This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Denim is unforgiving. Those thick seams, stacked layers, and stubborn fabrics have sent countless regular sewing machines straight to the junk pile. But here’s the thing—not all machines are built equal, and the difference between one that coasts through denim projects and one that chokes comes down to raw engineering: heavy-duty motors that won’t stall, metal frames that stay rock-solid under pressure, and presser feet designed specifically for the job.

Your choice of machine doesn’t just determine whether you can sew jeans; it determines how much control you actually have over the final product. The right sewing machine for jeans gives you that control back, transforming frustrating projects into genuinely satisfying work.

Table Of Contents

- Key Takeaways

- Top 6 Sewing Machines for Jeans and Denim

- Key Features for Sewing Denim Fabric

- Essential Needle and Thread Choices

- Stitch Options and Fabric Handling

- Sewing Techniques for Denim Projects

- Durability and Long-Term Performance

- Tips for Choosing Your Denim Sewing Machine

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Denim sewing demands machines with heavy-duty motors (1,100+ stitches per minute), metal frame construction, and adjustable presser foot pressure to handle 6-8 layers of thick fabric without stalling or breaking needles.

- Your needle and thread choices directly determine success—use 90/14 to 110/18 denim needles matched to fabric weight, paired with Tex 40-60 polyester thread that delivers 70-80% more breaking strength than standard thread.

- Walking feet and dual feed systems are non-negotiable for professional results, preventing fabric slippage and maintaining consistent stitch formation across bulky seams where standard presser feet fail.

- Real durability comes from metal gearing and reinforced components that withstand years of heavy use, backed by tiered warranties covering 25 years on mechanical parts and regular maintenance every 12-18 months to protect your investment.

Top 6 Sewing Machines for Jeans and Denim

You need a machine that won’t flinch when you stack multiple layers of 14-ounce denim under the presser foot. The right sewing machine combines punching power with precise control, letting you tackle everything from standard jeans to heavy workwear without constantly adjusting tension or breaking needles.

The right denim sewing machine combines punching power with precise control, tackling everything from standard jeans to heavy workwear without breaking stride

Here are six proven machines that handle denim like it’s their day job.

1. SINGER Heavy Duty Sewing Machine 4423

If you’ve battled thick denim seams, you know standard machines buckle under pressure. The Singer 4423 changes that equation with motor performance delivering 1,100 stitches per minute—60% stronger than typical models—and a metal frame that refuses to rattle when you’re topstitching jean hems.

Its extra-high presser foot lifter clears bulky fabric stacks without complaint, while adjustable pressure ensures smooth fabric handling on everything from lightweight chambray to 16-ounce workwear denim.

This heavy duty sewing machine earns its keep tackling real-world jeans projects.

Best For: Home sewers and hobbyists who regularly work with denim, canvas, and other heavy fabrics but don’t need industrial-grade equipment.

- Motor delivers 1,100 stitches per minute with 60% more power than standard machines, handling multiple denim layers and thick seams without bogging down.

- Metal frame construction keeps the machine stable at high speeds, eliminating the vibration and skipping you’d get from plastic-bodied models on heavy fabric.

- Extra-high presser foot lifter and adjustable pressure settings make it easy to work with bulky jean hems and layered seams that would jam lighter machines.

- Some users report the instruction manual lacks detail, making it harder to dial in proper tension settings for different denim weights.

- The foot pedal can be overly sensitive, requiring practice to control speed smoothly when topstitching or working on precise jean details.

- Despite the “heavy duty” label, the machine struggles with extremely thick fabrics like multiple layers of heavyweight canvas or leather, so it’s not truly industrial-strength.

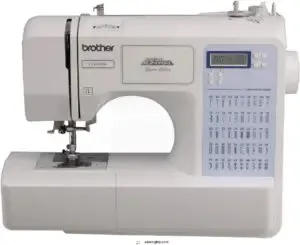

2. Brother Heavy Duty Sewing Machine

Brother’s ST371HD proves motor power isn’t just about speed—it’s about punching through six layers of denim without flinching. This heavy-duty sewing machine delivers the denim capability serious sewists demand, handling everything from lightweight chambray to sturdy workwear fabric with 37 built-in stitches that cover utility seams, decorative topstitching, and blind hems.

