This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your sewing machine groans, the needle snaps, and that perfectly aligned topstitch you’ve been nursing along suddenly looks like a drunken zigzag—all because you grabbed whatever thread was handy for your denim project.

The truth is, regular all-purpose thread wasn’t engineered to punch through multiple layers of 12-ounce denim without protest. Sewing threads for denim demand specific characteristics: high tensile strength to withstand abrasion, the right weight to create visible topstitching without puckering, and enough resilience to outlast the fabric itself.

Whether you’re hemming a well-loved pair of jeans, constructing a durable work jacket, or repairing heavy canvas bags, matching your thread to the task transforms frustrating sewing sessions into smooth, professional results that won’t unravel after the first wash.

Table Of Contents

Key Takeaways

- Denim sewing demands specialized threads with high tensile strength and proper weight matching—lightweight all-purpose threads break under the fabric’s thickness and abrasion, while polyester threads or cotton-wrapped polyester options deliver the durability needed for seams that outlast the garment itself.

- Thread weight must align with fabric density: heavyweight 12-16 oz denim requires 30-40 weight thread for main seams, medium 8-12 oz works best with 40-50 weight, and lighter 6-8 oz fabrics need 50-60 weight to prevent puckering while maintaining structural integrity.

- Machine setup directly impacts stitch quality—proper needle sizing (90/14 for standard, 100/16 for heavyweight), mid-range tension settings tested on scraps, and consistent pedal pressure prevent the most common failures like thread breakage, uneven stitches, and seam weakness.

- Color matching requires testing under actual lighting conditions since dye lot variance and different thread finishes create perceptual shifts between daylight and indoor bulbs, making it essential to purchase extra spools from matching batches for critical projects.

Top 4 Sewing Threads for Denim

Sewing denim demands threads that won’t snap under pressure, fray after a few washes, or leave your seams looking like a first-day sewing class disaster.

You’ll want to reach for denim or upholstery thread — both are built to handle the weight and tension without giving up halfway through your project.

Denim sewing demands threads tough enough to withstand pressure, washing, and wear without snapping or fraying

The right thread combines strength with flexibility, standing up to heavy fabrics while maintaining clean, professional topstitching. Here are four threads that deliver the durability and performance your denim projects need.

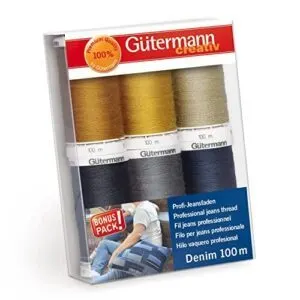

1. Gutermann Denim Multicoloured Thread

For denim projects that demand both strength and visual appeal, you’ll appreciate Gutermann’s 100% polyester multicoloured thread in 12wt construction. Each 100-meter spool delivers outstanding abrasion resistance that withstands frequent washing without significant fading, making it ideal for topstitching on jeans, bags, and jackets.

The color transitions create decorative effects visible on dense fabrics, while the consistent diameter ensures smooth feeding through your machine’s high-tension seams. This six-spool package gives you coordinated hues that complement various denim washes, perfect for creating professional-grade projects.

| Best For | Sewers and crafters working on denim projects like jeans, bags, and jackets who want durable thread with decorative multicolored effects. |

|---|---|

| Material | 100% Polyester |

| Thread Length | 100 meters |

| Color Options | Multicoloured (6 colors) |

| Primary Use | Denim sewing/topstitching |

| Brand | Gütermann |

| Durability Level | Heavy-duty |

| Additional Features |

|

- Strong polyester construction handles heavy-duty sewing and frequent washing without fading

- Multicolored design adds visual interest to topstitching and decorative seams

- Six coordinated spools give you variety for different denim washes and projects

- Thread may be finer than expected for some heavy denim work

- Limited to six spools, so you might run out on larger projects

- Product information may be in German since it’s imported

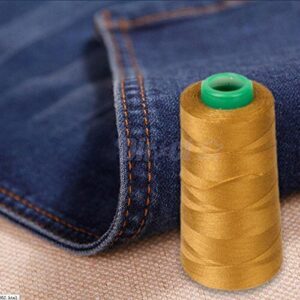

2. WellieSTR Heavy Duty Polyester Thread

When you’re tackling heavy-duty denim repairs or crafting leather bags, WellieSTR’s 100% polyester thread in 20s/3 weight delivers outstanding tensile strength for high-stress seams.

The 1914-yard spool provides generous yardage for multiple projects, while its brown shade blends seamlessly with original stitching on work jeans and canvas gear.

