This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your embroidery machine‘s needle might be the smallest component in your setup, but it’s pulling off the hardest job—punching through fabric thousands of times per minute while protecting delicate thread from friction, heat, and tension spikes.

Most embroiderers blame their thread or stabilizer when stitches start skipping or designs pucker, but nine times out of ten, the needle’s the culprit. The difference between a universal needle and a proper embroidery needle isn’t just marketing hype—it’s engineered precision that shows up in every stitch.

From Schmetz’s gold-plated workhorses to titanium-coated options that laugh at dense canvas, the right needle transforms frustrating projects into smooth runs.

Table Of Contents

Key Takeaways

- The difference between universal and embroidery needles isn’t marketing—embroidery needles feature larger eyes and specialized scarfs that prevent thread shredding and skipped stitches during high-speed, dense designs.

- Needle size numbers (like 75/11) decode instantly: the first digit shows metric diameter in hundredths of a millimeter, the second reflects American sizing, and matching this to your thread weight and fabric thickness eliminates 90% of stitching problems.

- Titanium and gold coatings aren’t just fancy finishes—they reduce friction by up to 40%, extend needle life significantly, and keep metallic or specialty threads from fraying during demanding projects.

- Swap your needles every 8-12 hours of stitching or immediately when you spot thread breaks and skipped stitches, because a dull needle will wreck your fabric and compromise stitch quality long before it visibly breaks.

Best Machine Embroidery Needles Reviewed

You’ve got plenty of needle brands to choose from, but not all of them deliver the same performance when you’re running high-speed embroidery projects.

I’ve tested the most popular options on everything from delicate knits to dense woven fabrics, so you know what actually works.

Here’s what you need to know about the top machine embroidery needles on the market right now.

The Janome JW8100 pairs perfectly with these needles thanks to its consistent tension control and smooth fabric handling.

1. Schmetz Embroidery Sewing Machine Needles

Schmetz quality stands out with their standard embroidery needles, engineered with a larger eye and specially contoured groove that accommodates specialty threads without snagging. You’ll find these needles in the 130/705H system, ensuring machine compatibility across most domestic machines.

For home sewers ready to pair these needles with a capable machine, the top-rated home sewing machines offer embroidery-ready features that handle specialty threads beautifully.

The 90/14 size manages medium-weight fabrics beautifully, while the widened groove reduces friction during dense embroidery runs.

Pairing it with the right thread weight is essential—our universal needle buying guide breaks down which sizes match your fabric and project type.

When you’re planning your thread selection, pair these with 40-weight rayon or polyester for best results. Their needle durability makes them a solid choice for multi-hour projects, though you’ll want to swap them every 8-10 hours of stitching.

| Best For | Home sewers tackling embroidery and decorative stitching who need reliable needles that handle specialty threads without constant breakage or skipped stitches. |

|---|---|

| Needle Size | 90/14 |

| Point Type | Medium Ball Point |

| Eye Design | Enlarged Eye |

| Brand | SCHMETZ |

| Pack Quantity | 25 |

| Machine Compatibility | All Home Machines |

| Additional Features |

|

- Larger eye and widened groove design reduces thread friction and shredding, especially with rayon and polyester embroidery threads

- Compatible with all domestic sewing machines using the standard 130/705H system, so no guesswork on fit

- 90/14 size works across a wide fabric range from silk to denim, making them versatile for different projects

- Not designed for industrial or heavy-duty machines, limiting use to home sewing setups

- Only available in 90/14 size in this pack, so you’ll need different needles for very lightweight or extra-heavy fabrics

- Need replacement every 8-10 hours of stitching, which can add up on cost for frequent embroiderers

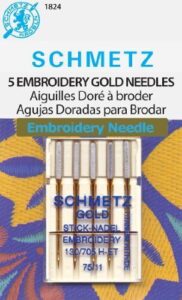

2. Schmetz Gold Embroidery Sewing Machine Needles

Upgrading to gold-coated needles takes your embroidery speed and needle durability to another level. Schmetz Gold embroidery needles feature a titanium nitride finish that glides through dense fabric with minimal friction—think of it as the non-stick pan of machine embroidery needles.

