This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

It’s a small, circular spool that holds the bottom thread in your machine, working in tandem with the top thread to create perfect stitches.

You’ll find bobbins tucked away in the machine’s base, ready to supply thread from below.

They come in different materials like plastic, metal, and aluminum, each with unique benefits.

When you’re sewing, the bobbin thread weaves with the top thread underneath the fabric, creating that smooth, professional look you’re after.

Choosing the right bobbin can make or break your stitching game—intrigued to learn more about this thread-spinning wizard?

Table Of Contents

Key Takeaways

- You’ll find bobbins hidden in your sewing machine’s base, holding the bottom thread that works with the top thread to create seamless, professional-looking stitches.

- Not all bobbins are created equal – you’ll need to choose the right type and material (plastic, metal, or aluminum) that’s compatible with your specific sewing machine to ensure optimal performance.

- Regular bobbin maintenance is crucial – you’ll want to inspect your bobbins for damage, clean them carefully, and replace them when they show signs of wear to prevent tension problems and potential machine damage.

- Proper bobbin tension and correct loading are key to achieving smooth stitches – you’ll need to master winding techniques, precise insertion, and subtle tension adjustments to guarantee your sewing projects look professional.

Bobbin Basics Explained

You’ve probably noticed that tiny spool of thread tucked away inside your sewing machine, but do you know how essential it’s to creating perfect stitches.

Your bobbin is the unsung hero of sewing, holding the lower thread that interlocks with the top thread to form seamless, sturdy stitches on every project you create.

The tiny bobbin: your sewing machine’s secret weapon for crafting perfect, seamless stitches with quiet precision.

What is a Sewing Machine Bobbin

In the sphere of sewing, the bobbin is your miniature thread hero, tucked away beneath the machine’s surface.

This tiny spool plays a vital role in creating perfect stitches, holding the underside thread that interlocks with the top thread.

Here’s what every sewist should know about bobbins:

- Understand your bobbin’s unique anatomy

- Recognize different bobbin materials

- Learn various bobbin types

- Master precise bobbin winding

- Choose the right bobbin for your machine to ensure perfect stitches

Purpose of a Bobbin in Sewing

A thread-tensioning marvel, the sewing machine bobbin is your fabric-binding partner in crafting perfect stitches. It strategically holds the underside thread, enabling precise fabric stitching through interlocking threads.

The bobbin’s role is critical in the stitching process, and its functions can be summarized as follows:

| Bobbin Purpose | Thread Role | Stitch Quality |

|---|---|---|

| Underside Thread | Dispensing | Lockstitch Creation |

| Tension Control | Interlocking | Fabric Joining |

| Stitch Support | Seamless Flow | Precise Positioning |

Your bobbin quietly guarantees each stitch’s foundation remains rock-solid, ensuring a high level of stitch quality through interlocking threads.

How Bobbins Work With The Top Thread

Ready to unravel the magic behind stitch formation? Your sewing machine’s bobbin and top thread dance together in perfect harmony, creating seamless seams.

Here’s how they collaborate:

- Bottom bobbin holds lower thread

- Top needle carries upper thread

- Threads interlock in fabric layers

- Lockstitch mechanics create balanced tension

- Precise thread interaction guarantees quality seams

Think of it like a textile tango – two threads moving in sync to craft your perfect project, with a result that showcases perfect harmony.

A harmonious textile tango where threads dance, weaving stories through every seamless stitch.

Types of Bobbins and Their Uses

After threading your top spool, understanding bobbins becomes your secret weapon.

Different machines demand specific bobbin materials – plastic, metal, or aluminum – each with unique characteristics.

Your sewing success hinges on selecting the right bobbins:

- Class 15 bobbins fit most home machines

- L Style works great for precision stitching

- M Class handles heavy-duty quilting projects

Choosing The Right Bobbin

In the context of sewing, choosing the right bobbin can make or break your project’s success, so you’ll want to pay close attention to your machine’s specific requirements.

Understanding the nuances of bobbin sizes, materials, and compatibility will help you avoid frustrating thread tensions and guarantee smooth, professional-looking stitches every time, which is crucial for a successful project.

Common Bobbin Styles and Specifications

You’ve learned what bobbins do—now let’s unpack the bobbin styles that power your sewing machine.

From Class 15’s flat profile to L Style’s versatility, each bobbin brings unique characteristics.

Singer bobbins and European models showcase fascinating variations in size and design.

Your machine’s performance hinges on matching the right bobbin type, so pay attention to those subtle differences.

With options like M Style for larger projects and Class 66 with curved sides, you’ll want to know your machine’s specific bobbin compatibility.

Understanding the importance of even winding and its impact on stitch quality can drastically improve your results, as seen in the discussion on even winding importance, which highlights the need for proper bobbin selection to achieve the best stitch quality.

