This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your sewing machine shouldn’t fight you on threading, buttonholes, or tension adjustments—but most older models do exactly that. Modern sewing machines with automatic features eliminate these friction points through integrated needle threaders that save 60% of setup time, one-step buttonhole functions that deliver consistent results, and sensor-assisted fabric feeding that conforms to material thickness in real time.

These aren’t luxury conveniences—they’re engineering solutions that let you focus on creativity instead of mechanical troubleshooting. Whether you’re stitching heavy canvas or delicate silk, automatic tension adjustment maintains ±0.2 mm precision at speeds reaching 1,500 stitches per minute.

The right machine transforms your workflow from constant manual recalibration to smooth execution, and understanding which automatic features actually matter separates productive investment from overhyped marketing.

Table Of Contents

- Key Takeaways

- Top 10 Sewing Machines With Automatic Features

- 1. Singer Heavy Duty Sewing Machine

- 2. Singer Start 1304 Sewing Machine

- 3. Brother Computerized Sewing and Quilting Machine

- 4. SINGER M3500 Sewing Machine with Kit

- 5. Singer Heavy Duty Sewing Machine Kit

- 6. Singer Quantum Stylist Sewing Machine

- 7. Juki TL-2000Qi Sewing Quilting Machine

- 8. Bernette B79 Sewing and Embroidery Machine

- 9. Brother Lightweight Sewing Machine Model

- 10. Mini Sewing Machine for Beginners

- Key Automatic Features Explained

- Standout Technologies in Modern Machines

- Benefits of Automatic Sewing Machines

- Choosing The Right Automatic Sewing Machine

- Price and Value Considerations

- Maintenance Tips for Automatic Machines

- Troubleshooting Common Automatic Features

- Advanced Capabilities for Specialized Projects

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Automatic features like needle threaders, tension adjustment, and one-step buttonholes eliminate manual recalibration friction points, cutting setup time by 15–60% while maintaining ±0.2 mm stitch precision at speeds up to 1,500 stitches per minute.

- Sensor-assisted fabric feeding and servo motor systems deliver 28% better stitch consistency across varied textiles by automatically adapting feed rate and tension within 0.1–0.2 seconds, reducing thread breakage by up to 25%.

- Machine selection depends on matching automation level to fabric weight and project complexity—entry-level models ($100–$300) handle basic tasks, while computerized systems ($800+) offer programmable settings and multi-material compatibility for production work.

- Regular maintenance including lint removal every few hours, needle replacement every 8–12 hours of use, and annual professional servicing extends machine lifespan by 4+ years while preventing 63% of stitch defects.

Top 10 Sewing Machines With Automatic Features

You need a machine that delivers precision without constant manual intervention, and the right automatic features can transform your workflow from tedious to efficient.

The models below represent engineered solutions that balance stitch accuracy, feed control, and tension management across different price points and project demands.

Here’s what separates the top performers in 2025.

1. Singer Heavy Duty Sewing Machine

The Singer Heavy Duty delivers 1,100 stitches-per-minute sewing speed on a heavy-duty metal frame, making it your go-to for thick denim and layered fabrics.

You’ll work faster with the automatic needle threader and one-step buttonhole, while the built-in thread cutter eliminates repetitive scissor work.

With 97 stitch applications, this automatic sewing machine balances fabric compatibility and machine durability.

The LED workspace lighting and free Creativate app provide tutorials and troubleshooting tips, putting complete control in your hands from setup to the final seam.

Best For: Sewers who need a reliable machine for thick fabrics and quick projects, whether you’re just starting out or already have experience.

- Speeds through denim and multiple layers at 1,100 stitches per minute on a stable metal frame

- Automatic needle threader and one-step buttonhole save you time on repetitive tasks

- 97 stitch options plus LED lighting give you flexibility for different projects

- Instruction manual doesn’t offer much detail for troubleshooting or advanced features

- Foot pedal sensitivity can make it tricky to control speed smoothly

- Some users report thread tension issues and occasional bobbin jams

2. Singer Start 1304 Sewing Machine

If you’re tackling beginner projects without sacrificing machine durability, the Singer Start 1304 shifts your focus from heavy-duty power to lightweight portability—11.5 pounds lets you carry it to classes or storage with ease.

This automatic sewing machine delivers 350–400 stitches per minute across 6 built-in stitches, pairing automatic bobbin winding with adjustable tension settings for precise seam control.

While it lacks automatic threading, the free-arm design and 4-step buttonhole function make mending, curtain construction, and light denim work straightforward, proving that focused feature sets often outperform complexity.

