This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ll find nylon dominates the market—it’s lightweight, water-resistant, and handles daily abuse without complaining.

Polyester offers similar benefits at a lower cost.

Canvas brings that classic look with natural breathability, though it’s heavier and needs waterproofing.

Leather screams luxury but requires maintenance.

For serious adventurers, Cordura nylon provides military-grade toughness, while ripstop fabrics prevent small tears from becoming major headaches.

PVC creates fully waterproof bags, perfect for marine activities.

Your choice depends on intended use—commuting, hiking, or school carries different demands.

The fabric selection process involves more considerations than you might expect.

Table Of Contents

Key Takeaways

- Nylon dominates the backpack market – You’ll find it in most modern packs because it’s lightweight, water-resistant, and handles daily abuse while offering superior durability compared to other materials.

- Different activities require different fabrics – You’ll need Cordura for heavy-duty adventures, ripstop nylon to prevent tears from spreading, or waterproof PVC for marine activities, based on your specific use case.

- Canvas offers classic style with trade-offs – You’ll get that timeless look and natural breathability, but you’re sacrificing weight and water resistance, unless you treat it with special coatings.

- Your budget affects fabric quality significantly – You’ll pay more for premium materials like Cordura that offer military-grade toughness, while polyester provides decent performance at lower costs for everyday use.

Types of Backpack Fabrics

You’ll find backpacks made from dozens of different materials, each designed to handle specific needs and budgets.

The fabric choice determines everything from how much weight your pack can carry to whether your gear stays dry in a downpour, which is crucial for keeping your belongings dry.

Cotton Canvas

Cotton canvas stands as the classic choice for backpack fabric types, offering that timeless, rugged appeal you’ve probably seen on vintage-style packs.

This natural cotton canvas material delivers solid canvas durability through its tight weave construction, making it a reliable backpack material guide staple.

However, canvas weight becomes a real consideration – these packs feel heavier than synthetic alternatives.

Canvas waterproofing requires special treatment since raw cotton absorbs moisture like a sponge.

Many manufacturers apply wax coatings or polymer treatments to boost water resistance.

Canvas blends often mix cotton with synthetic fibers, improving strength while maintaining that classic look.

Pure cotton canvas works great for urban commuting but struggles in wet conditions without proper treatment.

Canvas sustainability appeals to eco-conscious buyers since cotton grows naturally, though processing methods vary.

This canvas backpack fabric excels in style and moderate durability, but you’ll sacrifice some performance compared to modern synthetics.

It’s perfect when appearance matters as much as function.

Nylon

When you need a backpack that won’t let you down, nylon’s your best friend. This synthetic powerhouse dominates modern backpack construction for good reason.

You’ll find nylon backpack fabric in everything from school bags to hiking packs because it’s lightweight yet incredibly strong.

Nylon Denier ratings typically range from 210D to 420D in backpacks – higher numbers mean thicker, more durable threads. Nylon Coatings like polyurethane or silicone boost water resistance, while ripstop nylon features a special Ripstop Weave with reinforcing threads that stop tears in their tracks.

For serious durability needs, Ballistic Durability nylon uses 1000+ denier threads originally designed for military gear. Unlike polyester, nylon offers superior abrasion resistance and flexibility. However, it does need UV protection since prolonged sun exposure can weaken the fibers.

Nylon Backpacks handle moisture better than cotton alternatives, making them perfect for outdoor adventures where backpack fabric durability matters most.

Leather

While nylon dominates the technical backpack world, leather backpack materials offer something completely different: timeless style with serious substance.

You’ll find leather backpacks in boardrooms and coffee shops because they blend professional appeal with practical durability.

Leather durability comes from its natural fiber structure, which gets stronger over time.

Unlike synthetic backpack materials, leather develops character through use.

This leather patina process creates unique color variations and texture changes that make each bag distinctly yours.

It’s like watching your backpack grow a personality.

The main trade-off with leather backpacks is leather weight.

They’re substantially heavier than nylon alternatives, which matters if you’re carrying your pack all day.

