This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Walking feet move layers evenly through your machine, preventing that frustrating bunching effect. Roller feet glide smoothly over textured surfaces, while leveling tools keep your presser foot balanced when crossing bulky seams.

These attachments distribute pressure more effectively than standard feet, maintaining consistent stitch quality and preventing needle breakage. Whether you’re hemming heavy curtains or crafting leather bags, the right foot transforms challenging projects into manageable tasks.

Your machine’s compatibility matters—low-shank and high-shank systems require different attachments for superior performance, ensuring that you can work efficiently with your thick fabrics and achieve professional results with preventing needle breakage.

Table Of Contents

- Key Takeaways

- Sewing Thick Fabric Basics

- Choosing Right Presser Foot

- Sewing Machine Foot Techniques

- Top 10 Thick Fabric Feet

- 1. Bulky Seam Jumper Sewing Tool

- 2. Walking Foot for Sewing Machines

- 3. Walking Foot for Thick Material Sewing

- 4. Brother Sewing Machine Walking Foot

- 5. HONEYSEW Open Toe Walking Foot

- 6. Brother Open Toe Walking Foot

- 7. Wide Rolled Hem Presser Foot Set

- 8. Open Toe Quilting Darning Foot

- 9. Sequin Presser Foot Sewing Machine Accessory

- 10. Roller and Zigzag Sewing Machine Foot

- Machine Compatibility Matters

- Mastering Thick Fabric Sewing

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You’ll need specialized feet, like walking feet or compensating feet – These distribute pressure evenly and prevent the bunching, skipped stitches, and needle breakage that standard feet cause on thick materials like denim, canvas, and leather.

- Your machine’s shank type determines foot compatibility – Check if you’ve got a low-shank (¾ inch) or high-shank (1¼ inch) machine before buying, since different systems require specific attachments or adapters to work properly.

- Leveling tools and techniques keep your stitches consistent – Use leveling buttons, Jean-a-ma-jigs, or paper shims to keep your presser foot parallel when crossing bulky seams, preventing those frustrating tiny uphill stitches and oversized downhill loops.

- Proper needle selection and slow sewing prevent costly damage – Choose size 90-110 needles for thick fabrics, reduce your sewing speed over bulky areas, and inspect needles regularly to avoid breakage that can damage your machine or ruin your project.

Sewing Thick Fabric Basics

Working with thick fabrics requires understanding how your machine handles dense materials like denim, canvas, and multiple fabric layers.

Thick fabric sewing transforms from machine wrestling match to smooth sailing with the right techniques and tools.

You’ll encounter challenges such as uneven stitches, needle strain, and feed dog struggles when sewing uphill or downhill over bulky seams without proper techniques and equipment, including issues with dense materials and uneven stitches.

Understanding Fabric Types and Machine Limitations

Ever wondered why your sewing machine throws a tantrum when tackling denim or canvas?

Understanding fabric thickness limits and machine stress points prevents costly repairs and frustrating breakdowns.

Your machine faces these challenges with heavy materials:

- Feed dog limitations struggle to grip dense fabrics properly

- Needle size impact determines whether you’ll break or bend needles

- Fabric density effects cause uneven stitches and thread tension issues

- Machine stress points wear faster when forcing thick fabric through

Importance of Proper Foot Usage and Stitch Consistency

Your machine’s performance hinges on proper foot alignment and pressure adjustment.

Without the right thick fabric foot, you’ll battle inconsistent stitches and poor fabric feeding.

A quality fabric feeding foot maintains seam quality by ensuring even material flow.

When sewing thick materials, an even feed foot prevents the dreaded stitch length variations that plague heavy fabric projects.

Tips for Sewing Uphill and Downhill on Thick Fabrics

Uphill stitching creates tiny stitches when your machine climbs thick seams, while downhill stitching produces oversized loops.

Combat this by stopping with your needle down before bulky areas, then raising your presser foot.

Use leveling techniques to keep your heavy duty foot parallel during fabric feeding. A walking foot sewing setup helps maintain needle control when tackling these challenging terrain changes on thick materials.

Choosing Right Presser Foot

You’ll need the right presser foot to handle thick fabrics without damaging your machine or creating uneven stitches.

Specialized feet like walking feet, compensating feet, and zigzag feet with leveling buttons maintain proper fabric feeding and prevent costly repairs when sewing heavy materials like denim, canvas, or multiple fabric layers.

