This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Got stretchy or delicate fabrics? A Ballpoint needle is your best bet. Stitching elastic materials? Use a Stretch needle to avoid skipped stitches.

For precision on delicate fabrics, Sharps needles are perfect, while Quilting needles are reinforced for multilayered fabrics.

Want more tips? Stick around!

Table Of Contents

- Key Takeaways

- What Sewing Machine Needle Should I Use?

- Types of Sewing Machine Needles

- Needle Sizes Explained

- Choosing the Right Needle for Your Fabric

- Needle Maintenance Tips

- Needle Fitting and Installation

- Understanding Needle Anatomy

- Troubleshooting Needle Problems

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Choosing the right needle is like choosing the right tool for the job – it makes all the difference!

- Remember, a sharp needle is a happy needle. Replace it regularly to avoid skipped stitches and fabric damage.

- Don’t be afraid to experiment with different needle types – you’ll be surprised at the results!

- With the right needle, your sewing projects will be the envy of the town!

What Sewing Machine Needle Should I Use?

When deciding what sewing machine needle you should use, match the needle type to your fabric. For example, use a universal needle for woven fabrics and a Ballpoint needle for knits.

Types of Sewing Machine Needles

Choosing the right sewing machine needle can make a significant difference in your sewing projects. From universal needles suitable for various fabrics to specialized ballpoint and stretch needles for knits, selecting the correct type guarantees smooth stitching and prevents damage to your fabric.

Universal Needles

Universal needles are your go-to workhorses in the sewing world. They’re designed to handle a wide range of fabrics and thread thicknesses, making them incredibly versatile.

You’ll find they work well with most machines and produce quality stitches on various materials.

However, keep in mind that while they’re great all-rounders, they might not be the best choice for very delicate or stretchy fabrics.

Ballpoint Needles

Ballpoint needles are your go-to for stretchy and delicate fabrics. Unlike their sharp counterparts, these needles have a rounded tip that glides between fabric fibers without snagging. They’re perfect for knitted fabrics and stretchy knits.

When choosing a ballpoint needle, consider both fabric type and weight. Remember, the right Needle size can make or break your project, so don’t neglect this important detail!

Stretch Needles

When sewing stretch fabrics, you’ll want to reach for stretch needles. These specialized sewing machine needles are designed to tackle elastic materials without skipping stitches or damaging the fabric. They’re perfect for both thick and thin stretchy fabrics, offering durability and precision. Here’s what you need to know about stretch needles:

- Scarf shape reduces skipped stitches

- Medium ball point prevents fabric damage

- Ideal for lycra, spandex, and swimwear

- More flexible than regular needles

- Available in various sizes for different fabric weights

Sharps Needles

Sharps needles are your go-to for precision work. With their extra-fine points and slender blades, they’re perfect for densely woven fabrics and delicate materials. You’ll love how they glide through silk, microfiber, and even leather without leaving visible holes.

Remember to match your thread type to these needles for the best results. Don’t forget to replace them regularly to maintain that razor-sharp edge and prevent fabric damage.

Quilting Needles

In the realm of quilting, you’ll desire to elevate from sharps to specialized quilting needles. These needles are reinforced to handle multiple layers of fabric with ease.

They’re your go-to for advanced quilting projects, offering superior needle penetration and decorative stitching capabilities. Don’t confuse them with microtex needles, though!

Quilting needles come in various sizes and even colors, perfect for different thread types and topstitching needs.

Needle Sizes Explained

Understanding sewing machine needle sizes is essential for achieving perfect stitches. You’ll encounter two sizing systems – European (60-110) and American (8-18) – with the common size for dressmaking being 80/12, and you’ll need to choose the right size based on your fabric type.

European Vs. American Sizing

You’ll encounter two sizing systems for sewing machine needles: European and American. European sizes range from 60 to 110, while American sizes go from 8 to 18.

Don’t worry; they’re easily convertible! For example, a European 90 is equivalent to an American 14. This sizing applies to all needle types, including denim and leather needles.

Proper needle storage helps maintain their sharpness.

Common Sizes for Dressmaking

Now that you’re familiar with sizing systems, let’s talk about common dressmaking needles.

You’ll often find size 80/12 needles in your sewing kit. These versatile needles work well with a variety of fabrics and threads.

When considering what sewing machine needle you should use, remember that needle materials and compatibility play a key role.

Don’t forget about proper needle storage, cleaning, and occasional sharpening to maintain their performance.

