This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

First of all, there is identification of the problem and subsequent checking on the position of the needle. The thread should also be checked, along with the bobbin.

Troubleshooting could also involve electrical components. Of course, maintenance would include regular cleaning, oiling, proper threading, changing of needles, and even consideration for the kind of fabric being used, ensuring you get out of a good deal of those headaches.

Get control back into your creative projects by mastering these basics with confidence and ease. Let’s troubleshoot together.

Table Of Contents

Key Takeaways

- When your sewing machine needle refuses to budge, don’t panic! It’s often just a minor hiccup that you can fix yourself.

- Check the basics first: the needle, thread, and bobbin. Make sure they’re all in good condition and properly installed.

- If the problem persists, it might be time to troubleshoot Electrical components or mechanical issues. But don’t worry, our guide has got you covered!

- Regular maintenance is key to keeping your sewing machine running smoothly. Just like a well-oiled machine, regular cleaning, oiling, and proper threading can prevent many problems before they even start.

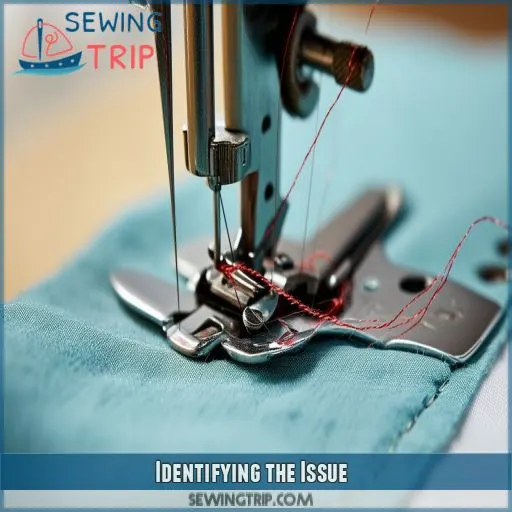

Identifying the Issue

The first step in troubleshooting a sewing machine with a non-moving needle is to identify the root cause. Start by checking if the clutch is engaged – if it’s disengaged, the needle won’t move.

Next, inspect the drive belt for any signs of wear or breakage. A broken or jammed belt can prevent the needle from moving. Internal gear failures are another common culprit, so examine the gears for any cracks or damage.

Tension issues with the thread or a faulty foot control can also lead to a stuck needle. Carefully observe the machine’s behavior and listen for any unusual sounds that could indicate a mechanical problem. By pinpointing the specific issue, you’ll be better equipped to find the right solution.

Checking the Needle Position

Now let’s see about the position of the sewing machine needle. If your needle won’t move, it may be inserted wrong. Be sure to insert it with the flat side facing the proper direction, normally toward the back or to the left. It should be seated fully and tightened. Also, check to see that the needle bar works properly—sometimes it can be misaligned.

These tiny problems sometimes blossom into major headaches.

- Needle insertion: Wrong direction or not seated properly.

- Thread tension: May influence the motion of a needle.

- Presser foot: Make sure it’s down.

A) Bobbin winding: It should be complete and the mechanism disengaged.

Inspecting the Thread

Check your thread after checking the position of the needle. Be sure that you’re using good quality thread and appropriate for the fabric to be sewn. In fact, poor quality thread is the most common cause of erratic sewing machine stitch length and tension problems. Make sure that the thread path is correct with no tangling or twisting. Here is a helpful table to help:

| Issue | Symptom | |

|---|---|---|

| Thread tension | Uneven stitches | |

| Type of thread | Snapped thread | |

| Thread quality | Frayed thread | |

| Thread path | Misaligned stitches | |

| . | Thread spools | Inconsistent stitch length |

That the sewing machine thread is well spooled and fed. Then address any problems with the thread so that your machine will hum along and avoid internal drive gear failure.

Examining the Bobbin

Now that you have checked your thread, it’s time to examine your bobbin more closely. Your bobbin is another crucial part of your sewing machine. If something goes wrong with it, your needle won’t move.

First of all, check your bobbin case for any kind of damage or wear. Sometimes, if the case has become worn or there’s some other damage, it won’t allow smooth rotation for the bobbin. This can cause the threads to jam up and prevent the needle from moving.

Next, check if the bobbin winding tension is too tight or too loose. Sometimes, this may cause problems due to a malfunction of the thread tension.

