This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

To correctly identify sewing machine needles, begin by studying the markings and color coding** on the needle packaging. These show the needle type, size, and suggested fabric usage.

To correctly identify sewing machine needles, begin by studying the markings and color coding** on the needle packaging. These show the needle type, size, and suggested fabric usage.

Most needles conform to standardized European (60-120) or American (8-18) size numbering systems.

Observe the needle visually or with a magnifier for size, point style, and quality. Refer to needle charts to match the appropriate size to your fabric weight and project requirements.

Employing the appropriate, intact needle guarantees good stitch quality and avoids missed stitches or damage.

With this understanding, you’ll be well-prepared to handle any sewing task effectively.

Table Of Contents

- Key Takeaways

- How to Identify Sewing Machine Needles?

- Needle Markings and Labeling

- Needle Compatibility

- Needle Inspection Techniques

- Needle Storage and Organization

- Needle Size Determination

- Needle Anatomy and Features

- Needle Replacement Guidelines

- Needle Brands and Quality

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Needle markings and color coding on packaging indicate needle type, size, and suggested fabric usage

- Observe needle size, point style, and quality visually or with a magnifier, and refer to needle charts to match the appropriate size to your fabric weight and project requirements

- Employ the appropriate, intact needle to guarantee good stitch quality and avoid missed stitches or damage

- Proper needle maintenance and storage in original packaging protects needles and makes it easy to grab the right one for your sewing machine

How to Identify Sewing Machine Needles?

To identify sewing machine needles, look for the size number (e.g. 80/12) and type (e.g. universal, ballpoint) printed on the needle package or the needle itself]. The needle size corresponds to the fabric weight, with higher numbers indicating thicker needles suitable for heavier fabrics.

Needle Markings and Labeling

You’ll encounter color coding on needle packages, indicating compatible fabric types and needle sizes. Needle size numbering systems and manufacturer logos are also displayed, providing crucial information for proper needle selection.

Color Coding on Needle Packages

The color bands on sewing machine needle packages are a handy way to quickly identify needle types and sizes. Look for the top color to indicate the needle type, like yellow for stretch or blue for denim. The bottom color shows the needle size. Keep your needles organized in their original packaging or a dedicated storage system for easy reference.

- Colored bands denote needle type and size

- Match colors to fabric and sewing needs

- Store needles properly to maintain condition

Needle Size Numbering Systems

Sewing machine needles come in a range of sizes, and understanding the numbering systems can help you choose the right one. European needle sizes range from 60 to 120, while American sizes go from 8 to 18. The higher the number, the thicker the needle – perfect for heavier fabrics. Just match the size to your project for smooth, consistent stitches.

Manufacturer Logos and Branding

Sewing machine needles often feature distinct logos and branding from top manufacturers like Singer and Schmetz.

These markings help identify needle type, size, and quality.

Look for color-coded bands on Schmetz needles or the iconic red shank on Singer needles.

Proper storage in original packaging protects needles and makes it easy to grab the right one for your Janome or Juki machine.

Dispose of damaged needles safely to avoid injury.

Start a collection of unique needle designs.

Needle Compatibility

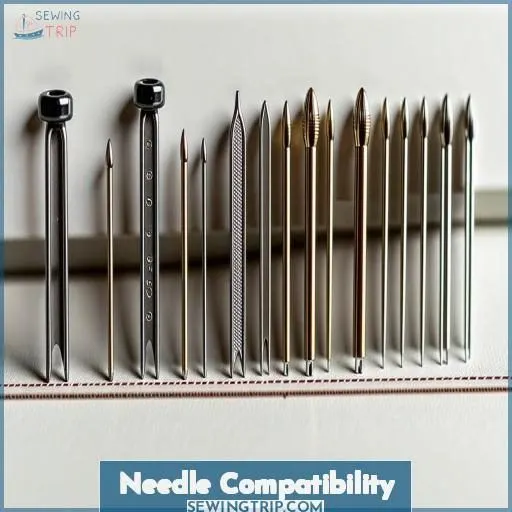

When selecting sewing machine needles, closely observe standardized sizing systems – this guarantees compatibility between the needle and your specific sewing machine. For particular fabrics like knits or leather, you’ll need specialized needles designed to manage their distinct properties without causing damage or skipped stitches.