Size Recommendations for Different Fabrics

When choosing needle sizes, remember: lighter fabrics need smaller needles, while heavier ones require larger sizes. For delicate silks, try a 60/8 needle. Cottons and linens work well with 70/10 or 80/12. Denim? Go for 100/16 or 110/18. Consider needle sharpness and durability for different materials. Don’t forget compatibility with your machine! Proper needle storage ensures they’re always ready when you need them.

Choosing the Right Needle for Your Fabric

Selecting the appropriate needle for your fabric is paramount in obtaining impeccable stitches. You’ll need to assess the caliber and nature of the fabric you’re working with, as various needles are crafted for specific materials such as fabrics of moderate weight, knits, elastic knits, and densely woven fabrics.

Medium-weight Fabrics

For medium-weight fabrics, you’ll want to strike a balance between needle durability and fabric compatibility. Universal needles are your go-to choice, typically in sizes 80/12 or 90/14. These workhorses handle a variety of materials without breaking the bank.

Store them properly to maintain sharpness, as needle cost can add up. While sharpening isn’t recommended, replacing them regularly guarantees peak performance.

You’ll find these needles readily available at most sewing supply stores.

Knit Fabrics

When working with knit fabrics, you’ll want to use a ballpoint needle. Its rounded tip slides between the fibers, preventing snags and runs.

Choose the right needle shape to match your fabric’s stretch level. Adjust your tension settings for satisfactory stitch quality, and don’t forget to pair it with suitable thread.

With these tips, you’ll be conquering knits like a pro in no time!

Elastic Knits

When working with elastic knits, you’ll need a special touch. Stretch needles are your best bet, as they’re designed to navigate these tricky fabrics. Here’s what you should keep in mind:

- Choose the right needle gauge for your fabric weight

- Consider using twin needles for decorative stitching

- Verify compatibility between your machine and your chosen needle

- Store needles properly to maintain their sharpness

Densely Woven Fabrics

When tackling densely woven fabrics, you’ll need a needle that’s up to the task. These fabrics require sharper, stronger needles to guarantee smooth fabric penetration and prevent thread shredding. Here’s a quick guide to help you choose:

| Fabric Type | Recommended Needle | Size | Thread Type | Stitch Length |

|---|---|---|---|---|

| Denim | Jeans/Denim | 100/16 | Heavy-duty | 3.0-4.0 mm |

| Canvas | Microtex | 90/14 | All-purpose | 2.5-3.5 mm |

| Corduroy | Sharp | 80/12 | All-purpose | 2.0-3.0 mm |

| Twill | Universal | 90/14 | All-purpose | 2.5-3.5 mm |

| Gabardine | Sharp | 80/12 | All-purpose | 2.0-3.0 mm |

Needle Maintenance Tips

Proper needle maintenance is essential for achieving high-quality stitches and prolonging the life of your sewing machine. You should replace your needle after each project or about every 6-8 hours of sewing, and always inspect it for signs of damage or wear, such as bent points or unusual thumping sounds during use.

When to Replace Needles

Now that you’ve chosen the right needle for your fabric, let’s talk about when to swap it out. Needle wear is inevitable, so replace your needle after every project or 6-8 hours of sewing.

Don’t try needle sharpening; it’s not worth the hassle. Instead, focus on proper needle disposal and cleaning.

Inspecting for Damage

Regularly inspect your needle for damage to ensure excellent stitching. Store needles properly to prevent bending and rust.

If you spot rust, gently remove it with fine-grit sandpaper. While you can’t sharpen needles at home, proper lubrication techniques can prolong their life.

After machine jams, always check for bending.

Signs of a Worn Needle

After assessing damage, it’s essential to recognize signs of a worn needle.

Listen for unusual thumping sounds during sewing – that’s your cue to check needle sharpness. If you’re experiencing frequent thread breakage or skipped stitches, your needle might be bent or dull.

Your fabric will thank you!

Needle Fitting and Installation

When fitting a new needle, make certain it’s oriented correctly with the flat side facing the back of the machine and push it up as far as possible before tightening the screw. To prevent the needle from dropping into the machine during installation, place a small piece of paper under the presser foot for added safety.

Proper Orientation

Regarding needle orientation, accuracy is paramount. The needle’s flat shank should face the machine’s rear. Like a puzzle piece, if it doesn’t fit smoothly, avoid forcing it. Correct needle placement is essential for optimal stitching and machine longevity. Proper alignment prevents errors and maintains sewing efficiency.

