This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

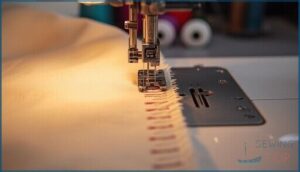

You’ve just finished a beautiful handmade t-shirt, but the inside seams look messy—threads unraveling, edges curling, nothing like the store-bought garments you admire. That’s where a serger changes everything. This specialized machine trims, wraps, and secures fabric edges in one smooth motion, creating those clean, professional seams you see inside quality clothing.

Unlike your regular sewing machine that simply stitches fabrics together, a serger prevents fraying while handling stretchy knits that would otherwise pucker or distort. Whether you’re constructing activewear that needs to move with your body or finishing seams that’ll withstand countless washes, understanding what this machine can do opens up new possibilities in your sewing projects.

Table Of Contents

Key Takeaways

- A serger trims, wraps, and secures fabric edges in one motion, creating professional seams that prevent fraying while handling stretchy knits that regular machines struggle with.

- Unlike regular sewing machines that use 1-2 threads, sergers use 3-4 threads with loopers to create overlock stitches that maintain fabric stretch and boost production speed by 30-50%.

- Sergers excel at finishing seams and constructing activewear but can’t handle precision tasks like buttonholes, topstitching, or zippers—making them powerful partners to regular machines, not replacements.

- Key features to prioritize include metal construction for durability, color-coded threading systems for ease of use, adjustable differential feed for fabric versatility, and independent tension controls for consistent stitch quality.

What is a Serger Used For?

A serger is a specialized sewing machine that finishes fabric edges with professional-looking seams while trimming away excess material in one smooth pass. It’s designed to prevent fraying, handle stretchy fabrics, and create durable seams that hold up through wear and washing.

Here’s what makes a serger different from your regular sewing machine and why it’s become essential for anyone serious about garment construction.

Defining a Serger and Its Purpose

A serger—also called an overlocker—is a specialized serger sewing machine that trims, sews, and finishes seams in one swift motion. Here’s what sets sergers apart in edge finishing and seam construction:

Different types of serger sewing machines offer anywhere from 2 to 8 thread configurations, each designed for specific fabric weights and finishing techniques.

- Uses multiple threads and loopers to create durable overlock stitches

- Encases raw fabric edges to prevent fraying

- Excels at fabric handling for knits and stretchy materials

- Delivers professional results through refined overlock techniques

Key Differences From Regular Sewing Machines

While regular sewing machines handle varied tasks—buttonholes, topstitching, quilting—sergers zero in on speed and specialized edge finishing. Here’s your overlock machine vs sewing machine breakdown:

Mastering core sewing skills to improve accuracy makes choosing between these machines easier since you’ll know exactly what finish quality you need.

| Feature | Regular Sewing Machine | Serger (Overlock Machine) |

|---|---|---|

| Speed Comparison | Slower seam finishing | Completes edges in seconds |

| Stitch Variety | 20+ stitch patterns | Focused on overlock stitches |

| Edge Finishing | Requires extra passes | Trims and finishes simultaneously |

| Thread Management | 1-2 threads with bobbin | 3-4 threads, no bobbin system |

| Maintenance Needs | Standard cleaning | Blade replacement, complex threading |

Sergers use differential feed to handle knits without stretching—something regular machines struggle with.

Why Sergers Are Essential in Sewing

Speed efficiency transforms your workflow—professional settings see production rates jump 30-50% with a serger sewing machine. That time savings comes from simultaneous trimming and finishing, skipping manual zigzagging entirely.

A serger boosts production speed by 30-50%, cutting finishing time through simultaneous trimming and edge sealing

Your overlock machine delivers seam quality that extends fabric longevity by preventing fraying and pilling. Professional edges in one pass mean you’ll construct garments faster while maintaining the polished look clients expect.

Pairing the right needle with your thread and fabric weight—choosing the correct sewing machine needle—prevents skipped stitches and keeps your overlock seams clean.

How Does a Serger Work?

A serger might look intimidating at first, but once you understand the basic mechanics, it’s easier to appreciate what makes it so efficient. The magic happens through a combination of multiple threads, specialized loopers, and a built-in cutting blade working together in one smooth motion.

If you’re ready to work with knits and activewear, learning how to sew stretch fabric will help you get professional results every time.

Let’s break down the three main components that make a serger different from your regular sewing machine.

