This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

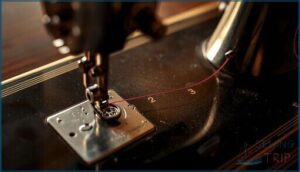

Threading a Singer sewing machine feels impossible until you understand one simple truth: every thread guide matters. Miss a single checkpoint along that numbered path, and you’ll deal with skipped stitches, tangled thread, or a needle that refuses to catch the bobbin.

Seasoned sewers can thread their machines in under thirty seconds because they’ve memorized the exact route from spool pin to needle eye. You’ll gain that same confidence once you learn the precise sequence.

This guide walks you through each preparation step, threading checkpoint, and bobbin setup method so your Singer produces smooth, even stitches on the first try.

Table Of Contents

Key Takeaways

- Missing a single thread guide in the numbered path from spool pin to needle causes skipped stitches and tangled thread, making every checkpoint essential for proper machine function.

- Raising the presser foot before threading releases the tension discs, while turning the needle to its highest point prevents thread breakage during the initial setup sequence.

- Drawing up the bobbin thread requires one complete handwheel rotation with the presser foot lowered so the hook catches the bobbin loop and brings both threads together through the needle plate.

- Replace your sewing needle every four to six hours of continuous sewing or after each project to prevent thread breakage, skipped stitches, and fabric damage from dull or bent needles.

Preparing Your Singer Sewing Machine

Before you thread your Singer sewing machine, you need to set up your workspace properly. A few simple preparation steps will make the threading process smoother and prevent common mistakes.

If you’re new to Singer machines, this guide on how to thread a Singer sewing machine walks you through each step with clear visuals.

Let’s walk through the essential setup tasks that’ll get your machine ready for threading.

Turning Off and Stabilizing The Machine

Before you even think about threading, power safety comes first. Turn your Singer sewing machine to the off position or unplug the power cord completely at the wall switch. This eliminates any risk of accidental starts during setup.

Next, confirm your machine sits on a stable, flat surface. A wobbly workspace leads to uneven stitches and frustration.

- Remove the foot pedal cord to prevent unexpected motor engagement

- Disconnect from power strips to avoid electrical surges

- Allow the motor to stop fully before touching any moving parts

Raising The Presser Foot and Needle

With the machine safely off, lift the presser foot lever to create clearance for threading. This raises the foot several millimeters away from the needle plate and releases the upper thread tension discs.

Next, turn the handwheel toward you until the needle reaches its highest point. Proper needle height adjustment prevents thread breakage and ensures smooth weaving when you begin threading your Singer sewing machine.

Understanding the role of the presser foot lifter is essential for achieving precise and consistent stitching.

Selecting Quality Thread and Bobbin

Choosing the right thread materials and bobbin sizes sets you up for smooth stitching. Use quality fiber blends like polyester or cotton that resist breakage and maintain balanced tension during weaving.

- 40 weight thread works for most general garments and mid-weight fabrics

- Metal or plastic bobbins must match your Singer model exactly to prevent jams

- Color matching your thread to fabric hides seams and delivers professional results

Quality matters when threading your sewing machine.

Using the right thread guide for sewing projects helps you match thread weight and fiber to your fabric for smoother stitching.

Locating Thread Guides and Spool Pin

Once you have your thread and bobbin ready, find the spool pin on top of your machine—usually on the right side.

Most modern Singers show a numbered threading path with small arrows that mark each thread guide from spool to needle. Check if your pin sits horizontal or vertical, then match it to your spool’s winding style for smooth upper thread feeding.

For more details on core threading components and their functions, consult detailed visual guides online.

Winding and Installing The Bobbin

The bobbin is the heart of your machine’s lower thread system, and loading it correctly makes all the difference.

You’ll need to wind it with thread first, then position it properly in the bobbin case. Let’s walk through each step so your stitches come out clean and consistent.

Proper Bobbin Winding Steps

Start at a slow speed to keep your thread from bunching or creating gaps. Guide the thread evenly onto the bobbin in tight, parallel turns, using the bobbin tension disks to maintain firmness.

Stop when the bobbin is nearly full, leaving a small gap at the top. Clip the thread tail cleanly to prevent unraveling during threading and sewing.