Standardized Needle Sizing

Sewing machine needles adhere to a standardized sizing system, facilitating the selection of the appropriate needle for your project. European needle sizes extend from 60 to 110, whereas American sizes range from 8 to 18. Consult a needle size comparison chart to align the correct needle thickness with your fabric weight. This standardization guarantees the compatibility of needles across different sewing machine brands.

Matching Needles to Sewing Machines

Regarding sewing machine needles, compatibility is essential. Your machine is engineered to operate smoothly with a specific needle system, usually the 130/705H. Refer to your machine’s manual to determine the appropriate needle type and size. Incorrect needles can result in missed stitches, thread breakage, and potential harm to your machine. Adhere to the recommended needle specifications for optimal functionality.

Specialty Needles for Specific Fabrics

Beyond the standard universal needles, specialty sewing machine needles are engineered to manage specific fabric types and sewing tasks with ease. From denim to leather, quilting to topstitching, there’s a needle designed to maximize your results. Assess your fabric and project requirements, then choose the right specialty needle for the task. Proper needle maintenance is crucial for ensuring the best performance.

| Needle Type | Fabric Compatibility | Advantages |

|---|---|---|

| Denim/Jeans | Denim, heavy fabrics | Prevents missed stitches and needle breakage |

| Leather | Leather, vinyl, faux leather | Sharp point and edges cut cleanly through material |

| Quilting | Multiple fabric layers | Reinforced shaft for piercing thick fabrics |

| Topstitch | Topstitching, decorative stitching | Larger eye and longer scarf for thicker threads |

| Twin/Triple | Parallel rows of stitching | Create multiple rows of stitching in one pass |

Needle Inspection Techniques

To properly identify sewing machine needles, carefully inspect their markings and features using visual examination techniques. Employ magnification tools like jeweler’s loupes or needle sizers to closely examine needle sizes and styles, ensuring you select the appropriate needle for your project.

Visual Examination

Visually examining sewing needles is a great first step. Look closely at the needle’s size, type, and condition. Check for any bends, nicks, or dullness that could affect performance. Inspect the eye, point, and shaft for signs of wear. This hands-on approach helps you identify the right needle for every material and project.

Magnification Tools

If your eyes aren’t what they used to be, magnification tools can be a game-changer for identifying sewing machine needles.

From jeweler’s glasses to thread counters, these non-visual methods make needle identification a breeze.

Pair them with proper storage solutions and needle care, and you’ll always have the right needle for every job.

Download our free printable needles guide for a handy reference.

Needle Sizers and Gauges

If you’re grappling with pinpointing a stray needle, endeavor to utilize a needle sizer or gauge. These convenient contraptions facilitate rapid measurement of the diameter and ascertain the size. Maintain a needle sizer within your sewing kit to effortlessly align needles to your endeavor. It’s an uncomplicated method to guarantee you’re utilizing the appropriate needle consistently.

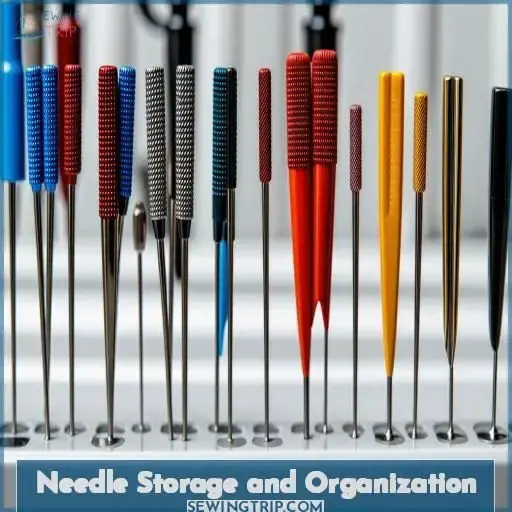

Needle Storage and Organization

Proper needle storage and organization are essential for easy identification and preventing damage. You can store needles in their original packaging, pincushions with compartments, or magnetic strips and cases, ensuring they remain organized and protected.

Original Packaging

Keeping sewing machine needles in their original packaging is the most secure storage option.

The plastic or paper containers safeguard needles from damage and allow for effortless retrieval of specific types such as embroidery, ballpoint, and universal.

Avoid mingling needles to prevent confusion.

Properly storing needles in their original packaging guarantees that they remain in impeccable condition until needed.