Gold needles are a game-changer for high-volume projects, and pairing them with the right embroidery machine needles for your fabric type ensures consistent stitch quality from start to finish.

The 75/11 size works brilliantly across woven and specialty fabrics, preventing thread fraying even with metallic or delicate threads. You’ll appreciate the machine compatibility across major home brands and the slightly rounded point that penetrates cleanly.

This needle selection guide choice extends needle life markedly under high-speed conditions, making frequent swaps less of a headache.

| Best For | Embroiderers working with metallic or specialty threads on dense fabrics who want to reduce needle changes and maintain smooth, professional stitching at higher speeds. |

|---|---|

| Needle Size | 75/11 |

| Point Type | Slightly Rounded Point |

| Eye Design | Enlarged Eye |

| Brand | SCHMETZ |

| Pack Quantity | 5 |

| Machine Compatibility | All Major Brands |

| Additional Features |

|

- Titanium nitride coating significantly reduces friction and extends needle life, especially during high-speed embroidery projects

- Enlarged eye and rounded point prevent thread fraying and fabric snagging, making it ideal for delicate metallic threads

- Universal compatibility with all major home embroidery machine brands means no guesswork about fit

- Higher price point compared to standard embroidery needles may add up if you go through multiple packs

- Packaging issues reported by some users, with needles occasionally arriving loose or damaged in transit

- Requires careful reading of product details to ensure you’re ordering the right size and type for your specific project

3. Xliuax Sewing Machine Needles

Looking for budget-friendly machine embroidery needles that still deliver? The Xliuax 90/14 pack gives you 80 high-speed steel needles—perfect for denim, leather, and canvas projects.

Sewing machine compatibility spans most home models, though you’ll want to verify fit before heavy use. Xliuax needle quality manages dense embroidery layers with sharp point needles designed for woven fabrics, but skip these for delicate silks.

A detailed sewing machine needle types chart breaks down blade diameter, groove width, and eye geometry to help you match needle construction with fabric weight and thread thickness.

Needle durability tests show solid performance on moderate-speed runs. While embroidery thread types like metallic may challenge these needles, they’re unbeatable for everyday stitch work when you’re testing designs or building skills.

| Best For | Sewers who tackle heavy-duty projects like denim or canvas on a budget and need a large supply of reliable needles for everyday embroidery and garment work. |

|---|---|

| Needle Size | 90/14 |

| Point Type | Universal Point |

| Eye Design | Standard Eye |

| Brand | Generic |

| Pack Quantity | 80 |

| Machine Compatibility | Most Home Machines |

| Additional Features |

|

- Value pack of 80 needles gives you plenty of backups for long-term projects without constant reordering

- High-speed steel construction handles tough fabrics like leather and denim with consistent piercing power

- Universal fit works with most home sewing machines, making them accessible for beginners and hobbyists

- Not ideal for delicate or thin fabrics—these are built for heavier materials, so silk and chiffon projects need different needles

- Compatibility isn’t guaranteed across all machine models, so you’ll want to double-check your manual before stocking up

- No warranty information provided, which means you’re taking a small risk on quality consistency across the full 80-needle set

4. Brother Embroidery Machine Needles

Brother-branded needles pair perfectly with your PR machines and most single-needle combos. This 100-piece set delivers 75/11 all-purpose needles, your workhorse for standard embroidery thread types and medium-weight fabrics. Brother needle quality shines in fabric piercing consistency, though you’ll swap them every 6,000 stitches or when thread breaks appear.