Inserting The Bobbin Into The Case

Hold the wound bobbin in your palm with the thread tail trailing to the left. Drop it into the bobbins case pocket so the opening faces outward and the case notch aligns with the machine’s hook housing.

- Push the case until you hear a firm, audible click

- Make certain the bobbin sits level, not tilted

- Check that thread flows smoothly through the tension slit

- Rotate the handwheel to confirm no resistance

Ensuring Correct Bobbin Thread Direction

After you insert the bobbin thread, confirm the thread unwinds counterclockwise when viewed from above. Pull the thread tail gently to the left—this ensures proper case alignment and tension synchrony with your upper threading path.

Wrong bobbin orientation causes loose loops and skipped stitches, so run a stitch quality check on scrap fabric. Correct thread exit direction means clean, balanced seams every time.

Threading The Upper Thread

Threading the upper thread is where most beginners get stuck, but your Singer machine actually makes it easier than you think.

Most models have numbered guides stamped right on the body that show you exactly where the thread should go.

Follow these three key steps to get your upper thread properly seated and ready to sew.

Following The Numbered Threading Path

Most Singer machines feature numbered guides stamped right on the face—your roadmap to smooth stitching. Following the Threading Sequence from spool pin to needle keeps your upper thread from tangling and sets up proper Tension Control for even stitches. Miss one thread guide, and you’ll chase skipped stitches all afternoon.

- Locate each numbered marker on your sewing machine before you begin weaving the thread through

- Pass the thread through every guide in order to maintain correct Thread Alignment and prevent needle breakage

- Inspect each guide for wear or burrs that could snag your thread during Guide Maintenance checks

Using Thread Guides and Tension Discs

Think of thread guides and tension discs as your machine’s steering wheel and gas pedal—they control Thread Alignment and speed as the upper thread travels from spool to needle. Each thread guide bends the path slightly, keeping tension steady while the tension disc grips just tight enough for clean stitches.

Regular Disc Cleaning prevents lint buildup that throws off Tension Adjustment and Stitch Optimization.

Utilizing Built-in Needle Threaders (if Available)

If your Singer sewing machine has a built-in Automatic Needle Threader, you’re in luck—this Threader Mechanism saves time and strain. Before engaging Automatic Threading, raise the presser foot and set the needle to its highest point for proper Needle Alignment.

Guide your thread through the hook, press the lever, and watch Thread Engagement happen instantly. Keep the Needle Threader clean with regular Threader Maintenance to prevent jams and guarantee smooth sewing machine threading every time.

Drawing Up The Bobbin Thread

Now that your upper thread is in place, you need to bring the bobbin thread up to the surface. This step connects both threads so they can work together to create stitches.

Here’s how to draw up the bobbin thread without tangling or missing it.

Lowering The Needle to Catch Bobbin Thread

Precision in needle timing makes the bobbin catch reliable and clean. Turn the handwheel toward you slowly until the needle reaches its lowest travel point, then back up slightly. This motion allows the hook to scoop the bobbin thread into a loop.

Follow these steps:

- Lower the presser foot to engage thread tension

- Hold the upper thread gently but firmly

- Rotate the handwheel through one complete cycle

- Watch for loop formation behind the needle

- Check that needle alignment stays centered throughout

Pulling Both Threads Through The Needle Plate

Once the loop forms, gently pull the upper thread upward to draw the bobbin thread through the needle plate opening. Both threads should emerge cleanly without twists.

Check that needle alignment remains centered and the plate opening is free of lint. Proper thread balance at this stage ensures smooth stitch formation and prevents tension issues during sewing.

Checking Thread Tension and Stitch Readiness

Before you start sewing, you’ll want to make sure both threads are feeding smoothly and creating balanced stitches. Run a test stitch on a scrap piece of fabric that matches what you’ll be sewing. Watch how the bobbin and upper thread weave together—they should lock in the middle of your fabric, not on the top or bottom surface.

If the stitches look loose or puckered, you’ll need a tension adjustment. Turn the tension dial slightly and test again until you get clean, even stitches. Check that the thread guide is holding your thread securely and that neither thread shows signs of breakage.

Fabric compatibility matters too, so adjust your sewing speed and tension based on whether you’re working with lightweight cotton or heavy denim. Your sewing machine performs best when everything’s balanced.