The metal needle plate keeps fabric feeding straight on thick seams, while Brother accessories like the walking foot and buttonhole foot turn complex jean construction into manageable steps you’ll actually enjoy.

Best For: Sewists who regularly work with denim and heavyweight fabrics and need a reliable machine that can handle multiple layers without stalling or skipping stitches.

- Sews through up to 6 layers of denim with a powerful motor that maintains 850 stitches per minute, making jean hems and thick seams straightforward instead of frustrating.

- Comes with 9 presser feet including a walking foot and heavy-duty needles right in the box, so you can start tackling denim projects immediately without hunting for extras.

- Metal frame and needle plate provide rock-solid stability when stitching heavy materials, reducing vibration and keeping your seams consistent even on bulky projects.

- Machine light is too dim for detailed work, so you’ll likely need to add a separate task light to see what you’re doing.

- No automatic thread cutter means you’re reaching for scissors after every seam, which slows down your workflow on longer projects.

- Power connector is fragile and can be damaged easily, plus the machine only works on US 120-volt power—using it elsewhere voids your warranty.

3. Janome Heavy Duty Sewing Machine

The Janome HD3000 answers the call with a heavy aluminum frame that won’t skip a beat at 860 stitches per minute, even when you’re topstitching triple-folded hems on 14-ounce denim. At 23 pounds, this machine stays planted when punching through layers other models can’t touch.

This heavy-duty sewing machine gives you 18 stitches and adjustable presser foot pressure—critical when you’re shifting between delicate pockets and reinforced belt loops. The free arm manages jean cuffs without wrestling, while the one-step buttonhole manages waistband closures.

Best For: Sewers who regularly work with heavy fabrics like denim, canvas, and leather and need a reliable workhorse that can handle multiple layers without stalling.

- Heavy aluminum frame and 23-pound build keep the machine stable when sewing through thick seams at full speed

- Adjustable presser foot pressure and 860 stitches per minute make it easy to switch between lightweight fabrics and heavy denim

- Free arm design and top-loading bobbin system simplify finishing jean hems and cuffs without awkward maneuvering

- Limited to 18 stitches with a three-step buttonhole, so it’s not ideal if you need advanced decorative options

- Smaller harp space and no walking foot capability mean large quilting projects are off the table

- Stitch selector display can be hard to read in low light, even with the built-in sewing light

4. Brother Computerized Sewing Machine

For sewers who want computerized controls without sacrificing the muscle to handle 12-ounce denim, the Brother CS7000X delivers 70 stitches and an LCD interface at 750 stitches per minute. You’ll get automatic threading and a metal frame that holds steady through jean hems up to 6 mm thick—roughly four layers of midweight fabric.

The included walking foot feeds multiple denim layers without shifting, while the extension table accommodates oversized projects like jackets. At 10.5 pounds, it balances portability with enough heft for consistent sewing precision on tough materials.

Best For: Sewers who want computerized convenience and stitch variety for occasional denim projects without the price or bulk of a heavy-duty machine.

- 70 built-in stitches with an LCD screen make it easy to switch between delicate fabrics and thick denim seams

- Includes a walking foot and extension table that help manage multiple denim layers and large projects like jackets

- Metal frame and 750 stitches-per-minute speed provide enough stability and power for hemming jeans and sewing medium-weight denim

- 10.5-pound weight and consumer-grade motor aren’t built for continuous heavy denim work like industrial machines

- 6 mm thickness limit (about four denim layers) means bulky seam intersections or heavy 14-ounce denim may cause issues

- Lower maximum speed than mechanical heavy-duty models can slow down long construction seams on denim garments

5. Brother Strong Tough Sewing Machine

When you need 850 stitches per minute through six layers of medium-weight denim, the Brother ST150HDH Strong and Tough delivers heavy-duty motors wrapped in a metal frame that won’t buckle under pressure.

