This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

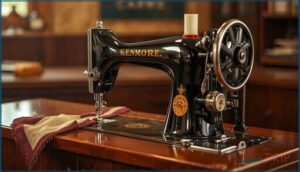

A $6.75 sewing machine sold through a mail-order catalog changed American home sewing forever. When Sears introduced the Kenmore brand in 1913, few could have predicted it would dominate household sewing for nearly a century. Those early four-drawer drop-feed machines weren’t flashy, but they worked—and kept working through Depression-era garment mending, wartime fabric rationing, and the polyester revolution of the 1970s.

Kenmore’s secret wasn’t innovation; it was partnering with manufacturers like White and Janome to deliver reliable machines at prices average families could actually afford. Today, you’ll find these vintage workhorses at estate sales and thrift shops, often still capable of stitching a straight seam.

Understanding Kenmore sewing machines history helps you identify which models are worth rescuing, what makes certain years more valuable than others, and why collectors prize specific features from different manufacturing eras.

Table Of Contents

- Key Takeaways

- Rise of Kenmore Sewing Machines

- Why Kenmore Isn’t Sold Today

- Most Popular Vintage Kenmore Models

- Finding Antique Kenmore Sewing Machines

- Value of Vintage Kenmore Models

- Buying and Using Old Kenmore Machines

- Case Study: 117-959 Model

- Factors in Repair Decision

- Dating a Vintage Kenmore

- Maintaining a Vintage Kenmore

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Kenmore sewing machines dominated American home sewing from 1913 to 2013 by partnering with manufacturers like White, Janome, and Maruzen to deliver reliable machines at accessible prices—starting at just $6.75—rather than through innovation.

- The most collectible vintage Kenmore models are the all-metal 117 series (1940s), 158 series (1960s-1970s), and 385 series (1965-2000s), which typically sell for $50-$200 but can reach $700 for desirable units in excellent condition.

- Sears’ 2018 bankruptcy and the termination of manufacturing partnerships—especially ending the Janome contract in 2013—permanently stopped Kenmore sewing machine production after a century of continuous availability.

- You can date your vintage Kenmore by its model prefix (117, 158, or 385) and should prioritize all-metal construction from the 1960s-1970s when shopping, since these machines offer superior durability and can last 25-30 years with proper maintenance costing just $50-$200 annually.

Rise of Kenmore Sewing Machines

When Sears launched its first Kenmore sewing machine in 1913, you witnessed the birth of an American manufacturing icon that would reshape home sewing for generations. That initial four-drawer drop-feed model sold for just $6.75—roughly $180 in today’s money—making quality sewing accessible to everyday families across the nation.

Sears launched the Kenmore sewing machine in 1913 for $6.75, making quality home sewing accessible to everyday American families

The Kenmore sewing machine history really took off during the 1930s and exploded after World War II, when Sears’ strategy centered on smart manufacturing partnerships with companies like White, Janome, and Soryu. This approach created early innovations that rivaled Singer’s offerings while maintaining lower price points, giving Kenmore significant market dominance.

By the 1960s, brand recognition had grown so strong that Sears offered more than 100 distinct models, from basic mechanicals to feature-packed machines with decorative-stitch capabilities. During this period, many Kenmore machines were supplied by Maruzen. Through catalog sales and expanding department stores, these production expansion efforts positioned Kenmore as the second-largest sewing machine supplier in North America—a demonstration of American manufacturing history at its finest.

Why Kenmore Isn’t Sold Today

If you’ve searched online for a new Kenmore sewing machine lately, you’ve probably noticed they’re nowhere to be found. The disappearance wasn’t gradual—it happened relatively quickly after a century of production.

Two major events brought Kenmore sewing machines to a complete stop: Sears’ financial collapse and the end of long-standing manufacturing agreements.

Sears Bankruptcy

When a retail giant crumbles, the brands it carried often fall with it. That’s exactly what happened when the Sears bankruptcy filing hit in October 2018, exposing $11.3 billion in liabilities and forcing asset liquidation across the board. The Sears department store shrank from over 3,500 locations to fewer than 700 practically overnight, decimating the distribution network that had kept Sears Kenmore machines in American homes for generations.

Financial impact rippled through every corner of the business, from the once-mighty Sears catalog to restructuring efforts that ultimately couldn’t save the brand’s manufacturing partnerships. The company’s downfall can be attributed to increased competition, especially from Walmart and Amazon.

End of Manufacturing Partnerships

Behind the bankruptcy headlines, a quieter collapse was unfolding. Sears terminated its Janome contract in 2013, ending production relationships that stretched back decades—White from 1933 to 1958, Soryu through 1977, and Janome’s dominant run until the final shutdown.