Less Common Bobbin Styles and Their Specifications

Beyond standard Class 15 and 66 bobbins, specialized styles exist for unique sewing needs.

Style U bobbins power commercial machines, tackling thick fabrics like leather with their robust 1-3/16" diameter.

European and Singer machines often require distinctive bobbin styles, including vertical surface mount options with terminal end designs.

You can find more information about purchasing Style U bobbins.

Your machine’s specific bobbin hook might demand a one-of-a-kind bobbin that guarantees precision stitching.

Factors to Consider When Selecting a Bobbin

Not all bobbins are created equal.

Your sewing machine’s performance hinges on selecting the right bobbin—matching material durability, thread type, and machine compatibility.

Cheap alternatives can cause tension nightmares and unexpected stitching drama.

Consider your machine’s specifications, thread weight, and tension control needs before buying.

Save yourself future headaches by investing wisely in the right bobbin.

Importance of Using The Right Bobbin for Your Machine

Grab the wrong bobbin, and you’ll trigger a sewing nightmare!

Machine compatibility isn’t just a suggestion—it’s a critical lifeline for your project’s success.

Mismatched bobbins can trigger tension problems, compromise stitch quality, and potentially cause long-term damage to your beloved sewing machine.

Always verify your machine’s specific bobbin requirements before diving into any creative endeavor.

Bobbin Composition and Care

You’ll want to choose your sewing machine bobbin carefully, as its material and condition directly impact your stitching quality.

Whether you’re working with metal, plastic, or aluminum bobbins, understanding their unique characteristics and maintaining them properly can make the difference between a smooth sewing experience and a frustrating one.

Metal Bobbin Composition and Care

When you’ve mastered your sewing machine model, metal bobbins become your trusty sidekick.

Crafted from treated steel, these powerhouses bring durability to your crafting table.

Here’s your metal bobbin survival guide:

- Prevent rust with dry storage

- Clean gently with soft cloth

- Inspect for nicks and damage

- Store away from moisture

- Replace when signs of wear appear

Their heavier weight stabilizes stitching in vintage machines, offering a performance edge that plastic just can’t match.

To guarantee longevity, consider specialized bobbin products for superior care.

Proper care guarantees these metal workhorses keep spinning smoothly, stitch after stitch.

Plastic Bobbin Composition and Care

Three key facts make plastic bobbins a sewist’s smart choice: lightweight design, affordable pricing, and surprising durability.

Clean your plastic bobbins regularly to prevent static buildup and thread compatibility issues. Store them in a cool, dry place and inspect for wear before each sewing project.

Consider buying new bobbins for peak performance. Small maintenance steps guarantee your plastic bobbin types perform flawlessly.

Aluminum Bobbin Composition and Care

Like a sleek sports car, aluminum bobbins zip through your sewing projects with lightweight precision.

Their quick-spinning design offers exceptional performance, but handle them carefully.

Prone to scratches, these delicate components demand gentle maintenance. Inspect regularly to prevent damage and guarantee peak bobbin function.

When used correctly, aluminum bobbins can elevate your sewing experience with their unique composition.

Fil-Tec Magna-Glide Cores and Their Benefits

If aluminum bobbins left you spinning, meet the Fil-Tec Magna-Glide cores – your sewing machine’s new best friend.

These magnetic marvels promise seamless stitching with unparalleled precision.

- Eliminates thread tension headaches

- Reduces lint like magic

- Prevents pesky backlash

- Delivers consistent polyester performance

- Maximizes stitches per bobbin

No more constant adjustments or thread drama – just smooth, professional results every single time.

Using the correct bobbin size guarantees even stitches.

Regular Inspection and Maintenance of Bobbins and Bobbin Cases

After exploring Magna-Glide cores, let’s keep your bobbins in top shape.

Regular bobbin case cleaning prevents lint buildup and potential damage. Check for wear weekly, running your fingers gently along the bobbin’s surface.

Lubricate the bobbins monthly to guarantee smooth operation. Always verify thread tension before starting a project.

Store bobbins in a clean, dry place to maintain their precision and performance.

Bobbin Compatibility and Usage Tips

You’ll want to pay close attention to your sewing machine’s bobbins compatibility, as using the wrong type can lead to frustrating stitching disasters.

Always inspect your bobbins and bobbin cases for damage before starting a project, and replace any worn or defective parts immediately to guarantee smooth, professional-looking results.

Interchangeability of Bobbin Styles

Ever wondered why your bobbins won’t swap seamlessly?

Bobbins compatibility isn’t a one-size-fits-all game. Here’s your quick guide:

- Style Matters: Not all Style L and Class 15 bobbins are created equal.

- Material Impact: Metal and plastic bobbins can wreak havoc on machine tension.