You’ll command 50 stitches—including five auto-sized buttonholes—plus a 7 mm stitch width for reinforced bar tacks at pocket corners. The 7-point feed dog system and metal needle plate prevent fabric flagging on thick seams, while denim sewing tips in the manual guide tension adjustments for topstitching.

At roughly $300, it’s your ticket to sewing speed optimization without industrial bulk.

Best For: Home sewers who regularly work with denim, canvas, and other heavy fabrics and want a reliable machine that can handle multiple layers without slowing down.

- Powers through six layers of denim at 850 stitches per minute thanks to a heavy-duty motor and metal frame that stays stable even on thick projects.

- The 7-point feed system and metal needle plate work together to move heavy fabric smoothly without puckering or jamming at the seams.

- Gives you 50 stitches including five auto-sized buttonholes, plus a 7mm width for reinforced bar tacks—all the tools you need for proper jeans construction.

- Some users report quality control issues like skipped stitches or inconsistent performance, especially on delicate fabrics where the heavy-duty setup isn’t ideal.

- Customer support and warranty claims have frustrated several buyers who ran into problems with their machines.

- A few people noticed a burning plastic smell during use, which raises questions about long-term durability despite the strong marketing claims.

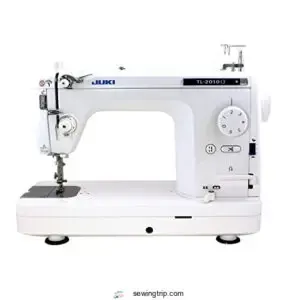

6. Juki TL-2010Q Sewing Quilting Machine

When precision meets brute force, the Juki TL-2010Q redefines what heavy-duty sewing machines can accomplish on denim and jeans. This straight-stitch powerhouse delivers quilting speeds up to 1,500 stitches per minute through thick denim layers, backed by an aluminum die-cast body that won’t flinch under sustained use.

You’ll wield a 12 mm knee-lifter for bulky hems, automatic thread trimming between seams, and adjustable presser foot pressure that masters everything from 10-ounce chambray to 16-ounce workwear denim.

For denim stitching that demands sewing precision without compromise, Juki maintenance rewards you with years of industrial-grade performance at around $1,199.

Best For: Sewers and quilters who regularly tackle heavy denim projects, jeans construction, or high-volume straight stitching and need industrial reliability without the bulk of a full factory machine.

- Blazing 1,500 stitches per minute with speed control lets you power through thick denim seams or slow down for precision work on multi-layer waistbands and hems.

- The 12 mm knee lifter and adjustable presser foot pressure make handling bulky jeans fabric effortless, while automatic thread trimming cuts down on handling time between seams.

- Built like a tank with an aluminum die-cast body and mechanical straight-stitch system that delivers consistent performance for years with minimal maintenance.

- Straight stitch only—no zigzag or decorative stitches, so you’ll need a second machine if your projects require variety beyond basic construction and topstitching.

- The light could be brighter for dark indigo denim, and some users report needing to press the foot pedal firmly to activate the thread cutter.

- At $1,199 it’s a significant investment, and the heavier semi-industrial build means it’s not as portable as typical domestic machines.

Key Features for Sewing Denim Fabric

You can’t just grab any sewing machine off the shelf and expect it to power through denim without a fight. Heavy fabrics demand specific features that separate basic machines from workhorses built to handle the job.

Let’s break down the five essential capabilities your machine needs to conquer thick layers and multiple seams without breaking a sweat.

Heavy-Duty Motor and Speed

Motor power separates machines that stall from those that punch through 14-ounce denim without breaking stride. You’ll want at least 1.0 to 1.5 amps to maintain torque output when sewing thick seams—anything less and you’re fighting the fabric instead of mastering it.

Speed control matters just as much: the Singer 4423’s 1,100 stitches per minute delivers sewing efficiency, but adjustable settings let you dial down for precision topstitching. The Singer 4423’s performance is a great example of heavy duty sewing capabilities.