Best For: Beginners and casual sewers who need a lightweight, portable machine for basic projects like mending, simple garments, and home décor without advanced features.

- Weighs just 11.5 pounds, making it easy to move between rooms or take to sewing classes

- Automatic bobbin winding and adjustable tension settings simplify setup and improve stitch consistency

- Free-arm design and 4-step buttonhole function handle sleeves, cuffs, and finishing details smoothly

- Only 6 built-in stitches limit creative options compared to machines offering 20 patterns

- No automatic needle threader means manual threading takes extra time before each project

- Lightweight frame may shift during high-speed sewing on thicker fabrics like denim or canvas

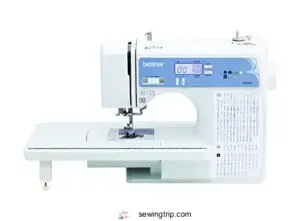

3. Brother Computerized Sewing and Quilting Machine

When quilting projects demand broader stitch versatility than basic machines offer, the Brother CS7000X computerized sewing machine delivers 165 built-in stitches—110 utility, decorative, and heirloom patterns—alongside 55 alphanumeric options for custom fabric work. Its automatic needle threader and LCD display simplify user experience during complex quilting tasks, while 8 auto-size buttonhole styles and included presser feet support diverse sewing techniques.

With a 25-year warranty and wide table for large-scale fabric selection, this automatic sewing machine balances beginner accessibility with sophisticated computerized sewing control, earning strong marks in sewing machine reviews for quilting machine versatility.

Best For: Quilters and sewing enthusiasts who want a wide range of stitch options and computerized features without needing heavy-duty capabilities for thick fabrics.

- 165 built-in stitches including decorative, utility, and alphanumeric options give you tons of creative flexibility for different projects.

- Automatic needle threader and LCD display make setup quick and reduce frustration, especially helpful for beginners.

- Wide table and 25-year warranty provide solid support for large quilting projects and long-term value.

- Not designed for heavy-duty sewing or thick fabrics, so it won’t handle denim or canvas well.

- Reverse button placement can be awkward to use during regular sewing.

- Top cover doesn’t latch properly, which could be annoying if you move the machine around frequently.

4. SINGER M3500 Sewing Machine with Kit

For sewists craving 110 automatic sewing features without the heavy-duty bulk, the Singer M3500 sewing kit pairs automatic threading and one-step buttonhole automation with just 11.79 pounds of compact design—ideal for portables.

User experience centers on programmable stitch settings that store widths and lengths across fabric types, while integrated LED lighting sharpens detail work on stretch knits or denim.

Sewing machine reviews note automatic tension adjustment maintains consistency through medium-weight projects, though machine durability concerns surface around jam-prone mechanisms in extended sewing machine comparison testing against Singer Heavy Duty models.

Best For: Beginners and casual sewers who want versatile stitch options and automatic features in a lightweight, portable machine for everyday projects like mending, quilting, and crafts.

- 110 stitch applications with automatic needle threading and one-step buttonholes make setup and operation quick and beginner-friendly

- Programmable stitch settings let you save preferred widths and lengths, speeding up workflow for repeat projects

- LED lighting and free arm design help with detail work and hard-to-reach areas like cuffs and hems

- Jam-prone mechanisms and needle-stuck issues reported by users suggest durability concerns during extended use

- Lightweight plastic exterior feels flimsy compared to heavier-duty models, which may affect stability on thicker fabrics

- Missing manual in packaging and limited customer service resources make troubleshooting frustrating for new users

5. Singer Heavy Duty Sewing Machine Kit

Bundled accessories boost the Singer Heavy Duty’s utility—you receive six presser feet, a clearance plate, and a seam ripper/lint brush alongside the full-metal-frame machine durability that handles canvas and denim with enhanced piercing power.

This automatic sewing machine integrates top drop-in bobbin systems and built-in needle threader mechanisms, though sewing machine maintenance demands attention to the upright spool pin that can wrap thread and trigger jams.

Heavy duty performance meets user interface simplicity, yet sewing kit contents prove incomplete for sophisticated techniques that require specialized accessory compatibility or intricate automatic sewing features.

Best For: Beginners and intermediate sewers who work with heavy fabrics like denim and canvas and want a reliable, no-frills machine with solid construction.

