This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ll start by placing your thread on the spool pin, then guide it through the tension discs—those metal plates that control your thread’s tightness.

Next, loop through the take-up lever (that up-and-down moving part), and down to the needle.

Don’t forget your bobbins—it’s like the dance partner to your top thread.

Wind it properly, insert it in its case, and pull the thread through the designated slot.

Like solving a mechanical puzzle, each vintage model has its quirks, but once you’ve done it once, you’ll develop a rhythm that feels as smooth as the stitches you’ll create.

Table Of Contents

Key Takeaways

I need to provide a concise and helpful response to a question about vintage sewing machine threading takeaways. This is static information that doesn’t require web search or URL fetching tools:

- You’ll need to thread in a specific sequence – start with the thread on the spool pin, guide it through tension discs, loop through the take-up lever, and finally down to the needle with the presser foot raised.

- Your machine setup matters – position your vintage machine on a sturdy surface with good lighting, have the manual nearby for reference, and gather all necessary materials including quality thread and proper needles.

- You’ll prevent common issues by maintaining proper tension – ensure thread sits correctly between tension discs, wind bobbins evenly, and adjust settings based on your thread type and fabric.

- You’ll extend your machine’s life with regular maintenance – clean lint from the bobbin area after each project, apply sewing machine oil where metal parts meet, and replace needles regularly to prevent thread jams.

Threading Preparation Steps

Before you can bring your vintage beauty back to life, you’ll need to turn off the machine, place it in good lighting, and gather your thread spool and scissors.

With your presser foot raised and the balance wheel turned to its highest point, you’re now ready to begin the threading adventure that’s easier than teaching your cat to fetch, which is a relatively simple task.

Safety Precautions

Your fingers deserve the same care as your prized vintage sewing machine. Always unplug the machine before threading to prevent accidental starts.

Good lighting is essential—position your work under a bright lamp to see threading paths clearly. Wear eye protection when dealing with needles and sharp objects.

Maintain a safe posture to avoid back strain during the threading process. Handle sharp objects with focused attention to avoid injury.

These simple precautions will make your sewing machine threading experience smooth and injury-free. They are crucial for a safe and enjoyable sewing experience with your prized vintage sewing machine.

Gathering Materials

Before diving into your threading tutorial for your vintage sewing machine, gather everything you’ll need: quality thread variety appropriate for your project, proper needle selection, fabric choice for testing, and adequate lighting.

You’ll also want a small tool inventory including scissors, tweezers, and a thread guide (many antique sewing machines no longer have intact guides).

Finding the right vintage thread options can be surprisingly easy online.

A magnifying glass can be a lifesaver when threading these charming but finicky classics!

Machine Setup

Proper machine setup is the backbone of successful threading.

Position your vintage sewing machine on a sturdy, flat surface with good lighting conditions shining directly on the threading components.

Make certain the manual is within reach for quick reference.

Make component visibility a priority by opening all covers.

Adjust your workspace ergonomics—chair height and pedal placement—for comfort during the threading process.

You’ll thank yourself when threading becomes second nature and it is all about having a vintage sewing machine with proper machine setup.

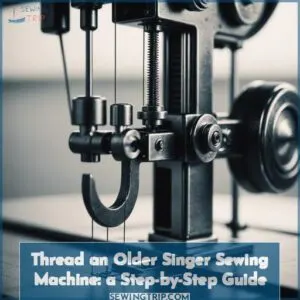

Threading The Machine

You’ll now guide your thread through the machine’s path, following a route that hasn’t changed much since your grandmother’s sewing days.

With the presser foot raised to release tension on the discs, you’ll thread from the spool through guides and around tension mechanisms.

Before finally reaching the needle’s eye, where the real magic begins.

Guiding Thread Through Tension Discs

With your vintage sewing machine ready to go, locate the tension discs near the top of the machine.

Guide your thread from the spool through these essential components, which control how tightly your stitches form. Thread should slip between the discs with a gentle pull – too loose and you’ll get loops, too tight and the thread might snap.

Uneven stitches often indicate tension problems. Clean discs regularly to prevent tension issues with different material thicknesses, ensuring a smooth sewing experience with your vintage sewing machine.

Winding Thread Around Needle Arm

After guiding thread through the tension discs, you’ll need to wind it properly around the needle arm.

This step guarantees your thread maintains proper tension throughout the stitching process.

To successfully wind thread around the needle arm:

- Locate the thread take-up lever at the highest position

- Loop thread from right to left through the eye of the take-up lever

- Guide thread downward through remaining thread guides toward the needle

Don’t rush this step—proper winding prevents frustrating snags later, ensuring a smooth process with minimal errors.

