This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Start by using a heavy-duty needle—size 16-18 works wonders for materials like denim or canvas.

Pair it with a strong, high-quality upholstery thread to keep stitches secure.

Adjust your machine’s stitch length and tension; longer stitches (around 3-4 mm) handle bulk better.

A walking foot or roller foot prevents slipping, while sharp scissors or a rotary cutter make cutting smooth.

To reduce bulk, try graded or flat-felled seams.

Practice tricky spots on scraps first—your seams (and sanity) will thank you later!

Table Of Contents

Key Takeaways

- Use a heavy-duty needle (size 16-18) and strong upholstery thread to handle thick materials like denim or canvas without breaking.

- Adjust your machine settings—opt for a longer stitch length (3-4 mm) and moderate tension (4-6) to ensure smooth sewing.

- Manage bulk with techniques like flat-felled seams or seam grading to prevent a lumpy finish and ensure durability.

- Equip yourself with essential tools like sharp scissors, a rotary cutter, clips, and a walking foot to avoid slippage and improve precision.

Choosing Right Needle

When tackling thick fabrics like denim or canvas, you’ll need to choose the right needle to prevent frustration and machine damage.

Your sewing success depends on matching needle size and type to the fabric’s weight.

So grab those heavy-duty needles sized 16-18 and get ready to sew like a pro.

Heavy-Duty Needles for Thick Fabrics

When tackling thick fabrics, your needle can make or break the project.

Heavy-duty needles, typically sizes 16-18, are your secret weapon for slicing through heavyweight materials like a hot knife through butter.

They’re built tough to prevent breakage, ensuring smooth stitching and preventing fabric frustration. Choose these robust needles to conquer even the most challenging fabric weights.

Universal Denim Needles for Canvas

After conquering hefty needles, let’s zero in on universal denim needles for canvas.

Size matters here – 90/14, 100/16, or 110/18 are your go-to champions.

These bad boys slice through canvas like a hot knife through butter, giving you clean, powerful stitches.

For ideal results, using a best canvas sewing machine with adjustable presser foot pressure is essential.

Pro tip: match your needle size to your canvas weight for maximum sewing swagger and precision.

Stretch Needles for Thick Knit Fabrics

Dive right into thick knit fabric sewing with stretch needles sized 90/14 or 100/16. These specialized needles flex and glide through polar fleece, sweatshirt material, and chunky sweater knits without causing fabric damage.

When using Stretch Needles, selecting the right type for your project is vital to achieve professional results.

Test your needle’s strength before starting – a quick fabric stretch test prevents needle breakage and guarantees smooth, professional stitching on those heavy-duty thick fabric layers.

Selecting Thread Type

When tackling thick fabrics, you’ll want to choose a thread that’s as tough as your project demands.

Opt for heavy-duty or upholstery thread with a higher weight number to guarantee your stitches stay strong and secure through every layer.

High-Quality Thread for Thick Fabrics

Picking the right thread is your secret weapon for sewing thick fabrics.

Strong, high-quality thread with the correct weight guarantees your projects stay rock-solid.

Match your thread to your fabric’s thickness – heavier materials demand robust threads that won’t snap under pressure.

Your thread’s weave and strength directly impact sewing performance and material durability, so choose wisely.

Heavy-Duty Thread for Upholstery

When tackling upholstery, your thread is your secret weapon.

Heavy-duty thread becomes essential for conquering challenging fabric durability challenges. Choose threads specifically designed for upholstery materials – they’re thicker, stronger, and built to withstand intense stitching stress.

Your fabric’s longevity depends on selecting the right thread that can handle heavyweight materials without breaking or fraying.

Thread Weight for Secure Stitches

Three key factors determine your thread’s performance on thick fabrics: weight, tension, and material composition. Mastering thread selection transforms your sewing from amateur to professional.

Understanding the different thread types is essential for achieving professional-looking results on various fabrics.

- Match thread weight to fabric thickness

- Balance thread tension for smooth stitches

- Choose high-quality cotton threads for durability

- Understand weight conversion for different thread types

- Test thread strength before major projects to ensure smooth stitches

Essential Sewing Tools

You’ll need specific tools to tackle thick fabrics like a pro, so get ready to upgrade your sewing arsenal.

