This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

First, check for thread jams or lint buildup around the wheel and bobbin area; these can act like gremlins blocking movement. Clean the area and add a dab of sewing machine oil to loosen things up.

Inspect the drive belt for wear or misalignment, and make sure the needle isn’t bent or dull.

Always turn the wheel counterclockwise—turning it the wrong way can cause jams.

If it’s still stuck or grinding, it might be a stripped gear or broken belt, so professional help might be your next stitch in time.

Table Of Contents

- Key Takeaways

- Common Handwheel Issues

- Diagnosing Handwheel Problems

- Cleaning The Handwheel Area

- Addressing Handwheel Malfunctions

- Preventing Handwheel Issues

- Importance of Tension and Threading

- Common Causes of Handwheel Problems

- Troubleshooting Handwheel Issues

- Regular Maintenance for Handwheel

- Professional Repair and Storage

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Always check for thread jams, lint buildup, or dry parts causing the handwheel to stiffen—cleaning and oiling can solve most issues.

- A bent needle, misaligned bobbin, or broken drive belt can stop the handwheel from working—inspect these areas before seeking professional help.

- Regular maintenance, like cleaning, lubrication, and proper storage, prevents common problems and keeps your handwheel running smoothly.

- If the handwheel’s still stuck after basic fixes, don’t force it—reach out to a professional to avoid further damage.

Common Handwheel Issues

If your sewing machine’s handwheel is acting up, it’s usually caused by a few common issues.

These issues include stiffness or thread jams.

Understanding these problems can save you time, frustration, and possibly a trip to the repair shop.

Stiff Handwheel Causes

A sewing machine handwheel stuck or stiff often points to lint buildup blocking movement, tension issues, or a dry machine needing lubrication.

A bent shaft or worn gears could also jam things up, making the handwheel wobbly or loose.

Clear debris, oil the parts, and inspect for damage to get your machine running smoothly again.

Erratic Needle Movement

Erratic needle movement can leave you frustrated mid-project. Often, it’s a sign of needle alignment or timing issues. Check for a bent needle or broken parts causing problems.

Motor speed could also be inconsistent.

Start with sewing machine troubleshooting—inspect the handwheel’s function. These sewing machine handwheel problems might need adjusting to fix your sewing machine handwheel not turning smoothly.

Uneven Stitches

Uneven stitches giving you grief? They’re often tied to tension problems, needle issues, or mismatched thread quality.

For smoother stitches:

- Inspect the needle. A bent needle disrupts sewing.

- Tweak sewing machine tension. Balance upper and bobbin threads.

- Choose quality thread. Cheap ones knot easily.

- Check the bobbin case. Dirt or damage hinders flow.

Keep that handwheel spinning smoothly!

Thread Tangles

Thread tangles can leave you pulling your hair out—literally. Causes? Misthreaded machine, wrong bobbin type, or loose upper threading.

Fixing tangles starts with re-threading and re-checking the bobbin.

To prevent them, always thread with the presser foot raised and use quality thread. A smooth handwheel can save the day—keep it clean and lubricated.

Regular maintenance, including sewing machine oil, can help prevent thread tangles.

| Cause | Prevention Tip |

|---|---|

| Misthreading | Double-check threading steps |

| Poor-quality bobbin thread | Use compatible bobbins |

| Poor-quality thread | Invest in quality thread |

| Dust build-up | Regularly clean the machine |

| Tension issues | Adjust and test tension |

Machine Jams

When your sewing machine handwheel is jammed, thread jams or lint buildup are often culprits.

Troubleshooting steps include checking the bobbin case, re-threading the machine, and inspecting for debris.

Prevention tips? Regular cleaning and lubrication.

If the sewing machine handwheel’s not turning or seems stripped, stop forcing it—seek repair options before causing further damage.

Diagnosing Handwheel Problems

When your sewing machine’s handwheel acts up, knowing where to look can save you time and stress.

Start by checking obvious trouble spots like the bobbin case, drive belt, and needle—it’s easier than you think!

Checking Bobbin Case

A misaligned or dirty bobbin case can mess with your sewing machine handwheel.

Start with bobbin case cleaning—remove lint and dust buildup.

Check for bobbin case damage; even small cracks can cause bobbin problems.

Verify proper bobbin insertion and bobbin case alignment to get things running smoothly.

If issues persist, consider bobbin case replacement for effective sewing machine maintenance. You can find the right replacement parts by checking out bobbin case options.