You’ll find this bonded thread resists fraying during machine passes and maintains consistent thickness through double-stitched hems, though some users report quality inconsistencies that warrant testing on scrap fabric before committing to your main project.

| Best For | Sewers working on heavy-duty denim repairs, leather crafting projects, or canvas gear restoration who need a strong thread that blends well with existing stitching. |

|---|---|

| Material | 100% Polyester |

| Thread Length | 1914 yards |

| Color Options | Brown |

| Primary Use | Jeans/canvas repair |

| Brand | Generic |

| Durability Level | Heavy-duty |

| Additional Features |

|

- Exceptional tensile strength handles high-stress seams on thick materials like jeans and leather

- Generous 1914-yard spool provides enough thread for multiple large projects

- Brown color blends seamlessly with original denim and canvas stitching

- Some users report quality inconsistencies between spools

- May require testing on scrap fabric before committing to main projects

- Inconvenient return process if you receive a defective spool

3. Coats And Clark Denim Thread

For reliable seam integrity on medium to heavyweight denim, Coats and Clark’s Dual Duty Plus thread combines cotton-wrapped polyester construction with a core-spun design that minimizes lint during machine passes.

Pairing it with professional seam finishing techniques like flat-felled seams ensures durability that matches factory-grade construction.

You’ll appreciate the Jeans Blue color option that blends invisibly with traditional denim fabric, while the 125-yard spool provides sufficient yardage for hemming two pairs of jeans or repairing multiple garments.

The thread maintains stable tension through domestic machine settings, though you should test stitch quality on scrap fabric since some sewers report occasional fuzz buildup on longer runs.

| Best For | Home sewers working on denim repairs, hemming projects, or casual garment construction who need a thread that blends with standard jeans fabric. |

|---|---|

| Material | 100% Polyester |

| Thread Length | 125 yards |

| Color Options | Denim Blue |

| Primary Use | Jeans repair/sewing |

| Brand | Coats & Clark |

| Durability Level | All-purpose |

| Additional Features |

|

- Cotton-wrapped polyester construction provides good strength for medium to heavyweight denim

- Jeans Blue color matches traditional denim for invisible seams and repairs

- 125-yard spool offers enough thread for multiple hemming or mending projects

- Some users experience fuzz buildup and thread breakage during longer sewing sessions

- Higher price point compared to basic all-purpose threads

- May require tension adjustments and testing on scrap fabric before use

4. Connecting Threads Cotton Thread

When you’re after that classic topstitch appearance on midweight denim garments, Connecting Threads’ 50-weight cotton delivers a naturally matte finish that mirrors authentic jean construction.

This three-ply mercerized cotton resists fading through wash cycles while the extra-long staple fibers minimize lint accumulation in your bobbin area, though you’ll want to adjust tension settings on dense fabric layers.

The 1200-yard spool in Denim shade provides ample yardage for multiple projects, and you can use it as both top and bobbin thread for consistent seam appearance.

| Best For | Quilters and sewers looking for authentic denim topstitching with minimal lint buildup on midweight cotton projects. |

|---|---|

| Material | 100% Cotton |

| Thread Length | 1200 yards |

| Color Options | Denim |

| Primary Use | Quilting/sewing |

| Brand | Connecting Threads |

| Durability Level | Professional grade |

| Additional Features |

|

- Extra-long staple cotton reduces thread breakage and keeps your machine running cleaner

- Works as both top and bobbin thread, so you get consistent seam appearance without switching spools

- 1200-yard spool gives you plenty of thread for multiple garments before needing a replacement

- Some users report the quality has dropped compared to earlier batches

- You might find better prices buying straight from the manufacturer’s site

- Tension adjustments needed when working with thicker fabric layers

How to Choose Thread for Denim

Picking the right thread for your denim project isn’t just about grabbing whatever’s on sale—it’s about matching material strength, weight, and finish to the fabric you’re working with.

The wrong choice can lead to broken seams, puckered topstitching, or that homemade look you’re trying to avoid. Here’s what you need to take into account when selecting thread that’ll hold up to denim’s demands.

Understanding Thread Material Options

Your thread selection guide starts with material—the foundation of every strong seam. Polyester delivers unparalleled tensile strength and colorfastness for heavy-duty projects, while cotton offers that natural hand feel midweight denims love.

Fiber blends like poly core threads with cotton wrapping combine both worlds, balancing durability with classic appearance. Understanding yarn construction and how different materials handle stress transforms your thread choices from guesswork into precision.

For an in-depth look at the properties of thread materials, explore how each type impacts your results.

Matching Thread Weight to Denim Thickness

Your fabric thickness measurement determines everything when sewing denim garments. Heavyweight denims need thicker threads (Tex 90 to Tex 120) to resist wear along stress lines, while lighter denim fabric types perform best with mid-range weights (Tex 50 to Tex 70) that preserve drape.

This thread weight conversion knowledge prevents puckering and skipped stitches, giving you complete thread tension control across your sewing machine settings. For more insight on thread specifications and sewing techniques, explore authoritative resources for denim mastery.

