This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

With walking foot technology and reinforced frames, they transform impossible canvas projects into weekend victories. Whether you’re crafting marine sails or heavy-duty bags, the right machine becomes your workshop’s secret weapon.

So what makes one canvas machine worth your money while another collects dust? Let’s dive into eight machines that actually deliver.

Table Of Contents

- Key Takeaways

- Best Heavy Duty Sewing Machines for Canvas

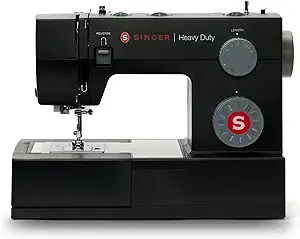

- 1. SINGER Heavy Duty Sewing Machine Kit

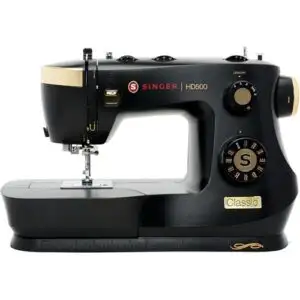

- 2. SINGER Heavy Duty Sewing Machine Classic

- 3. Heavy Duty Portable Leather Sewing Machine

- 4. Heavy Duty Bag Sewing Machine

- 5. Guoydir Heavy Duty Portable Sewing Machine

- 6. SINGER 4432 Heavy Duty Sewing Machine

- 7. SINGER Heavy Duty Sewing Machine 4432

- 8. Industrial Leather Sewing Machine Heavy Duty

- Key Features for Canvas Sewing Machines

- Industrial Vs. Domestic Models Compared

- Applications: Marine, Upholstery, and More

- How to Choose The Right Machine for Canvas

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Motor power matters most – Look for machines with 60% more strength than standard models and speeds of 1,100-3,000 stitches per minute to handle thick canvas layers without stalling or skipping stitches.

- Walking foot technology prevents fabric bunching – This mechanism grips both fabric layers simultaneously, ensuring even feeding through multiple canvas layers and eliminating the puckering that ruins heavy-duty projects.

- Frame construction determines longevity – Metal frames (cast iron or steel) provide stability and vibration dampening that plastic components can’t match, especially during high-speed operation on demanding materials.

- Industrial models outperform domestic machines for serious work – While domestic heavy-duty machines cost $200-$500, industrial units ($2,500+) deliver 2,000-5,000 stitches per minute with continuous operation capability and 25+ year lifespans.

Best Heavy Duty Sewing Machines for Canvas

Canvas work doesn’t have to be a wrestling match with your sewing machine. The right heavy duty sewing machine makes all the difference between frustrated attempts and clean, professional results.

These eight models pack the punch you need for marine canvas repairs, heavy upholstery work, and everything in between.

1. SINGER Heavy Duty Sewing Machine Kit

Why settle for basic when you can discover canvas mastery? The SINGER Heavy Duty Sewing Machine Kit delivers impressive accessory value with bonus tools worth up to $120, including specialized presser feet for canvas projects.

This beginner-friendly powerhouse works with multiple fabric layers at 1,300 stitches per minute, thanks to its metal frame construction. User feedback consistently highlights its kit versatility for heavy-duty sewing applications.

The walking foot mechanism prevents fabric slippage during canvas sewing, making it ideal for outdoor gear and marine projects.

Best For: DIY enthusiasts and beginners who need a reliable machine for canvas, denim, and multi-layer fabric projects without breaking the bank.

- Powerful motor handles thick materials like canvas and denim at up to 1,300 stitches per minute

- Includes $120 worth of bonus accessories including walking foot for even fabric feeding

- Metal frame construction provides stability and durability for heavy-duty projects

- Can be too fast and loud for some users, especially beginners

- Upright spool pin design causes thread to wrap and jam frequently

- Speed control is sensitive and tends to accelerate quickly from a stop

2. SINGER Heavy Duty Sewing Machine Classic

Looking for serious Motor Power? The SINGER Heavy Duty Classic delivers 60% more strength than standard models, pushing through thick canvas at 1,100 stitches per minute.

Frame Durability comes from its full metal construction—this machine won’t wobble during demanding projects.

You get 32 built-in stitches with adjustable settings to handle different projects. The machine comes with a solid 25-year warranty on the head.