Overlock Stitching Explained

What makes an overlock stitch different from what your regular sewing machine creates? The serger sewing machine uses loopers and multiple threads to wrap around fabric edges, forming a secure, interlocking chain.

This overlock stitch formation excels at edge finishing while allowing fabric stretch—perfect for seam stability in knits. Thread tension adjustments control how tightly the overlocking hugs your material, preventing fraying beautifully.

The Cutting Mechanism

Precision is what sets a serger apart in fabric trimming—the cutting knife slices away excess as you sew, leaving perfectly even edges for overlock seam finishing. You’ll find the blade positioned just ahead of the needles, and knife adjustment lets you control how much gets trimmed.

Regular blade maintenance keeps your edge trimming sharp, while serger safety features protect your fingers during cutting action.

For detailed guidance on choosing between your machines for specific projects, explore when to use a serger versus a regular sewing machine.

Role of Multiple Threads and Loopers

Threading systems on a serger coordinate loopers and needles to lock fabric edges in place—usually three or four threads weave together for secure seam finishing. Your looper settings control how threads wrap around the edge, while thread tension determines stitch formation quality.

- Upper loopers form the overedge wrap on top of your fabric

- Lower loopers carry edge finishing thread beneath the material

- Needle threads anchor the center for stability during fabric feeding

- Proper looper coordination prevents skipped stitches and breakage

- Tension balance across all threads creates professional, stretchy seams

Finishing Seams and Preventing Fraying

One of the biggest reasons sewers invest in a serger is to finish seams that won’t unravel or fray over time. When you overlock the edges of your fabric, you’re creating a barrier that holds everything in place, even through repeated wear and washing.

Let’s look at the specific ways a serger accomplishes this and why it makes such a difference in your finished projects.

Overlocking Edges for Durability

When you overlock edges with a serger, you’re building a fortress around every seam. The multi-thread overlock distributes stress across fabric edges, securing fibers and reducing fraying—especially on looser weaves. Proper thread tension keeps edges flat and clean, while the trimmed border stays uniform. This edge finishing technique delivers fabric stability and seam reinforcement that holds up under repeated laundering and wear.

| Fabric Type | Overlock Benefit | Durability Impact |

|---|---|---|

| Lightweight wovens | Neat, narrow edges | Minimizes raveling |

| Knit fabrics | Stretch preservation | Prevents edge creep |

| Loose weaves | Secured fiber structure | Reduces abrasion |

| Delicate materials | Clean professional finishes | Long-term edge integrity |

Enclosing Raw Fabric Edges

A serger’s real magic lies in how it wraps raw fabric edges inside the overlock stitch—sealing them completely. This seam enclosure technique folds the edge, securing it within interlocking threads for exceptional fray prevention.

You’re not just trimming; you’re creating a fabric edge finishing system that locks fibers in place. The result is raw edge treatment that stays flat, resists snagging, and delivers professional fabric sealing every time.

Professional Seam Finishes

When you want seams that look custom-made instead of homemade, a serger delivers that edge trimming and fabric finishing in one pass.

Professional finishing isn’t just about appearances—the stitch quality creates durable seams that resist stress and washing. Overlock techniques boost seam security by compressing layers together, preventing puckering and curl.

That’s why serging transforms garment construction from amateur to polished, giving you the confidence of commercial-level seam finishing.

Sewing Knit and Stretchy Fabrics

Working with knits can feel tricky if you’re using a regular sewing machine—the fabric stretches, puckers, or refuses to cooperate. A serger changes everything by handling stretchy materials with ease, keeping seams flexible and preventing that annoying wavy distortion.

Here’s how it makes sewing knits feel like second nature.

Maintaining Fabric Stretch

You don’t need to worry about losing stretch—that’s where sergers shine. They preserve fabric elasticity through differential feed and stretch-friendly overlock stitches that move with the material. Here’s how they protect knit recovery:

- Balance tension across multiple threads to prevent flattening

- Use proper needle settings to minimize distortion

- Maintain seam integrity without restricting movement

This means your stretchy fabrics stay stretchy, even after countless wears.