However, leather’s natural abrasion resistance handles daily wear better than many synthetic options.

Leather treatment is essential for longevity.

Regular conditioning prevents cracking and maintains flexibility.

While synthetic backpack fabric durability relies on manufacturing quality, leather gets better with proper care.

When considering backpack fabric selection, leather works best for urban environments and professional settings rather than wilderness adventures.

Denim

While leather offers luxury, denim backpacks bring that classic American cool factor you’ll recognize anywhere.

These fabric workhorses use heavyweight cotton twill with that signature diagonal weave pattern.

Denim backpack features you’ll appreciate:

- Denim durability stands up to daily abuse better than basic cotton

- Denim weight typically ranges from 12-16 ounces, providing solid structure

- Denim treatments like stone washing or distressing add character over time

The tight denim weave creates natural abrasion resistance, though it won’t match synthetic backpack materials for weather protection.

Denim backpacks develop personality as they age – perfect for students wanting fabric types that look better with wear.

PVC

PVC fabric offers excellent waterproof backpack material properties at budget-friendly prices.

This synthetic material provides complete PVC waterproofing and comes in vibrant PVC colors from neon to classic black.

While PVC durability isn’t as strong as nylon, proper care guarantees years of use.

For successful projects, remember to use clips instead of pins to avoid damaging the material.

PVC applications include school bags and transparent PVC security backpacks.

| Feature | PVC Performance |

|---|---|

| Waterproofing | 100% waterproof barrier |

| Cost | Budget-friendly option |

| Colors | Wide range available |

| Weight | Heavier than nylon |

For backpack fabric comparison, PVC excels in wet conditions but requires regular cleaning.

Its backpack fabric waterproofing capabilities make it ideal for rainy climates, though it’s less breathable than other materials.

Durability of Backpack Fabrics

When you’re hauling heavy gear or trekking through rough terrain, you’ll want fabrics that can handle serious abuse without falling apart.

Your backpack needs to be tougher than your toughest day out there.

The most durable backpack materials combine advanced weaving techniques with high-strength synthetic fibers to create fabrics that resist tears, punctures, and everyday wear better than your average school bag.

Cordura

When you’re looking for a backpack that can handle serious abuse, Cordura stands out as the gold standard.

This heavy-duty fabric delivers up to four times more abrasion resistance than regular nylon, making it perfect for hikers, commuters, and anyone who’s tired of replacing torn backpacks.

Cordura Durability comes from high-tenacity nylon 6,6 fibers that undergo special air-jet texturizing.

Lab tests show Cordura withstands over 100,000 cycles in abrasion testing – that’s way beyond what you’ll encounter in normal use.

The 1000D version offers tear resistance ratings exceeding 225N, so you won’t worry about sharp rocks or rough handling.

For enhanced durability, consider that tight weave minimizes tearing, a factor also essential in tote bag construction.

Cordura Waterproofing isn’t fully waterproof on its own, but it sheds light rain effectively.

Many manufacturers add polyurethane coatings for enhanced water resistance, though you’ll still want a rain cover for heavy downpours.

Cordura Applications shine in military, tactical, and premium hiking backpacks.

Brands like Mystery Ranch and Eastpak use it because it balances weight with ruggedness perfectly.

Cordura Maintenance requires gentle hand-washing with mild detergents – skip the heat drying to preserve those protective coatings that make this backpack fabric so durable.

Rip-Stop Nylon

When you’re searching for backpack fabric strength that goes the extra mile, ripstop nylon stands as your reliable companion.

This backpack fabric features a reinforcement weave that creates a distinctive grid pattern across the surface.

Think of it like adding a safety net to your gear bag.

The secret lies in how tear propagation works.

Those thick reinforcement threads interrupt any rips before they can spread, boosting tear resistance by up to 400% compared to regular nylon.

You’ll find denier options ranging from lightweight 30D for daypacks to robust 210D for heavy-duty adventures.