Sewing machine compatibility extends across PE770 and LS2125i models, but verify your embroidery machine specs first. Needle selection here prioritizes reliability over specialty coatings, making needle replacement economical when you’re cranking out volume projects.

| Best For | Embroiderers running high-volume projects on Brother machines who need an affordable stock of reliable 75/11 needles for everyday fabric weights. |

|---|---|

| Needle Size | 90/14 |

| Point Type | Medium Ball Point |

| Eye Design | Enlarged Eye |

| Brand | SCHMETZ |

| Pack Quantity | 5 |

| Machine Compatibility | All Major Brands |

| Additional Features |

|

- 100-needle bulk pack keeps you covered for months of regular embroidery work without constant reordering

- Brother-branded quality ensures proper fit and alignment with PE770, LS2125i, and similar machine models

- 75/11 all-purpose size handles most standard embroidery threads and medium-weight fabrics reliably

- Needles may need replacement around 6,000 stitches, requiring more frequent swaps for heavy users

- Some customers report inconsistent durability with occasional needles breaking or bending prematurely

- Compatibility limited to specific Brother models, so you’ll need to verify your machine before purchasing

5. Organ Embroidery Machine Needles

Precision stitching demands Organ Needles—this 20-piece set splits evenly between 75/11 and 90/14 sizes, covering light-to-medium fabrics and heavier embroidery work. That oversized eye manages metallic threads without shredding, while the chisel point geometry improves machine compatibility across Bernina, Brother, and similar embroidery machines.

Needle durability here sits in the budget-friendly zone, so swap them after dense projects. Pro Tip: Match the 90/14 size to 40-weight thread for smoother embroidery needle selection and fewer mid-project headaches.

| Best For | Hobbyists and home embroiderers who need affordable, reliable needles for decorative stitching with standard and metallic threads across various fabric weights. |

|---|---|

| Needle Size | 75/11 |

| Point Type | Ball Point |

| Eye Design | Standard Eye |

| Brand | Organ/Brother |

| Pack Quantity | 100 |

| Machine Compatibility | Brother Models |

| Additional Features |

|

- Large eye design handles metallic and specialty embroidery threads without shredding or breaking during high-speed stitching

- Two versatile sizes (75/11 and 90/14) cover most common embroidery projects from lightweight to medium-heavy fabrics

- Compatible with multiple domestic sewing machine brands including Bernina and Brother, making them a flexible choice for mixed machine households

- Budget-tier quality means you’ll need to replace needles more frequently than premium options, especially after dense or high-volume projects

- 20-piece count may run out quickly for serious embroiderers who work on multiple large projects

- May require trial and adjustment for specific machine-fabric-thread combinations since they’re general-purpose rather than specialized needles

Types of Machine Embroidery Needles

Your embroidery machine doesn’t care about your creative vision if you’re using the wrong needle type. Each needle design fulfills a specific purpose—from the point shape that interacts with your fabric to specialized coatings that extend tool life on high-speed machines.

Let’s break down the four main categories you’ll encounter so you can match the right needle to every project.

Universal Vs. Embroidery Needles

Here’s the thing: universal needles won’t ruin your project, but they’ll compromise stitch quality and thread tension on dense designs.

Embroidery needles feature a larger eye and specialized scarf that reduce friction and skipped stitches—key for fabric compatibility across knits and wovens. Needle flexibility differs too; machine embroidery needles handle high-speed stitching better, improving needle durability.

Smart needle selection between needle types directly impacts your finished work. Understanding language patterns can also improve your embroidery design skills.

Sharp Point Needles

Sharp point needles slice cleanly through woven fabrics like cotton and denim without snagging threads. Their slim, tapered point geometry creates precise stitch formation on tightly woven materials.

Brands like Schmetz and Organ use nickel-plated steel for breakage prevention and durability. You’ll want these for canvas, poplin, or layered work—they’re your go-to when fabric compatibility demands clean penetration rather than fiber separation.

Ballpoint Needles

Ballpoint tips glide between knit fibers instead of cutting them—think of it as maneuvering through a maze rather than bulldozing through walls. That rounded geometry boosts needle durability on jersey and stretch blends, preventing snags and maintaining fabric interaction integrity.