Features of Specialized Presser Feet for Thick Fabrics

Specialized thick fabric feet transform your sewing experience with innovative features.

Transform your thick fabric struggles into smooth, professional sewing with the right specialized foot.

The sprung foot design tips forward and backward for smooth seam navigation over bulky layers. Walking foot sewing technology provides dual feed mechanisms, ensuring fabric feeding stays consistent from above and below.

Heavy duty foot construction handles denim, canvas, and multiple layers while maintaining perfect stitch quality throughout your project, utilizing walking foot sewing technology.

Benefits of Using a Zigzag Foot With a Leveling Button

Your zigzag foot’s leveling button transforms thick fabric sewing from a wrestling match into smooth sailing.

This button functionality locks your sewing machine foot level, ensuring consistent fabric feeding over bulky seams.

You’ll achieve perfect level stitches without machine strain, making seam navigation effortless.

The leveling button prevents your heavy fabric from bunching, delivering professional results every time.

You can find a zigzag leveling foot online.

The leveling button prevents your heavy fabric from bunching, delivering professional results every time, with a leveling button that ensures smooth sailing.

Alternatives to Leveling Buttons for Smooth Sewing

When your thick fabric foot lacks a leveling button, don’t panic.

Jean-a-ma-jig and Hump Jumper tools act as foot splints, sliding under your sewing machine foot’s heel.

Paper shims or fabric shims work equally well for fabric handling.

These alternatives keep your thick fabric foot level when tackling bulky seams, ensuring smooth stitching without machine strain, and are useful for fabric handling.

Sewing Machine Foot Techniques

You’ll need proper techniques to handle thick fabrics without damaging your machine or creating uneven stitches.

These methods include using leveling buttons, adjusting presser foot pressure, and employing support tools to maintain consistent stitch quality across bulky seams.

They are essential for maintaining consistent stitch quality and ensuring your sewing projects turn out as expected.

Using The Leveling Button for Even Stitches

Most modern sewing machines include a zigzag foot with a leveling button that’s your secret weapon for consistent stitch quality on thick fabric.

Press and hold the button while lowering your presser foot to lock it level, preventing foot pop during bulky seam crossings.

This leveling button use guarantees smooth downhill sewing ease, and the button return action happens automatically, ensuring a consistent stitch quality.

Adjusting Presser Foot Pressure for Different Fabrics

Your sewing machine foot needs the right pressure to handle different fabric thickness levels effectively.

Too much pressure crushes delicate materials, while too little causes feeding issues and poor stitch quality.

Most machines have adjustable pressure settings that you can fine-tune for superior results.

- Test pressure settings on fabric samples before starting your actual project

- Reduce pressure for lightweight fabrics to prevent puckering and distortion

- Increase pressure for heavy fabric to guarantee proper feeding through the machine

Utilizing Tools Like Jean-a-ma-jig or Hump Jumper for Support

Beyond adjusting pressure, you’ll discover game-changing tools that transform thick fabric challenges.

Jean-a-ma-jig benefits include preventing presser foot drops while Hump Jumper uses extend to any bulky seam situation. These alternative tools slide under your sewing machine foot, creating level surfaces for smooth stitching.

You can find products for Jean-a-ma-jig online.

| Tool Feature | Jean-a-ma-jig | Hump Jumper | DIY Alternative |

|---|---|---|---|

| Cost | Under $4 | Under $4 | Free cardboard |

| Durability | High-grade plastic | Multiple shapes | Temporary use |

| Tool storage | Compact design | Various sizes | Easy disposal |

Top 10 Thick Fabric Feet

You’ll find these ten specialized presser feet transform your thick fabric sewing from frustrating to effortless.

Each foot addresses specific challenges you face when working with heavy materials like denim, canvas, and multi-layered fabrics.

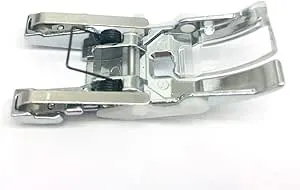

1. Bulky Seam Jumper Sewing Tool

Leveling your presser foot becomes effortless with this dual-purpose tool that tackles thick seams like a pro.

You’ll get two thickness options—1/8" and 3/16"—to handle everything from jean hems to quilted layers.

Simply slip it under your presser foot’s back edge, and it creates the horizontal position needed for consistent stitches.

No shank adapter required, and it works with Brother, Babylock, Kenmore, and most machines.

This little game-changer prevents skipped stitches and needle breakage while maintaining perfect stitch quality over bumps.