Metal Frame Construction

A metal interior frame is the bedrock of any machine built to dominate denim—it’s what keeps your needle bar and feed dogs aligned when you’re punching through four layers of 14-ounce fabric. Frame material and structural integrity directly control vibration, which means cleaner topstitching and fewer skipped stitches at speed.

- Frame stability prevents flex under high presser foot pressure, maintaining straight seams on heavy-duty projects

- Metal durability outlasts plastic chassis that crack under cumulative stress from thick denim

- Vibration control reduces needle deflection, cutting breakage and thread shredding during fast sewing

- Heavy duty construction combines frame strength with high-torque motors in heavy-duty sewing machines

- Long-term performance: metal-framed heavy-duty sewing machines allow easier servicing without frame distortion over years of use

For best results, consider using a machine with features suitable for heavy duty sewing to handle dense fabrics.

Adjustable Presser Foot Pressure

When you’re wrestling four layers of denim at a cross seam, presser foot pressure control becomes your secret weapon. Adjustable presser foot pressure lets you dial in the exact downward force needed—tighter for heavy fabrics to grip feed dogs and prevent skipped stitches, looser for transitions to avoid puckering.

This foot adjustment directly controls denim feeding and stitch quality, transforming a stalled needle into smooth, powerful penetration through dense fabric layers.

High Presser Foot Lifter

When you’re stacking six layers of denim at a cross seam, standard presser foot clearance won’t cut it. High presser foot lifters—reaching up to 12mm on industrial models—give you the extra fabric clearance you need to slide thick denim under the foot without forcing or distorting it.

This extra lift prevents needle deflection, reduces skipped stitches, and keeps your seams smooth and professional. It’s the difference between struggling through hems and executing them flawlessly.

Dual Feed System

Beyond that high lift, you’ll want a dual feed system that grips fabric from above and below simultaneously. While you’re wrestling those six-layer seams, synchronized top and bottom feed dogs advance both sides evenly, eliminating the slippage that tanks stitch consistency.

This synchronized fabric control keeps your layers aligned perfectly—critical when topstitching jean hems and waistbands where every stitch shows. It’s the difference between amateur and professional results.

Essential Needle and Thread Choices

Your machine is only as strong as the needle and thread you feed through it—get this wrong, and even the best denim rig will struggle. Choosing the right needle type, size, and thread strength isn’t just a technical detail; it’s what separates clean, bulletproof seams from busted stitches and skipped threads.

Let’s cover what you actually need to know to keep your denim projects running smoothly.

Denim Needle Types and Sizes

Picking the right needle is where denim sewing gets real. Your denim needle selection determines whether you’ll breeze through layers or battle deflection and breakage. Here’s what matters:

- Needle sizes 90/14 to 100/16 handle standard to heavyweight denim (10–14 oz) without sacrificing stitch quality

- Reinforced jeans needles feature sharp points designed specifically for dense twill penetration

- 110/18 needles conquer extra-heavy workwear fabrics and multi-layer seams where lesser needles fail

Match fabric thickness to needle size—this is your foundation for impeccable construction.

Thread Strength for Jeans

Your thread choice makes or breaks denim durability. Heavy core-spun polyester around Tex 40 delivers roughly 70–80% more breaking strength than standard spun thread—that’s the difference between seams that hold and seams that fail.

For topstitching and high-stress zones like belt loops, step up to Tex 60 cotton-covered polyester. Adjust thread tension carefully; stronger threads demand precision to avoid puckering.

Match thread weight to your machine’s capability and your denim weight for bulletproof construction.

Changing Needles for Heavy Fabrics

Your needle deteriorates faster on denim than lighter fabrics—expect about 40% shorter lifespan. Change to a fresh 100/16 jeans needle before each heavy project; don’t push a dulled one through multiple layers.

Watch for skipped stitches, audible knocking, or fabric snags—these signal replacement time. A worn needle damages seams permanently and strains your machine’s motor.