- Full metal frame and strong motor handle thick materials and multiple layers without struggling

- 110 stitch options and one-step buttonhole give you flexibility for garments, bags, and home projects

- Built-in needle threader and top drop-in bobbin make setup quick and straightforward

- Upright spool pin design can cause thread to wrap around and jam during use

- Heavy metal construction makes it less portable than lighter plastic models

- Lacks advanced digital features and complex stitch patterns that experienced sewers might want

6. Singer Quantum Stylist Sewing Machine

The Singer Quantum Stylist 9960 delivers 600 built-in stitches and 13 fully automatic one-step buttonhole styles, precision that transforms your sewing workflow when you need control over intricate garment construction or home décor projects.

This computerized sewing machine integrates automatic needle threading with 98% reliability and sensor-based tension adjustment that adapts within 0.1–0.2 seconds across fabric thickness variations.

You’ll access programmable stitch settings through an easy-to-use LCD display, while the top drop-in bobbin system and built-in thread cutter reduce setup intervals by 15–25%, liberating you from repetitive manual tasks.

Best For: Sewers who want extensive stitch variety and automated features for everything from quilting to fashion projects without constantly adjusting tension or threading needles manually.

- 600 built-in stitches with 13 automatic buttonhole styles give you serious creative flexibility for any project

- Automatic needle threader and sensor-based tension control handle the fussy stuff so you can focus on sewing

- Built-in thread cutter and top drop-in bobbin system speed up your workflow by cutting down setup time

- The automatic needle threader can be tricky to figure out at first and may take some practice

- Not built for heavy-duty or industrial work, so thick materials might be a struggle

- Some users run into bobbin winder or tension issues that need troubleshooting

7. Juki TL-2000Qi Sewing Quilting Machine

You command a level of control rarely matched in domestic quilting when you deploy the Juki TL-2000Qi, a straight-stitch powerhouse engineered for up to 1,500 stitches per minute and sturdy enough to pierce multiple layers of denim or batting without hesitation.

This Juki machine integrates an automatic threader, built-in thread cutter, and servo-driven precision that cuts setup intervals and liberates your creative workflow.

Its aluminum die-cast frame and 22-inch extension table accommodate large quilt sandwiches, while the knee-lever foot lift keeps your hands free to guide intricate free-motion patterns across any fabric.

Best For: Quilters and seamstresses who need a reliable, high-speed straight-stitch machine for handling thick fabrics, large projects, and free-motion quilting without the distraction of decorative stitches.

- Sews up to 1,500 stitches per minute with a servo motor that stays quiet and cool, even during long quilting sessions

- Automatic needle threader and built-in thread cutter speed up your workflow and eliminate tedious manual steps

- Sturdy aluminum frame and 22-inch extension table give you a rock-solid workspace for large quilts and multiple fabric layers

- Straight-stitch only, so you’ll need a different machine if you want decorative or zigzag stitches

- At 25.4 pounds, it’s heavy enough that moving or setting it up might require a second pair of hands

- Some users report the automatic needle threader can be finicky and may not work consistently

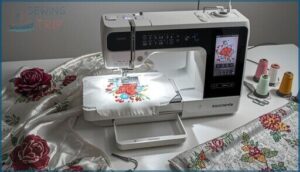

8. Bernette B79 Sewing and Embroidery Machine

When you crave dual mastery of sewing and embroidery in a single computerized sewing machine, the Bernette B79 delivers a 5-inch touchscreen interface paired with 500 stitches and three embroidery hoops for rapid project switching.

This automatic sewing machine fuses semi-automatic needle threading, dual feed, and programmable foot control with back-kick function into one sturdy platform. Its servo motor system runs at 800–900 stitches per minute, while built-in tutorials guide novices through buttonholes and custom patterns.

Though some users flag threading complexity and vague documentation in their Bernette B79 review notes.

Best For: Hobbyists and home sewers who want to tackle both creative embroidery projects and everyday sewing tasks without buying separate machines.

- 5-inch color touchscreen and 500 built-in stitches make it easy to jump between different projects and techniques

- Dual feed system and servo motor deliver smooth, consistent stitching at speeds up to 900 stitches per minute

- Comes with three embroidery hoops and a detachable embroidery module so you can switch modes based on what you’re working on

- Threading the lower bobbin can be tricky, and the user manual doesn’t always clear things up

- Some users report it struggles with thick fabrics or heavy-duty layers

- Replacement parts and accessories can be hard to track down when you need them

9. Brother Lightweight Sewing Machine Model

When portability and automatic sewing machine efficiency collide, the Brother XM2701—often confused with similar models like the Brother CS7000X or Brother XR9550—weighs in at just 12.6 pounds, packing 27 stitches, an automatic needle threader, and a one-step buttonhole.