Best For: Beginners to advanced sewers working on thick seams, jeans, quilts, or layered fabrics.

- May require practice for first-time users to position correctly.

- Not ideal for very delicate or thin fabrics.

- Limited to manual adjustment during sewing sessions.

- Prevents skipped stitches and needle breakage on bulky seams.

- Dual-thickness design accommodates different sewing needs.

- Compatible with most sewing machine brands without extra adapters.

2. Walking Foot for Sewing Machines

When your machine struggles with multiple fabric layers, a walking foot becomes your best ally.

This specialized attachment features its own set of feed dogs that work alongside your machine’s built-in system.

The upper feed dogs grip and move fabric from the top while the lower ones push from underneath, creating a dual-action system that prevents fabric shifting and guarantees even feeding through thick materials like leather, vinyl, or quilted layers.

You’ll achieve consistent stitches without the frustration of uneven seams or puckering that typically occurs with standard presser feet, ensuring a smooth and even finish with thick materials.

Best For: Quilters, sewing enthusiasts, and DIYers working with thick, layered, or slippery fabrics like leather, vinyl, or knits.

- Not suitable for extremely heavy-duty industrial sewing.

- Requires proper installation and setup for effective use.

- Regular cleaning needed for maintaining smooth performance.

- Ensures even fabric feeding for consistent stitches on thick materials.

- Reduces fabric shifting and puckering during sewing.

- Compatible with most sewing machine brands for versatility.

3. Walking Foot for Thick Material Sewing

How can you tackle those frustrating thick seam challenges that make your machine struggle?

This snap-on walking foot delivers the solution you’ve been seeking.

Compatible with Singer, Brother, and Toyota machines, it handles 4-6 layers of denim and leather with ease.

The dual feeding action grips fabric from above while working in sync with your machine’s feed dogs below.

You’ll achieve professional results on heavy materials without the typical puckering or uneven stitches that plague thick fabric projects.

Best For: People who need precise and smooth sewing on thick materials like denim, leather, and multi-layered fabrics.

- Dual feeding action ensures even fabric movement and prevents puckering.

- Compatible with Singer, Brother, and Toyota machines for versatility.

- Handles up to 6 layers of thick fabrics like denim and leather with ease.

- Requires a compatibility check with your specific machine model before purchase.

- Not suitable for extremely thick materials beyond 6 layers.

- Regular cleaning needed to maintain optimal performance.

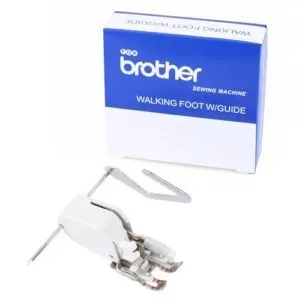

4. Brother Sewing Machine Walking Foot

When you’re wrestling with thick layers that make your machine groan, Brother’s walking foot becomes your secret weapon.

This powerhouse attachment features dual feed systems that grip fabric from above and below, eliminating the dreaded fabric drift that ruins perfectly planned seams.

You’ll sew forward and backward with confidence on leather, vinyl, and multiple fabric layers, making your quilting and heavy-duty sewing just got exponentially easier.

Compatible with Brother PQ-1500S, PQ-1300, DZ1500 models, plus select Janome machines, it transforms challenging projects into smooth sailing.

Best For: Quilters, tailors, and sewing enthusiasts working with thick fabrics or multiple layers.

- Dual feed system for smooth and even fabric feeding.

- Compatible with Brother and select Janome models for versatility.

- Handles heavy-duty materials like leather, vinyl, and upholstery with ease.

- Compatibility limited to specific machine models.

- No additional accessories or tools included.

- Requires proper installation for optimal use.

5. HONEYSEW Open Toe Walking Foot

Beyond traditional walking feet, the HONEYSEW Open Toe Walking Foot brings modern innovation to thick fabric sewing.

You’ll appreciate its open toe design that provides clear visibility for decorative stitching while maintaining the heavy-duty construction needed for multiple fabric layers.

This foot’s guide bar helps you manage tricky materials like plaids and knits with precision.

Compatible with most low-shank machines including Singer, Brother, and Kenmore, it’s an affordable upgrade that transforms your sewing experience on challenging fabrics.

Best For: Home sewers and quilting enthusiasts who need better visibility and control when working with thick, tricky fabrics.

- Limited to low-shank machines, not suitable for high-shank models.