You’ll notice improved thread flow and embroidery precision compared to sharp point needles, making ballpoint needles essential for elastic materials in machine embroidery needle selection.

Specialty and Titanium-Coated Needles

When you’re tackling metallic embroidery or high-sheen specialty threads, titanium coatings become your friction-fighting ally. These coated needle tips reduce heat buildup and boost needle durability during dense, elaborate designs. Gold-plated or titanium-nitride finishes claim smoother thread passage than standard sharp needles or ballpoint needles.

You’ll pay more upfront, but titanium needles resist wear and minimize thread fray, making them worth every penny for reflective yarn work.

Machine Embroidery Needle Sizes and Selection

Picking the right needle size isn’t guesswork—it’s a precise match between your thread weight, fabric type, and the finish you’re after. Those cryptic numbers stamped on every needle actually tell you exactly what diameter you’re working with, and knowing how to decode them changes everything.

Here’s what you need to understand to nail your needle selection every time.

Understanding Needle Size Numbers (e.g., 75/11)

Ever wonder why needle packaging lists two numbers side by side? That dual format—like 75/11 or 80/12—decodes Machine Embroidery Needles sizing instantly. The first digit represents Metric Conversions (needle diameter in hundredths of a millimeter), while the second reflects American sizing. Needle Size Charts and Needle Types clarify this split system, ensuring your needle selection aligns with Fabric Thickness and Thread Compatibility for impeccable stitching. Understanding scientific study summaries is essential for methodological rigor in various fields.

- 75/11: Standard all-purpose size for medium-weight fabrics

- 60/8: Ultra-fine for delicate silks and lightweight materials

- 80/12: Heavier option for denser weaves and thicker threads

- Needle Diameter: European number (75 = 0.75mm thickness)

- Needle Chart: Quick reference tool matching size to fabric weight

Matching Needle Size to Thread Weight

Once you’ve decoded needle sizing, pair it with Thread Weight for peak Embroidery Optimization. Heavier 40 wt threads demand 80/12 or 90/14 needles to prevent fraying, while lighter 60 wt threads thrive with 60/8 to 75/11 sizes.

Mismatch these, and you’ll face skipped stitches or fabric puckering—clear signs your Needle Calibration is off. Check your Needle Chart, test on scrap fabric, and watch Stitch Quality soar.

Choosing Needle Size for Fabric Types

Beyond thread weight, Fabric Density drives your needle size choice.

Lightweight cottons sing with 75/11 Sharp Needles, maintaining ideal Thread Tension and Stitch Formation. Medium fabrics? Bump to 80/12. Heavy canvas or denim demand 90/14 to 100/16—anything smaller causes Needle Flex and skipped stitches.

Test Material Compatibility on scraps first; proper fabric selection prevents heartache mid-project.

Key Features of Embroidery Needles

Not all embroidery needles are built the same—and the differences matter more than you’d think. The eye, scarf, coating, and tip shape all work together to determine whether you’ll get perfect stitches or a tangled mess.

Let’s break down the four key features that separate high-performance needles from the ones that’ll make you want to throw your hoop across the room.

Needle Eye and Groove Design

The eye and groove work like a highway system for your thread—get them right, and you’ll see perfect stitches every time. Here’s what makes this design critical:

- Eye Geometry creates 0.2–0.3 mm clearance around your embroidery threads, preventing friction that causes breaks during high-speed runs

- Groove Optimization guides thread smoothly from needle to fabric, minimizing heat buildup and maintaining consistent thread flow across woven and knit materials

- Fabric Interaction depends on properly matched groove depth—shallow grooves suit delicate fabrics, while deeper channels accommodate heavier threads without snagging

Sharp needles and universal needles feature different eye configurations, so matching needle size to your thread weight isn’t optional.

Regular needle maintenance means inspecting for burrs or groove wear that compromise stitch quality.