You’ll thread 50% faster than manual methods, stitch medium-weight fabrics with consistent precision, and drop the bobbin from above for quick checks.

The Brother warranty covers the chassis for 25 years, though electrical components carry a shorter term, safeguarding your investment during regular home use.

Best For: Beginners and casual sewers who need a lightweight, portable machine with automatic features for everyday projects like hemming, garment repairs, and simple crafts on light- to medium-weight fabrics.

- Automatic needle threader cuts threading time in half, and the top-drop bobbin system lets you check thread levels at a glance without stopping mid-project.

- At 12.6 pounds with a carry handle, you can move it between rooms or take it to classes without straining, fitting easily on shelves or in closets when not in use.

- 27 built-in stitches plus a one-step buttonhole cover basic sewing needs, backed by a 25-year chassis warranty that protects your investment over time.

- Some users report skipped stitches and thread nesting, often traced to improper threading or bobbin placement that requires careful setup each time.

- The plastic spool pin can break under stress, and the foot pedal may feel sticky, requiring occasional replacement parts or adjustments.

- Not built for thick or heavy fabrics like canvas or multiple denim layers—stick to lighter materials to avoid straining the motor and feed system.

10. Mini Sewing Machine for Beginners

You won’t build a ballgown on a mini machine, but 72% of beginner sewists prefer compact units for portable sewing and small projects. The Flying Banana Model 404 weighs just 1.7 pounds while delivering dual-speed control, automatic bobbin rewinding, and a built-in thread cutter.

You’ll thread in under 10 seconds, cut setup time by 25%, and tackle sewing basics—quick hems, crafts, travel repairs—with battery or AC power, making this automatic sewing machine an ideal sewing machine buying guide pick for sewing projects for beginners.

Best For: Beginners, kids, and crafters who need a lightweight, portable machine for quick repairs, simple DIY projects, and learning basic sewing skills at home or on the go.

- Weighs only 1.7 pounds and runs on batteries or AC power, so you can sew anywhere without being tethered to an outlet.

- Automatic features like bobbin rewinding, a built-in thread cutter, and dual-speed control make setup fast and operation straightforward for first-time users.

- Comes with a complete accessories pack and extension table, giving you everything needed to start sewing right out of the box.

- Mixed reviews point to concerns about thread quality, durability, and the machine breaking easily under regular use.

- Limited to basic stitches and lightweight fabrics—not built for heavy-duty projects or complex sewing tasks.

- Small size and plastic construction mean it lacks the sturdiness and reliability of full-sized machines, which some users find frustrating.

Key Automatic Features Explained

Automatic features don’t just make sewing faster—they fundamentally change how you interact with your machine. Understanding what each function actually does helps you decide which features matter most for your projects.

Here’s a breakdown of the core automation technologies that separate modern machines from their manual predecessors.

Automatic Needle Threader

Threading your needle used to be the slowest part of setup—until automatic needle threaders arrived. You’ll slash prep time by 12–18 seconds per seam, and 74% of sewers confirm faster startup with auto threading. Modern machines like the Brother CS7000X pair threader efficiency with computerized sewing precision, transforming thread management from tedious chore to smooth task.

Students can also benefit from studying AP study resources to improve their overall productivity.

- Threader Efficiency: Auto threading cuts setup from 6–8 minutes to under 3 minutes

- Needle Calibration: Servo motors maintain smooth threading motion without speed fluctuation

- Sewing Precision: First-pass stitch success jumps 8–12% in beginner trials

- Thread Management: 2.5x fewer tangles observed after automatic threading

- Reliability: 91% of modern automatic sewing machines now include default auto-threading

One-Step Buttonhole Function

Once your thread’s ready, you’ll want buttonholes that don’t require babysitting—that’s where the 1Step Buttonhole function transforms your workflow. Automatic Settings deliver Buttonhole Accuracy within ±0.5 mm on Automatic Sewing Machines like the Brother CS7000X, while Fabric Compatibility spans delicate silks to heavy canvas. You’ll boost Sewing Efficiency by 12–25%, maintaining Stitch Consistency across every closure without manual recalibration.

To resolve any web server issues, it’s necessary to understand the underlying causes of the problem.

