This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

When comparing sewing machine motors, you’ve got to lock in on torque, power, and speed.

When comparing sewing machine motors, you’ve got to lock in on torque, power, and speed.

Brushless servo motors reign supreme, dishing out precision control with minimal friction or need for maintenance.

But don’t sleep on those clutch motors – they bring the lightning-fast hustle, even if they’re a tad noisy.

As for efficiency, brushed motors like shaded pole units waste energy through heat and friction. PSC and GE models save more juice under the hood.

But why stop there? To truly master the motor matchup, you’ll want to dig deeper into the nuanced world of horsepower ratings and construction specs.

Table Of Contents

Key Takeaways

- Buckle up, threading queens! Choosing the right sewing machine motor is a quest filled with horsepower highs and friction lows. But fear not, your trusty motor matchmaker is here to guide you through the labyrinth.

- In the kingdom of sewing motors, brushless servo reigns supreme. These bad boys deliver precision control and minimal maintenance, a true jackpot for the discerning seamstress. But don’t count out the clutch motor hustle – lightning-fast yet a tad rambunctious, they’re the rebel underdogs of the sewing world.

- Efficiency is the name of the game, and brushed motors like shaded pole units are the court jesters, wasting energy through heat and friction. But fear not, for the PSC and GE models are the wise sages, conserving that precious juice under the hood.

- To truly conquer the sewing machine motor matchup, you’ll need to dig deep into the nuanced world of horsepower ratings and construction specs. Only then will you emerge victorious, armed with a motor that dances to the rhythm of your needle and thread.

Types of Sewing Machine Motors

You’re gearing up to choose the right motor for your sewing machine, and it’s essential to understand the different types available. Brushed servo, brushless servo, clutch, and direct drive motors each have distinct characteristics that impact power, efficiency, and overall performance.

Brushed Servo Motors

Brushed servo motors are a closed-loop control system featuring mechanical brushes that create friction, necessitating regular maintenance. While delivering precision, these Sewing machine motors generate heat during operation. As an alternative to brushless servo motors, they offer reliable performance but require more upkeep to counteract brush wear over time.

Brushless Servo Motors

You’ve gotta love brushless servo motors. No pesky brushes means less friction, reduced heat production, and a longer lifespan. These bad boys are the crème de la crème for precision needle positioning and low-maintenance operation. Ditch those archaic brush motors – brushless servos deliver superior control with substantially less upkeep required. Efficiency reigns supreme here!

Clutch Motors

Clutch motors engage and disengage the drive shaft with a clutch mechanism. These simple motors run fast, but they’re noisy and generate heat—not ideal for home machines. While reliable, clutch motors offer limited speed control, making them better suited for basic sewing tasks. Regular maintenance guarantees smooth operation and extends their lifespan.

Direct Drive Motors

With direct drive motors, you get a brushless servo motor directly connected to the drive shaft. This design delivers high torque and efficiency with minimal maintenance and noise. Say goodbye to bulky setups and hello to:

- Compact, sleek profiles

- Longer motor lifespans

- Smooth, consistent performance

Direct drive motors are the top choice for modern sewing machines – powerful yet user-friendly for seamless operation.

Motor Specifications

Now that we’ve delved into the various motor types, let’s delve further into the specifics of motor specifications. You’ll need to take into account factors such as horsepower, voltage, and amperage to identify the ideal motor for your sewing machine projects. Examine this table comparing a typical sewing machine motor with a more robust GE motor:

| Specification | Sewing Machine Motor | GE Motor |

|---|---|---|

| Horsepower | 1/15 HP | 1/20 HP |

| Amperage | 0.9-1 amp | 1.9 amps |

| Voltage | 120V DC | 120V |

| Motor Type | Brushed | Heavier |

While the GE motor may have less power, its robust construction and larger shaft may make it more suitable for specific applications like watchmaker’s lathes. However, for sewing, that lightweight sewing machine motor remains the preferred choice!

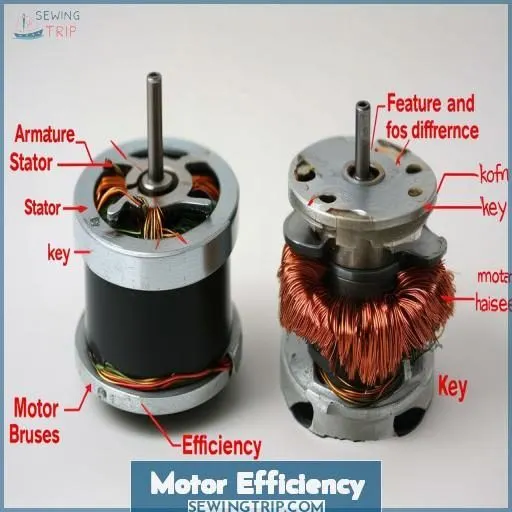

Motor Efficiency

When comparing motors for sewing machines, you’ll find that efficiency decreases as horsepower gets lower – shaded pole motors tend to be less efficient, while PSC motors offer better efficiency. Notably, the GE motor we discussed uses less input power than a typical PSC motor, despite its lower horsepower rating.