Contract terminations severed overseas manufacturing pipelines that had sustained the brand, transforming Kenmore sewing machines from retail fixtures into sought-after relics of American home craftsmanship.

Most Popular Vintage Kenmore Models

When collectors talk about vintage Kenmore machines worth hunting down, three model series come up again and again. Each one represents a different era of manufacturing and brings its own strengths to the table.

Let’s look at what makes the 117, 158, and 385 series stand out from the crowd.

Kenmore 117

When you think of workhorses from the 1940s, the Kenmore 117 series deserves your attention—these vintage sewing machines represent some of White Manufacturing’s finest rotary mechanism designs. Produced under Sears’ contract from the late 1930s into the early 1950s, your Kenmore 117 likely features that distinctive dark brown crinkle finish that collectors instantly recognize.

Models like the heavy-duty 117.959 weren’t just pretty faces; they could tackle everything from delicate garments to leather upholstery without breaking a sweat. With all-metal construction and that unique rubber wheel pulley drive, these Kenmore model variations exemplify an era when Kenmore sewing machine history was built on durability, not disposability.

Kenmore 158

Your hands-on experience with the Kenmore 158 series will reveal why collectors call these Maruzen Manufacturing-built machines “top shelf” among vintage Kenmore sewing machines. These all-metal construction powerhouses from the 1960s–1970s deliver heavy-duty usage capabilities that plastic-laden modern machines can’t match:

- 1.0-amp motors provide outstanding torque for denim and canvas

- Dual-belt drive systems eliminate frustrating slippage mid-project

- Cam compatibility expands your stitch library through interchangeable discs

- Class 15 bobbin systems guarantee you’ll find parts decades later

- Low-shank design accepts standard Singer-style presser feet

Model identification starts with that “158” prefix—your gateway to understanding Kenmore sewing machine models that genuinely earn their “workhorse” reputation.

Kenmore 385

When you discover a Kenmore 385 sewing machine, you’re holding a Janome Manufacturing achievement that debuted in 1965 and evolved through the 2000s. Early Japan-made models deliver dependable motor performance with 0.6-amp engines, while later Taiwan-assembled variants earned 25-year warranties.

Stitch capabilities range from 10-pattern mechanical dials to computerized systems offering 951 functions. Parts availability remains strong—just reference your full model number (385.xxxxxx) since designs changed across decades.

Dating machines requires examining both the 385 prefix and country-of-origin markings, helping you pinpoint whether your vintage Kenmore sewing machine hails from the ’70s or ’90s.

Finding Antique Kenmore Sewing Machines

Where can you track down antique Kenmore sewing machines today? Thrift store finds remain your best bet—Goodwill alone operates over 3,300 locations across North America, regularly rotating sewing machines through their inventory.

Online marketplace tips point you toward eBay, where hundreds of Kenmore models generally list between $50 and $300. Estate sale hunting yields functioning machines often priced under $150. Specialty dealers offer reconditioned units around $100 with warranties.

Community recommendations consistently highlight ShopGoodwill.com and local classified ads. Identifying Kenmore models through their prefix numbers (117, 158, 385) helps you target specific eras in the history of Kenmore sewing machines.

Value of Vintage Kenmore Models

You’ve found a vintage Kenmore tucked in a garage sale—but what’s it actually worth? The value of vintage Kenmore models hinges on several condition factors working together. Most mid-century Kenmore sewing machines sell between $50 and $200 through typical market channels, though desirable 1950s–1970s units (especially the 158 and 385 series) can reach $175 to $700.

Price benchmarks depend on:

- Working condition – functional mechanics versus cosmetic pieces

- Completeness – original accessories, manuals, and foot pedals

- Model rarity – limited-run designs command premiums

- Era influence – pre-1980 machines attract higher vintage sewing machine value

- Cabinet quality – original furniture adds $100–$400

Mint-condition Kenmore sewing machine value occasionally exceeds $1,000 at specialized auctions, but that’s the exception rather than the rule in today’s resale market.

Buying and Using Old Kenmore Machines

So you’ve found a vintage Kenmore and you’re ready to bring it home—what now? These machines can run for decades if you treat them right, but they do need some basic care and attention.

Here’s what you should know about keeping your old Kenmore in working order and what features are actually worth seeking out.

Maintenance Tips

Your vintage Kenmore deserves more than wishful thinking—it needs a maintenance rhythm that honors its century-long engineering legacy.

Needle replacement every 6 to 8 hours of sewing is essential; this low-cost swap prevents skipped stitches and protects delicate internal timing.

Lint management demands attention too—skip the canned air, which drives debris deeper and invites moisture corrosion. Instead, manually clean the hook race and feed dogs after every project.