- Warranty period is only 7 days, which might be too short for some buyers.

- Interest-free payment plans may not be available in all regions.

- Open toe design provides clear visibility for precise decorative stitching.

- Heavy-duty construction ensures durability and consistent fabric feeding.

- Compatible with most low-shank sewing machine brands.

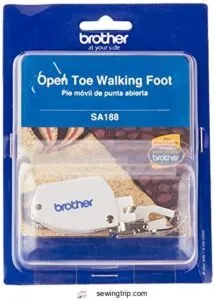

6. Brother Open Toe Walking Foot

The Brother Open Toe Walking Foot transforms challenging sewing tasks into manageable projects.

You’ll appreciate its built-in fabric feeding system that controls multiple layers and prevents shifting during quilting or decorative stitching.

This genuine Brother accessory features an open toe design for enhanced visibility, making it perfect for matching prints and handling slippery fabrics.

Its heavy-duty construction handles thicker materials with ease, while precision engineering guarantees peak performance, making it a solution for professional results on demanding fabrics with compatible low-shank machines.

Best For: Quilters and sewers who need precise fabric control on low-shank machines, especially for thicker or slippery materials.

- Limited compatibility to low-shank machines.

- Requires verification of machine compatibility before purchase.

- May involve a learning curve for beginners.

- Built-in fabric feeding system prevents shifting during quilting.

- Open toe design improves visibility and stitch placement.

- Heavy-duty construction handles thicker fabric layers effectively.

7. Wide Rolled Hem Presser Foot Set

This hemming powerhouse transforms tedious hem work into effortless precision.

You’ll get six interchangeable feet creating 1/4" to 1" rolled hems in one smooth pass.

The guide automatically turns raw edges under twice, eliminating pre-folding and ironing steps that eat up your time.

Perfect for medium to heavy fabrics, this set works with most low-shank machines using snap-on adapters.

While older machines might need compatibility checks, the professional results make this investment worthwhile for sewers tackling frequent hemming projects.

Best For: Sewers who frequently work with medium to heavy fabrics and need efficient, professional-looking hems.

- Creates multiple hem sizes (1/4" to 1") in one step.

- Saves time by turning raw edges under without pre-folding or ironing.

- Compatible with most low-shank snap-on sewing machines.

- Compatibility with older machines may require additional checks or adapters.

- Designed primarily for medium to heavy fabrics, less ideal for lightweight materials.

- Users may need to reposition the needle for accurate hem alignment.

8. Open Toe Quilting Darning Foot

When you’re quilting thick materials or working with multiple fabric layers, the Open Toe Quilting Darning Foot becomes your secret weapon.

Its spring-loaded mechanism prevents fabric from lifting with the needle, eliminating those frustrating skipped stitches that plague thick material projects.

The open toe design gives you crystal-clear visibility of your stitching line, making it perfect for free motion quilting and embroidery work.

This foot moves effortlessly up and down with your needle, crossing even the bulkiest seams without breaking stride.

Best For: Quilters and sewists working with thick materials or multiple fabric layers who need precision and better stitch visibility.

- Spring-loaded mechanism prevents skipped stitches.

- Open toe design enhances stitch visibility.

- Compatible with most low-shank snap-on sewing machines.

- Not compatible with high-shank or industrial machines.

- Requires proper installation and adjustment for best results.

- Regular cleaning and maintenance needed for longevity.

9. Sequin Presser Foot Sewing Machine Accessory

Wedding gowns and evening wear demand precision when you’re working with sequined fabrics.

This specialized foot eliminates the tedious task of removing beads before sewing, letting you glide through embellished materials without thread breaks or needle deflection.

The streamlined metal base prevents fabric snagging while maintaining consistent stitch quality.

You’ll handle delicate sequins and beaded trims effortlessly, whether you’re working on bridal couture or fashion projects.

It’s universally compatible with most industrial machines, making professional results achievable for both large-scale productions and intricate custom work.

Best For: Professional tailors and fashion designers working on sequined garments like wedding dresses and evening gowns.

- May not fit older or vintage sewing machines.

- Limited to users familiar with industrial sewing equipment.

- Requires a specialized guide set for certain trims.

- Saves time by eliminating manual bead removal.

- Provides smooth and consistent sewing on embellished fabrics.

- Universally compatible with most industrial sewing machines.

10. Roller and Zigzag Sewing Machine Foot

This dual-purpose foot tackles your trickiest sewing challenges with ease.