Inspecting Drive Belt

A faulty drive belt might be why your sewing machine handwheel’s not turning.

Check the belt condition for cracks or wear. Verify the belt tension is neither too loose nor too tight—it’s all about balance.

Misalignment or improper belt routing can also cause issues.

If damaged, a belt replacement might save your broken sewing machine handwheel quickly!

Needle Condition Check

A worn drive belt isn’t the only culprit—your sewing machine needle could be sabotaging you too. Needles matter, especially when the handwheel refuses to cooperate.

- Bent needles can jam mechanisms.

- Dull needles snag fabric, leading to uneven stitching.

- Use the correct needle type and size for your project.

Inspect and replace needles regularly to avoid more sewing machine problems.

Cleaning The Handwheel Area

Cleaning the handwheel area is essential for keeping your sewing machine running smoothly.

By removing dust and debris, then adding a bit of lubrication, you’ll prevent stiffness and keep everything moving like it should.

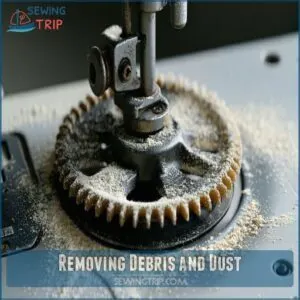

Removing Debris and Dust

If your sewing machine handwheel’s jammed, start with basic cleaning tips.

Dust and lint love hiding in tight spots. Grab a small brush—like an old toothbrush—and sweep out debris. For stubborn areas, vacuum safely with a nozzle attachment.

Regular lint removal prevents buildup and keeps your sewing machine handwheel troubleshooting simple. This step alone boosts maintenance and performance!

Lubricating Moving Parts

Give your sewing machine handwheel the care it craves with proper lubrication.

- Use the right oil—specialized sewing machine oil avoids clogs or damage.

- Apply sparingly to moving parts, preventing oil spills that attract dust.

- Wipe away excess oil after application to maintain cleanliness.

This boosts sewing machine handwheel maintenance and performance!

Unplugging The Machine Before Cleaning

Before tackling sewing machine handwheel repair, safety first—unplug that machine!

Failing to do this risks electrical shock or damaging your machine.

It’s a small step with big benefits for machine care.

Cleaning tips start here: disconnect the power, eliminate hazards, and focus on proper sewing machine maintenance tips.

A little prep goes a long way in sewing machine care.

Reassembly and Testing

Once the cleaning’s done, piece everything back together, securing the handwheel and other parts snugly. Don’t over-tighten screws.

Run post-reassembly checks by rotating the handwheel manually—listen for odd noises.

Try an initial test run with light fabric, watching stitch quality. If it’s off, use troubleshooting tips to confirm motor function.

Handwheel repair done? You’re golden!

Addressing Handwheel Malfunctions

When your sewing machine’s handwheel won’t cooperate, it can make even simple projects feel impossible.

Let’s tackle the most common problems, so you can get back to sewing smoothly.

Handwheel Won’t Turn

If cleaning didn’t solve your handwheel problems, a stuck handwheel might mean one of these: A poorly threaded bobbin can also prevent the handwheel from turning, so check your bobbin compatibility carefully.

- Internal jam: Check for tangled thread or debris near the bobbin.

- Motor seized: Let the machine cool down if overheated.

- Belt broken or gear stripped: Inspect for wear or damage.

- Sewing machine handwheel stripped: Seek professional help if gears won’t grip.

Handwheel Turns Backwards

A backward-turning sewing machine handwheel screams trouble.

Reverse rotation causes can include tangled threads, gear problems, or belt issues.

Check for jams or misaligned parts. Rotate the handwheel gently to spot internal damage.

Avoid forcing it—it might worsen motor direction or create a sewing machine handwheel jammed mess.

Stay sharp; small fixes beat replacing costly components!

Overheating Motor Considerations

Overheating your sewing machine motor can jam everything up fast.

Check for fan issues—dust buildup or a broken fan stalls motor cooling. A blown thermal fuse or faulty overload protection could also be culprits.

Let your machine rest between long projects and follow preventative measures like regular cleaning.

For serious motor overheating, use a sewing machine repair guide or call a pro.

Preventing Handwheel Issues

You can avoid frustrating handwheel problems by using proper threading, the right needle, and a good-quality bobbin.

Regular maintenance, like cleaning and oiling, keeps your machine running smoothly and saves you costly repairs down the road.

Proper Threading Techniques

Tangled threads and skipped stitches could mess with your sewing machine handwheel.