Market Performance shows consistent demand among canvas professionals who need reliable Canvas sewing capability.

Best For: Home sewers and small business owners who need to work with heavy fabrics like denim, canvas, and upholstery materials regularly.

- Powerful motor with 60% more strength than standard machines handles thick fabrics at 1,100 stitches per minute

- Full metal frame construction provides excellent stability and reduces vibration during heavy-duty projects

- 25-year limited warranty on the machine head shows manufacturer confidence in long-term durability

- Mostly plastic construction in non-frame components may feel less premium than expected

- Limited instructions included with machine, requiring manual download for complete guidance

- No embroidery or advanced decorative features for users wanting more creative options

3. Heavy Duty Portable Leather Sewing Machine

These portable leather machines pack serious punch where regular sewing machines just can’t cut it. You get servo motor perks like dial-in speed control and extra torque for tough DIY leather work.

The walking foot design tackles thick stuff—we’re talking up to 16-ounce leather.

Heavy duty industrial sewing machines in this category feature cast-iron construction, guaranteeing portable model durability. Market growth drivers include expanding leather goods demand.

Industrial sewing machines with heavy duty leather sewing machine capabilities accommodate diverse leather stitching techniques for professional and hobbyist applications requiring heavy duty sewing applications.

Best For: Leatherworkers, upholstery professionals, and serious hobbyists who need industrial-strength stitching power in a portable package for thick materials like leather, canvas, and vinyl.

- High-speed 1,800 stitches per minute with servo motor control for efficient, precise work

- Handles heavy materials up to 16 oz leather with walking foot mechanism and adjustable thread spacing

- Portable 6.3lb design with cast-iron construction provides durability without sacrificing mobility

- Limited to specific heavy-duty materials and may require frequent thread spacing adjustments

- No warranty information or customer support details provided for long-term reliability

- Manual and automatic modes could lead to user error without proper training or experience

4. Heavy Duty Bag Sewing Machine

The WOUDY heavy duty bag sewing machine transforms raw canvas into professional-grade products with its 210W all-copper motor. You’ll achieve 1,500–1,700 stitches per minute while handling bag material thickness up to 18mm through multiple layers. This red powerhouse features stitching speed control and automatic wire cutting for fluid automation integration. The 110V motor energy efficiency keeps operating costs low during high-volume runs.

Canvas sewing applications include tarps, shopping bags, and industrial sacks.

These machines tap into growing demand in packaging and manufacturing. They’re built specifically for tough jobs that require threading through thick, stubborn materials without missing a beat.

Best For: Small businesses, workshops, and DIY enthusiasts who need to sew heavy-duty materials like canvas, denim, and industrial bags efficiently.

- High-speed stitching at 1,500-1,700 stitches per minute with powerful 210W all-copper motor for professional results

- Handles thick materials up to 18mm with adjustable needle pitch and automatic wire cutting for smooth operation

- Portable design with ergonomic textured handle makes it easy to use in small workshops or home settings

- Heavy weight makes frequent transportation difficult and limits mobility during use

- Steep learning curve for beginners unfamiliar with industrial-grade sewing equipment

- Higher price point compared to standard home sewing machines may not fit all budgets

5. Guoydir Heavy Duty Portable Sewing Machine

When portability meets industrial performance, the Guoydir Heavy Duty Portable Sewing Machine delivers outstanding value for canvas projects. This lightweight 6.6-pound unit operates at 1800-2000 stitches per minute, handling up to fourteen layers of material with consistent stitch quality.

Perfect for marine canvas repairs and heavy-duty bag construction, it offers excellent material compatibility across burlap, leather, and synthetic fabrics. The cost efficiency of this industrial sewing machine makes professional-grade canvas sewing accessible, earning high user satisfaction ratings for both field repairs and workshop applications.

Best For: Industrial professionals, marine canvas workers, and DIY enthusiasts who need portable heavy-duty stitching for thick materials like canvas, burlap, and leather bags.