The metal roller prevents fabric slipping and puckering on stretchy materials like jerseys, while the Teflon surface glides smoothly over leather and vinyl without sticking.

You’ll get professional results on heavy knits and synthetic materials that typically cause headaches.

Compatible with most low-shank machines from Singer, Brother, and Babylock, it snaps on quickly following your manual.

Two specialized feet in one package means you’re equipped for any thick fabric project, and with the Teflon surface, you can work on a variety of materials, including those that are typically challenging, like stretchy materials.

Best For: Sewing enthusiasts and professionals working with leather, vinyl, or stretchy fabrics who need precise and smooth stitching on challenging materials.

- Prevents fabric slippage and puckering on stretchy or heavy materials.

- Compatible with most low-shank sewing machines from popular brands.

- Includes two specialized feet for versatility in handling tricky projects.

- Some Singer machines may require a low-shank adapter.

- May not fit high-shank or specialty sewing machines.

- Limited to use on low-shank snap-on compatible models.

Machine Compatibility Matters

You can’t simply grab any thick fabric foot and expect it to work with your sewing machine.

Different machines use specific attachment systems, from low-shank and high-shank fittings to brand-specific designs like Bernina’s unique system.

So you’ll need to match the right foot to your machine’s specifications, ensuring compatibility with your sewing machine.

Low-shank and High-shank Sewing Machines

You’ll need to identify your machine’s shank type before buying sewing machine feet for thick fabric.

Low-shank machines measure ¾ inch from screw to footplate and accept universal foot fit options.

High-shank models, typically industrial machine feet, measure 1¼ inches and require adapters.

These shank height differences determine adapter foot usage compatibility, so measure your machine first to avoid purchasing incompatible accessories.

Many options exist for machines using these feet, including those that can help with thick fabric and require specific adapter foot usage.

Singer Slant Shank Machines and Unique Feet

Singer slant shank machines from the 1950s-60s present unique challenges for thick fabric sewing.

These vintage sewing machines require specific feet due to their angled presser bar design.

Here’s what makes them special:

- Backward-slanted connection between presser bar and foot shaft

- Higher fitting than standard low-shank sewing machine feet

- Needle angles forward toward you during operation

- Well-crafted feet with excellent build quality for heavy fabric projects

Finding compatible sewing machine foot options requires knowing your Slant Shank ID.

Foot Availability remains limited compared to modern machines, but Adapter Solutions exist for certain attachments.

Vintage Sewing enthusiasts often focus on Collecting Feet specifically designed for these models, as standard thick fabric feet won’t fit properly without modifications.

They prioritize heavy fabric projects and understand the importance of proper foot compatibility.

Brand-specific Feet for Husqvarna Viking and Pfaff Machines

Husqvarna Viking and Pfaff machines require brand-specific presser foot designed for their unique systems.

You’ll find Viking foot types work exclusively with their models, while Pfaff foot types integrate with IDT system feet for enhanced fabric control.

Aftermarket options exist, but adapter compatibility varies between brands, and these specialized sewing machine feet handle thick fabric better than generic alternatives, ensuring peak performance.

Bernina Machines and Attachment Systems

Bernina machines feature a distinctive attachment system that requires specific adapters for universal presser foot compatibility. You’ll need Bernina-specific sewing machine feet or converters to use standard attachments.

Their precise Swiss engineering demands proper foot compatibility for maximum stitch regulation.

Here’s what you need to know about Bernina attachments:

- Bernina Adapters – Convert universal feet to work with Bernina’s unique mounting system

- Specialty Feet – Brand-specific leather sewing foot and thick fabric attachments available

- Stitch Regulation – Proper sewing machine attachments guarantee consistent stitch quality

- Bernina Maintenance – Regular cleaning of attachment points prevents mechanical issues

- Professional Support – Local dealers provide training for advanced sewing machine feet usage

Mastering Thick Fabric Sewing

You’ll need specific techniques to prevent needle breakage and maintain consistent stitches when working with thick fabrics like denim, canvas, and multiple layers.

Proper needle selection, controlled sewing speed, and regular equipment inspection will help you achieve professional results while protecting your machine from damage.

Preventing Needle Damage and Breakage

When your needle takes a beating from thick fabrics, you’re walking into expensive repair territory.

Choose the right needle size for your fabric thickness – size 90 needles handle denim and canvas without snapping.

Keep your foot alignment perfect and stitch slowly through bulky areas.

