. Set your stitch length to 3–4 mm and ease thread tension to avoid puckering. A twin needle gives a professional two-line finish with built-in stretch.

- Gentle pressing with steam before stitching helps the fold hold its shape

- A longer stitch length prevents the tight-stitch tunneling that distorts soft jersey

- Troubleshooting common hemming problems starts with testing tension on scrap fabric first

Best Practices for Hemming Denim

Denim demands respect — skip the prep and it’ll fight you every step. Prewash first to avoid shrinkage, then dry completely before sewing hems. A double fold hem keeps raw edges tidy and durable.

Here’s your quick-start checklist:

- Swap to size 100/110 denim needles for clean stitching through thick layers

- Use a walking foot to feed fabric evenly and prevent puckering

- Set stitch length to 3.0–3.5 mm for strong topstitching denim results

Trim bulky hem allowance at seam intersections, press sharply, and backstitch at both ends. Troubleshooting common hemming problems? It almost always starts with skipped pressing.

Tips for Hemming Delicate or Sheer Fabrics

Sheer and delicate fabrics are the divas of your fabric stash — beautiful, but they need careful handling. Start with Prewashing Fabric gently in cold water to prevent distortion later.

For Fabric Stabilization, slide tissue paper or wash-away stabilizer underneath before you stitch — it’s a game changer. Choose a fine needle, size 60/8 to 70/10, and loosen your upper tension slightly.

A Rolled Hem or Blind Hem keeps the Fabric Edge nearly invisible. For Invisible Stitching on sheers, hand sewing with a slip stitch beats machine work every time. Match your thread, and the hem practically disappears.

Creative and Decorative Hem Ideas

A hem doesn’t have to be purely functional — it can be the detail that makes a garment feel intentional and finished. Whether you want something casual and relaxed or a little more polished, there are techniques that go well beyond the basic straight stitch.

Here are a few ideas to get you started.

Adding Decorative Stitches to Hems

Your hem doesn’t have to be invisible — it can be the detail people actually notice. With your sewing machine’s built-in options, decorative stitch patterns like scallops or geometric motifs become easy hem embellishments.

Smart thread choices do the heavy lifting: contrast colors make stitch placement pop, while matching tones keep it subtle. Adjust your stitch length for the effect you want, and press thoroughly before edge finishing for clean, professional results.

Frayed Hem for Casual Garments

Sometimes the most intentional-looking finish is the one you don’t stitch down. A frayed edge finish gives casual hem styles — think jeans, canvas jackets, cotton skirts — that relaxed, effortlessly cool texture you can’t fake.

Here’s how to control the fray without losing the look:

- Mark your finished length, then cut ¼ inch lower for controlled fringe formation.

- Stitch a straight line just above the raw edge to anchor the fray.

- On fast-unraveling denim, a simple straight stitch beats a rolled hem or double fold hem here.

- Wash inside-out on a gentle cycle — skip the dryer entirely.

- Trim loose threads regularly to keep textured hem effects intentional, not wild.

Fringe control methods make all the difference between artfully casual and just unraveling.

Zigzag and Overlocked Hem Techniques

Not every fabric edge needs a frayed, casual vibe — sometimes you want clean, polished control. That’s where a zigzag stitch and overlocking shine as reliable hemming techniques.

For a solid zigzag hem, set your stitch width to 3 and length to 1.5, stitching about ¼ inch from the raw edge. This edge finishing method manages knits beautifully without breaking under stretch.

| Technique | Best Fabric | Stitch Tension |

|---|---|---|

| Zigzag Stitch | Knits, lightweight | Medium, balanced |

| 3-Thread Overlock | Woven, delicate | Slightly loose |

| 4/5-Thread Overlock | Denim, heavy knits | Firm, snug |

Overlocking takes fabric edge finishing further by trimming and encasing the raw edge simultaneously — hem stability in one pass. Always test your overlock settings on scrap first.

Common Hemming Mistakes and How to Avoid Them

Even experienced sewists run into the same handful of hemming problems — and most of them are totally preventable. The good news is that once you know what to watch for, fixing your process is pretty straightforward.

Here are the most common mistakes beginners make and how to sidestep them.

Uneven Hemlines From Improper Measurement

Precision is what separates a polished garment from one that frustrates you mid-project. Most hem irregularities trace back to measuring errors — measuring from different reference points, ignoring fabric shrinkage, or eyeballing hem allowance instead of using a hem gauge. These sewing inconsistencies compound quickly.

Here’s how to lock in proper hem alignment every time:

- Measure from the floor up, not from the waistband down

- Use a measuring tape and hem gauge together for consistency

- Mark your hem line with chalk before folding

- Prewash fabric first to eliminate surprise shrinkage

These simple garment construction tips and sewing techniques keep your hemline honest.

Mistakes Due to Skipping Ironing Steps

Skipping the iron is one of the sneakiest ironing errors beginners make — and it shows up fast. Without pressing techniques before and after stitching, your fabric edge finishing gets wobbly, hems shift, and seam integrity suffers with every wash. Fabric distortion creeps in because unpressed fibers don’t hold their position.