Needle Scarf and Its Importance

That groove matters, but the scarf is where your needle geometry really proves itself. This tiny indentation on the back of embroidery needles guides fabric interaction during each puncture, controlling thread tension and preventing skipped stitches.

Sharp point and universal point needles use different scarf designs—match your needle size to fabric type, and check during needle maintenance for wear that kills stitch quality.

Coatings and Finishes (e.g., Titanium, Gold)

Coatings upgrade your embroidery needles from workhorses to marathon runners. Titanium benefits show up fast on dense fabrics—up to 40% longer lifespan and smoother penetration on synthetics. Gold finishes often signal premium manufacturing tolerances, while thermal performance improvements keep thread integrity intact during high-speed runs.

Coating types worth your attention:

- Titanium or titanium-nitride – Reduces friction and heat buildup; pairs beautifully with polyester and rayon threads

- Gold-colored treatments – May indicate tighter tolerances; verify actual performance claims versus decorative marketing

- Hard-wear surfaces – Lower fabric fraying on challenging materials; minimal gains on lightweight cotton

Needle durability jumps when coatings resist corrosion from stabilizers and humidity. You’ll notice the difference with ballpoint needles on knits and sharp point tips on wovens—smoother feeding, fewer skipped stitches. Universal point needles benefit less; save your budget for specialty applications. Match needle size to thread weight, then let coatings handle the stress.

Pro Tip: Gentle cleaning preserves coating integrity—skip abrasive tools that scratch protective layers and compromise your investment.

Needle Tip Shapes Explained

Tip geometry dictates how your needle interacts with fabric threads—push between fibers or pierce clean through. Sharp point needles slice woven cotton with surgical precision, while ballpoint needles nudge knit loops aside without snagging. Universal point splits the difference, handling mixed-weight projects when you can’t swap mid-design.

| Tip Style | Best For |

|---|---|

| Sharp Point | Woven fabrics, dense layers, crisp penetration |

| Ballpoint (Rounded) | Knits, jersey, stretchy materials—prevents runs |

| Universal Point | Mixed fabrics, light threads, casual projects |

| Twin Needles | Parallel stitch lines, decorative hems, pintucks |

| Superstitch Needles | Metallic threads, specialty finishes, delicate work |

Edge sharpness deteriorates with use—dull tips snag fibers and fracture threads. Point durability varies by needle materials; titanium-coated tips outlast standard steel on synthetic blends.

Fabric interaction improves when you match tip geometry to textile structure, reducing puckering and skipped stitches. Swap needles every 8–10 hours of stitching to maintain clean penetration and protect your machine’s timing.

Pro Tip: Test questionable needle sharpness by dragging the tip across your thumbnail—smooth glide means sharp, catching means replace.

Test needle sharpness on your thumbnail—a smooth glide means it’s sharp, while catching signals it’s time to replace

Preventing Needle Problems in Embroidery

Your needle is the unsung hero of every embroidery project—until it starts causing problems. Broken threads, skipped stitches, and fabric damage don’t just happen randomly; they’re your machine’s way of waving a red flag.

Let’s walk through the warning signs, prevention strategies, and maintenance habits that’ll keep your needles performing like champions.

Signs It’s Time to Change Needles

Your embroidery needles won’t send you a polite retirement notice—they’ll just start wrecking your work. Watch for thread breakage, skipped stitches, or fabric damage beneath your design; these needle wear signs mean it’s time to swap in a fresh one.

Most machine embroidery pros replace needles every 8–12 hours of stitching to maintain stitch quality and protect needle lifespan, ensuring your needlework stays impeccable across different embroidery techniques.

Preventing Needle Breakage and Skipped Stitches

Skipped stitches and snapped needles don’t happen by accident—they’re preventable when you master these fundamentals.

- Needle Inspection & Replacement – Check for nicks or burrs regularly and swap out dull embroidery needles before they compromise stitch quality or damage fabric.

- Thread Tension & Machine Calibration – Balance tension settings and verify your machine embroidery setup to minimize needle deflection during demanding needlework.