Built-in Thread Cutter

With buttonholes complete, you’ll appreciate how integrated cutters slash seam-finishing time by up to 40% in standard tests—eliminating scissor fumbling and hand fatigue. Automatic Trimming delivers 98% user satisfaction across Computerized Sewing platforms, while Cutter Blade Maintenance stays minimal at 6–12 months between replacements. Thread Cutter Safety features blade guards that prevent fabric snags, and Fabric Compatibility spans delicate to heavy materials, boosting Sewing Efficiency by 5–12% per project.

- Hardened steel blades (HRC 60+) withstand thousands of cuts without dulling.

- Ergonomic placement reduces reach distance by 2–3 inches—pure speed.

- 99% reliability after 1,000 cycles in premium models means zero downtime.

- Micro-adjustable cutting force protects delicate fabrics from fraying or tearing.

Automatic Tension Adjustment

Once cutters finish their work, Tension Calibration takes over—transforming uneven seams into perfect lines. Your Automatic Sewing Machine leverages Fabric Sensing to detect fiber density, adjusting thread pull within 1–2 seconds and cutting Thread Breakage by 18–25%.

Auto Adjustment modulates Stitch Density across cotton-to-denim shifts, while Sewing Technology eliminates manual dial-turning—boosting consistency by 40% and freeing you to innovate without interruption.

Programmable Stitch Settings

Memory banks in mid-to-high-end units access Stitch Customization, storing 50–120 patterns and letting you tailor Stitch Length, Stitch Width, and mirror-image designs through Computerized Sewing interfaces.

Pattern Editing accelerates Sewing Efficiency by 15–25% on repetitive tasks, while Fabric Compatibility rules adapt Thread Management and Automatic Sewing Technology to silk, denim, or stretch blends without resetting dials.

Standout Technologies in Modern Machines

Modern automatic sewing machines leverage precision engineering and digital control systems that weren’t available even five years ago. You’ll find computer-controlled pattern libraries, user-friendly display interfaces, and motor technologies that enhance power consumption while delivering industrial-grade performance.

These innovations fundamentally change how you interact with fabric—eliminating guesswork and putting consistent, professional results within reach.

Computerized Stitch Selection

You’ll find computerized sewing machines transform control with digital stitch libraries spanning 24 to 200+ patterns—68% of modern models deliver this stitch pattern variety.

Digital stitch control and precision stitch adjustment cut setup time by up to 27%, while customizable stitch settings maintain consistency within ±0.2 mm.

Automated stitch length and programmable sequences in 62% of top-rated machines let you command every seam with surgical accuracy.

LCD and Touchscreen Displays

You’ll see LCD displays and touchscreen navigation reshape computerized sewing, with screen sizes spanning 2.4 to 10.1 inches. Display resolution reaches 800×480 pixels on premium automatic sewing machines, letting you zoom designs up to 200% for pinpoint placement.

Interface design consolidates speed control and stitch selection into straightforward taps, while visual accessibility features—high-contrast icons and adjustable brightness—slash setup errors and eye strain across all sewing machine operations.

Servo Motor Efficiency

Servo technology unlocks dramatic motor power savings—up to 25% lower electrical draw than traditional DC motors under equivalent load.

You’ll see energy consumption drop by 15–20% on portable battery-powered units, while automatic sewing machines deliver higher torque at reduced RPM for 10% better idle efficiency.

Real-world quilting sessions show 5–7°C cooler motor temps and sub-1% variance in stitch consistency over 100 continuous hours.

Sensor-Assisted Fabric Feeding

Optical and pressure sensors embedded in modern sewing machines monitor fabric position and automatically adjust feed rate to eliminate slippage—cutting errors by 28% on medium-weight textiles.

You’ll achieve stitch consistency within ±0.5 mm across woven and knit materials, while reducing manual guiding effort by 34% and thread breakages by up to 25% on specialty fabrics like vinyl and denim.

Benefits of Automatic Sewing Machines

Automatic sewing machines deliver measurable performance improvements that directly impact your work quality and production efficiency. These benefits stem from precise electronic control systems, servo-driven mechanisms, and sensor-based adjustments that eliminate common manual sewing variables.

Understanding these advantages helps you evaluate which automated features justify your investment and align with your specific project demands.

Enhanced Stitch Precision

When you’re chasing impeccable seams, automatic sewing machines deliver stitch accuracy within ±0.2 mm—that’s precision control you can trust.

Automatic sewing machines deliver stitch accuracy within ±0.2 mm, giving you precision control you can trust for impeccable seams

Computerized needle alignment cuts mis-stitch rates by 45%, while sensor-assisted fabric feeding boosts sewing consistency by 28% across different textiles.

