This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Universal needles work for most woven fabrics, while ballpoint needles prevent runs in knits.

Sharp needles pierce tightly woven materials cleanly, and stretch needles handle spandex blends without skipping stitches.

Quilting needles power through multiple fabric layers easily.

Needle sizes range from 60/8 for delicate silks to 120/19 for heavy denim, with European sizing appearing first, followed by American numbers.

Match your needle to fabric weight – lightweight fabrics need smaller needles, heavyweight materials require larger ones.

The right needle makes all the difference between professional results and frustrating snags.

Table Of Contents

- Key Takeaways

- Sewing Needle Types

- Needle Size Selection

- Needle Materials and Uses

- Needle Care and Handling

- Choosing Right Needle

- Considering Fabric Type and Weight

- Matching Needle to Fabric for Best Results

- What is The Best Way to Store My Sewing Machine Needles?

- How Can I Tell When It’s Time to Replace My Sewing Needle?

- How Do I Safely Dispose of Used and Damaged Sewing Needles?

- Are There Any Tricks for Threading The Eye of a Sewing Needle More Easily?

- What Are The 7 Different Types of Sewing Needles?

- What Are Different Sewing Machine Needles Used For?

- How to Know What Needle to Use When Sewing?

- What is The Difference Between Sewing Needle 80 12 and 90 14?

- How Do I Identify The Correct Needle Size for My Project?

- Whats The Difference Between European and American Needle Sizes?

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Match your needle to your fabric weight – You’ll use 60/8 needles for delicate silks, 80/12-90/14 for medium cottons, and 100/16-110/18 for heavy denim to prevent fabric damage and thread breaks.

- Choose the right needle type for your fabric structure – You’ll need ballpoint needles for knits to slip between fibers, sharp needles for tightly woven materials, and stretch needles for spandex blends to avoid skipped stitches.

- Replace your needles regularly to maintain stitch quality – You’ll know it’s time when you hear popping sounds, see skipped stitches, or notice thread breakage after 8-10 hours of use.

- Store and handle needles properly to extend their life – You’ll prevent damage by keeping them in labeled containers, holding them by the shank when inserting, and storing them in dry places away from moisture.

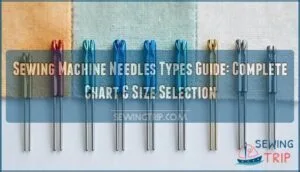

Sewing Needle Types

You’ll find five main needle types that match different fabric needs: universal needles work for most projects.

Ballpoint needles slip through knits without damage, stretch needles handle elastic materials, sharp needles cut cleanly through woven fabrics, and quilting needles pierce multiple layers with ease.

Perfect needle choice transforms your sewing from frustrating fabric fights to smooth, professional stitches every time.

Each needle type has a specific point design and structure that makes your stitching smoother and prevents fabric damage.

Universal Needles for General Fabrics

Universal needles serve as your sewing foundation for most fabric types.

These versatile tools feature slightly rounded points that work beautifully with woven materials like cotton, linen, and lightweight synthetics.

You’ll find excellent fabric compatibility with universal needles, delivering consistent stitch quality across various projects.

Their needle versatility shines when paired with standard threads, making thread pairing simple.

Following best practices, choose needle size 80/12 or 90/14 for medium-weight fabrics to achieve superior results with your sewing machine needles.

Proper selection guarantees you match needle size to fabric weight, preventing damage and thread breakage.

Ball Point Needles for Knit Fabrics

Designed specifically for knit fabrics, ballpoint needles make sewing smoother and easier.

Their unique rounded needle tip shape slides gently between the fibers, rather than piercing them, which works wonders for preventing snags and skipped stitches.

This makes them perfect for knit fabric types like rib knits, jerseys, and fleece.

For a variety of options, consider specialized knit products.

Proper stitch formation relies on matching needle size to the fabric weight, so check a needle size guide to choose the right one.

Ballpoint needles vary in size, making them versatile for different knit projects.

Whether you’re sewing lightweight jersey or thicker fleece, using proper ballpoint sewing machine needles guarantees clean results and preserves your fabric’s integrity every time.

Stretch Needles for Elastic Fabrics

Stretch needles are your go-to for elastic fabrics like Lycra or spandex.

Stretch needles are the secret weapon for conquering challenging elastic fabrics with confidence and precision.

They guarantee smooth stitching, handle fabric tension expertly, and prevent common issues like puckering or skipped stitches.