Regular needle inspection catches wear before breakage ruins your leather sewing foot or canvas sewing foot investment.

Maintaining Stitch Quality and Consistency

Consistent stitches depend on balancing foot pressure with needle size and stitch length settings.

Your fabric feeding improves when you adjust these elements together rather than separately.

Test different combinations on scraps first—denim sewing foot works differently than canvas sewing foot.

Proper seam leveling prevents tension issues.

Remember, sewing machine feet and fabric feed work as partners, not opponents.

Tips for Sewing Tricky Fabrics Like Fur and PVC

Fur and PVC fabrics demand special handling techniques beyond standard thick fabric approaches.

These materials create unique challenges that require specific Fur Sewing Tips and PVC Stitching Techniques.

Here are five Sticky Fabric Solutions for successful sewing:

- Use clips instead of pins – Avoid marking PVC and preserve waterproofing

- Apply light spray starch – Stiffen faux fur for easier cutting and handling

- Choose a Teflon foot or vinyl sewing foot – Prevents sticking during fabric feeding

- Brush fur fibers – Align pile direction before sewing for cleaner seams

- Extend stitch length – Use 4-5mm stitches for better grip through thick layers

Consistent Fabric Feed prevents bunching while Preventing Needle Breaks maintains your sewing machine foot performance.

Importance of Regular Needle Inspection and Maintenance

Your sewing machine needs regular checkups just like your car.

Inspect your needle after every thick fabric project for Needle Wear Signs like burrs or bends.

A Bent Needle Risks skipped stitches and fabric snags.

Check Thread Tension Impact on stitch quality.

Following a Maintenance Schedule Benefits prevents costly sewing machine repair and guarantees smooth Fabric Damage Prevention during future projects.

Frequently Asked Questions (FAQs)

What foot should I use for thick fabric?

Like threading a needle in the dark, choosing the wrong foot spells disaster.

You’ll want a compensating foot or walking foot for thick fabrics.

They keep everything level and prevent skipped stitches on bulky seams.

What is the best sewing machine foot for thick fabric?

You’ll want a walking foot or dual feed foot for thick fabrics.

These feet feed fabric from above and below simultaneously, preventing uneven stitching and bunching on materials like denim, canvas, or multiple layers.

How to adjust sewing machine foot for thick fabric?

Think of your machine as climbing a mountain—you’ll need proper footing.

Raise the presser foot lever to its highest position, use the leveling button to lock it flat, then sew slowly over bulky seams.

What is the best stitch setting for thick fabric?

Use a longer stitch length (3-4mm) and reduce presser foot pressure for thick fabrics.

Choose a straight stitch over zigzag to prevent bunching.

Test on scraps first—you’ll avoid costly mistakes and achieve professional results.

What thread weight works best for thick fabrics?

Heavy-duty thread weights of 40 or 50 work phenomenally well for thick fabrics.

You’ll get stronger seams that won’t snap under pressure.

Heavier threads like 30 weight handle denim and canvas beautifully without breaking.

How often should I oil my machine sewing thick materials?

Oil your machine after every 8-10 hours of thick fabric sewing since heavy materials create more friction and debris.

Check your manual’s recommendations, but thicker fabrics definitely demand more frequent maintenance than regular sewing.

Can I use regular scissors to cut thick fabrics?

Regular scissors won’t cut thick fabrics cleanly and will dull quickly.

You’ll need fabric shears with sharp, heavy-duty blades or rotary cutters for clean edges.

Sharp tools prevent fraying and make cutting easier.

What causes thread to keep breaking on thick seams?

Thread breakage isn’t rocket science—you’re likely using the wrong needle size or tension setting.

Switch to a size 90-110 needle, reduce upper tension, and sew slowly to prevent snapping on thick seams, as this will help prevent snapping.

Should I backstitch when starting thick fabric seams?

Skip backstitching at the start of thick seams.

Instead, leave long thread tails and tie them off later.

Backstitching creates extra bulk that can jam your machine or cause uneven stitches on heavy fabrics.

Conclusion

Mastering thick fabric sewing transforms from an uphill battle into smooth sailing when you’re equipped with the right sewing machine foot for thick fabric.

These specialized tools act as your steady compass, guiding you through challenging materials with confidence. You’ll prevent needle breakage, maintain consistent stitches, and tackle projects that once seemed impossible.

Whether you’re working with denim, canvas, or leather, investing in quality presser feet elevates your craftsmanship and opens doors to professional-grade results every time.