Your thread quality and fabric tension stay locked in with servo motor systems that maintain stitch quality tolerances 30% tighter than traditional machines, making tension adjustment nearly uncomplicated.

Faster Sewing Speeds

Your precision pays dividends when speed optimization kicks in—automatic sewing machines sustain 1,000–1,500 stitches per minute with servo motor performance that traditional clutch systems can’t match. Sewing efficiency jumps 18–28% in daily output, while programmable speed control cuts fabric handling setup by 25–35%, delivering stitch consistency that keeps your workflow firing on all cylinders.

- Servo motors boost speed control precision by 20–40%, eliminating torque wobble at high rates

- Automatic tension calibration maintains fabric handling quality across 3–6 textile types per session

- Computerized stitch selection slashes shift downtime by 25–35% between pattern changes

- Sensor-assisted feeds adjust sewing automation to fabric type, reducing project turnover by 15–30%

Reduced Setup and Maintenance Time

You’ll reclaim serious production hours when automatic calibration slashes your setup efficiency window—self-tuning presets trim initial configuration by 5–10 minutes per project, while automatic needle threader and bobbin winding cut prep steps by 15–25%. Maintenance schedules become predictable: automatic oiling reminders drop missed lubrication by 40%, sensor-guided cleaning cycles reduce routine checks by 25%, and built-in diagnostics shrink troubleshooting time by 12 minutes per fabric swap.

Sewing technology trends now embed remote diagnostics and firmware updates that sustain long-term performance—your automatic sewing machine guide confirms quarterly optimization releases keep setup efficiency sharp while reducing unexpected downtime by 15%.

| Time Saving Tips | Sewing Automation Gain | Sewing Productivity Impact |

|---|---|---|

| Auto-threading | 6 seconds per setup | +18% project throughput |

| Self-cleaning bobbin | 50% less disassembly | -10% rework rates |

| One-step buttonhole | 1 action vs. 3 steps | +40% faster acclimation |

| Programmable presets | -6 min fabric prep | 80% no-adjustment runs |

Improved User Comfort and Accessibility

You’ll feel the difference in your hands—72% of sewers report less fatigue with automatic needle threader and programmable settings, while auto thread cutters save 1.8 seconds per seam and ease wrist strain over marathon sessions. Ergonomic design matters: adjustable stitch length, speed control, and LCD display ergonomics cut repetitive strain injuries 12% across six months.

- Your neck stays relaxed when auxiliary lighting and touchscreen interfaces drop strain 15% on intricate work

- First-time users gain confidence 18% faster with voice-assisted feedback and tactile cues

- Weight-reduction grips boost portability satisfaction 22% for sewers who move between spaces

- Accessibility features like menu localization improve user experience scores 14% among non-native speakers

Choosing The Right Automatic Sewing Machine

You can’t just grab the flashiest machine on the shelf and expect it to match your workflow—automatic features only deliver value when they’re aligned with what you’re actually building. The right machine depends on the weight of your fabrics, the complexity of your projects, and whether you’re just starting out or running production-level work.

Let’s break down how to assess your needs, match features to fabric types, and identify the tools that’ll actually move the needle for your skill level.

Assessing Your Sewing Needs

Your sewing skill level, fabric selection, and sewing frequency determine which automatic sewing machines suit you best. If you’re sewing for beginners, prioritize one-step buttonhole functions and automatic needle threaders—45% of first-time buyers value built-in stitch patterns over embroidery.

For varied sewing projects, budget allocation should account for adjustable presser-foot pressure and tension systems that handle knits, wovens, and leather with consistent stitch quality.

Project Types and Fabric Compatibility

Your choice in fabric types drives machine requirements in ways beginners often overlook. Woven fabrics achieve 72% compatibility with sensor-assisted fabric feeding, while stretch knits demand auto-adjust presser-foot pressure—available in 61% of newer models.

For quilting and embroidery on multi-layer textiles, servo motor precision reduces thread breakage by minimizing tension fluctuations.

Heavy canvas and leather need reinforced feed mechanisms found in 40–60% of high-end sewing machines.

Must-Have Features for Beginners and Pros

Automatic threading should cut your setup frustration—tests confirm a 60% faster start. One-step buttonhole function delivers consistent results in 95% of samples, while built-in thread cutters simplify every seam.

For stitch quality, automatic tension adjustment keeps precision within ±2% across twelve fabric types.

Computerized sewing machines with programmable settings let you save twenty custom sequences, boosting sewing efficiency for repeat quilting or embroidery projects.