- Powerful 1800-2000 stitches per minute with ability to handle up to 14 layers of material

- Lightweight at 6.6 pounds making it highly portable for field work and mobile repairs

- Excellent value at $99-140 compared to traditional industrial machines costing much more

- Not suitable for household sewing or precision work requiring neat, detailed stitching

- Can be uncomfortable to hold for extended periods despite being relatively lightweight

- Has a learning curve for beginners and may require tension adjustments for different materials

6. SINGER 4432 Heavy Duty Sewing Machine

With its motor strength rated 60% stronger than standard machines, the SINGER 4432 handles canvas projects at up to 1,100 stitches per minute. You get 32 built-in stitches plus 110 stitch applications for adaptable canvas work.

The heavy-duty metal frame ensures durability and stability during demanding projects. Included accessories cover basic needs like an all-purpose foot and buttonhole foot.

User ratings average 4.5 stars across 90+ reviews, making this SINGER heavy-duty sewing machine a reliable choice for serious canvas sewing.

Best For: Sewers who work with heavy fabrics like canvas, denim, and upholstery and need a reliable machine that can handle demanding projects at high speeds.

- Motor is 60% stronger than standard machines with speeds up to 1,100 stitches per minute

- Heavy-duty metal frame provides excellent stability when sewing through multiple layers

- 32 built-in stitches plus 110 applications give you plenty of options for different techniques

- Some users report bobbin case alignment issues requiring frequent adjustments

- Foot pedal can be overly sensitive making precision work challenging

- Doesn’t include a physical manual, only available online

7. SINGER Heavy Duty Sewing Machine 4432

Within the SINGER Heavy Duty sewing machine models lineup, the 4432 stands out for serious canvas work. Motor Power drives through multiple fabric layers at 1,100 stitches per minute with 60% more piercing strength than standard machines.

Frame Durability comes from the all-metal internal construction and stainless steel bed plate that won’t flex under pressure.

Stitch Options include 32 built-in patterns with adjustable length and width settings. Canvas Handling improves through adjustable presser foot pressure and extra-high lift clearance.

User Reliability shows 85% satisfaction rates across heavy fabric applications.

Best For: Sewers who need a reliable workhorse for heavy fabrics like canvas, denim, and upholstery projects without breaking the bank.

- Powerful motor handles thick materials at 1,100 stitches per minute with 60% more piercing power than standard machines

- All-metal frame construction and stainless steel bed plate provide excellent stability and durability for long-term use

- 32 built-in stitches with adjustable settings plus features like one-step buttonhole and reverse stitching offer versatility

- Some users report build quality issues including needle breakage and bobbin feed problems during operation

- Speed control can be inconsistent with sudden increases that make precision work challenging

- Machine runs loud and may struggle with certain fabric types despite being marketed as heavy-duty

8. Industrial Leather Sewing Machine Heavy Duty

The Industrial Leather Sewing Machine Heavy Duty represents the height of leatherworking equipment. These machines deliver impressive motor power up to 550 watts and stitch speeds reaching 3,300 stitches per minute. You’ll handle leather thicknesses up to 7/16 inches with ease.

Industrial sewing machines require maintenance every 8 hours but offer a lifespan expectancy exceeding 25 years. Heavy-duty leather sewing machine models feature walking foot mechanisms and reinforced frames.

This industrial sewing machine investment ranges from $500 to $2,000 for serious heavy-duty sewing machine applications.

Best For: Professional leatherworkers, upholstery shops, and manufacturers who need to sew thick materials like leather, canvas, and heavy fabrics at high speeds with industrial reliability.

- Exceptional power and speed with up to 550 watts and 3,300 stitches per minute for professional productivity

- Handles extremely thick materials up to 7/16 inches with walking foot mechanism for even feeding

- Built for longevity with 25 year lifespan and robust cast metal construction that minimizes vibration

- Heavy weight (60-82 lbs) and large size make these machines stationary and require dedicated workspace

- High upfront investment cost ranging from $500-$2,000 compared to domestic sewing machines

- Requires frequent maintenance every 8 hours of operation and specialized knowledge for repairs

Key Features for Canvas Sewing Machines

Working with canvas isn’t like sewing cotton sheets. You need a machine that won’t quit when faced with thick, layered materials that fight back at every stitch.

The magic happens when you combine a walking foot (which grips both fabric layers), extended stitch options for reinforcement, and a motor that doesn’t bog down under pressure. Get these three things right, and those intimidating canvas projects become totally doable.