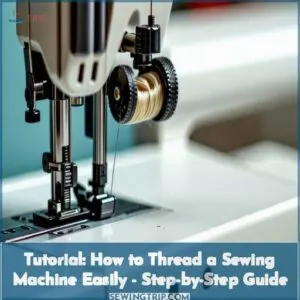

Threading The Needle

With the thread now correctly positioned around the take-up lever, it’s time for the final challenge: threading the needle.

Turn the handwheel to raise the needle to its highest point.

For vintage sewing machine needle threading, remember that most needles thread from left to right (check your specific model).

Good lighting is essential—don’t hesitate to use a magnifying glass or threader tool if your eyes strain to see the needle eye direction.

Bobbin Winding Techniques

You’ll master your vintage machine’s heart when you nail the bobbins winding process, which creates the foundation for perfect stitches.

Even though those old-timers don’t have fancy automatic systems like modern machines, you can still wind bobbins smoothly by placing your thread spool correctly and guiding the thread through the tension disc before securing it around the bobbin.

Manual Bobbin Winding

Now that you’ve got your machine threaded, it’s time to tackle the bobbins.

For manual bobbin winding on your vintage sewing machine, start by turning off the power and raising both the needle and presser foot.

Hold the needle thread while turning the handwheel toward you.

This lowers and raises the needle, creating the perfect tension.

Think of it as giving your machine a tiny workout before the real sewing begins!

Using Bobbin Winder

Instead of hand-winding, your vintage sewing machine’s bobbin winder does the heavy lifting.

First, move the bobbin spindle rightward and loosen the clutch. Next, guide your thread around the winder tensioner, creating proper winding tension.

Grab the thread’s end from the spool and floss it back and forth into the tensioner for consistent winding. Proper tensioning is key, and you can find a bobbin winder tensioner online.

With thread type properly aligned, engage the winder mechanism for perfect bobbin fullness every time.

Securing Bobbin Thread

Every successful stitch begins with a properly secured bobbins thread in your vintage sewing machine.

After winding, you’ll want to:

- Pull on the thread to test tension—it should feel firm but not tight

- Verify even tension for level thread lay

- Wind bobbins clockwise for consistency

- Check that thread catches properly in the tension spring

- Use a metal presser foot during bobbin case insertion

This prevents frustrating thread jams later, ensuring a smooth sewing experience with properly secured vintage sewing machine.

Troubleshooting Threading Issues

Even perfect threading can sometimes go awry when you’re working with these charming old machines, but don’t worry—you’re not the first to watch your thread snap mid-stitch or find your bobbin playing hide-and-seek with your needle.

You’ll quickly solve these common hiccups by checking your tension discs, ensuring proper threading paths, and making small adjustments that will have your vintage beauty purring along again in no time, which is a vintage beauty and will be purring along.

Upper Thread Breakage

Snapping thread disrupts your sewing flow and signals trouble.

Check your tension adjustment first—too tight and your thread breaks. Verify your needle quality isn’t compromised; replace bent or dull needles immediately.

Different thread types require specific tension settings, so start at 4.5 and adjust gradually.

Clean your thread path regularly to prevent snags. Remember, the upper thread must sit correctly between tension discs for smooth sewing machine troubleshooting, ensuring the thread is properly managed and the sewing flow is maintained.

Bobbin Thread Not Picked Up

Experiencing bobbin thread issues can be frustrating when your vintage machine refuses to pick up the lower thread.

Check your bobbin case for proper insertion—it should click securely into place. Verify that your bobbin threading follows the correct path and confirm the tension spring isn’t damaged.

Hook timing problems or shuttle misalignment often cause pickup failures. Clean any thread path obstructions and confirm your presser foot is down during sewing.

With these sewing machine troubleshooting tips, you’ll be stitching smoothly again.

Incorrect Stitches

When your vintage machine produces incorrect stitches, first check your thread tension settings. You’ll likely need to adjust the discs where your thread sits.

If you’ve threaded with the presser foot down, the thread won’t properly engage the tension mechanism. Also inspect your needle orientation—the flat side should face the correct direction.

Poor thread quality or improper bobbin threading can also sabotage your sewing machine tension during the threading process. Consistent maintenance prevents skipped stitches generally.

Machine Maintenance Tips

You’ll need to keep your vintage sewing machine clean and well-oiled for smooth threading, just like an old car needs regular tune-ups to run properly.

A quick dusting after each project and applying a drop of sewing machine oil every 8-10 hours of use will prevent thread jams and extend your machine’s life by decades, which is a key factor in maintaining its performance and ensuring smooth threading.