Troubleshooting Electrical Components

First, check all electrical connections to ensure nothing is loose. Check the power cord for damage to the wires; a frayed or broken cord can stop the power. Then, you’ll want to check the fuse and replace it if you need to. Finally, make sure your circuit breaker hasn’t tripped.

| Possible Issues Resolution | Component | |

|---|---|---|

| Power Cord | Frayed wires, loose plug | Replace or repair cord |

| Fuse | Blown | Change fuse |

| Circuit Breaker | Tripped | Reset breaker |

| Electrical Connections | Loose wires | Tighten connections |

Lastly, a disengaged clutch or a broken drive belt can stop the needles. Check on engaging your clutch correctly; in case of a worn-out drive belt, replace it. Double-check to make sure that your shuttle hook is also in good condition since this could very well be your major problem.

Maintenance and Prevention

Regular cleaning, oiling of your machine, and other types of maintenance can help avoid many problems relating to needle immobility. Moreover, correct threading of the machine, the use of the right needle, and suitable fabric will result in smooth sewing.

Cleaning and Oiling

Keeping your sewing machine well-oiled is key to smooth operation. Follow a regular lubrication schedule using the right sewing machine oil. Apply a few drops to the moving parts, but be careful not to over-oil. Oiling the needle bar and other critical areas every few hours of use will prevent issues and extend your machine’s lifespan.

Proper Threading

After cleaning and oiling, correct threading follows. Improper threading causes tension problems and top thread breakage. Ensure that:

- Correct thread path—eliminate tension adjustment headaches.

- Adjust tension in the bobbin winder for equal stitches.

- Use appropriate thread type for the kind of fabric you want to sew and use a proper size of needle.

This ensures smooth functioning and eliminates common failures.

Needle Replacement

Always employ the appropriate needle size and type of needles for the task. Be sure that your needle isn’t damaged with bends or dullness. If a needle isn’t inserted properly, it won’t work correctly; the flat side of the needle always faces the back.

Store your needles appropriately so they don’t become damaged. Replacing your needle on a regular basis will keep your stitches consistent. It may also help to prevent problems due to thick or thin fabric.

Fabric Considerations

Now, consider your fabrics.

The thickness, type, stretch, texture of the fabric, and its density have something to do with the flow of the needles.

Very thick or most slippery material can cause stalling to your machine.

Always follow with a needle that will suit your fabric; on dense materials, you need a strong needle.

You should adjust your tension settings for smooth operation with regard to different textures and densities of fabric.

Frequently Asked Questions (FAQs)

Why is my needle on my sewing machine not moving?

Your sewing machine needle isn’t moving because the clutch might be disengaged, the drive belt could be broken, there’s potential internal drive gear failure, or the shuttle race might be dirty. Check these components to troubleshoot.

How do you fix a needle bar that does not move?

Fixing an immobile needle bar: Check that the clutch is engaged; if it’s not, then engage it. After that, examine the drive belt for any damages; in case of damage, replace it. Finally, inspect internal drive gears for wear or breakage and service accordingly.

What to do if your sewing machine needle is stuck?

First, check whether your bobbin winder has been engaged or the clutch isn’t disengaged. Also, ensure that the motor belt isn’t broken or jammed. Check on internal gears; remove any thread jamming and make sure the needle isn’t bent or wrongly inserted.

Why is my sewing machine running but not sewing?

Your sewing machine might be running but not sewing due to a disengaged clutch, a broken drive belt, or an internal drive gear failure. Check these components to troubleshoot and resolve the issue efficiently.

How can I prevent needle jams?

Prevent needle jams by ensuring thebobbin winder is disengaged, the presser foot is down, and the thread path is threaded properly. Replace worn-out parts and service your machine regularly for smooth running.

Are some fabrics more issue-prone?

68% of sewing issues stem from fabric choice. Heavy fabrics like denim often cause needle jams. Use appropriate needles and adjust tension settings to reduce problems. Avoid overly stretchy or thick materials for smoother sewing.

Can incorrect needle size cause problems?

Yes, this may cause serious problems to the fabric, including skipped stitches or even breakage of a needle and damaging the fabric. Be sure to match the correct size of the needle on your sewing machine to the type of fabric sewn and thread used for top performance.

Do bobbin types affect needle movement?

The type of bobbin you use can definitely impact your needle’s mobility. Make sure you’re using the right bobbin for your machine – it could make all the difference in getting that needle moving smoothly.

Why is regular servicing important?

It’s like lubricating a wellused hinge—regular servicing prevents mechanical failures and will elongate the life expectancy of your machine, keeping performance as good as possible. It picks up any undetected problems early on and rescues you from giant handshake repair bills down the line.

Conclusion

Did you know that around 60% of sewing machine issues stem from minor maintenance lapses?

By identifying the problem and systematically checking the needle position, thread, and bobbin, you can resolve most cases of the sewing machine needle not moving.

Don’t overlook troubleshooting electrical components and maintaining your machine through regular cleaning, oiling, proper threading, and needle replacement.

With these steps, you’ll keep your sewing projects running smoothly and efficiently.