Here’s what makes ripstop nylon your backpack’s best friend:

- Prevents small snags from becoming gear disasters

- Maintains strength even in ultralight designs

- Handles temperature swings from -40°C to +60°C

- Compresses to 30% of original size for storage

- Delivers up to 1200mm water resistance

Most manufacturers offer coating options like polyurethane treatments for enhanced weather protection.

You’ll get exceptional backpack fabric tear resistance without the bulk, making it perfect for outdoor enthusiasts who refuse to compromise on durability.

Polyester Pack Cloth

Beyond ripstop nylon’s reinforced grid pattern, polyester pack cloth offers excellent polyester durability for budget-conscious buyers.

This backpack fabric properties champion resists UV damage better than nylon while maintaining decent water repellency through DWR treatments.

Common deniers range from 210D to 600D, with higher numbers indicating stronger polyester backpack fabric.

| Property | Performance |

|---|---|

| Tensile Strength | 150-200 PSI |

| Abrasion Resistance | 20,000+ Martindale cycles |

| UV Resistance | Superior to cotton/nylon |

| Water Repellency | Good with DWR coating |

| Cost Effectiveness | 15-25% cheaper than Cordura |

Most mass-market backpacks use polyester because it balances backpack fabric durability with affordability, making it perfect for school bags and casual day packs.

Making a Backpack

Understanding how backpacks are made gives you insight into why certain fabrics perform better than others. The manufacturing process involves specific steps that determine the final product’s durability and functionality.

Cutting The Fabric

You’ll need precise cutting tools and pattern layout to create professional backpack pieces. Industrial machines slice fabric with less than 2mm error margin, while laser cutters prevent fraying on synthetics.

Here’s the cutting process:

- Pattern layout – Mark designs before cutting for proper alignment

- Automated cutting systems – Process up to 400 yards per hour in large-scale production

- Layer cutting – Stack multiple fabric layers for efficiency

- Fabric waste reduction – Modern techniques cut waste by 12%

- Automation tech – Guarantees consistent backpack fabric construction quality

To find the right tools, consider a backpack fabric cutter. These backpack fabric sewing tips help manufacturers maintain strict tolerances while meeting backpack fabric yardage requirements and design considerations.

Pressing and Molding The Fabric

After cutting your fabric pieces, you’ll shape them through heat setting and molding techniques.

Industrial presses apply temperatures between 120-180°C to synthetic backpack fabrics, creating 3D forming for ergonomic panels.

This fabric stabilization process bonds foam inserts for back support and flattens cotton canvas to prevent wrinkling.

Shape retention improves when reinforced sections get pressed, adding structure to critical areas, which is crucial for the overall shape retention and ensures that the backpack fabric materials maintain their form during construction and use, thanks to these molding techniques.

Sewing The Fabric

Once pressing shapes your backpack fabrics, industrial sewing machines take over the construction process.

These powerhouse machines use heavy-duty nylon thread and precise stitch patterns to create durable seams that’ll last through countless adventures. To purchase one, consider the machine’s product details.

Here’s how backpack fabric sewing works:

- Thread Choice – Heavy-duty nylon thread provides over 60N stitch strength for reliable performance

- Stitch Types – Double-stitch and bar-tack reinforcement increase durability by 25% at stress points

- Needle Selection – Industrial needles handle thick backpack fabrics without damaging synthetic materials

- Reinforcement Techniques – Strategic placement of extra stitching prevents failure at load-bearing seams

The magic happens with 6-8 stitches per centimeter, creating that solid feel you expect from quality backpack construction.

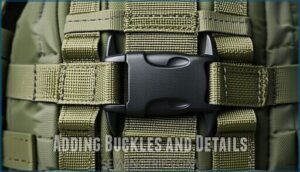

Adding Buckles and Details

With your backpack’s fabric sewn together, it’s time to add the hardware that makes it functional. This stage transforms a simple fabric shell into a working backpack through careful attachment of buckles, zippers, and other essential details.