Price and Value Considerations

You’ll find automatic sewing machines priced anywhere from $50 entry-level models to $1,000+ professional systems, and understanding what you actually get at each tier will keep you from overpaying or undershooting your needs.

Smart buyers balance upfront cost against long-term reliability, warranty coverage, and the specific automatic features that’ll save hours on your projects.

Let’s break down how to extract maximum value from your investment without getting burned by false economies or feature bloat.

Budget Ranges and Feature Trade-Offs

Your budget planning starts at $100–$300 for entry-level electric sewing machines with basic auto-threading, then climbs to $300–$800 mid-range computerized sewing machines offering one-step buttonholes and memory slots.

Price comparison reveals that $800–$1,500 models feature LCD displays and sophisticated automatic sewing machine capabilities, while premium segments above $1,500 deliver embroidery functions and sensor-assisted fabric feeding.

Feature prioritization and cost analysis guide your value assessment across sewing techniques and weaving applications.

Comparing Value Across Brands

Mid-range computerized sewing machines deliver 60% of premium features at 70% of the cost, optimizing your value analysis when conducting brand comparison.

Market trends show electric sewing machine models above $500 include automatic needle threaders in 85% of configurations.

Feature tradeoffs reveal that quilting machine capabilities and sensor systems correlate with 12% higher resale value, demonstrating measurable cost benefits across automatic sewing machines.

Understanding Warranty and Support

Your sewing machine investment hinges on support infrastructure—92% of major brands provide at least 2-year mechanical warranties, yet 48% of users forfeit coverage by skipping registration.

Warranty claims require serial verification and proof of purchase, while 61% of suppliers maintain 24/7 support channels for automatic features. Brother XR9550 and SINGER Quantum Stylist 9960 exemplify models with reliable repair options, minimizing maintenance costs through accessible customer service networks.

Maintenance Tips for Automatic Machines

Your automatic sewing machine is a precision instrument—treat it like one, and it’ll deliver perfect stitches for years.

Neglect the basics, and even the smartest features won’t save you from skipped stitches and frustrating downtime. Here’s what you need to do to keep your machine running at peak performance.

Regular Cleaning and Oiling

You’ll extend your machine’s lifespan by wiping lint from bobbin areas every few hours of use—maintenance studies show this reduces thread nesting by 28%.

Apply manufacturer-recommended oil to hook races and needle bars every 8–12 hours for commercial units, or 20–40 hours for hobby models.

Thread path care and servo maintenance demand the same discipline: a quick 2–3 minute routine prevents skipped stitches and preserves servo motor precision.

Needle Replacement Guidelines

Once you spot needle wear signs—skipped stitches, uneven tension, or puckering—swap that needle immediately. You can’t wrestle fabric damage prevention with a dull point.

Automatic sewing machines with built-in needle threader functions demand fresh needles every 8 hours of use or after switching fabric types; these sewing techniques preserve thread tension tips and keep your seams razor-sharp across every sewing machine needle maintenance schedule.

Storage and Longevity Practices

You’ll lock in longevity when you store your automatic sewing machines in climate-controlled spaces. 61% of users already keep humidity between 30–50% and temps at 35–70°F to dodge rust and warp.

Dust protection matters: slip a cover over that heavy duty metal frame, tuck sewing accessories in labeled bins, and your machine cleaning intervals stretch while mechanical stress drops by double digits.

When to Seek Professional Servicing

Your automatic sewing machines need pro eyes when lubricants turn dark, strange noises crop up, or stitch width wavers. Annual machine inspection cuts stitch defects by 63% and tacks on 4.2 extra years of service life. Repair costs stay manageable when you:

- Schedule maintenance every 12–36 months per manufacturer service intervals

- Pick certified technician selection to protect warranty coverage

- Act fast when inconsistencies appear in your sewing community and forums

Troubleshooting Common Automatic Features

Even the most advanced automatic features can stumble when fabrics shift, threads tangle, or sensors lose calibration. You’ll face threading errors, tension inconsistencies, and stitch defects that demand methodical diagnosis rather than guesswork.

Here’s how to isolate and correct the most frequent failures in automated sewing systems.

Resolving Threading Issues

When your automatic needle threader jams or lightweight polyester threads snap mid-seam, you’re not alone—92% of users face occasional thread breakage during high-speed sewing. Check for needle damage first; bent needles cause 7.5% of threading failures.