Proper threading is crucial; follow the thread path exactly, checking for snags.

Tension control matters—too tight or loose spells trouble.

Use the right needle type and verify that your bobbin is wound smoothly.

Nail this, and you’ll sidestep frequent troubleshooting jams and sewing machine repair nightmares.

Bobbin Selection and Size

Choosing the right bobbin can make or break your sewing machine’s performance. Use bobbin types that match your machine’s specs—check the manual!

A mismatched bobbin can throw off bobbin tension or even break the sewing machine handwheel.

Keep bobbin winding smooth, avoid overfilling, and inspect for bobbin case issues. Compatibility prevents costly sewing machine repairs and headaches!

Needle Choice and Condition

A bent or dull needle can wreak havoc on your sewing machine handwheel. Always inspect for needle sharpness or rust before starting.

Use the correct needle size for your fabric, and avoid sewing with damaged or bent needles.

Keep a stash of sewing machine tools handy for quick needle replacement—it’s simple sewing machine repair that saves headaches later!

Regular Maintenance Schedule

Keeping your sewing machine handwheel in top shape means sticking to a regular maintenance schedule.

Plan routine checkups, including cleaning tips like clearing lint and debris. Apply sewing machine lubrication to keep things running smoothly.

Watch for worn parts needing replacement.

Service frequency depends on usage—light sewing? Every six months. Heavy-duty projects? Clamp down on cleaning and oiling monthly.

Importance of Tension and Threading

If your tension or threading is off, it can throw your sewing machine—and its handwheel—into chaos.

Taking a moment to adjust tension and properly thread the machine helps prevent frustrating jams.

This will keep everything running smoothly.

Upper and Bobbin Tension Adjustments

Proper tension makes all the difference when tackling sewing machine handwheel issues. Start with a tension guide in your manual.

Adjust the upper thread tension first—too tight or loose leads to uneven stitches.

Tension troubleshooting includes checking the bobbin tension; it should resist slightly when pulled.

Balanced tension keeps your machine smooth, reducing handwheel adjustment headaches later.

Hook Area Cleaning

A clogged hook area can throw your sewing machine handwheel into chaos.

Grab hook cleaning tools to clear debris and tackle lint buildup with effective lint removal methods.

Regular inspections and cleaning frequency prevent buildup around essential sewing machine parts. After cleaning, add sewing machine handwheel lubrication for smooth operation. Respect your machine, and it’ll respect your projects!

Preventing Skipped Stitches

Don’t let skipped stitches wreck your projects! Double-check your needle type and thread quality—they work like a team.

Adjust the tension, as loose settings can cause gaps.

Clear out lint or thread jams near the bobbin; they mess up sewing machine timing.

If your sewing machine handwheel’s not turning smoothly, inspect threading and address bobbin issues promptly.

Common Causes of Handwheel Problems

Handwheel problems often come from common culprits like thread jams, broken belts, or dust buildup.

If your machine feels stuck or overheated, it’s time to check for these sneaky issues.

Thread Jams

Thread jams can freeze your sewing machine handwheel faster than you’d expect. Snag the culprit with these quick tips:

- Clear tangled thread from the bobbin area.

- Keep the bobbin case clean for smooth sewing.

- Double-check your sewing machine threading.

- Adjust tension to prevent snags.

- Identify thread types to match your project.

A little care keeps jams away!

Broken Belt or Gears

If the handwheel’s jammed, your sewing machine belt or gears might be toast. A broken belt often causes jerky movement or no spin at all. Cracked gears? They’ll stop the action cold.

| Issue | Signs to Look For | Required Action | Tools Needed | Stay Ahead Tips |

|---|---|---|---|---|

| Broken Belt | No handwheel movement | Belt replacement | Screwdriver, belt | Regular checks |

| Cracked Gears | Grinding noises | Gear repair | Gear lubricant | Lubrication needs |

| Belt Slipping | Uneven rotation | Tighten/replace belt | Wrench, new belt | Adjust tension |

| Missing Teeth | Skipping motion | Gear inspection | Gear replacement | Preventative steps |

| Fraying Belt | Visible wear | Replace belt | Belt, cleaner | Clean parts often |

Lint Buildup and Dust

Lint buildup in the sewing machine handwheel is like sand in gears—it gums up the works.

Regular cleaning prevents dust from sneaking into tight spaces. Use a soft brush or tweezers for lint removal, and compressed air for stubborn spots.

Air filtration in your sewing space helps, too.