- Brand Exclusivity: Stick to manufacturer-recommended bobbin types to prevent potential damage.

Precision is your sewing secret weapon!

Inspecting Bobbins and Bobbin Cases for Damage

Spotting bobbin damage before it wreaks havoc on your sewing project is a sewist’s superpower.

Check your bobbin case for telltale signs like scratches, cracks, or bent edges that can derail smooth stitching.

Shuttle damage often hides in plain sight, waiting to create thread nests or tension nightmares.

Run your fingers gently along the bobbin case, feeling for burrs or uneven surfaces.

When in doubt, pull out a magnifying glass and play detective—your machine’s performance depends on these tiny troublemakers.

Replacing Damaged Bobbins Immediately

Regularly inspect your sewing machine bobbin for damage to prevent unexpected sewing interruptions.

Catching bobbin problems early saves you time and frustration.

- Identify hairline cracks, warps, or bent edges that compromise performance

- Check for uneven thread distribution or unusual bobbin rotation

- Replace damaged bobbins immediately to maintain smooth stitching quality

Don’t let a compromised bobbin derail your creative project – swift action is your sewing machine’s best defense.

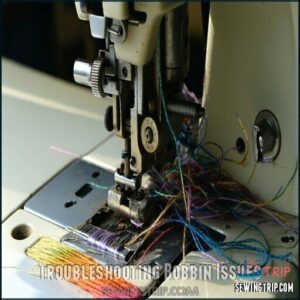

Troubleshooting Bobbin Issues

When your sewing project starts unraveling faster than your patience, it’s time to tackle those pesky bobbin problems head-on.

Understanding common thread issues and learning quick fixes will transform you from a frustrated sewist into a confident machine troubleshooter who can solve bobbin challenges in seconds.

Thread Problems and How to Fix Them

Thread problems can sabotage your sewing project faster than a dull needle! When your bobbin thread misbehaves, it’s time for some machine detective work.

Skipped stitches and bunched-up threads usually signal tension troubles. Start by checking your bobbin tension – a quarter-turn counterclockwise might solve most issues.

Bobbin tension too tight

Skipped stitches

A quick machine tune-up can get you back to smooth sailing in no time!

Bobbin Looping and How to Prevent It

When stitches start looping, your bobbin tension might be the sneaky culprit.

Gently tighten the top thread tension, keeping an eye on your needle and fabric weight.

A well-maintained sewing machine prevents these pesky bobbin problems.

Pro tip: balance thread tension like a tightrope walker – precise adjustments make all the difference in creating smooth, professional-looking seams.

Thread Snapping and How to Avoid It

When thread snaps mid-seam, your sewing machine whispers its frustration.

Mastering thread snapping prevention requires understanding bobbins tension, needle size, and thread quality.

Verify even bobbin winding, use sharp needles matched to your fabric, and select high-quality thread.

Regular machine maintenance prevents unexpected thread breakage and keeps your creative flow smooth and uninterrupted, ensuring a seamless sewing experience with proper maintenance.

Incorrectly Loaded Bobbins and How to Fix Them

After battling thread snags, you’ll want to master bobbin loading precision. Bobbin loading errors can transform your sewing project into a tangled nightmare. Your machine demands careful attention to detail.

- Check bobbin placement for secure seating

- Inspect tension screws on the bobbin case

- Clear out lint buildup for smooth operation

- Verify thread path before starting your project

Proper bobbin insertion means gently nestling it into the case, ensuring the thread winds smoothly. Watch for subtle signs of misalignment—a wiggling bobbin case or uneven stitches can signal trouble.

Addressing bobbin thread tension problems can also prevent these issues. Clean the shuttle area regularly, and you’ll prevent most sewing machine meltdowns. Small adjustments make big differences in your crafting journey.

Using a Bobbin Effectively

You’ll want to master your sewing machine’s bobbin to create flawless stitches every time.

By understanding how to wind, insert, and adjust your bobbin’s tension, you’ll guarantee smooth, professional-looking results that’ll make your sewing projects shine.

Tips for Winding a Bobbin Correctly

When stuck threads threaten your sewing project, mastering bobbin winding becomes your secret weapon.

Wind your thread clockwise using full speed, maintaining consistent tension settings. Follow your thread guide carefully, creating even layers without overfilling.

Pro tip: slow down if the bobbin looks lumpy, and always check your machine’s specific bobbin winding techniques for smooth, professional results every time, using full speed.

How to Insert a Bobbin Into Your Sewing Machine

Like a puzzle piece sliding into place, your sewing machine bobbin demands precision and care during insertion.

Before loading, always turn off your machine for safety.

Essential bobbin insertion tips:

- Identify your machine’s loading style (top or front)

- Follow the correct threading path carefully

- Clean the bobbin case before inserting

Top-loading machines require dropping the bobbin with thread unwinding counterclockwise. For front-loaders, make certain the metal extension points upward. Gently push the bobbin case until it clicks securely, maintaining a smooth, gentle motion.