The right combination of walking foot technology, reinforced stitching, and unstoppable motor power transforms impossible canvas projects into weekend victories

Walking Foot Mechanism and Large Bobbin

When canvas fights back against your needle, the walking foot becomes your secret weapon for taming thick, stubborn fabrics that would otherwise bunch and pucker. This mechanism provides enhanced material feed control by gripping both fabric layers simultaneously.

Large bobbins reduce thread changes during Heavy Duty Canvas Sewing Machine operations, while the Walking Foot Leather Industrial Sewing Machine design ensures stitch consistency across multiple canvas layers for Marine Canvas Sewing Machines applications.

Stitch Length and Presser Foot Lift

Think of stitch length and presser foot lift as the precision controls that separate amateur work from professional-grade canvas construction. Preferred stitch length ranges from 4-9mm for heavy-duty canvas sewing machines, while lift height adjustment accommodates varying fabric thickness impacts.

- Material feed control requires proper presser foot pressure for consistent seaming

- Industrial sewing machine features include 16mm presser foot lift capacity

- Stitch options adapt to different canvas weights and project requirements

Automatic Lubrication and Reverse Feed

Your machine’s engine might purr like a kitten, but without proper lubrication, it’ll roar like an angry lion within hours of heavy canvas work. Automatic lubrication systems deliver oil precisely where friction builds, extending your heavy-duty sewing machine’s lifespan considerably.

Meanwhile, reverse feed lets you backstitch through thick canvas layers, locking seams that won’t budge under stress—essential for marine applications.

Durability and Frame Construction

A heavy-duty sewing machine’s frame is like the foundation of a house—everything else depends on it holding steady under pressure. Canvas demands machines built with excellent frame materials and component quality for stress resistance during intensive use.

Key durability factors include:

- Metal frame construction – Cast iron or steel frames provide vibration dampening

- Reinforced motor mounts – Prevent flex during high-speed operation on durable fabrics

- Quality bearings – Extend lifespan expectancy through consistent performance

Your heavy duty canvas sewing machine investment pays off when the durable frame maintains precision through years of demanding projects.

Industrial Vs. Domestic Models Compared

When it comes to sheer muscle, industrial machines leave domestic models in the dust.

They chew through thick canvas layers at a blazing 2,000-3,000 stitches per minute—more than double what home machines can manage at their 1,300 stitch peak.

The price gap reflects this capability difference, with industrial units costing $280-$5,595 compared to domestic heavy-duty models under $300.

Performance Differences and Applications

Industrial vs. Domestic heavy duty sewing machines show stark performance gaps in real-world canvas applications. Industrial models deliver stitch quality consistency at 2,000-5,000 stitches per minute while handling multiple material layers through durable cast iron construction. Marine canvas applications demand this reliability. Domestic models, conversely, offer user-friendly interfaces for casual use.

| Feature | Industrial | Domestic |

|---|---|---|

| Speed Range | 300-5,000 SPM | Up to 800 SPM |

| Material Layer Capacity | 10+ layers canvas | 2-4 layers utmost |

| Frame Construction | Cast iron/steel | Plastic components |

| Maintenance Demands | Scheduled intervals | Frequent adjustments |

Heavy duty canvas sewing machines in industrial settings excel at continuous operation with minimal downtime. Industrial sewing machine features include automatic lubrication and enhanced motor strength for demanding textile production environments.

Price Ranges and Value for Money

When choosing a heavy-duty sewing machine for canvas, understanding price tiers helps you make smart decisions. Entry-level domestic models cost $200-500, while industrial sewing machines start around $2,500. Feature assessment reveals domestic units handle basic canvas projects, but industrial models power through multiple layers at 2,000+ stitches per minute. One key difference is that industrial machines offer durability due to their heavy-duty construction.