With a specially rounded ballpoint tip, these needles glide between fibers instead of piercing them, preserving the fabric’s integrity and preventing runs.

The needle composition is designed for stretch seams, supporting projects with high elasticity.

You can find various needle options online.

Pair your stretch needle with lightweight polyester or elastic-appropriate threads for flawless results.

Popular brands like Schmetz or Organ offer reliable options, making stretch needles and proper thread pairing a must for any elastic-heavy project.

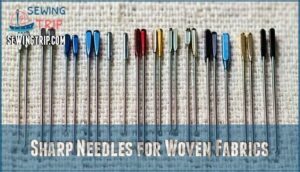

Sharp Needles for Woven Fabrics

Sharp needles are perfect for woven fabrics, cleanly piercing without snagging or puckering and delivering smooth, even stitches. They’re especially effective on delicate materials like silk or higher-density cotton.

With their strong point and precision design, these machine needles handle various threads with ease. To achieve superior results, you’ll need the proper needle size and tension.

- Key features:

- Guarantees clean fabric penetration

- Enhances stitch quality

- Suitable for dense, woven materials

- Boosts needle durability

- Improves thread compatibility

Quilting Needles for Multiple Layers

Quilting needles are designed to tackle thick layers effortlessly. Their slim Needle Point Shape guarantees precise Layer Penetration Force without causing damage.

To achieve top Quilting Stitch Quality, follow these tips:

- Use smaller needle sizes for thin fabrics and Batting Compatibility.

- Larger needle sizes work best for dense layers.

- Maintain Thread Tension Balance for consistent stitches across quilts.

Needle Size Selection

Choosing the right needle size guarantees smooth stitching and prevents fabric or thread damage.

It’s all about matching the needle size to your fabric’s weight and thickness for ideal results, which can be considered a complete concept to achieve the best outcome.

European and American Sizing Systems

Sewing machine needles come in two primary sizing systems: European (Metric) and American (Imperial).

European sizes reflect needle diameter in millimeters (e.g., 90 means 0.9 mm), while American sizes use a simple scale.

Dual labels like 90/14 help with size conversion, and choosing correctly guarantees smooth stitches and prevents fabric damage.

Smaller numbers handle lightweight fabrics, while larger ones suit heavier materials, and it is essential to refer to a needle size chart for fabric matching.

Remember—understanding system origins makes sewing stress-free!

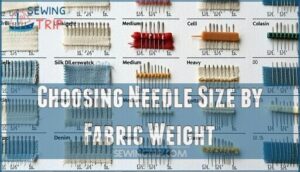

Choosing Needle Size by Fabric Weight

Fabric weight matters when choosing sewing machine needles.

Use smaller needle sizes (like 60/8) for lightweight fabrics such as silk to prevent snags. Medium fabrics like cotton pair well with an 80/12 size.

For heavy fabrics like denim, opt for 100/16 or larger. A needle size chart guarantees smooth stitching and thread compatibility every time.

Needle Size for Lightweight Fabrics

Lightweight fabrics like silk, chiffon, and voile call for finer needle sizes between 60/8 and 75/11.

These smaller needles glide smoothly through delicate materials without causing puckering or snags. Pair them with fine threads for clean, precise results.

Remember, matching needle sizes to both your fabric type and thread choices guarantees stitch issues and confirms professional-looking finishes.

Explore the options for specialized fabric needles to achieve the best results. Keep a needle size chart handy—it’s a great reference for selecting the perfect size for your next project!

Needle Size for Medium Weight Fabrics

Medium fabric examples like cotton or linen pair best with needle sizes 11/80 or 14/90.

These sizes create the perfect balance for thread compatibility and stitch quality impact.

Consult a needle size chart for guidance, and use universal needles for versatility.

A proper needle and thread combination guarantees smooth sewing, so explore the best needle brands for added reliability.

Needle Size for Heavyweight Fabrics

For heavyweight fabrics like denim or canvas, use a jeans needle or leather needle in sizes 16/100 to 18/110.

Pair with heavy thread choices for durable seams. Adjust your stitch length for smoother penetration and fewer skips.

Watch for needle damage signs, as dull needles can ruin projects. Matching needle size with fabric weight guarantees precision stitching every time.

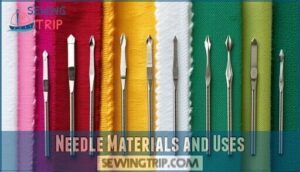

Needle Materials and Uses

Choosing the right needle material is essential for achieving smooth and precise stitches on different fabrics.