Prioritize sewing machine handwheel care to keep stitches smooth.

Machine Overheating

Overheating can cause more than a stiff handwheel—it can fry your motor, shortening its lifespan and piling on repair costs.

Here’s how to cool things down:

- Take breaks: Avoid long sewing sessions to prevent overheating.

- Check cooling systems: Make sure vents are free of dust.

- Inspect thermal fuses: Replace faulty ones to protect your motor.

Troubleshooting Handwheel Issues

If your sewing machine handwheel’s acting up, don’t stress—it’s usually fixable with a few straightforward steps.

From checking the bobbin area to oiling moving parts, you can tackle most issues with a little patience and attention.

Inspecting Bobbin Area

If your sewing machine handwheel’s acting up, the bobbin area might be the culprit.

Check for lint buildup or thread jams causing friction. Remove debris with a brush, inspect for a worn bobbin case, and verify proper bobbin placement.

Bobbin tension shouldn’t feel overly loose or tight—test adjustments after cleaning to avoid further sewing machine handwheel problems.

Re-threading The Machine

Sometimes, thread jams or tension issues come down to improper threading.

Take a fresh approach by re-threading your machine. Carefully follow the thread path, making sure it’s smooth and snag-free.

Double-check the bobbin threading too—incorrect bobbin winding could cause those troubleshooting jams.

This simple step might save your sewing machine handwheel from frustration, transforming chaos into flawless stitching.

Accessing Internal Parts

A broken handwheel doesn’t mean game over! Access internal parts by following these steps:

- Unplug the machine – safety first.

- Gather tools needed – screwdriver, tweezers, flashlight.

- Remove screws and covers – reach internal areas carefully.

- Identify faulty components – belt, gears, or handwheel.

- Repair vs. replace – decide to fix or opt for sewing machine handwheel replacement.

Applying Oil to Moving Parts

Once you’ve accessed the internal parts, it’s time to apply sewing machine oil.

Locate the handwheel’s moving parts and key access points. Use a tiny oil quantity—precision matters! Avoid over-lubricating.

Stick to sewing machine oil for best results, and repeat lubrication frequency based on use.

A well-oiled handwheel turns smoothly, making sewing machine handwheel repair much simpler.

Regular Maintenance for Handwheel

Keeping your sewing machine’s handwheel in good shape isn’t hard, but it does require regular attention.

By addressing issues quickly, you’ll avoid bigger problems down the road.

Scheduling professional servicing and storing your machine properly are also important.

Scheduling Servicing

A broken sewing machine handwheel might call for professional help.

Regular servicing keeps things running smoothly and avoids costly fixes later.

Schedule a check-up to keep the warranty valid and plan for:

- Service frequency based on usage.

- Cost estimates so there are no surprises.

- Finding reputable repair shops near you.

- Preventative maintenance planning to avoid downtime.

Addressing Issues Promptly

When tackling a broken handwheel sewing machine, act fast! Ignoring small problems spirals into costly repairs. Quick fixes or preventative care prevent bigger headaches.

Spotting handwheel problems early saves repair costs and lessens downtime.

| Warning Signs | Quick Action | Benefit |

|---|---|---|

| Stiff handwheel | Lubricate gears | Smoother operation |

| Unresponsive | Problem diagnosis | Avoid deeper issues |

| Jammed threads | Remove and rethread | Prevent further damage |

Covering The Machine

Protect your machine by using a good cover—it’s like sunscreen for its parts! Dust prevention matters if you want to avoid future issues like a broken handwheel sewing machine fix.

Here’s what to do:

- Use fitted machine covers for all-around protection.

- Avoid plastic covers; fabric ones breathe better.

- Cover immediately after use to block dust buildup.

Dust prevention and machine covers are important for protecting your sewing machine.

Storing The Machine Appropriately

Your sewing machine handwheel deserves a little TLC, even in storage.

Pick a dry spot with low humidity and minimal dust, like a closet with good airflow. Use a cover to keep debris out.

Safe transport matters too—avoid banging it around.

Proper sewing machine storage prevents future headaches, reducing the need for costly sewing machine repair services or handwheel fixes.

Professional Repair and Storage

If your handwheel issues persist, it’s time to call in a professional to avoid making things worse.

Don’t forget proper storage—keeping your machine covered and dust-free can save you from future headaches!

Seeking Professional Help

If regular maintenance didn’t fix your sewing machine handwheel, it’s time to call the pros. A faulty sewing machine handwheel often needs expert repair.