Ensuring Secure Fit

Once you’ve oriented your needle correctly, it’s imperative to establish a secure fit. Advance the needle as far as possible before tightening the screw. This prevents wobbling and potential breakage. Consider these tips for needle management**:

- Store needles in a magnetized case, keeping them organized and easy to access

- Dispose of dull needles in a designated sharps container

- Keep a needle sizing chart handy for quick reference

Using Paper Under the Foot

Once you’ve verified your needle’s secure, it’s time to tackle a common issue: thread jamming during needle insertion.

Here’s a pro tip: place a small piece of paper under the presser foot before lowering it. This simple trick prevents the thread from getting caught, reducing fabric puckering and skipped stitches.

It’s a game-changer for maintaining proper tension and achieving flawless stitching every time.

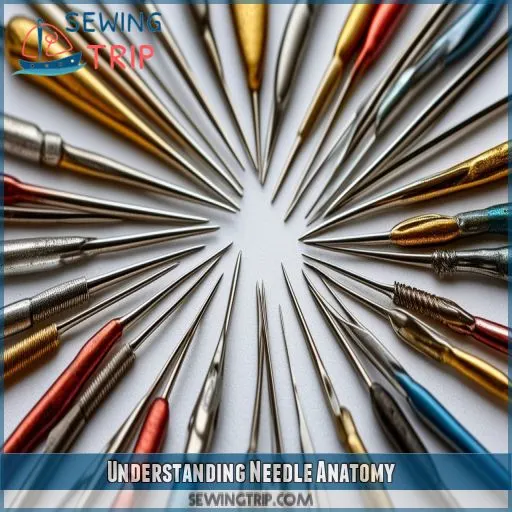

Understanding Needle Anatomy

To choose the right sewing machine needle, you’ll need to understand its key parts: the eye, shaft, shank, point, and scarf. Each component plays an essential role in how the needle functions, affecting your stitching quality and the types of fabrics you can work with effectively.

Eye

The eye of a sewing machine needle is critical for smooth threading and stitch formation. Eye shape and size are designed to accommodate various thread types. Eye material and design guarantee durability, while eye reinforcement prevents thread fraying. A well-designed needle eye can improve sewing precision and reduce thread breakage, enhancing your overall sewing experience.

Shaft

The shaft of your sewing machine needle is essential for smooth stitching. It’s the part that determines needle thickness and durability. Here’s what you need to know:

- Thicker shafts are ideal for heavier fabrics, while thinner ones suit delicate materials.

- Some shafts have special coatings to enhance needle lubricity, reducing friction.

- The shaft’s shape can vary, impacting how it penetrates different fabrics.

Choose wisely, and you’ll be on your way to perfect stitches!

Shank

Moving from the shaft, let’s examine the shank. It’s the top part of the needle that fits into your machine.

You’ll notice a flat side on the shank – this is essential for proper orientation. When inserting the needle, align this flat side correctly.

Shank thickness and length vary, so verify compatibility with your machine.

Proper shank alignment is key to avoiding errors and achieving perfect stitches.

Point

The point of a needle varies in shape, essential for different fabrics.

- Sharp points: Ideal for woven fabrics, ensuring clean penetration.

- Ball points: Perfect for knits, preventing fabric snags.

- Fine points: Best for delicate materials, maintaining fabric integrity.

- Industrial points: For heavy-duty tasks, balancing needle durability and performance.

Scarf

The scarf of a sewing machine needle is more than just a fancy term. It’s the indentation above the eye that allows the hook to grab the thread and form a stitch. Understanding this part of the needle’s anatomy can help you master your machine and achieve perfect stitches. Here’s a quick guide to needle features:

| Feature | Function | Importance |

|---|---|---|

| Scarf | Thread capture | Essential for stitch formation |

| Shape | Fabric penetration | Affects needle performance |

| Eye | Thread passage | Important for smooth sewing |

| Point | Initial fabric entry | Determines stitch quality |

| Shank | Machine attachment | Guarantees proper needle fit |

Troubleshooting Needle Problems

When you’re experiencing needle problems, it’s imperative to identify the specific issue you’re facing. Common problems include fabric being pushed into the throat plate, needle breakage, and fabric bunching behind the presser foot, each requiring a different troubleshooting approach.

Fabric Pushed Into Throat Plate

Now that you understand needle anatomy, let’s tackle a common issue: fabric getting pushed into the throat plate.

This frustrating problem often stems from using an incorrect needle or mismatched thread tension.

To prevent it, always choose the right needle for your fabric type and size. Adjust your thread tension carefully, and make sure your throat plate is clean and free from debris.

You’ll be stitching smoothly in no time!

Needle Breakage

Needle breakage usually indicates issues like incorrect needle type, needle sharpness, or needle angle. Prevent this by:

- Matching the needle to fabric correctly.