For hem stability that actually lasts, press each fold crisp and flat. It’s a non-negotiable step in solid sewing techniques and tips and hemming basics overall.

Choosing The Right Thread and Needle Sizes

Just like pressing sets your hem in place, pairing the right thread weight and needle sizes keeps everything from falling apart — literally. A 70/10 works beautifully on delicate sheers; bump up to a 90/14 for midweight cotton. For fabric compatibility, match cotton thread to natural fibers and polyester to stretch. Get these sewing notions and tools right, and your stitch tension stays balanced throughout.

- Use 70/10–80/12 needles for lightweight fabrics

- Use 90/14–100/16 for denim or canvas

- Match thread color to your fabric for invisible hems

- Always test settings on scrap fabric first

Step-by-Step Hemming for Beginners

Now that you know what mistakes to watch out for, it’s time to actually sew. The whole process breaks down into three simple steps that anyone can follow. Here’s exactly what to do.

Folding, Pressing, and Pinning The Hem

A crisp hem starts with solid fabric preparation and the right pressing tools. Match your iron’s heat to your fabric, then press that first fold about half an inch deep—this is your hem allowance. For a double fold hem, press again at your final depth, usually one to two inches.

Pinning methods matter too: place rust-resistant pins perpendicular to the edge, spacing them every two to three inches. This folding and pressing combo keeps your hemline even all the way around, setting you up for stitching success.

Stitching The Hem for a Professional Finish

Your stitching determines whether that hem looks homemade or expertly crafted. Set your sewing machine to a stitch length between 2.0 and 2.5mm for most fabrics—that sweet spot balances strength with flexibility. Adjust stitch tension so the thread lies flat without puckering. A straight stitch works beautifully for double fold hems, while a blind hem technique keeps stitches nearly invisible from the right side.

What makes professional finishing work:

- Match thread color exactly to your fabric

- Keep your hem allowance fully supported on the machine bed

- Backstitch at both ends for hem reinforcement

- Test stitch variations on scrap fabric first

Final Pressing for a Polished Look

A final press transforms your hem from “done” to done right. Heat and steam work together to lock fabric fibers in place—that crease stays sharp even after hours of wear.

Use a pressing cloth on delicate materials to avoid shine, and press from the wrong side first to prevent scorching. Let the garment cool flat for a full minute before handling; this sets the edge and prevents waviness.

Check hem alignment under bright light, then give the right side a gentle sweep with your iron. That polished look? It’s all in those fabric finishing steps.

Frequently Asked Questions (FAQs)

How do you sew hems?

You know the saying: measure twice, cut once. Hemming follows that wisdom—measure and fold your fabric, press it flat, pin securely, then stitch using a straight or blind hem stitch matched to your fabric weight.

How do you Hem your clothes?

Start by measuring your desired hem length with a hem gauge, then press a clean fold. Pin in place, choose the right stitch technique for your fabric selection, and finish with a final press for professional results.

Can you sew a hem from the right side?

You can hem from the right side by folding the edge inward and topstitching near the fold.

This approach gives you visual control, especially helpful on knits, denim, and fabrics where precision matters most.

How do you sew a blind hem?

You’ll achieve near-invisible results once you fold fabric wrong-side-up, attach your blind hem foot, and set a zigzag stitch that barely kisses the fold—catching just one thread.

How do you make a perfect Hem?

Accurate measuring with a hem gauge, careful pressing, and matching thread create professional results.

Control stitch length and tension, choose stable fabric, finish raw edges with seam finishing or edge binding, and press thoroughly for lasting hem stability.

How do you sew a double fold Hem?

Practice your fold techniques by turning the raw edge under once, then doubling it back to hide frayed threads. Press hard after each turn, pin flat, then sew close to that inner crease.

How to stitch a hem for beginners?

Start by folding your fabric edge to the desired allowance and pressing it flat with an iron. Pin securely, then use a straight stitch on your sewing machine, keeping consistent seams throughout.

What are the 5 basic steps in hemming?

First, measure your hem allowance—usually 5 to 4 cm. Press the raw edge once, fold again, then pin securely. Stitch close to the inner fold, and press for a clean finish.

How to make a perfect hemming?

Think of hemming like building a house—foundation matters most. Perfect hemming demands a precise hem allowance, matched needle choice, aligned fabric grain, consistent stitch tension, backstitching ends, a thorough iron press, and selecting proper types of hems for your project’s professional finish.

What is the best stitch pattern for hemming?

The blind hem stitch creates nearly invisible results on dress pants and formal wear.

Straight stitches work best for woven fabrics like cotton, while zigzag stitches accommodate knit fabric stretch without breaking during wear.

Conclusion

Your first hemming disaster won’t be your last—even pros still unpick wonky stitches now and then. But armed with these sewing hem tips for beginners, you’ll troubleshoot faster and waste less fabric.

The difference between amateur and polished isn’t talent; it’s knowing when to press, measure twice, and match your technique to your material. Stop overthinking it. Grab your iron, pin that fold, and stitch with confidence.