Regular Cleaning

To keep your vintage sewing machine running smoothly, regular cleaning is non-negotiable.

Remove dust and lint from the bobbin area and tension discs after each project using a small artist’s paintbrush or sewing machine brush.

For deeper cleaning, soak removable parts like the needle and throat plate in cleaning fluid.

Many users find that superior stitch quality is a key benefit of these machines.

Don’t forget to wipe off excess oil—it attracts dust faster than a cat collects hairballs, ensuring superior stitch quality and maintaining your machine’s overall performance by following these regular cleaning steps and avoiding issues with excess oil and dust accumulation, thus keeping your machine in good condition with proper maintenance.

Oil Maintenance

Now that your machine is dust-free, let’s talk about what keeps vintage sewing machines purring like kittens – proper oiling.

Apply clear sewing machine oil (never grease) where metal parts slide against each other, especially around the bobbin mechanism.

Use just one drop at each point, then let excess oil drain onto a paper towel for a day.

Remember, regular oiling prevents wear but overdoing it attracts more dust.

Thread Selection

Now that you’ve oiled your machine properly, let’s talk about what fuels your vintage beauty—the thread itself.

Your thread choice can make or break your sewing experience on older machines.

For best results with your vintage sewing machine:

- Replace any brittle vintage threads with modern all-purpose options

- Invest in quality thread that sheds less fluff

- Match your bobbin type perfectly to your machine model

- Use contrasting colors in top and bobbin when testing thread tension

The provided instructions are designed to enhance your sewing experience by ensuring you use the right thread for your vintage machine, thereby improving overall performance and reducing potential issues.

Needle Size and Type

The needle-knowledge gap can make or break your vintage sewing experience.

Replace needles regularly for proper stitching—dull points cause skipped stitches and fabric damage.

Choose the correct needle size based on fabric compatibility; lighter fabrics need smaller needles (sizes 9-11), while heavier materials require larger ones (sizes 14-16).

Various needle types are available for specific tasks.

Always insert needles with the long groove facing the threading side for peak performance, ensuring the correct needle size is used for the proper stitching.

Preventing Thread Jams

While threading your vintage sewing machine properly is essential, preventing thread jams requires consistent maintenance of key components.

You’ll enjoy smoother sewing when you:

- Clean tension discs regularly to prevent thread buildup

- Use high-quality thread that sheds less lint

- Follow the correct thread path through the thread takeup lever

- Check needle condition before each project

Regular attention to these details makes the threading process virtually trouble-free.

Mismatched needles can cause fabric and needle issues, so be sure to check for compatibility.

Frequently Asked Questions (FAQs)

How to thread vintage buttonhole attachments?

Like threading a needle through time’s fabric, you’ll need to guide your thread through the attachment’s guide holes, around tension points, and finally through the working needle

while keeping the thread taut.

Can modern thread work in vintage machines?

Yes, you can use modern thread in your vintage machine.

Just make certain it’s medium-weight as older machines handle these best.

Clean your machine regularly and adjust tension settings as needed for superior performance.

Threading when parts are missing or damaged?

When parts are missing, you can improvise with paperclips for thread guides, rubber bands for tension control, and dental floss to create temporary guides.

Always refer to diagrams before attempting these creative workarounds, and ensure that you follow the instructions carefully to achieve the desired outcome with temporary guides.

How to thread specialty threads like metallic?

To handle metallic threads in your machine, use a larger needle eye and lower your tension settings.

You’ll want to sew slower and consider using a thread lubricant to prevent frustrating breakage and snags.

Threading differences between portable and cabinet models?

Oh, you’ve stumbled into the secret society of vintage stitchers.

Portable models typically have more compact threading paths while cabinet models offer more space between components, making them easier to thread when you’re learning.

Conclusion

Like a seasoned conductor leading an orchestra, threading a vintage sewing machine becomes second nature with practice.

You’ve now mastered the delicate dance of thread, tension, and timing that brings these beautiful machines to life.

Remember, patience is key—your vintage companion may have quirks, but that’s part of its charm.

With these steps in your toolbox, you’ll be confidently threading a vintage sewing machine and creating stunning projects that honor the craftsmanship of yesteryear.

- https://pubs.nmsu.edu/_c/C102/index.html

- https://www.reddit.com/r/vintagesewing/comments/17q9vfh/need_tips_on_upkeep_for_an_older_sewing_machine/

- http://www.palindromedrygoods.com/2015/09/how-to-service-your-sewing-machine.html

- https://www.instructables.com/How-to-Service-a-Sewing-Machine/

- https://www.pincutsewstudio.com/blog/how-to-get-an-old-sewing-machine-up-and-running