Consumer satisfaction data shows 89% of users report success with heavy fabrics when choosing machines above $1,000. Industrial cost seems steep initially, but warranty impact matters – commercial units offer lifetime coverage versus 25-year domestic warranties. For serious canvas work, that investment pays dividends.

| Category | Price Range | Key Features |

|---|---|---|

| Entry-Level | $200-500 | Basic canvas capability, 1,100 SPM |

| Semi-Pro | $1,000-2,500 | Walking foot, metal frame construction |

| Industrial | $2,500+ | Continuous operation, automatic lubrication |

| Premium | $5,000+ | Large bobbins, synchronized pullers |

Maintenance and Longevity

Like any workhorse in your shop, these canvas-crushing machines need regular care to keep delivering decades of reliable service. Industrial sewing machines demand more frequent oiling and cleaning than domestic models, but they’ll reward your preventative measures with peerless longevity.

| Maintenance Task | Industrial Models | Domestic Heavy Duty |

|---|---|---|

| Cleaning Techniques | Daily brush cleaning, weekly deep clean | Weekly cleaning sufficient |

| Oiling Frequency | Every 8 hours of operation | Monthly lubrication |

| Part Replacement | 5-10 year intervals | 2-5 year intervals |

| Storage Solutions | Climate-controlled preferred | Standard room temperature |

| Preventative Measures | Professional service annually | DIY maintenance adequate |

Well-maintained heavy-duty sewing machines deliver 10-25 years of reliable canvas stitching. Your sewing expertise grows alongside these mechanical partners, making proper storage solutions and regular maintenance essential investments in your craft.

Applications: Marine, Upholstery, and More

Heavy-duty canvas sewing machines transform challenging projects across multiple industries. Whether you’re repairing marine canvas and sails, crafting upholstery and leather goods, or manufacturing banners, luggage, tarps, tents, and sporting equipment, these specialized machines handle tough materials that would jam standard home machines.

Marine Canvas and Sail Repairs

Beyond routine maintenance lies the demanding world of Marine Canvas and Sail Repair. These heavy-duty canvas sewing machines tackle UV Damage Prevention through specialized UV-resistant thread applications. Professional Repair Longevity demands machines handling multiple canvas layers at 2,000+ stitches per minute.

Essential repair capabilities include:

- Seam Restitching Techniques for torn sailcloth and enclosures

- DIY Repair Kits compatibility for emergency patching

- Repair Cost Analysis justification through extended canvas life

Canvas Work on Boats and Sails requires walking foot mechanisms and large bobbins for consistent tension control.

Upholstery, Leather, and Banners

Think your trusty household sewing machine can handle thick upholstery fabric or supple leather—you’re in for a rude awakening when the needle bends and the motor strains under pressure.

Heavy duty canvas sewing machines power through multiple upholstery fabric layers with specialized machine needle types and enhanced thread strength selection.

Professional leather stitching techniques require machines that won’t buckle under dense materials, while banner material durability demands consistent tension control for vinyl and synthetic fabrics.

Luggage, Tarps, Tents, and Sporting Goods

When you’re stitching together gear that needs to survive the great outdoors, your sewing machine becomes the unsung hero of adventure preparation. Heavy-duty sewing machines excel at reinforcing backpack stress points and creating durable tent pole sleeves.

Industrial sewing capabilities handle sporting goods materials like ripstop nylon and cordura while maintaining tarp seam strength.

Your canvas projects demand machines that won’t buckle under pressure when building reliable outdoor gear with exceptional luggage stitch durability.

How to Choose The Right Machine for Canvas

Finding the right heavy duty sewing machine for canvas comes down to knowing what your projects actually demand. You can’t just pick any machine and hope it works.

You’ll want to think through fabric thickness, how much sewing you’re doing, what features matter most, and what you can actually spend. Getting this balance right means you won’t end up with a machine that’s either overkill or can’t handle what you throw at it.

Assessing Project Needs and Fabric Types

Your canvas projects won’t forgive the wrong machine choice—thick sailcloth demands different power than delicate upholstery fabric. Start by measuring fabric weight and material durability requirements.

Heavy marine canvas needs complete thread compatibility and sturdy stitch requirements, while lighter canvas projects allow more flexibility.

Project complexity determines your heavy-duty sewing machine specs—simple repairs versus intricate weaving patterns require different capabilities when choosing a sewing machine for demanding sewing projects.

Selecting Machine Features for Canvas

Once you’ve pinned down your project requirements, the hunt for specific machine features becomes your roadmap to canvas sewing success. Motor Power drives through thick layers—look for 1.0+ amp motors for demanding Canvas Projects.

Walking foot Feed Mechanism prevents fabric shifting better than standard pressure feet.

Heavy Duty Sewing Machine models need sturdy Frame Material like cast iron or steel construction.