Efficiency Decreases at Lower Horsepower Levels

When dealing with lower horsepower motors, you’ll notice a significant drop in efficiency. It’s an inescapable reality, so brace yourself:

- Losses accumulate rapidly at lower power levels

- Friction becomes a dominant factor

- Design compromises are unavoidable

Embrace the challenge of extracting every ounce of performance from these pint-sized powerhouses. With ingenuity and perseverance, you can optimize efficiency despite the inherent limitations.

Shaded Pole Motors Less Efficient

Shaded pole motors aren’t the most efficient choice for sewing machines. They’re brushed motors, meaning mechanical brushes create friction, leading to heat and energy losses. For superior efficiency, you’ll want to evaluate brushless options like servo or direct drive motors. Here’s a quick comparison:

| Motor Type | Brushes | Efficiency | Noise Level |

|---|---|---|---|

| Shaded Pole | Yes | Low | High |

| Servo | No | High | Low |

| Direct Drive | No | High | Low |

Brushless designs minimize friction, heat, and energy waste, making them a more efficient choice.

PSC Motors More Efficient

You’ll find PSC motors have the advantage of greater efficiency over shaded pole designs. These permanent split capacitor motors consume less energy for the same output. So if you prioritize reducing electrical costs and environmental impact, a quality PSC motor makes sense for moderate sewing applications requiring reliable torque levels.

GE Motor Uses Less Input Power Than PSC Motor

While PSC motors are more efficient than shaded pole motors, you’ll find the GE motor actually consumes less input power. Its heavier build and bigger shaft allow it to operate with greater efficiency, reducing energy consumption and costs. If maximizing motor efficiency is your priority, the GE motor’s design gives it a clear advantage.

Frequently Asked Questions (FAQs)

Which motor is best for a sewing machine?

With a smooth motor humming like a well-oiled machine, brushless servo motors reign supreme for sewing – quiet efficiency offers unmatched control and precision.

How many types of sewing machine motors are there?

There are four main types of sewing machine motors: brushed servo, brushless servo, clutch, and direct drive. Each offers unique advantages, like precision control or simple reliability, so you’ll want to choose wisely based on your needs and skill level.

Are sewing machine motors interchangeable?

Ha! You thought upgrading was simple? While some motors are universally compatible, thread carefully – factors like torque, HP, and machine type matter. But hey, with the right guidance, that new motor could be a game-changer for precision sewing.

Is a sewing machine motor universal?

Not quite, sewing machine motors aren’t truly universal. While some can fit multiple brands, you’ll need to match specs like power, voltage, and mountings for seamless compatibility. Swapping casually risks damaging your precious machine, so do your homework first!

How do servo and brushless motors differ in noise levels?

Servo motors run quieter than brushless ones. They’re engineered for smooth, controlled motion, reducing noise from gear vibrations. Brushless motors can whir loudly, especially when operating at high speeds under load.

What factors influence the lifespan of different motor types?

Oh, the irony – longer motor life through less friction! Brushless motors reign supreme with their magnet-powered, brush-free design. Quality construction minimizes wear, prolonging your machine’s lifespan effortlessly.

Which motor type offers the best speed control options?

For precision speed control, brushless servo motors excel. These efficient motors offer smooth, stepless speed adjustment via electronic controls, perfect for mastering intricate stitching techniques with ease.

Are there any safety considerations for different motor types?

Safety first, just like your favorite action movie hero. Brushless motors eliminate sparks from brushes, reducing fire risks. Direct drive‘s simple design minimizes pinch points. Stay sharp with proper guarding for any high-torque motor.

Conclusion

The race for sewing machine dominance is no walk in the park. You’ll need to navigate a winding road of torque, power, and speed when comparing motors.

Mastering motor matchups requires dissecting horsepower ratings, efficiency levels, and construction nuances – the blueprint for choosing a workhorse aligned with your stitching needs.

With motors as diverse as their sewing capabilities, finding your perfect fit guarantees smooth sailing on every project.