Test on scrap denim first, then sew with confidence. Fresh needles mean bulletproof construction.

Stitch Options and Fabric Handling

The right stitch settings can make or break your denim project, so you’ll want a machine that gives you real control over how it works. Beyond just picking a needle and thread, your machine needs to offer the flexibility to adjust stitch length and width, plus a solid range of built-in stitches for different tasks.

Here’s what to look for regarding stitch options and fabric handling capabilities.

Variable Stitch Length and Width

Your machine’s ability to adjust stitch length directly impacts seam efficiency on denim. Heavier fabrics like 12–16 oz denim demand longer stitches—usually 3.0–4.0 mm—to prevent puckering and needle drag across thick layers.

Shorter settings work for lighter denims, but pushing too hard creates friction that weakens seams. Adjustable thread tension paired with variable stitch length gives you precision control, ensuring your stitches hold without sacrificing fabric integrity across every project weight.

Built-in Stitch Variety

Stitch variety separates machines that merely survive denim from those that truly master it. Your options matter—whether you’re locking down reinforcement bar tacks at stress points or adding decorative flair to custom jackets.

Heavy-duty domestic machines generally offer:

- Utility stitches (23–50 patterns) for construction seams

- Stretch-capable stitches for modern denim blends

- Automated buttonholes for consistent waistband closures

- Decorative options for visible embellishment

More stitches mean more control over stitch density, fabric flex, and thread tension across varying weights.

Free Arm for Cuffs and Hems

Sliding a pant leg over the free arm transforms hemming from a wrestling match into smooth circular stitching. This design exposes a narrow cylindrical support—usually 15–20 cm long—that lets you rotate heavy denim continuously without repositioning bulk.

You’ll eliminate fabric manipulation headaches, reduce drag on the feed mechanism, and nail consistent topstitching on visible hems. Free arm benefits shine brightest when hemming cuffs or addressing localized repairs on jeans, where precision and sewing efficiency matter most.

Buttonhole and Decorative Stitches

Your buttonhole quality determines whether jeans survive repeated wear. Modern heavy-duty machines deliver 1–8 dedicated buttonhole styles with automatic one-step programming, handling standard jeans buttons effortlessly.

Decorative stitching adds visual impact—use longer 3.5–4.5 mm lengths on dark indigo for visibility. Adjust stitch density for fabric weight, switch to 90/14 needles, and stabilize layers beneath decorative work. Topstitch thread creates prominent patterns.

Slower speeds prevent distortion when stitching across thick waistband intersections. Test settings on scrap stacks matching your exact layer count first.

Sewing Techniques for Denim Projects

Having the right machine is only half the battle—knowing how to actually use it makes all the difference when you’re working with denim. The techniques you apply, from prepping your fabric to finishing your hems, are what separate solid work from work that’ll last.

Let’s walk through the core approaches that’ll help you get professional results every time.

Proper Fabric Preparation

Before needle meets fabric, you’ve got to prep your denim properly—it’s non-negotiable. Start by prewashing to control fabric shrinkage, which usually runs 12–16% in raw denim.

Check grain alignment by folding with selvedges matched; rippling signals distortion that’ll twist your seams later.

Test colorfastness on dark indigo by soaking a hidden section, then press your fabric with steam to stabilize shape. These steps separate polished results from frustrating rework.

Adjusting Tension and Pressure

Getting tension and pressure right transforms your denim work from frustrating to impeccable. Start with your machine’s mid-range upper thread tension—usually around 4–5 on a 0–9 scale—then adjust incrementally as fabric thickness changes.

Lower presser foot pressure when stacking multiple denim layers; this prevents drag while maintaining consistent stitch formation. Heavy-duty machines handle this balancing act better, but you’re controlling the outcome.

Test on scraps matching your actual seam thickness before committing to your garment.

Using Walking Foot or Jeans Presser Foot

Here’s where a walking foot or jeans presser foot becomes your secret weapon. Unlike standard feet that can tilt and stall on thick seams, a walking foot synchronizes upper and lower feeds, keeping all layers moving together.