Constructing Activewear and Apparel

Once you’ve got that stretch under control, you’re ready to build real athletic wear—leggings, sports bras, running gear. Sergers create stretch-compatible seams that move with your body, trim excess bulk for lightweight comfort, and finish edges quickly without topstitching. Fine gauge threads reduce weight, while integrated cutting speeds up your workflow.

| Construction Element | Why It Matters |

|---|---|

| Stretch stitching | Moves with fabric without breaking |

| Overlock seams | Minimizes bulk at seam allowances |

| Fine gauge threads | Reduces garment weight for comfort |

| Edge finishing | Creates professional, fray-free results |

| Integrated trimming | Speeds up production workflow |

Preventing Runs and Distortion

Balanced tension control and proper differential feed keep your stitches from puckering or pulling—that’s how you stop runs before they start.

Overlock stitches secure fabric edges without adding bulk, so seams stay stable even when you stretch the material.

Thread management matters too; consistent speed and stitch length prevent sudden gathering that creates distortion in delicate knits.

Creating Decorative and Functional Stitches

A serger isn’t just about finishing edges—it opens up a whole new world of creative stitching techniques. You can use it to add decorative touches that look professional, or create functional finishes that make your garments more polished.

Here are three ways you’ll use your serger beyond basic seam finishing.

Rolled Hems and Lettuce Edges

Your serger opens the door to elegant edge finishing with rolled hems and playful lettuce edges. Rolled hems fold fabric twice into a delicate, narrow finish—perfect for scarves and lightweight garments where you want minimal bulk.

Lettuce edges create those fun, wavy ruffles on knits by adjusting your serger settings and differential feed.

Both techniques demand attention to stitch quality and fabric handling, so practice on scraps first.

Flatlock Seams and Decorative Stitching

Flatlock techniques let you build low-profile, stretchy seams that shine in activewear and athleisure projects. This decorative edging method uses a 3- or 4-thread overlock stitch that lies nearly flat, maintaining fabric compatibility with knits while adding visual interest through seam finishing.

- Adjust tension to balance thread coverage on both fabric sides

- Use contrasting colors for bold, ribbed decorative effects

- Keep seam allowances narrow—around 1/4 inch—for cleaner results

- Press lightly after serging techniques to set stitches without puckering

You’ll achieve stretch stitching that’s functional and eye-catching.

Gathering and Ruffling Fabric

Controlled fullness transforms plain seams into striking design elements when you master fabric gathering on your serger. Adjust your differential feed to a higher ratio—usually 2:1—and watch gathered edges form automatically as you sew.

This fabric manipulation creates even ruffle techniques without basting threads, giving you pleat control that’s fast and consistent. You’ll simplify sewing techniques while adding texture through strategic serging.

Serger Capabilities and Limitations

Sergers are powerful tools, but they’re not miracle workers—they excel at specific tasks while falling short on others. Knowing what your serger can and can’t handle helps you work smarter, not harder.

Let’s break down the real capabilities and limitations so you can use your serger alongside your regular machine like a pro.

What Sergers Can Do

Think of your serger as a finishing powerhouse—it trims, sews, and seals edges in one swift motion. You’ll master overlock stitches for fabric handling, rolled hems on delicate materials, and flatlock seams for activewear.

Serger basics include edge finishing at speeds exceeding 1,300 stitches per minute, gathering with differential feed, and maintaining stretch in knits.

With proper machine maintenance and tension adjustments, you’re equipped for professional sewing techniques.

Tasks Unsuitable for Sergers

Precision stitching demands a level of control that your serger can’t quite deliver. While overlock machines transform garment construction with knits, they fall short on tasks requiring straight-line accuracy or specialized sewing technology.

Here’s where sewing machines outperform your serger:

- Woven fabric limitations: Dense weaves need precise seam control, not overlocked edges

- Non-stretch seams: Rigid finishes require backstitching that sergers handle poorly

- Heavy-duty upholstery: Reinforced seams demand specialized equipment beyond overlock capabilities

- Leather crafting: Non-threaded edges need different stitching methods entirely

- Buttonholes and topstitching: These precision tasks require dedicated feet and straight stitches

Complementing a Regular Sewing Machine

Your serger and sewing machine work together like partners on a team—each handling what it does best. The sewing machine constructs seams and adds details like buttonholes, while your overlock machine finishes edges and trims fabric in one pass. This workflow optimization means faster seam finishing without adjusting zigzag tensions, and machine integration creates professional results that neither tool achieves alone.

| Task | Sewing Machine | Serger |

|---|---|---|

| Seam construction | Assembles garment pieces | Finishes raw edges quickly |

| Edge trimming | Requires separate cutting | Trims while overlocking |

| Fabric handling | Best for wovens, precision work | Excels with knits, stretch fabrics |

| Stitch options | Buttonholes, topstitching, zippers | Rolled hems, overlock, flatlock |

| Workflow role | Primary construction tool | Finishing and edge specialist |

Tips for Choosing and Using a Serger

Getting the right serger and learning to use it well can feel overwhelming at first, but it doesn’t have to be. A few smart choices upfront will set you up for success, and with some basic know-how, you’ll be serging like a pro in no time.