Always turn the handwheel toward you to prevent potential jams and guarantee proper bobbin placement. Your attention to detail here guarantees seamless sewing performance.

Adjusting Bobbin Tension for Smooth Stitching

The bobbin tension symphony demands precision. Your sewing machine’s smooth performance hinges on masterful tension adjustments.

Here’s your roadmap to perfection:

- Fine-tune the bobbin case screw with microscopic movements

- Test stitches after each slight adjustment, watching thread behavior

- Detect telltale tension symptoms like thread looping or unexpected resistance

Incorrect thread placement is a common problem. When bobbin thread tension sings just right, your stitches will dance across fabric with professional grace, and the result is a testament to the importance of masterful adjustments and smooth performance.

Common Mistakes to Avoid When Using a Bobbin

Seven out of ten sewists stumble with bobbin problems, but you can dodge these pitfalls.

Tension problems often stem from incorrect threading or uneven winding.

Verify your sewing machine bobbin is compatible, undamaged, and precisely inserted.

Check thread tension, wind carefully, and follow your machine’s manual to prevent frustrating bobbin thread disruptions that can derail your creative projects.

Frequently Asked Questions (FAQs)

Do you need a bobbin for a sewing machine?

Imagine a thread highway without a pit stop—that’s a sewing machine without a bobbins.

You absolutely need a bobbin to create complete, interlocking stitches.

It’s the unsung hero holding your fabric’s bottom thread, ensuring your project looks professional.

What is the purpose of a bobbin on a sewing machine?

You’ll need a bobbin to create the bottom thread in your sewing machine.

It works with the top thread to form interlocking stitches, ensuring your fabric stays securely sewn together without unraveling.

Where is the bobbin on a sewing machine?

Like a hidden dance partner beneath the fabric, you’ll find the bobbin nestled in a special compartment under your sewing machine’s needle plate.

It’s typically accessed by opening a small door or removing a cover on the machine’s base.

What is the difference between a bobbin and a spool?

You’ll find a bobbin nestled inside your machine, holding lower thread, while a spool sits on top with upper thread.

They’re different: bobbins are smaller, rotate inside the machine, and provide the bottom thread for stitching.

How does a bobbin affect stitch quality?

Like a conductor guiding an orchestra, your bobbin’s tension and placement directly impact stitch quality.

Proper threading, clean bobbin case, and correct tension guarantee smooth, even stitches that’ll make your sewing projects appear professionally crafted, with proper threading being key to achieving this.

What are signs my bobbin needs replacing?

You’ll know your bobbin needs replacing when threads tangle frequently, stitches look uneven, or the bobbin looks worn.

Check for fraying edges, inconsistent tension, and difficulty winding thread smoothly during your sewing projects.

How do I store spare bobbins properly?

82% of sewists struggle with tangled bobbins.

Store your spares in a sealed, labeled container, keeping them dust-free and organized.

Color-code or use clear compartments to easily identify thread types and prevent moisture damage.

Can bobbins impact sewing machine noise?

Misaligned or worn bobbins create friction and vibration, leading to increased sewing machine noise.

Check your bobbin’s condition, verify proper installation, and replace damaged ones to minimize unwanted sounds during stitching.

Are pre-wound bobbins worth using?

Pre-wound bobbins: your time-saving sidekick or sneaky saboteur?

They’ll zip through projects faster, but watch out for tension quirks.

Quality matters more than convenience, so choose wisely and test before committing to a bulk purchase, considering the importance of quality.

How long do bobbins typically last?

Your bobbins can last years if you’re gentle.

Clean them regularly, avoid dropping, and replace when worn or damaged.

Quality matters—metal usually outlasts plastic.

With proper care, one bobbin might serve you through hundreds of sewing projects.

Conclusion

Ultimately, mastering what’s a sewing machine bobbin transforms your crafting experience.

You’ll discover that this tiny thread carrier is more than just a machine component—it’s your secret weapon for professional-looking stitches.

By understanding bobbin types, maintenance, and compatibility, you’ll elevate your sewing skills.

Don’t underestimate this small but mighty hero; invest time in learning its nuances, and watch your projects shine with precision and finesse.

- https://www.allfreesewing.com/Basics-and-Tutorials/What-Does-a-Bobbin-Do

- https://aspenleitervacuum.com/sewing-machine-bobbins/

- https://love-sew.com/blogs/blog/how-does-a-sewing-machine-work

- https://www.reddit.com/r/sewing/comments/cakbwo/question_why_do_sewing_machines_need_a_bobbin/

- https://undergroundcrafter.com/2020/07/19/sewing-basics-all-about-bobbins/