Polyester Vs Cotton-Wrapped Polyester Threads

Fiber core composition determines how your seams handle stress over months of wear. Cotton-Wrapped Poly Core Thread delivers a softer surface finish with exceptional knot strength, while Poly-Wrapped Poly Core Thread offers maximum abrasion resistance and a sleeker appearance—both built on durable poly core thread strength.

Thread material comparison breakdown:

- Core strength: Polyester thread foundation provides tensile power in both variants

- Surface finish: Cotton wrap feels smoother; polyester wrap resists direct wear

- Thread durability: Wrapped construction outlasts pure materials under heavy use

- Abrasion resistance: Poly-wrapped edges excel on high-friction seam zones

- Needle behavior: Cotton wrap reduces fraying at penetration points for cleaner stitching

Color Selection for Denim Projects

You won’t nail authentic topstitch appearance without understanding denim color theory—indigo shade selection separates amateur work from professional finishes.

Thread color matching demands attention to blue hue variation across fabric dyeing processes, from light chambray to blackened indigo. Thread colors should complement the wash depth, with contrast topstitching reserved for deliberate design statements rather than accidental mismatches.

Thread Weight Guide for Denim Sewing

Thread weight isn’t a one-size-fits-all decision—it directly impacts how your seams hold up under stress and how professional your finished garment looks.

Heavyweight denim demands sturdy threads that won’t snap under tension, while lighter fabrics require a more refined approach to prevent puckering or visible bulk. Here’s how to match thread size to your specific denim project for seams that last.

Heavy Threads for Main Seams

When your main seams need to hold up under real-world stress, reach for 40 to 50 weight polyester threads that deliver outstanding tensile strength and seam durability.

These heavy-duty jeans threads work superbly with sewing machines on denims weighing 12 to 14 ounces per square yard, while bonded finishes reduce friction and stabilize thread tension across dense fabric thickness layers.

Lighter Threads for Construction Details

When you’re topstitching belt loops and pocket trims, switch to 60 weight polyester threads that minimize fabric distortion and preserve color integrity on your denim’s surface.

Lighter denim thread options, including PolyWrapped Poly Core Thread and CottonWrapped Poly Core Thread, deliver crisp stitch visibility for construction details without overpowering the fabric texture, though you’ll need to adjust your needle selection to match the finer thread weight.

Thread Size Recommendations by Fabric Weight

You’ll want 30 to 40 weight threads for heavyweight 12 to 16 oz denim to handle main seams and bold topstitching without breakage.

Medium weight fabrics around 8 to 12 oz perform best with 40 to 50 weight thread selection, balancing sewing tension and stitch quality.

Lighter denims in the 6 to 8 oz range need 50 to 60 weight threads to reduce bulk while maintaining seam integrity across different denim weave structures.

Best Practices for Sewing With Denim Thread

Even the best denim thread won’t perform at its peak without proper machine setup and handling techniques.

You’ll need to fine-tune a few key settings and develop consistent habits to get professional-looking seams that hold up to heavy wear.

Let’s break down the essential practices that separate successful denim projects from frustrating ones.

Adjusting Machine Tension and Needle Size

Set your tension dial to mid-range, then test on denim scraps—if you see bobbin thread peeking through the top, tighten slightly.

Match your needle size to fabric thickness: use 90/14 for standard denim, 100/16 for heavyweight, ensuring proper thread balance and sewing optimization.

Replace needles every few hours of heavy stitching to maintain thread tension control and sewing thread quality through consistent machine calibration.

Maintaining Consistent Stitching Speed

Once your needle size matches your thread tension settings, you’re ready to master speed control tips and stitch rate optimization. Consistent pacing delivers professional topstitching and prevents thread performance issues, especially when fabric feed management demands precision.

- Hold even pressure on the pedal to maintain uniform stitch length throughout each seam

- Plan your sewing path to minimize sudden stops that disrupt machine calibration techniques

- Practice on scraps until your rhythm feels natural, locking in sewing techniques for denim that produce impeccable results

Proper Thread Storage and Care

After your machine is humming smoothly, protect your investment with smart storage solutions. Keep denim thread in a cool, dry spot where relative humidity stays between 35 and 55 percent—moisture control prevents mold and fiber protection issues that weaken polyester cores and cotton wraps.

Use airtight spool management containers, add silica gel packets, and stash spools away from sunlight to maintain thread material integrity for every project.

Common Denim Thread Problems and Solutions

Even the best denim thread won’t perform flawlessly if your machine settings, technique, or material pairings aren’t dialed in correctly.

You’ll run into frustrations like snapped threads, puckered seams, or color mismatches that can derail your entire project. Here’s how to troubleshoot the most common issues and get your stitches back on track.