Here’s what you need to focus on to make the most of your machine.

Key Features to Consider

When you’re ready to invest in a serger, build quality matters. Metal components in critical parts guarantee your machine survives years of use.

Look for color-coded easy threading systems that simplify thread management, adjustable differential feed to handle various fabrics without puckering, independent thread tension controls for each serger stitch, and variable motor speed for precise control.

Don’t overlook included presser feet that expand your creative options.

Threading and Tension Adjustments

Threading a serger intimidates many sewers, but modern easy threading systems and jet-air threading take the guesswork out. You’ll thread through eight specific points—needles and loopers—following your machine’s color-coded diagram.

Tension control dials on each thread path let you fine-tune stitch quality. Start with factory settings, then adjust as needed.

Practice serger calibration on scrap fabric to master thread management and achieve consistent stitch optimization every time.

Maintenance and Troubleshooting

Once you’ve mastered tension adjustments, regular preventive care keeps your machine humming. Clean lint from feed dogs and blade housing weekly, and replace needles based on fabric type.

Uneven stitches signal thread tension issues or misaligned paths—recheck your threading order. Dull blades cause fraying, so schedule blade maintenance quarterly.

For persistent problems requiring serger repair, consult a qualified technician. These troubleshooting tips optimize sewing efficiency and extend your machine’s life.

Frequently Asked Questions (FAQs)

What is a serger machine & how does it work?

A serger is a specialized sewing machine that uses multiple threads and loopers to create overlock stitches along fabric edges, trimming excess material as it sews for clean, professional seam finishes.

What does a serger do?

A serger trims fabric edges while simultaneously stitching an overlock seam that prevents fraying.

This edge finishing and seam construction happen in one pass, making serging faster and more professional than traditional sewing methods.

What is a serger in sewing?

A serger is a specialized sewing machine that uses multiple threads and loopers to create overlock stitches while trimming fabric edges—giving you professional seam finishes that prevent fraying on knits and wovens alike.

Why should you buy a serger machine?

Think of it as upgrading from a bicycle to a sports car—a serger delivers professional finishing, manages stretchy fabrics effortlessly, and speeds up your workflow, making garment construction faster and more polished than any standard sewing machine alone.

Why do you need a serger for a sewing machine?

A serger enhances your sewing machine by delivering professional finishing, fabric protection, and sewing efficiency.

It prevents fraying, maintains stretch in knits, and streamlines home decor projects—making the serger stitch essential for polished results.

How do you use a serger machine?

To sew seams that won’t come unraveled, thread your serger through loopers and needles, adjust tensions for balanced overlock stitches, align fabric edges with the blade, then feed material steadily while the knife trims.

Why use a serger instead of a sewing machine?

A serger delivers professional edge finishing with overlock stitches that prevent fraying, while trimming fabric as you sew—creating time efficiency and fabric savings that standard sewing machines can’t match.

What are the benefits of using a serger?

You’ll slash your sewing time in half while protecting edges from fraying.

Sergers deliver professional finishes, boost edge durability, and handle stretchy fabrics effortlessly—giving you superior sewing versatility and speed.

When would you use a serger?

You’ll reach for your serger when finishing raw edges on wovens, constructing stretchy activewear, creating rolled hems, or speeding through seam allowances.

Basically, whenever fabric edge finishing and overlock stitch quality matter most.

Can I use a serger for regular sewing?

You can’t fully replace your sewing machine with a serger. While it finishes edges beautifully, a serger lacks buttonholes, topstitching, and zipper precision—so treat it as a powerful partner, not a substitute.

Conclusion

Over 60% of sewists report their serger transformed how they approach garment construction—that’s the confidence you gain when seams stop fraying and knits finally cooperate.

Now that you understand what’s a serger used for, you’re equipped to finish projects with that polished, ready-to-wear quality. Your fabric edges will stay secure through every wear and wash, turning ambitious sewing plans into garments you’ll actually want to keep.