Buckle Types vary by purpose. Plastic side-release buckles handle quick adjustments, while metal buckles offer maximum strength for heavy loads. Zipper Selection matters too – outdoor backpacks need waterproof zippers, while school bags can use standard coil zippers.

| Hardware Component | Manufacturing Process | Quality Standard | Purpose |

|---|---|---|---|

| Buckles | Injection-molded with high-pressure presses | Secure attachment tested | Load distribution and adjustment |

| Zippers | Anti-rust coating application | Metal construction for durability | Compartment access and weather protection |

| Reflective Details | Heat-sealed at 130-150°C | Visibility enhancement tested | Safety in low-light conditions |

| Logo Embroidery | Multi-needle machines, 2,000 stitches average | Brand identification quality | Product identification and aesthetics |

Reinforcement Methods include bar-tack stitching at stress points. Detail Placement follows ergonomic principles – shoulder strap adjusters sit where you can reach them easily. Multi-needle machines handle logo embroidery with precision, creating lasting brand identification. Many designs incorporate various buckle styles for different applications.

These backpack materials and backpack hardware work together during backpack construction, ensuring your finished product performs reliably under real-world conditions.

Bringing The Pieces Together

After securing all buckles and details, you’ll assemble the pre-cut panels using industrial adhesives at high-stress points.

Multi-needle stitching integrates major compartments through component integration techniques. Box-stitch reinforcement connects straps for 30kg load capacity.

Quality control includes drop tests from one-meter heights. These stitching techniques and seam reinforcement methods guarantee your backpack materials withstand daily use.

While proper hardware attachment completes the manufacturing process, it is essential to ensure that all components are securely attached to provide 30kg load capacity and maintain the overall quality of the backpack, which has undergone rigorous quality control measures.

Weight Capacity of Backpacks

Understanding your backpack’s load capacity isn’t just about fabric strength—it’s about your safety too.

Most experts recommend carrying no more than 20% of your body weight for adults, dropping to 10-15% for kids.

Fabric strength matters here: high-denier materials like Cordura handle heavier loads better than basic polyester.

Frame types and load distribution systems help manage weight, but material limits still apply.

Even the toughest backpack fabric weight ratings won’t protect your back from overloading.

For lighter loads, consider how cotton offers versatility.

To avoid health issues, backpacks shouldn’t exceed 10% of body weight.

Factors to Consider When Buying a Backpack

When you’re shopping for a new backpack, the fabric directly affects how well it’ll handle your daily adventures and how long it’ll last.

Smart buyers focus on five key factors: weight tolerance, comfort, size, number of pockets, and protection level.

Weight Tolerance

When your backpack’s loaded beyond its fabric strength limits, you’re asking for trouble.

Nylon 1000D handles up to 70 kg before tearing, while cotton canvas maxes out at 20 kg.

Durable backpack fabrics like Cordura withstand over 250 lbs per square inch.

Look for seam reinforcement at stress points – double-stitched seams boost strength by 60%.

Bar-tack stitching handles 35 kg loads safely.

Material limits matter because poor-quality fabric leads to seam failure above 18 kg.

UV exposure reduces nylon’s load capacity by 15% over three years.

Smart load distribution through reinforced webbing prevents catastrophic failure at attachment points, ensuring seam reinforcement is crucial.

Comfort

Feeling comfortable during long treks depends heavily on your backpack’s fabric and design features. Backpack fabric breathability plays a vital role – mesh panels and perforated materials prevent that sweaty back syndrome we all dread.

Padding material in shoulder straps and back panels distributes weight evenly, reducing pressure points that cause discomfort. Strap design matters more than you’d think.

Wide, contoured backpack straps with backpack fabric padding won’t dig into your shoulders like thin alternatives. Ventilation systems keep air flowing between your back and the pack, preventing moisture buildup.

Weight distribution through proper ergonomic features transforms how your pack feels. Some fabrics naturally offer better backpack fabric comfort – nylon with mesh backpack fabric lining beats heavy cotton canvas any day.

These design elements work together, turning a potential burden into a comfortable companion for your adventures.

Size

Three key dimensions matter when sizing your backpack correctly.