Industrial Sewing Machine Features include large bobbins and extended Stitch Options for versatility.

Evaluating Brand Reputation and Reviews

When you’re shopping for a heavy duty sewing machine that can handle canvas, brand reputation is your best starting point. Here’s what the data actually shows:

Review Consistency – SINGER Heavy Duty models consistently earn 4.5+ star ratings across platforms, with stitch quality mentioned positively in 11.6% of reviews.

Expert Opinions – Independent reviewers uniformly recommend SINGER 4452, 4432, and 4423 models for demanding canvas applications.

Warranty Coverage – Look for manufacturers offering 90+ day warranties, which generally correlate with greater durability confidence.

Customer reviews highlight durability praise in 10.7% of feedback, while motor issues appear in 13.5% of complaints across industrial sewing machine brands.

Budget Considerations and Warranty

Investing in a heavy-duty canvas sewing machine isn’t just about the upfront price tag—it’s about finding the sweet spot between your budget and long-term value. Budget machines under $300 work for small business startups, while industrial sewing machines require higher initial investment but deliver greater longevity.

| Feature | Budget Machines | Industrial Models |

|---|---|---|

| Initial Investment | $150-$300 | $1,500-$5,500 |

| Warranty Length | 1-2 years | 3-5 years |

| Repair Costs | Higher frequency | Lower maintenance |

Extended warranties protect your heavy duty canvas sewing machine investment, especially when tackling demanding canvas projects regularly.

Frequently Asked Questions (FAQs)

What thread weight works best for canvas?

Like choosing the right armor for battle, selecting proper thread weight determines whether your canvas project survives heavy use.

For canvas work, use 69-138 weight polyester or nylon thread with size 18-22 needles, with Material Strength Considerations matching your Marine Applications and fabric thickness requirements.

Can these machines handle vinyl and leather?

Absolutely, these heavy-duty machines excel with vinyl sewing and leather thickness up to several millimeters.

Industrial sewing machines use specialized needle types and durable feed mechanisms for upholstery sewing projects requiring precise thread selection.

How much space do industrial models require?

When you’re setting up industrial sewing equipment, you’ll need way more space than you might expect. These heavy-duty fabricator machines eat up at least 8-12 square feet each, and that’s just the machine itself. You’ll also want to think about how your operators will move around comfortably—nobody wants to be cramped up all day working on intricate stitching.

Getting your shop layout right and finding smart storage solutions can make a huge difference in how smoothly everything runs.

Whats the maximum fabric thickness these handle?

Peak Ply Capacity varies between domestic and industrial sewing machines when handling heavy-duty projects. Domestic models usually handle 6mm total thickness, while industrial sewing machine units power through 10mm or roughly 15 denim layers with proper Feed Dog Adjustment.

- Material Density Impact – Thread Thickness Limit determines penetration power, with Needle Size Matters requiring 18/110+ needles for heavy-duty leather sewing machine applications

- Walking Foot Systems – Industrial models with synchronized feed mechanisms handle multiple canvas layers more effectively than standard presser feet

- Motor Specifications – Heavy-duty sewing machines need adequate torque to maintain consistent stitching through dense weaving without stalling or skipping stitches

Do heavy duty machines need special needles?

Most industrial sewing machines demand specialized needle point types and sizes.

Canvas work requires leather needles or heavy-duty points that penetrate thick fabric layers without thread compatibility issues affecting stitch quality.

Conclusion

Your canvas projects don’t have to remain pipe dreams gathering dust in your workshop. These eight heavy duty sewing machines for canvas deliver the muscle needed to transform ambitious visions into finished masterpieces.

Each machine offers unique strengths—from walking foot precision to industrial-grade construction. The right choice depends on your specific needs and budget.

With proper selection, your next canvas project becomes less about wrestling with limitations and more about unleashing your creative potential through reliable, professional-grade stitching power.

- https://www.dainessewing.com/blog/exploring-the-best-sewing-machines-for-heavy-fabrics-and-thick-materials

- https://durabilitymatters.com/heavy-duty-sewing-machines/

- https://www.accio.com/plp/canvas-sewing-machine

- https://www.sewingmachinefun.com/how-much-does-a-sewing-machine-cost/

- https://edisonvacuums.com/sewing-machine-repair-is-it-worth-it-2024/