Lubrication needs are straightforward: apply sewing-machine oil to moving parts, especially after storage. Control storage conditions by avoiding humidity swings that rust metal components.

When troubleshooting Kenmore sewing machines exceeds your comfort level, professional servicing options preserve both function and historical value.

Features to Look For

When you’re sizing up a vintage Kenmore sewing machine, mechanical condition tells the story. Turn the handwheel by hand and feel for smooth, grind-free rotation.

Electrical components matter too: inspect cords, test the foot pedal’s variable speed control, and confirm the motor starts without hesitation.

Stitch quality separates the gems from the clunkers. Run test stitches at multiple lengths to catch skipped stitches or tension issues.

Build quality shines in all-metal gear trains (common on 1960s–1980s Kenmore models) and Class 15 bobbin compatibility.

Case Study: 117-959 Model

Let’s talk about one machine that captures everything great about post-war Kenmore sewing machines—the 117-959. White manufactured this rotary mechanism beauty in 1948, and it’s become something of a legend among collectors who know their stuff.

What makes the 117-959 special? You’ll notice it right away when you fire it up. That distinctive “growl” comes from its friction-wheel motor driving the balance wheel—it’s the sound profile that tells you you’re working with authentic White craftsmanship. Here’s what sets this Kenmore model apart:

- All-metal construction that’s built to outlast modern plastic alternatives

- Rotary hook design delivering powerful, consistent stitches on heavier fabrics

- Side-loading bobbin case that’s simple to thread and maintain

- Cabinet integration with mid-century furniture styling that looks great in any sewing room

The presser foot system uses an older two-pronged attachment, so you won’t snap on modern low-shank feet without adapters. Still, if you’re hunting for a vintage sewing machine that represents Kenmore sewing machine models at their finest, the 117-959 delivers.

Factors in Repair Decision

Deciding whether to repair a vintage Kenmore isn’t always straightforward. You’ll want to weigh a few key factors before you commit time and money to restoration.

Let’s break down the main considerations that’ll help you make a smart choice.

Repair Cost Analysis

How much should you budget when your vintage Kenmore needs professional attention? Repair costs usually land between $75 and $180 for most domestic machines, though vintage models often push toward the higher end due to specialized labor. Regional price variations can affect quotes considerably—metropolitan shops charge more than rural technicians.

The real trick in troubleshooting is understanding repair cost factors before you commit. You’ll face part sourcing challenges with discontinued Kenmore parts, sometimes adding weeks and dollars to your bill.

DIY vs. professional becomes your central decision point: simple cleaning and oiling you can handle yourself, but timing issues or frozen mechanisms demand expert hands. When repairing vintage sewing machines, apply the 75-percent rule—if repair costs exceed three-quarters of your machine’s current value, replacement makes better financial sense. Smart factors in repair decision-making keep your hobby sustainable.

Machine Quality Assessment

Once you’ve weighed repair costs, your next step is checking what you’re actually working with. Machine quality assessment separates the true workhorses from the clunkers. Here’s what to examine:

- Material Composition – All-metal gears and aluminum frames from the 1960s–1970s mean decades of reliable service ahead.

- Gear Durability – Japanese-made models retained steel internals when competitors switched to plastic, dodging common failure points.

- Stitch Consistency – Test zigzag and straight stitches across multiple fabric weights to verify feed-dog strength.

- Motor Performance – Listen for smooth acceleration; vintage 1-amp motors hit 1,100+ stitches per minute without strain.

- Longevity Factors – Machines showing 40+ years of use with original metal parts construction prove their vintage craftsmanship worth preserving.

Maintenance Impact Evaluation

After gauging your machine’s build quality, you’ll want to factor in how maintenance shapes repair decisions. Proper servicing frequency—every 6 to 12 months for heavy users, 12 to 24 months for occasional sewers—can stretch a Kenmore’s life 25 to 30 years.

Lubrication effects are dramatic: oiled gears resist wear and deliver smoother stitches. Cleaning protocols prevent lint buildup that causes jams and costly breakdowns.

The economic impact? Scheduled maintenance runs $50 to $200, while deferred care leads to $75-plus repairs. Repairing vintage sewing machines makes financial sense when you commit to consistent upkeep.

Dating a Vintage Kenmore

How exactly do you pinpoint when your Kenmore rolled off the assembly line? Dating a vintage Kenmore starts with hunting down its model number—usually stamped on the machine’s base or tucked behind the faceplate. That three-digit prefix tells you everything: 117 models hail from the 1940s–1950s White Manufacturing era, 158 machines dominated the 1960s–1970s Japanese production years, and 385 units mark the late-1970s through 1990s Taiwanese chapter of Kenmore sewing machine history.