Each type, like denim or leather needles, has unique features designed to handle specific materials and sewing tasks efficiently.

Denim Needles for Thick Fabrics

Sewing denim successfully depends on using the right tool: a jeans needle. These sewing machine needles feature a sharp, blade-like point and sturdy shaft to handle thick fabrics like denim, corduroy, or quilts.

Prevent breakage and skipped stitches by matching needle size to fabric type.

Here’s a quick guide:

- 80/12: Lightweight denim (chambray).

- 90/14: Midweight denim.

- 100/16: Thick denim.

- Use heavy-duty thread for stronger seams.

- Pair needle and thread properly.

Leather Needles for Leather and Suede

Leather needles, often called Glover’s needles, are designed with a sharp triangular needle point for easy penetration through tough materials like leather, suede, and vinyl.

Pair them with thicker threads to match your project’s leather thickness and use longer stitch lengths to prevent material tearing.

Slow stitching guarantees smooth, consistent results since the needle holes are permanent.

Brands like Schmetz offer reliable sewing machine needles for suede stitching, and a Teflon foot minimizes material sticking.

Embroidery Needles for Specialty Threads

Switching to embroidery means using machine needles designed for precision.

Embroidery needles stand out with their larger needle eye design, ideal for specialty thread types like metallic threads.

These needle types minimize thread fray and skipped stitches, ensuring smooth, professional stitching.

Pair them with appropriate stabilizers and adjust your machine settings for the thread type.

Leading embroidery needle brands like SCHMETZ offer reliable options, making them essential for projects requiring delicate threads and detailed designs.

Repair Needles for Mending and Darning

For mending fabrics effectively, repair needles are indispensable. Darning needles, ideal for visible mending, glide through thick fabrics, handling larger holes with ease.

Curved needles shine in tight spots like fabric boxes. Keep a range of needle types handy for repair projects.

Proper needle threading and regular needle maintenance guarantee smooth sewing, while troubleshooting prevents skipped stitches during challenging repairs.

Darning is a technique to recreate the original weave and mend holes, utilizing darning needles for visible mending.

Needle Care and Handling

Taking care of your sewing machine needles guarantees they last longer and perform their best.

Handle them carefully, check for signs of wear, and replace them as needed to avoid stitching issues, which is crucial for maintaining the best performance of your sewing machine.

Proper Storage and Handling Techniques

Smart needle organization starts with proper storage containers like labeled cases or magnetic strips.

You’ll prevent rust by keeping needles in dry places away from moisture. Regularly checking for signs of needle wear guarantees peak sewing performance.

Master these handling techniques to extend needle life:

- Hold needles by the shank when inserting into your machine

- Store in compartmentalized cases for easy identification

- Use magnetic strips for quick access during projects

- Keep storage areas dry for effective rust prevention

- Inspect regularly as part of your needle maintenance routine

Signs of Worn or Damaged Needles

You’ll know it’s time to replace your sewing machine needle when telltale signs appear.

A wornout needle creates frustrating sewing problems that can ruin your projects.

Watch for these warning signals:

- Skipped Stitches and uneven stitches indicate needle sharpness has diminished

- Thread Breakage and popping sounds during sewing reveal needle damage

- Bent Needles cause fabric snags and poor stitch quality

Replace needles immediately when these issues arise.

Cleaning and Inspecting Needles

After spotting those telltale signs of wear, it’s time to give your needles some attention. Needle care starts with gentle cleaning methods—use a lint-free cloth to wipe away fabric fibers and dust buildup.

Inspecting for damage requires good lighting to spot bent tips or burrs that’ll snag your fabric. A magnifying glass helps reveal subtle imperfections your eyes might miss during needle troubleshooting.

Check needle sharpness by examining the point under bright light.

Proper storage solutions prevent damage between uses—keep needles in labeled containers or magnetic holders. Never ignore a wornout needle—your projects deserve better than skipped stitches.

Replacing Needles for Optimal Performance

When your sewing machine starts producing skipped stitches or thread breaks, it’s signaling time for needle replacement.

Fresh needles prevent fabric damage and guarantee consistent stitch quality.

Needle Wear Signs appear gradually, so regular inspection matters:

- Check for burrs or nicks on the needle point

- Listen for popping sounds during stitching

- Watch for thread shredding or breaking frequently

- Test Bent Needle Check by rolling on flat surface

- Replace after 8-10 hours of use regardless

Proper needle insertion and Storage Solutions extend needle life substantially.