- Fabric Preparation – Stabilize materials properly and match needle type to fabric, preventing stress that causes breakage during intricate embroidery techniques.

Proper Needle Installation and Maintenance

Installing your needle correctly is half the battle—but ongoing machine calibration and daily checks complete the picture. Remove the presser foot, lift the needle clamp high, and slide your sharp point embroidery needles in with the flat side back.

Confirm thread tension, verify needle alignment, and test stitch quality. Routine maintenance prevents drama mid-project and keeps your embroidery machine humming smoothly through every sewing machine needles swap.

Safe Needle Storage Tips

A magnetic tray or labeled storage containers will save you hours of frustration and prevent bent tips. Keep your embroidery needles dry to avoid corrosion, organize by type—sharp point, jeans needles, ballpoint—and store away from dust. Wash hands before handling to extend needle life.

Smart needle organization streamlines embroidery project planning and protects your investment in quality sewing machine needles.

Frequently Asked Questions (FAQs)

What is the difference between sewing and embroidery machine needles?

Your standard sewing machine needles pierce fabric fast with sharp points built for basic thread delivery, while embroidery needles feature larger eyes, deeper grooves, and specialized scarfs that prevent decorative thread shredding during dense stitching.

What are the different types of needle tip shapes?

Needle tip shapes fall into three core geometries: sharp tips pierce woven fabrics cleanly, ballpoint tips push knit fibers apart gently, and titanium-coated micro tips handle delicate embroidery techniques with precision thread and needle compatibility.

What are the benefits of using coated needles?

Titanium and gold coatings slash friction, letting thread glide smoothly through the eye—especially with metallics.

You’ll see longer needle longevity, fewer breaks, and cleaner stitches, even at high speeds on demanding fabrics.

How often should needles be changed?

You should swap your embroidery machine needles every 8–12 hours of dense stitching to maintain stitch quality. Change frequency depends on fabric type—replace immediately if threads shred or stitches skip.

What is the purpose of a needle book for organizing needles?

A well-designed needle book transforms chaotic storage into organized inventory management.

You’ll protect delicate points from damage, quickly identify sizes at a glance, and track replacement needs—essential needle care that prevents mid-project emergencies.

Can I use sewing needles for machine embroidery?

Think of it like running a marathon in dress shoes—technically possible, but you’ll pay for it.

Sewing machine needles lack the wider eye and specialized scarf embroidery needles provide, risking thread fraying, skipped stitches, and fabric damage on dense designs.

How often should I replace embroidery needles?

Change your needles every 8 to 12 hours on rigid fabrics or after each delicate project. Watch for skipped stitches and thread fraying—both signal it’s time for fresh steel.

Do different thread brands require specific needles?

Most thread brands don’t demand unique needles, but specialty threads—metallic, textured, or heavyweight embroidery thread—perform best with larger-eye needles.

Test your thread-needle pairing on scrap fabric to confirm thread compatibility and stitch quality before starting projects.

What causes needles to bend during embroidery?

Improper needle installation, dense fabric layers, and mismatched thread weight all create bending stress. Strikes on thick seams or incorrect embroidery techniques increase lateral forces, while poor thread tension magnifies the load on your embroidery machine’s shaft.

Are needle brands interchangeable across embroidery machines?

Can you swap needle brands freely? Not always—needle fittings, groove geometry, and thread compatibility vary. Manufacturers recommend brand-specific embroidery needles for peak machine embroidery performance, though some sewing machines accept universal embroidery standards with proper testing.

Conclusion

Picture your next project running flawlessly—thread gliding through fabric, zero skips, crisp edges on every letter. That’s what happens when you stop guessing and start matching machine embroidery needles to your actual materials.

Whether you’re stitching delicate silks or punching through denim, the right needle eliminates 90% of those mystery problems that used to derail your work. Swap your needles every eight hours of stitching, and watch your embroidery transform from temperamental to bulletproof.