Check service reviews and compare repair costs. Use warranty claims if applicable.

Reliable sewing machine repair shops can replace the sewing machine handwheel or identify recurring issues.

Don’t let broken parts slow you down!

Following Manufacturer’s Recommendations

Trust the user manual—it’s packed with safety tips, maintenance schedules, and troubleshooting guides specific to your sewing machine.

Warranties often require following these guidelines, so don’t skip them.

Whether it’s a broken sewing machine handwheel or a wobbly one, sticking to the manual can prevent bigger headaches. And hey, it’s cheaper than voiding your warranty!

Preventive Maintenance Tips

Don’t ignore preventive maintenance—it’s the secret to a smooth-running sewing machine handwheel.

Regular cleaning keeps lint from gumming things up.

Use sewing machine oil for moving parts and make sewing machine handwheel adjustments as needed.

Always check the belt for wear and see that the bobbin setup is clean.

Stay ahead with regular oiling to keep things flawless.

Storage to Prevent Dust Accumulation

Keeping your sewing machine free from lint buildup starts with smart storage.

Protect it from dust and grime with these simple tips:

- Use dust covers or airtight containers.

- Store in a clean, dry location.

- Keep cleaning supplies handy for regular cleaning.

- Avoid storing near vents or windows.

Follow preventative measures to maintain your sewing machine handwheel’s performance.

Frequently Asked Questions (FAQs)

How to fix a sewing machine handwheel?

Start by unplugging your machine, removing debris, and applying sewing machine oil to the handwheel.

Check for tangled thread, replace the needle, make certain the threading is correct, and inspect internal parts.

If it’s still stuck, consult a pro.

Why is my hand wheel not moving the needle?

Your handwheel probably isn’t moving the needle because of thread jams, improper bobbin placement, or a stiff mechanism.

Check for tangles in the bobbin area, clean debris, and lubricate the moving parts for smooth operation.

What is the function of the hand wheel on a sewing machine?

The handwheel on a sewing machine lets you manually control the needle’s movement.

It gives precision for tasks like threading the needle or starting stitches.

It guarantees accuracy when you need a steady, careful touch.

Why is my sewing machine hand wheel stiff but?

A stiff handwheel usually means debris, lack of oil, or jammed threads.

Check for lint buildup, oil critical moving parts, and inspect the bobbin area.

If it’s still tight, professional servicing might be needed.

How do I safely dismantle a handwheel?

Unplug the machine.

Remove the needle and presser foot.

Unscrew the side cover carefully. Loosen the handwheel bolt, slide off the handwheel, and keep track of screws.

Clean and reassemble thoughtfully.

Can a handwheel repair kit fix jams?

Imagine you’re in the middle of a sewing project, and your machine suddenly jams, leaving you stuck.

A handwheel repair kit can help if the issue is mechanical – like gears or debris buildup – but it won’t fix deeper motor or alignment problems.

How do I identify handwheel gear damage?

Look for worn or broken teeth on the gears behind the handwheel.

A clicking sound, uneven movement, or resistance while turning are signs.

Open the machine carefully, inspect gears, and check the user manual.

Are aftermarket handwheels compatible with machines?

Swapping handwheels is like fitting puzzle pieces—some aftermarket options work, but double-check compatibility with your machine’s model.

Mismatched parts can cause headaches, so stick to trusted brands or consult your manual before buying.

What tools are needed to fix a handwheel?

You’ll need screwdrivers, sewing machine oil, a lint brush, tweezers, and possibly pliers.

A flashlight helps spot hidden debris.

For stubborn issues, grab the user manual or call in a pro for assistance.

Conclusion

Fixing a broken sewing machine hand wheel doesn’t have to feel like deciphering hieroglyphics.

Start by checking for simple culprits like lint, thread jams, or a bent needle. Keep your drive belt and moving parts clean and lubricated.

Always treat your machine gently—turn the wheel the right way and follow proper maintenance.

If it’s still stuck, seek professional help before further damage occurs.

Regular care keeps your handwheel running smoothly and your projects frustration-free.

- https://sewyoursoul.com/how-to-fix-a-sewing-machine-handwheel/

- https://sewingtrip.com/sewing-machine-handwheel-problems/

- https://sewingmachinebuffs.com/how-to-fix-sewing-machine-handwheel/

- https://sewing.patternreview.com/SewingDiscussions/topic/123403

- https://leatherworker.net/forum/topic/115700-singer-45w2-lefty-question/