Choosing Right Needle

You’ll achieve better sewing results when you match your needle to your fabric’s weight and type.

Consider your project’s specific needs, from delicate silk that requires a 70/10 universal needle to heavy denim that demands a 110/18 jeans needle for clean, professional stitches.

Considering Fabric Type and Weight

Your fabric’s personality determines which needle it needs. Lightweight fabrics like chiffon and silk pair with thin needles (60/8 to 75/11), while heavyweight fabrics such as denim and canvas require robust needles (100/16 to 110/18).

A fabric weight guide makes this simple—think thin fabric, thin needle; thick fabric, thick needle.

Fabric type matters equally. Knits need ballpoint needles to slip between fibers, while wovens work with universal or sharp points.

Check your needle size chart for fabric compatibility. The right sewing machine needles prevent puckering, skipped stitches, and thread breaks. Your fabric weight and needle size must match perfectly.

Matching Needle to Fabric for Best Results

Perfect needle selection transforms your sewing from frustrating to fabulous. Start with a Fabric Compatibility Chart to match needle types with your material’s weight and weave. Thread Type Influence plays a huge role—thick threads need larger needle sizes, while delicate ones require finer options.

Your needle point matters too. Sharp needles work best for woven fabrics, while ballpoint needles slip between knit fibers without snagging.

This needle selection prevents fabric damage and guarantees smooth stitching. Project-Specific Examples help clarify choices: use 90/14 universal needles for cotton quilting, or 75/11 stretch needles for jersey tops.

The right combination creates superior Stitch Quality Impact, preventing skipped stitches and thread breaks. Needle Damage Prevention starts with smart matching.

What is The Best Way to Store My Sewing Machine Needles?

Proper needle storage keeps your sewing machine needles sharp and organized.

Use needle storage containers or magnetic needle holders to prevent damage and loss.

Label each compartment by needle types and sizes for quick identification.

Store needles in a dry location with rust prevention tips like silica gel packets.

Keep broken needles separate from good ones to avoid confusion during sewing projects.

How Can I Tell When It’s Time to Replace My Sewing Needle?

Three telltale Needle Wear Signs signal replacement time: skipped stitches, Thread Breakage, and fabric damage.

Stitch Quality Issues like uneven seams indicate worn needles affecting needle performance.

Use the Bent Needle Test—place your needle’s shank on a flat surface to check alignment.

Your sewing machine needles guide suggests these warning signs:

- Popping sounds when piercing fabric

- Pulling or snagging delicate materials

- Visible burrs or hooks on the needle tip

Needle Replacement Frequency prevents project disasters.

How Do I Safely Dispose of Used and Damaged Sewing Needles?

Used sewing machine needles pose a real safety risk.

Don’t toss them in regular trash where they can cause needle sticks. Instead, collect them in a sturdy container like an old pill bottle or dedicated sharps container.

Label it clearly, seal tightly when full, and take it to your local pharmacy or recycling center that accepts sharps for proper needle disposal.

Consider recycling metal supplies to minimize environmental impact.

Are There Any Tricks for Threading The Eye of a Sewing Needle More Easily?

Threading sewing machine needles becomes effortless with these proven Threading Techniques.

Good Lighting Tips and proper Thread Prep make all the difference when working with tiny needle eyes.

- Wet thread ends slightly to reduce fraying and create smoother thread insertion

- Use Needle Threaders for quick, accurate threading without eye strain

- Try Eye Magnification tools or magnifying glasses for better visibility

- Fold thread over needle and pinch tightly for easier insertion

Threading a needle can be simplified by using the right method.

What Are The 7 Different Types of Sewing Needles?

You’ll encounter seven main sewing machine needles in your toolkit: Universal needles handle most fabrics, ballpoint needles work with knits, sharp needles pierce woven materials, stretch needles tackle elastic fabrics, quilting needles manage multiple layers, denim needles power through thick materials, and leather needles cut through tough surfaces.

Each needle type serves specific fabric requirements and project needs.

For example, wedge point needles are designed for use with leather and vinyl.

What Are Different Sewing Machine Needles Used For?

Different sewing machine needles tackle specific jobs like specialized tools in your toolkit.

Universal needles handle most fabrics, while ballpoint needles slip through knits without snagging.

Sharp needles pierce tightly woven materials, and stretch needles prevent skipped stitches on elastics.