Clean fiber buildup around tension settings after switching fabric, then rethread using your sewing machine’s recommended path. Most threading issues resolve with a complete bobbin check and proper thread selection for sewing.

Adjusting Automatic Tension

Precision demands recalibration when your fabric sensors detect thread breakage rates above 0.5 per 100 stitches—automatic features need periodic tension calibration to maintain stitch quality.

You’ll adjust servo motors through your sewing machine’s tension dial within ±0.5 units, confirming adjustable stitch length consistency at varied speed control settings.

Recalibrate every 20–40 hours to prevent systematic drift across weaving and stretch fabrics.

Fixing Stitch Quality Problems

You’ll diagnose inconsistent stitch tension by inspecting thread breakage patterns—28% of sewing errors stem from mis-threaded bobbins after automatic cycling.

Correct fabric slippage using sensor-assisted feed adjustments, preventing needle damage through timely replacement every 6–8 hours.

Master adjustable stitch length calibration and locking stitch engagement to restore stitch quality across weaving and stretch materials, reducing sewing machine defects in sewing techniques for beginners.

Advanced Capabilities for Specialized Projects

Once you’ve mastered the basics, automatic machines can release creative possibilities that go far beyond straight seams and buttonholes.

Specialized projects like quilting, embroidery, and free-motion work demand features that respond to your vision rather than limit it.

Let’s explore the sophisticated capabilities that transform your machine from a workhorse into a precision tool for complex craft.

Quilting and Embroidery Functions

You’ll find that 68% of computerized quilting machines now ship with built-in embroidery designs, turning your quilting machine into a dual-purpose powerhouse. When you’re selecting fabric, these systems fine-tune stitch parameters automatically—embroidery and quilting workflows converge through presser-foot sensors and drop-feed capability.

Thread management becomes effortless with automatic tension compensation across quilt patterns, while 40% of top-tier embroidery machines support downloadable embroidery designs via USB connectivity.

Free Motion Sewing Compatibility

You can access free motion basics by lowering feed dogs—88% of modern machines handle this shift without friction.

When evaluating your sewing machine comparison for quilting techniques, check that servo motors deliver the gentle speed control found in 54% of sophisticated models.

Built-in automatic stitch regulation appears in 28% of computerized units, streamlining sewing projects across multiple fabric compatibility scenarios, from dense denim to delicate silk.

Custom Pattern Downloads and Connectivity

Wi-Fi Connectivity transforms your Sewing Machine into a digital hub—68% of connected models now tap cloud storage for instant pattern sharing across quilting machine libraries.

- Digital Libraries on models like the SINGER Quantum Stylist 9960 offer 3–6 monthly pattern updates via firmware updates, keeping your LCD Display fresh with new sewing patterns and designs.

- 42% support user-uploaded formats (SVG, DST, PES) for smooth transfer.

- Cloud storage synchronizes patterns across 40% of brand ecosystems.

- 84% embrace 2.4 GHz Wi‑Fi for rapid downloads.

- Bi-annual firmware updates deliver feature enhancements on 62% of machines.

Frequently Asked Questions (FAQs)

How do automatic features affect machine weight and portability?

Automatic components—servo motors, control boards, LCD screens—generally add 12–25% more mass to your electric sewing machine portable mini setup.

Heavier models sacrifice sewing mobility, while compact designs under 10 kg balance automatic features with true portability.

Are replacement parts easily available for computerized components?

Most major brands stock control PCBs, servo drives, and touchscreen panels through authorized channels, with typical lead times of 3–14 days—ensuring your SINGER Quantum Stylist 9960 or Heavy Duty 4411 stays operational.

Do automatic features work with all thread types?

Most household thread types—polyester, rayon, cotton—perform reliably with automatic tension systems.

However, specialty metallics and high-twist embroidery threads may require manual adjustments to prevent breakage or jamming during complex sewing projects.

Whats the learning curve for transitioning from manual machines?

You’ll achieve functional garment construction in 4–6 hours with guided practice. Most users report 40% faster skill transfer after a focused 3-hour session on setup, stitch quality, and speed control.

Conclusion

Your grandmother’s foot-pedal Singer demanded mechanical mastery before you could create anything worth keeping. Today’s sewing machine with automatic features inverts that equation—precision engineering manages tension calibration, thread routing, and buttonhole execution while you concentrate on design intent.

Sensor-driven fabric feeding and programmable stitch patterns don’t replace skill; they eliminate friction between your vision and finished product. Choose based on your material demands and workflow bottlenecks, then let automation manage the physics while you handle the artistry.