- Replacing needles showing dullness.

- Checking for bending after machine jams.

- Ensuring proper needle lubrication for smoother operation.

Taking these steps reduces breakage and ensures smoother stitching.

Fabric Bunching

Fabric bunching can be a headache, but it’s fixable. Check your needle angle and needle tension—these often cause problems. Make sure your needle thread is correctly threaded. Also, verify the needle guide is positioned correctly. Minimizing needle vibration can also help, ensuring smoother stitching. Swapping needles might solve the issue, especially if they’re old or bent.

Frequently Asked Questions (FAQs)

How do I know which sewing machine needle to use?

Think of selecting a needle like choosing shoes for a hike. For heavy-duty fabrics like denim, use a Denim needle, but for delicate, stretchy fabrics, opt for a Stretch needle to avoid mishaps.

What is a 90 14 needle used for?

A 90/14 sewing machine needle is perfect for medium to heavy-weight fabrics like denim, corduroy, and canvas. It handles thicker threads effortlessly, ensuring smooth, even stitches without breaking or bending. Keep sewing efficiently!

What is the 80 12 needle used for?

Think of the 80/12 needle as your Swiss Army knife in sewing. It’s perfect for medium-weight fabrics like cotton and polyester, giving you smooth, precise stitches without the hassle. Ideal for dressmaking and general sewing tasks.

What is a 70 9 sewing needle used for?

A 70/9 sewing needle is perfect for lightweight fabrics like silk, organza, and sheer materials. It’s delicate enough to prevent fabric damage, ensuring smooth stitching without bunching or snagging. Use it for fine, delicate projects.

What size are sewing machine needles?

Imagine sewing delicate silk fabric only to have it tear. Sewing machine needles range in size from 60 (for sheer fabrics) to 110 (for thick fabrics like denim). Choose the right size to match your fabric.

What are the different types of sewing machine needles?

Use different sewing machine needles for specific tasks: universal for general sewing, ballpoint for knits, stretch for elastic fabrics, sharps for quilting, and microtex for precision. Choose the right type for best results.

What are the best sewing machine needles?

For the best sewing machine needles, go for Schmetz. They offer exceptional durability and a wide variety suitable for all fabrics. Universal needles cover most needs, while specialty needles like ballpoint and stretch add versatility.

How do I choose a sewing machine needle?

Choose your needle based on fabric type: Universal for general use, Ballpoint for knits, Stretch for high elasticity, Sharps for dense fabrics. Match needle size to fabric weight; lighter fabrics need smaller needles.

What does a sewing machine needle do?

A sewing machine needle is like a pen’s nib; it carries the thread, pierces the fabric, and forms stitches, ensuring your designs come to life smoothly and accurately with the right tension and precision.

Can you use a universal sewing machine needle?

Yes, you can use a universal sewing machine needle. It’s suitable for various fabrics like cotton, polyester, and blends. Just make sure it matches the weight of your fabric for best performance and stitch quality.

Are sewing machine needles color-coded?

Yes, sewing machine needles are color-coded by some brands. Schemtz color-codes the needles’ shafts, indicating types like universal (no color), stretch (yellow), and embroidery (red). This simplifies selecting the right needle for your project.

Can I use vintage machine needles?

Yes, but make sure vintage needles fit smoothly in your machine and check for wear or damage. Modern needles often provide improved performance and durability, so consider these for best sewing results.

Do sewing machine needle brands matter?

Absolutely, needle brands make a difference. Choosing a reputable brand like Schmetz instead of generic ones guarantees less breakage, improved performance, and longer-lasting needles. Don’t compromise on quality; it’s worthwhile to avoid the inevitable sewing headaches.

What’s the best needle for metallic thread?

You should use a metallic needle for metallic thread. Its larger eye prevents shredding and breakage, ensuring smooth sewing. Look for sizes ranging from 80/12 to 90/14 for best results.

How to store unused sewing machine needles?

Treat your sewing machine needles like gold. Store them in labeled containers or organize them in a pin cushion, using compartments to separate types and sizes. This keeps them pristine and simplifies needle selection for future projects.

Conclusion

Don’t let uncertainty about needle types hinder you.

By understanding which sewing machine needle you should utilize, your projects won’t only appear more polished but also endure longer.

Remember to align your needle with your fabric and replace it frequently to prevent skipped stitches and fabric damage.

With the appropriate needle, you’ll achieve accurate stitching, seamless seams, and long-lasting outcomes.

Embark on your next project with assurance and the right needle as your companion.