Pincushions and Organizers

Pincushions and organizers are a clever way to keep your sewing machine needles neatly stored and easily accessible. Look for pincushions with labeled compartments to sort needles by size and type. Clear storage boxes with dividers allow you to see your entire needle collection at a glance. Magnetic strips let you display color-coded needles for quick identification.

Magnetic Strips and Cases

Magnetic strips and cases offer a sleek, organized way to store your sewing needles.

The magnetic surface keeps sharp points secure, while clear compartments let you easily identify each size and type.

Dritz’s needle case even has a built-in threader and bodkin for traditional craft needles.

This safe, visible storage ensures your twin needles and specialty sharps stay in pristine condition.

Needle Size Determination

When determining the appropriate needle size for your sewing project, consult the fabric weight and thickness guidelines provided by the needle manufacturer or refer to a needle size chart. The needle packaging itself also typically indicates the recommended fabric types and weights for that particular size.

Fabric Weight and Thickness

The weight and thickness of your fabric will determine the ideal needle size. Lighter fabrics like silk or chiffon require smaller needles, like a size 60/8 or 70/10. Heavier fabrics like denim or leather need larger needles, such as 90/14 or 100/16. Check the needle gauge, length, and finish to make sure it’s compatible with your project’s fabric texture and sewing needs.

Needle Size Charts

Consult a handy needle size chart to determine the right sewing machine needle for your project.

These charts provide easy needle size comparisons, letting you convert between European and American sizing.

Use the guide to match needle thickness to your fabric weight – thinner needles for lightweight fabrics, thicker ones for heavy materials.

With the right needle size, your sewing will be smooth and precise.

Packaging Information

The needle package provides key details for size determination.

Look for the European and American numbers, usually 60/8 to 110/18.

Schmetz needles have color bands – the top color indicates the needle type, while the bottom color shows the size.

Storing needles in their original packaging keeps them organized and protected.

Refer to the packaging when selecting the right needle for your project.

Needle Anatomy and Features

When identifying sewing machine needles, pay close attention to the needle point style, as different point shapes are designed for specific fabric types and stitch applications. Additionally, the shaft thickness and eye shape are key anatomical features that impact needle performance and functionality.

Needle Point Styles

The needle point style is essential for sewing success. Here are the main needle tip shapes:

- Sharp points for woven fabrics

- Ball points for knits to avoid skipped stitches

- Cutting points for leather and vinyl

- Wedge points for quilting through multiple layers

Needle point sharpness, thickness, curvature, and durability vary by fabric type. Always use a sharp, undamaged needle for best results.

Shaft Thickness

The shaft thickness, or needle size, is essential for proper fabric penetration. Thicker shafts are used for heavy fabrics like denim, while thinner shafts are suitable for lightweight materials. The shaft length also varies, with longer shafts for thick fabrics and shorter ones for delicate projects. The surface finish and coating type impact needle longevity and performance.

| Shaft Thickness | Fabric Type | Needle Size |

|---|---|---|

| Thin | Lightweight | 60-80 |

| Medium | Medium | 80-100 |

| Thick | Heavy | 100-120 |

Eye Shape and Size

The eye of the sewing machine needle is the small hole at the top where the thread passes through. Its shape and size can impact the needle’s performance. Look for needles with elongated eyes that are wide enough to accommodate thicker threads without fraying. The eye’s position and length also affect how smoothly the thread feeds through.

Needle Replacement Guidelines

When working with sewing machine needles, it’s essential to replace them often and observe for signs of wear and damage. Correct needle installation is also key to guaranteeing smooth stitching and avoiding problems such as skipped stitches, fabric damage, or needle breakage.

Frequency of Replacement

You should replace your sewing machine needles regularly, regardless of fabric type or if they’ve hit a pin. Needles have a limited lifespan and can become damaged over time, affecting stitch quality. Check your needles periodically and replace them every 8-12 hours of use or whenever they show signs of wear. Proper storage also helps extend their lifespan.

Signs of Wear and Damage

Over time, sewing machine needles can become worn and damaged, affecting their performance.

Look for signs like discoloration, dullness, deformation, rust, or a worn groove – these indicate it’s time to replace the needle.

Continuing to use a damaged needle can lead to skipped stitches, thread breakage, and even fabric damage.

Don’t take the risk – swap it out for a fresh, sharp one.