Internal dimensions determine actual storage space for your gear, while external dimensions affect how the pack fits in overhead bins or tight spaces.

Volume capacity, measured in liters, tells you exactly how much stuff you can carry.

Your torso length directly impacts pack fit and comfort—measure from your C7 vertebra to your iliac crest.

Consider backpack fabric denier ratings too, as heavier fabrics reduce internal space.

Smart backpack fabric yardage optimization means manufacturers balance durability with weight.

Higher denier fabrics require more backpack fabric yardage, affecting final pack dimensions and your carrying experience.

Number of Pockets

Pocket organization becomes a game-changer when backpack materials support smart backpack design. Your pocket functionality depends on proper pocket placement throughout the bag.

Front panels work best for quick-access items, while side pockets handle water bottles perfectly. Hidden pockets in back panels offer pocket security for valuables like passports or cash.

Modern backpack fabric allows manufacturers to create specialized pocket customization options. Mesh pockets provide breathability for damp clothes, while padded compartments protect electronics.

Consider how different pocket materials complement your main backpack materials – waterproof zippers pair well with treated fabrics. Smart backpack design considerations include pocket depth, opening width, and closure types.

These backpack features directly impact your daily organization system.

Protection

Before diving into protection features, consider what you’re actually defending against.

Your backpack needs to shield contents from water, tears, and daily wear. Here’s what matters most:

- Water resistance – Look for fabrics with DWR coatings or PU treatments that offer 1500mm hydrostatic head ratings for reliable rain protection

- Tear resistance – Ripstop weaves prevent small punctures from becoming major rips, reducing tear spread by 80% compared to plain fabrics

- Abrasion resistance – Cordura nylon withstands 300+ friction cycles, while polyester works for lighter use but shows wear faster

Impact protection comes from padded inserts that absorb 60% of drop forces. UV protection prevents fabric degradation – polyester handles sun better than nylon.

For enhanced breathability, consider natural fabric options. Choose backpack fabric durability based on your adventures, not just looks.

Cotton Backpacks

When choosing cotton canvas for your backpack fabric durability needs, you’re getting a material that’s been trusted for generations. Cotton canvas backpacks offer impressive durability with abrasion resistance ratings between 10,000–12,000 Martindale cycles, making them perfect for daily wear and tear.

Canvas durability shines in its dense weave construction, showing 15% better tear resistance than lighter builds. You’ll find organic cotton options that use 62% less energy during production, appealing to eco-conscious buyers seeking vintage aesthetics.

However, cotton waterproofing requires attention. Untreated cotton absorbs up to 23% of its weight in water, so look for waxed treatments that reduce water uptake by 68%. Cotton blends maintain the natural breathability that’s 35-40% higher than synthetics while reducing skin irritation by 30%.

These backpack fabrics decompose naturally within 5-10 months, making them an environmentally responsible choice. Regular maintenance keeps your cotton canvas backpack performing well for years.

PVC Backpacks

PVC backpacks deliver serious waterproofing power thanks to polyvinyl chloride’s impermeable barrier.

You’ll find transparent PVC models perfect for security checks at stadiums and schools.

PVC durability handles daily wear, though it’s less flexible than alternatives in cold weather.

PVC cleaning couldn’t be easier—just wipe down surfaces.

PVC colors stay vibrant with proper care, though prolonged sunlight exposure can cause fading.

These waterproof backpacks excel in wet conditions with welded seams preventing water intrusion, making PVC applications ideal for outdoor adventures and everyday use.

For enhanced protection, consider backpacks with welded seam technology.

Choosing The Right Backpack Fabric for Your Needs

Matching your backpack fabric to your specific needs prevents buyer’s remorse and guarantees years of reliable service.

Activity Type determines everything—ultralight hikers need Dyneema’s strength-to-weight ratio, while students can opt for affordable polyester.

Climate Considerations matter too; tropical adventurers require waterproof coatings, whereas desert travelers prioritize UV resistance.