This maintains feed control and prevents fabric creep that throws off alignment. The result? Consistent stitch length across bulky intersections and better needle protection from deflection.

For denim projects demanding precision, this specialty foot isn’t optional—it’s how you guarantee professional results every time.

Hemming and Finishing Tips

Once you’ve conquered those bulk seams, hemming’s where precision separates amateurs from pros. Start by pressing your fold line—this sets the crimp and prevents bubbling.

Maintain a 0.75-inch hem allowance minimum; it resists fraying through countless wash cycles. Aim for 7–9 stitches per inch on heavyweight denim to balance seam strength without overtaxing your needle. Use corespun polyester thread for maximum durability.

Press again after stitching. That final heat sets everything in place, giving you hems that hold their shape and look factory-finished.

Durability and Long-Term Performance

A sewing machine is only as good as its ability to hold up over time, and that’s where the real test begins. You need something built to last through dozens of projects, not just one or two, which means paying attention to how it’s made, what kind of backup you’ll get if something goes wrong, and how you’ll keep it running smoothly.

Let’s look at what separates the machines that stick around from the ones that don’t.

Machine Build Quality

Metal frames and all-metal drive components are where durability lives. Heavy-duty sewing machines built with reinforced steel chassis and gearing withstand years of punishing denim work without flex or fatigue.

The gearbox strength matters—metal gears outlast plastic ones by decades under heavy use. Structural integrity directly translates to consistent stitch formation through thick seams.

Enhanced motor durability and vibration control keep your machine locked in place, delivering reliable performance on every jeans project.

Warranty and Support

Quality machines deserve quality backing. Heavy-duty denim sewing machines usually carry tiered warranties—25 years on mechanical parts, 5-6 years on electronics—giving you real protection where it counts. Here’s what separates smart buyers from regretful ones:

- Repair costs run $75–$100 per service without warranty coverage

- Electronic board repairs cost $150–$300 or more out-of-warranty

- Authorized service centers handle both warranty and paid repairs seamlessly

- Extended protection plans add years of coverage beyond standard terms

Register your machine immediately to lock in long-term support and simplify future claims.

Maintenance Requirements

Regular maintenance keeps your investment running strong for 10–20 years or longer. Professional servicing every 12–18 months—or every 6–9 months if you’re sewing daily—prevents costly repairs down the line.

Between shop visits, handle routine machine cleaning, lint removal from bobbin areas, and frequent needle changes, especially after heavy denim projects.

This preventive care protects motor strength, maintains consistent performance, and catches wear before it becomes expensive. Think of it as insurance for durability.

Tips for Choosing Your Denim Sewing Machine

Picking the right denim sewing machine comes down to understanding what your projects actually demand—and being honest about what you’ll realistically use.

You’ll want to balance raw performance with features that fit your workflow, without overpaying for capabilities you don’t need.

Let’s walk through the core decisions that separate a machine that’ll last you years from one that’ll frustrate you after a few projects.

Matching Machine to Project Needs

Here’s the reality: your machine selection hinges on what you’re actually building. Hemming a pair of jeans demands different muscle than constructing a jacket from scratch.

Domestic heavy-duty models handle occasional repairs and single-layer work beautifully, while industrial units crush high-volume projects and thick multi-layer construction.

Match your sewing capacity to project scaling—don’t overkill a simple hem, but don’t underpower ambitious denim builds. Know your fabric thickness upfront, then choose accordingly.

Evaluating Budget Vs. Features

Here’s where smart spending separates the amateurs from the pros: you don’t need every stitch option to conquer denim. Entry-level heavy-duty models like the SINGER 4423 deliver 1,100 stitches per minute and proven denim-piercing power without draining your wallet.

Mid-range Brother machines add computerized control and stitch variety for minimal budget jumps. Premium Juki units? They’re engineered for relentless production speed and precision.

Identify your actual needs—occasional repairs versus regular builds—then invest accordingly. That’s cost-effective strategy.