Wing needle uses create decorative holes, blind stitch needles hem invisibly, and industrial needle types power through heavy-duty projects.

How to Know What Needle to Use When Sewing?

Perfect needle selection depends on matching your fabric type to the right needle size and point style.

You’ll avoid common stitching headaches by considering these key factors:

- Fabric weight – Use smaller needles (60/8-75/11) for lightweight materials, larger ones (90/14-110/18) for heavy fabrics

- Fabric structure – Choose ballpoint for knits, sharp for wovens

- Thread thickness – Match needle eye size to thread weight

- Project requirements – Consider topstitching or specialty needs

What is The Difference Between Sewing Needle 80 12 and 90 14?

Two key needle sizes show clear differences in their applications.

The 80/12 needle works perfectly for lightweight to medium fabrics like cotton and linen, while the 90/14 handles medium-weight materials including denim and canvas.

European sizing indicates diameter, with 90 being thicker than 80, which affects fabric compatibility and stitch quality impact substantially.

How Do I Identify The Correct Needle Size for My Project?

Start by examining your fabric weight and consulting a needle size chart.

Match thin fabrics with smaller needle sizes like 70/10, while heavy materials need larger sizes like 100/16.

Consider thread weight too—thicker threads require bigger needles.

Check thread compatibility with your chosen needle and thread combination.

Different needle brand choices offer various size systems, so read packaging carefully for proper selection.

Whats The Difference Between European and American Needle Sizes?

Understanding needle sizing systems can feel like deciphering a secret code, but it’s simpler than you think.

European sizes measure needle diameters in hundredths of millimeters, while American sizes use a basic numbering scale.

Here’s your quick reference for sizing differences:

- European sizes range from 60-110 (representing 0.6mm-1.1mm diameters)

- American needle sizes span 8-18 with no direct metric conversion

- Size equivalents appear as 80/12 or 90/14 on packaging

- Needle charts show both systems for easy comparison

Frequently Asked Questions (FAQs)

What are different sewing machine needles for?

Like selecting the right brush for painting, you’ll choose different sewing needles based on your fabric’s weight and type.

Universal needles handle most projects, while ballpoint works for knits and sharp needles pierce dense wovens perfectly.

What is a 90-14 needle used for sewing machines?

A 90/14 needle works perfectly for medium-weight fabrics like cotton, linen, and canvas.

You’ll get clean stitches without damaging your fabric.

It’s the go-to choice for most quilting projects and everyday sewing tasks.

What are 100-16 needles used for?

About 85% of sewers underestimate needle size importance.

You’ll use 100/16 needles for heavyweight fabrics like denim, canvas, upholstery materials, and thick leather.

They’re perfect when you’re tackling multiple fabric layers or heavy-duty projects.

Which is bigger, a 24 or 26 needle?

A 26 needle is bigger than a 24 needle. Higher numbers indicate thicker needles designed for heavier fabrics. You’ll use 26 needles for extra-heavy materials like canvas or multiple fabric layers.

Can I use hand sewing needles in machines?

Picture trying to fit a square peg in a round hole—that’s what happens with hand needles in machines.

You can’t use them because they lack the flat-backed shank that machine needles need for proper positioning.

Why does my needle keep breaking during sewing?

Your needle’s breaking because you’re likely using the wrong size for your fabric, forcing it through thick layers, or it’s dull from overuse.

Check your needle size matches your material thickness first.

Do different needle brands fit all sewing machines?

Surprisingly, you can’t just grab any needle brand and expect it to work perfectly!

Most standard needles fit universal machines, but some specialty brands require specific shanks, so always check your machine’s manual first.

What causes skipped stitches with new needles?

Several factors cause skipped stitches even with new needles.

You’re likely using the wrong needle type for your fabric, inserting it incorrectly, or your machine timing needs adjustment by a technician.

Should I change needles between different thread types?

You don’t need to change needles when switching between regular threads of similar weight.

However, you should switch to specialty needles like metallic or topstitch needles for those specific thread types.

Conclusion

Mastering this sewing machine needles types guide transforms you from a frustrated stitcher into a fabric-conquering champion.

You’ll never again battle skipped stitches, torn materials, or broken threads when you match the right needle to your project.

Remember that universal needles handle most tasks, while specialty needles tackle specific challenges like stretch fabrics or heavy denim.

Keep various sizes on hand, replace them regularly, and watch your sewing skills soar to professional levels effortlessly.