Your backpack fabric buying guide should include these essential factors:

- Budget Constraints – Premium fabrics like X-Pac cost more but deliver exceptional backpack fabric durability

- Aesthetics Preference – Canvas offers vintage appeal while nylon provides modern functionality

- Fabric Maintenance – Synthetic materials resist stains better than natural fibers

Backpack fabric water resistance varies dramatically between materials.

Polyester naturally repels moisture better than cotton, while coated fabrics offer complete waterproofing.

Consider backpack fabric qualities like tear resistance for rough handling and abrasion resistance for heavy loads.

Smart backpack material selection balances performance, price, and purpose—don’t overpay for features you won’t use.

Frequently Asked Questions (FAQs)

What fabric are backpacks made of?

Think of backpack fabric as your gear’s armor against the elements.

You’ll find nylon in most modern packs—it’s lightweight, strong, and water-resistant.

Polyester offers budget-friendly durability with UV protection, while ripstop nylon prevents tears from spreading through reinforced weaving.

What materials make up modern-day backpacks?

Modern backpacks use nylon, polyester, canvas, and specialized materials like Cordura or Dyneema.

You’ll find nylon in most outdoor packs for its durability and water resistance, while polyester dominates budget options for everyday use, making Dyneema a notable exception for its unique properties.

What are the different types of backpack materials?

Nylon dominates 60% of modern backpacks, offering lightweight durability. You’ll find ripstop nylon, ballistic nylon, polyester, canvas, leather, and specialized materials like Dyneema creating different performance levels for various needs.

What materials are used in backpack production?

Backpacks use various materials depending on their purpose.

You’ll find nylon in most outdoor packs for its strength and water resistance.

Polyester works well for school bags since it’s affordable and fade-resistant.

Canvas offers durability for rugged use.

What materials are used in eco-friendly backpacks?

Like turning plastic bottles into something useful, you’ll find eco-friendly backpacks made from recycled polyester, organic cotton, hemp, and innovative ECOPAK fabric.

That transforms twenty plastic bottles into every yard of durable material, making it a highly eco-friendly option.

What materials are used in anti-theft backpacks?

You’ll find anti-theft backpacks use ballistic nylon, ripstop fabric, or reinforced polyester for cut-resistance. They incorporate steel mesh panels, RFID-blocking materials, and lockable zippers to deter thieves effectively.

What fabric is used in backpacks?

Like choosing armor for battle, you’ll find backpacks crafted from tough nylon, polyester, or canvas.

Nylon’s your go-to warrior—lightweight yet strong.

Polyester offers budget-friendly protection, while canvas brings old-school durability to your adventures, making polyester a notable choice for its affordability.

What material is used for sports backpacks?

Sports backpacks typically use durable nylon or polyester fabrics. You’ll find ripstop nylon for tear resistance, ballistic nylon for heavy-duty use, and mesh panels for breathability during workouts.

What is the best fabric for backpack lining?

Surprisingly, you’ll want ripstop nylon for your backpack’s lining—it’s lightweight, breathable, tear-resistant, and strong enough to handle daily abuse while keeping your gear organized.

What is the best type of fabric for a backpack?

Nylon’s your top choice for durability and weather resistance.

Ripstop nylon prevents tears from spreading, while ballistic nylon handles heavy abuse.

For budget-friendly options, polyester works well but won’t last as long.

Conclusion

Understanding what fabric backpacks are made of helps you make smarter buying decisions.

Each material serves different purposes—nylon excels for daily use, canvas offers classic style, while Cordura handles extreme conditions.

Your choice should match your specific needs and budget.

Whether you need waterproof PVC for marine adventures or breathable cotton for casual outings, the right fabric makes all the difference in your backpack’s performance and longevity.

- https://en.wikipedia.org/wiki/Backpack

- https://www.reddit.com/r/Ultralight/comments/koi177/backpack_max_weight_limit/

- https://pmc.ncbi.nlm.nih.gov/articles/PMC6267109/

- https://www.mammut.com/us/en/stories-guides/how-much-weight-can-a-backpack-hold

- https://www.advnture.com/features/how-much-should-backpack-weigh