Proper Needle Installation

Correctly inserting your sewing machine needle is essential for fluid, uniform stitching.

Begin by aligning the smooth side of the needle with the needle clamp.

Then carefully push it all the way up until it reaches its limit.

Verify that the needle is firmly in place before threading your machine.

Consult your manufacturer’s instructions for the optimal needle insertion method for your particular model.

Needle Brands and Quality

When considering needle brands and quality, look for reputable manufacturers known for their consistency and reliable performance. Highly regarded brands like Schmetz, Singer, and Organ have built strong reputations by producing high-quality needles that deliver precise stitching and durability.

Top Sewing Needle Manufacturers

In the realm of sewing machine needles, the preeminent brands are renowned for their excellence, uniformity, and ingenuity. Schmetz, Singer, Groz-Beckert, and Dritz stand as industry luminaries, providing a diverse array of needle materials, treatments, packaging, and costs to cater to every sewing endeavor. These needles are readily available, facilitating the effortless selection of the ideal complement for your project.

- Needle materials: Encompassing a spectrum of metals and coatings to ensure durability and efficacy

- Needle finishes: Chrome, titanium, and other treatments for seamless stitching

- Needle packaging: Transparent cases, color-coding, and size labeling for swift identification

- Needle pricing: Spanning from cost-effective to premium choices to accommodate any budget

Reputation and Performance

Regarding sewing machine needles, the brand selection matters significantly. Reputable manufacturers, such as Schmetz, Organ, and Groz-Beckert, are highly esteemed for their needle resilience, longevity, and adaptability. These needles are engineered to work seamlessly with various sewing machines, guaranteeing consistent, trouble-free performance irrespective of the project. Investing in high-quality needles yields returns in the long term.

Needle Consistency and Reliability

Selecting a dependable needle brand guarantees consistent performance and sturdiness. Appropriate needle care, such as storing them securely and replacing worn ones, lengthens their life. Picking the suitable needle for your fabric and machine is crucial. Invest in a high-quality brand like Schmetz or Organ for optimal outcomes. With the right needle, your sewing will be seamless and effortless.

Frequently Asked Questions (FAQs)

Are sewing machine needles marked?

Unravel the enigma with a discerning gaze. You’ll perceive inscribed bands on numerous needles, indicating their magnitude and function – a tangible guide to sewing proficiency.

Do all sewing machine needles fit all machines?

No, you’ll need to make sure your machine’s needle system matches the needles. Most home machines use the 130/705H system, but always consult your manual.

What do the different colors on sewing machine needles mean?

A Time Lord’s sewing adventure! Those colors indicate needle type – red for universal, yellow for stretch, blue for denim. Needle selection empowers fabric potential – choose judiciously for stitching perfection.

What do the numbers mean on sewing machine needles?

The numbers on sewing needles indicate their size—the higher the number, the thicker and more robust the needle for tackling heavier fabrics. Lighter fabrics require lower-numbered, finer needles to prevent damage.

How can I tell if a needle is facing the correct direction?

Can’t tell if the needle’s correctly placed? Look for the flat side – that should be facing front or left. The eye opening also indicates the proper orientation – have you checked that yet?

What do the different colored bands on needles signify?

The colored bands on needles indicate size and type. Consult a needle guide to match the color code to the size and type you need for your fabric.

How do I know if a needle is compatible with my machine?

Consult your machine’s manual for the suggested needle system (e.g., 130/705H). This guarantees compatibility with the needle’s dimensions, type, and shaft that are appropriate for your specific machine model.

Can I reuse a needle after it has been used?

Like a worn-out tire, a dull needle risks shredding fabric. Replace it after every project—your machine and stitches deserve a fresh, sharp point.

What is the difference between industrial and domestic sewing needles?

Industrial needles have thicker, sturdier shafts to tackle heavy fabrics, while domestic needles are thinner and more delicate for lighter materials in home machines.

Conclusion

Mastering the art of discerning sewing machine needles will enhance your sewing proficiency.

With this thorough guide, you’ll confidently choose the appropriate needle for any fabric, guaranteeing impeccable stitch quality.

Attend to the packaging labels, size charts, and visual inspection techniques to match the ideal needle to your endeavor.

Embrace this newfound wisdom, and let your creations illuminate with flawless craftsmanship.