Considering Portability and Size

Heavy machines—often 20–30 pounds—demand real estate. A Janome HD3000 at 23.2 pounds needs a stable workspace, while lighter 14.5-pound models like the Singer 4423 offer mobility without sacrificing denim power. Your choice hinges on where you sew.

Home-based? Invest in that heavier unit for stability. Traveling to classes or workshops? Portable designs under 18 pounds keep you nimble.

Storage solutions and compact footprints matter too—measure your table depth and cabinet space before committing.

Frequently Asked Questions (FAQs)

What machine do I need to make jeans?

You’ll need a machine with a motor rated 7–0 amps—capable of handling 6–8 denim layers without stalling.

Pair it with size 90/14 needles, polyester thread, and a walking foot for smooth feeding over thick seams and hemming projects.

What kind of sewing machine is good for jeans?

You’ll want a machine that threads the needle between power and precision. Look for a heavy-duty motor (1,100+ stitches per minute), metal frame construction, adjustable presser foot pressure, and a high presser foot lifter—these features let you conquer thick denim layers without breaking stride.

Do you need a special needle to sew jeans?

Absolutely. Denim needles have reinforced shafts engineered to resist bending when penetrating tightly woven fabrics. Their sharp, acute points pierce cleanly, reducing skipped stitches.

A 90/14 or 100/16 jeans needle paired with heavy-duty thread delivers reliable penetration and consistent stitch formation through dense denim layers.

Can normal sewing machines sew jeans?

Most household machines can handle standard jeans when you use the right setup—proper denim needles, adjusted tension, and a walking foot make the difference. However, heavy-duty models excel where basic machines struggle with thick seams and multiple fabric layers.

How do I choose the right needle size?

Match denim needle selection to fabric weight: lightweight denim needs 80/12 or 90/14 needles, midweight requires 90/14 or 100/16, and heavyweight demands 100/16 to 110/18 for proper needle penetration without breakage.

What type of thread is best for top-stitching?

Top-stitching denim demands thread that won’t surrender under pressure—think cotton-wrapped polyester in 30 wt or Tex 40, blending synthetic strength with traditional matte finish for bold, lasting seams.

Can I repair jeans using a sewing machine?

Yes, you can repair jeans with your machine—hemming, patching, and reinforcing seams all work fine. Use a 90/14 denim needle, heavy thread, and adjust your presser foot for thick intersections.

How to add distressing effects to denim?

You can achieve distressed denim through mechanical abrasion like hand sanding, chemical fading with bleach or permanganate, enzyme washing for controlled breakdown, or laser distressing—the most sustainable finishing method that preserves fabric strength while creating authentic worn patterns.

What is the best way to attach jeans buttons?

Start by marking your button placement through the buttonhole with the jeans fastened. Use a small awl to create a pilot hole, then hammer the tack into the cap on a hard surface, keeping it perfectly vertical to prevent bending.

How often should I replace my sewing machine needle?

Replace your needle every 6–8 hours of sewing, but heavy-duty denim work demands more frequent changes—closer to 4–6 hours—because fabric density and sewing speed markedly accelerate needle wear factors.

Conclusion

Industrial sewing facilities report that machines handling denim routinely process over 15,000 linear feet of fabric annually—that’s nearly three miles of seams under constant mechanical stress.

Your sewing machine for jeans needs to match that level of endurance, even at home scale. When you’ve got the right motor capacity, frame rigidity, and presser foot control dialed in, denim stops being an obstacle and becomes exactly what it should be: just another fabric you completely own.

- https://sinofinetex.com/what-is-the-average-weight-of-jeans/

- https://sanvt.com/blogs/journal/demim-oz-guide

- https://www.longancraft.com/blogs/fabric-knowledge/denim-weight-guide-what-you-need-to-know-for-your-jeans

- https://denimhunters.com/denim-wiki/denim-explained/denim-weight/

- https://www.mhthread.com/blog/products/jeans-needle-sizes-for-hemming