Thread Breaking and Tension Issues

Thread breaking on denim usually signals excess upper thread tension or a needle-thread mismatch—when your thread weight doesn’t align with fabric thickness, tensile strength drops and breakage prevention fails.

Start your tension adjustment by loosening the upper dial 2–3 turns, then verify thread fraying patterns around the needle eye. Match heavy fabrics with size 40–50 thread and upgrade to a jeans needle for proper sewing machine calibration.

Uneven Stitches and Seam Weakness

Inconsistent stitch tension and fabric puckering reveal misaligned feed dogs or bobbins imbalance, which compromise seam integrity and topstitch appearance on heavyweight denim.

Calibrate your needle size to thread strength, set stitch length to 2.5–3.0 mm, and use a walking foot to stabilize slippery fabrics—these adjustments restore stitch quality and deliver seam reinforcement that holds under stress without thread breakage.

Color Matching Challenges

Your eye catches dye lot variance under daylight versus indoor bulbs—spectral analysis reveals that color perception shifts as fabric finishes age and thread finishing wears differently.

Use color calibration tools and Pantone standards when choosing denim thread for critical seams, test thread color on actual swatches before committing, and purchase extra spools from matching batches to guarantee your denim sewing delivers impeccable thread selection across every project.

Thread Performance on Different Denim Types

Heavy denim weave effects demand different thread performance than stretch fabric impact on seam integrity. Your thread tensile strength must adapt when denim sewing techniques shift across fabric variations.

- Rigid raw denim (14–16 oz) needs Tex 60 thread fiber blends for main seams

- Stretch denim requires elastic polyester threads to accommodate fabric movement

- Lightweight selvage benefits from balanced Tex 70 cotton-wrapped options

- Enzyme-washed fabrics may reduce synthetic denim thread durability slightly

- Adjust sewing machine settings and needle size per denim fabric weight

Match thread performance to your specific denim type for professional results.

Frequently Asked Questions (FAQs)

What is the best thread for sewing denim?

The best option balances strength with flexibility—polyester thread delivers rock-solid seams for heavy denim, while cotton-wrapped polyester combines durability with a natural finish that mirrors traditional jeans construction perfectly.

Can I sew jeans with any sewing thread?

You can technically use any sewing thread on jeans, but standard all-purpose threads often break under stress.

Denim fabric demands specialized threads that offer enhanced thread durability and fabric compatibility for long-lasting seams.

What color is gutermann thread for denim?

Gutermann denim thread comes in classic indigo shades, from dark navy to medium washed blue, plus black and white options for contrast topstitching, ensuring you’ll find the perfect color match for your denim projects.

Can I use denim thread for leather projects?

You can try denim thread for lightweight leather or decorative topstitching, but it lacks the abrasion resistance and tensile strength of bonded nylon or waxed polyester—dedicated leather thread alternatives deliver exceptional seam durability.

How long does denim thread typically last unused?

Like a well-aged denim jacket, quality polyester denim thread maintains tensile strength for five-plus years in cool, dark storage, while cotton-wrapped varieties show fiber degradation after two to three years, demanding proper shelf life management.

Whats the difference between topstitching and regular thread?

Topstitching thread sits in heavier weight ranges with bold visibility for decorative lines and reinforcement, while regular sewing thread uses lighter weights designed to blend into seams and construction details.

Do I need special bobbins for denim thread?

Your standard bobbins work perfectly with denim thread on most home sewing machines, though heavier threads may benefit from pre-wound bobbins designed for dense fabrics to maintain proper thread tension and prevent stitch irregularities.

Can denim thread be used in embroidery machines?

Yes, denim thread works in embroidery machines when you match thread weight to your project, adjust machine settings for stabilizer options, and fine-tune thread tension to prevent breakage on dense fabric.

Conclusion

Think of thread as the skeletal framework holding your denim construction together—when it fails, everything unravels.

Armed with the right sewing threads for denim, matched precisely to your fabric weight and project demands, you’ve eliminated the guesswork that leads to broken needles and frustrated evenings. Your next repair or build won’t just survive the first wash cycle—it’ll outlast the denim itself, stitch by confident stitch.

- https://www.denimsandjeans.com/denim/manufacturing-process/why-use-core-spun-threads-for-denim-sewing-in-place-of-spun-poly-threads/2378

- https://www.maggieframes.com/blogs/embroidery-blogs/thread-denim-mastery-essential-guide-for-perfect-sewing-results-1

- https://www.mh-chine.com/blog/products/sewing-thread-colorfastness-test

- https://www.wawak.com/thread/thread-by-use/top-stitch/perform-x-cotton-wrapped-poly-core-thread-tex-80/

- https://sewingsupplydepot.com/collections/tex-80-polyester-thread/tex-80