Your serial number lookup adds precision. Post-1960 Kenmore model numbers encode manufacturer and feature details, while the separate serial plate helps narrow production to specific years through parts documentation. For a visual dating guide, check whether your machine sports all-metal construction (earlier eras) or plastic trim (1980s onward).

Catalog cross-reference seals the deal—Sears “wishbook” archives let you match your model to exact catalog years. These manufacturer era codes aren’t just numbers; they’re timestamps connecting you to a century of American home sewing evolution.

Maintaining a Vintage Kenmore

Once you’ve dated your vintage Kenmore, regular maintenance keeps it stitching for decades. Oiling techniques matter—drop 1–2 points of sewing machine oil on the needle bar and take-up lever every six months.

Lint removal is equally important: brush the bobbin case and feed dogs after every 8–10 hours to prevent skipped stitches. Check needle compatibility by matching size to fabric, swapping needles every major project.

Electrical safety demands inspecting cords for cracks before each use. Storage solutions like fitted covers shield metal parts from dust and humidity, ensuring your vintage Kenmore machine stays ready for the next repair or restoration challenge.

Frequently Asked Questions (FAQs)

When did Kenmore stop making sewing machines?

Right around the early 2000s, Janome production ended, marking when Kenmore stopped making new sewing machines—well before Sears’ 2018 bankruptcy sealed the brand’s shift away from manufacturing partnerships with Japanese manufacturers altogether.

How can I tell how old my sewing machine is?

Your Kenmore’s model number and serial number hold the key. Look for the identification plate on the machine’s front base—those prefixes like 117, 158, or 385 reveal manufacturer codes and production date ranges instantly.

How old are Kenmore sewing machines?

You’ll date your vintage Kenmore sewing machine using its model number and catalog records. These antique sewing machines span 1913 to 2013, with serial number dating revealing machine age tiers across the 117, 158, and 385 model series ages.

Who made Kenmore sewing machines in 1977?

If you owned a 158 series Kenmore in 1977, Maruzen Manufacturing built it in Japan—not Janome.

These all-metal workhorses represented Japanese OEMs’ manufacturing prowess before plastic components reshaped sewing machine production scope forever.

When was a Kenmore sewing machine made?

You can trace your machine’s manufacturing timeline through its model number guide and serial number lookup, which reveal production era details spanning 1913 to 2013 across partnerships with White, Singer, and Janome manufacturers.

Should you buy a vintage Kenmore sewing machine?

If you’re working with budgets under $200 and need a beginner-suitability workhorse for straightforward project needs, buying a vintage Kenmore machine offers cost effectiveness.

Provided you account for repair feasibility and feature limitations compared to computerized models.

What is the oldest Kenmore sewing machine?

The oldest Kenmore sewing machine debuted in Sears’ Fall 1913 catalog—a treadle-powered, four-drawer drop-feed model priced at $ This marked the brand’s historic entry into home sewing before disappearing from catalogs in

Did singer make a Kenmore sewing machine?

Did Singer make a Kenmore? Yes, though Singer’s role in Kenmore sewing machine manufacturing was limited compared to White and Janome.

Singer briefly crafted select Kenmore models during the 1970s, adding diversity to Sears’ brand collaboration strategy.

Does Sears make Kenmore sewing machines?

No, Sears never manufactured Kenmore sewing machines—they contracted partners like White, Janome, and Juki. After bankruptcy in 2018, Transformco now licenses the Kenmore brand, with production handled by external manufacturers.

Who made old Kenmore sewing machines?

From gleaming factory floors to your grandmother’s sewing room, Kenmore sewing machines carried a fascinating secret. White Sewing Machine Company dominated the White era through 1958, before Japanese sourcing shifted production to Soryu, Maruzen, and ultimately Janome—each manufacturer leaving distinct fingerprints on Kenmore brand history that help you identify makers today.

Conclusion

Picture a 1960s Kenmore humming under a basement bulb, still stitching buttonholes after sixty years—that’s the legacy you’re buying into. These machines weren’t built to impress; they were built to last. That’s exactly why they’re still worth your attention today.

Understanding Kenmore sewing machines history transforms thrift-shop hunting into treasure hunting. You’ll spot the difference between a disposable plastic model and a metal workhorse worth restoring.

- https://en.wikipedia.org/wiki/Kenmore_(brand)

- https://pungolivinghome.com/home-2/our-collection-2/kenmore/

- http://www.ashleyandthenoisemakers.com/kenmore-machines

- https://www.facebook.com/groups/291023511046957/posts/1146688652147101/

- http://steelsewing.blogspot.com/2018/05/1950s-kenmore-sewing-machines.html