Troubleshooting Common Threading Issues

Even when you follow every step correctly, threading issues can still pop up from time to time.

The good news is that most problems have simple fixes once you know what to look for. Let’s walk through the most common threading troubles and how to solve them quickly.

Identifying Threading Mistakes

When your stitches skip, loop underneath, or tension feels off, you’re likely dealing with threading mistakes. Check if you skipped a thread guide or missed the tension discs—both cause uneven stitch quality and thread breakage.

Good sewing machine troubleshooting starts with reviewing each threading step carefully, and checking for bobbins errors like incorrect thread direction or loose case placement also create tension issues.

Resolving Thread Jams and Breakage

Thread jams often start with a simple fix: turn off your machine, raise the presser foot, and gently remove tangled thread from the bobbin area. Clean out lint with a small brush to restore smooth operation.

If you’re facing repeated thread breakage, switch to high-quality thread and check that your bobbin winds evenly without loose spots or bubbles.

When to Re-Thread or Replace The Needle

Consistency in stitch quality tells you when it’s time to act. Replace your needle if you hear clicking sounds, notice skipped stitches, or see frayed seams—these signal needle wear that causes thread breakage and fabric damage.

After replacing, rethread your sewing machine completely to reset tension and guarantee proper needle threading. This simple habit prevents most stitching problems before they start.

Frequently Asked Questions (FAQs)

What are common threading mistakes?

As they say, measure twice, cut once. Common threading pitfalls include skipping thread guides, incorrect bobbin direction, bent needles, improper tension disc engagement, and loose bobbin winding causing breakage and stitch problems.

How to thread a Singer sewing machine?

Threading a Singer sewing machine involves proper bobbins management and upper threading techniques.

Follow the numbered path on your machine, guiding thread through tension discs and guides for clean, balanced stitches.

How to thread the needle on a Singer sewing machine?

The smallest loop demands the steadiest hand. Guide your Singer’s upper thread down through the last guide, then slip it carefully through the needle eye from front to back.

How do you thread a sewing machine?

Start by raising the presser foot and locating the threading canal.

Follow threading instructions on your sewing machine threading guide to pass thread through each guide and tension disc before reaching the needle.

What is the best thread for sewing workwear?

For heavy duty work garments that face daily wear, spun polyester thread offers the best balance of strength and affordability, while bonded nylon works for extreme abrasion resistance.

How to thread a Singer sewing machine step by step?

Turn off your Singer sewing machine and raise the presser foot.

Wind the bobbin evenly, thread the upper path through guides and tension discs, then draw up the bobbin thread for balanced stitching.

How to thread a sewing machine for beginners?

For beginners, follow your sewing machine threading guide closely, starting with machine maintenance and sewing safety.

Master bobbin management, upper thread threading through the threading canal, and thread types before attempting complex projects.

How do you thread a spool on a Singer sewing machine?

Place your spool on the spool pin so it unwinds smoothly to the right. Secure it with the spool cap, ensuring proper spool alignment.

This prevents tangling and sets up clean upper thread threading through the tension adjustment path.

How to thread a Singer 7256?

Follow the numbered threading path on your Singer 7256 from spool pin through guides and tension discs to the needle, then draw up the bobbin thread for proper needle alignment and thread tension.

How often should I replace my sewing machine needle?

Like rotating your car’s tires, needle sharpness fades with use.

Replace your sewing machine needle after every project or roughly every four to six hours of continuous sewing to prevent thread breakage and fabric damage.

Conclusion

That frustrating tangle of thread and fabric transforms into perfect rows of stitches once you master the numbered path. Every guide, every checkpoint, every bobbin loop plays its role in capturing the rhythm your Singer was built to deliver.

You now know how to thread a Singer sewing machine from spool pin to first stitch. Practice this sequence three times, and your hands will find each checkpoint without hesitation. Your next project starts with confidence, not confusion.

- https://www.singer.com/manuals

- https://manuals.singer.com/Manuals/RetrievePDF/836

- https://shrsl.com/31sj9

- https://www.magnetichoop.com/blogs/news/how-to-thread-a-singer-sewing-machine-step-by-step-visual-guide

- https://www.maggieframes.com/blogs/embroidery-blogs/ultimate-step-by-step-guide-to-threading-singer-sewing-machines