Arm yourself with sharp scissors, a reliable rotary cutter, and sturdy clips to make cutting and handling heavy materials a breeze.

Sharp Scissors for Cutting Thick Fabric

After threading your project with high-quality thread, grab your sharp scissors – your secret weapon for conquering thick fabric.

Quality cutting matters. Invest in professional-grade scissors with sturdy blades that slice cleanly through canvas, denim, and upholstery materials.

Keep them razor-sharp with regular maintenance, and always cut on a dedicated cutting mat to protect both your scissors and work surface.

Rotary Cutter for Accurate Cuts

Ready to level up your rotary cutter game?

Sharp blades are your secret weapon for precision cutting with thick fabrics.

Invest in a high-quality rotary cutter with replaceable blades and pair it with a self-healing cutting mat.

Keep your blade clean and aligned, and replace it the moment you notice any dulling or drag.

Understanding rotary cutter types is essential for choosing the right tool for your specific needs.

Your fabric deserves nothing less than razor-sharp accuracy.

Clips for Holding Thick Fabric

Slicing through your fabric with a rotary cutter? Now secure those hefty layers with fabric clips.

Forget traditional pins that can’t handle thick materials.

Binder clips or specialized thick fabric clips are your secret weapon for seam management.

They’ll hold bulky denim, canvas, or leather in place without leaving holes, giving you rock-solid control during sewing.

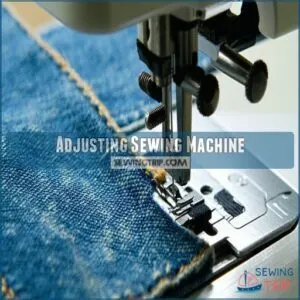

Adjusting Sewing Machine

You’ll need to fine-tune your sewing machine to handle thick fabric like a pro, which means mastering stitch length and tension adjustments.

Set your machine’s settings carefully, and you’ll breeze through heavy materials without skipping a stitch or causing fabric puckering.

Setting Right Stitch Length and Tension

After grabbing your sharp scissors and clips, it’s time to master stitch calibration for thick fabric.

Dial in your tension control between 4 and 6 to prevent thread breakage. Bump up your stitch length to help needles penetrate dense materials.

Remember, sewing precision isn’t about perfection—it’s about understanding how fabric resistance impacts your stitching game.

Adjusting Presser Foot Pressure

You’ll want to fine-tune your presser foot pressure when tackling thick fabrics to prevent fabric slipping or bunching. Different materials require unique pressure settings—too tight, and you’ll crush delicate layers; too loose, and your fabric will drift.

Carefully adjust the foot pressure dial, testing on scrap fabric until you achieve smooth, even fabric guidance that matches your specific project’s thickness.

Using portable sewing machines can be beneficial for sewing thick fabrics due to their adjustable stitch length and pressure settings, as seen in portable sewing machines.

Using Teflon or Non-Stick Presser Foot

In the midst of thick fabric challenges, a Teflon or non-stick presser foot becomes your secret weapon against fabric slippage.

This specialized foot glides smoothly over challenging materials, reducing friction and preventing sticky situations.

It’s a game-changer for sewing machine maintenance, giving you precise foot pressure control and helping you conquer even the most stubborn thick fabric sewing techniques with a secret weapon.

Sewing Techniques

When tackling thick fabrics, you’ll need more than just standard sewing skills to conquer those heavy-duty materials.

Master the right techniques like using a walking foot, adjusting your stitch length, and practicing on scrap fabrics.

This will help transform challenging textiles into professional-looking projects.

Using Walking Foot or Roller Foot

After fine-tuning your machine settings, grab a walking foot or roller foot to master thick fabric sewing techniques.

These special presser foot types work like magic, helping you manage multiple layers with precision.

They grip fabric evenly, preventing bunching and ensuring smooth fabric movement under the needle, making even the chunkiest materials glide like butter.

Starting and Ending With Smaller Stitches

When battling thick fabric, your secret weapon is strategic stitch control.

Kick off and wrap up each seam with tiny, tight stitches to anchor your work like a pro.

This technique locks thread tension and guarantees seam security, preventing unraveling on those heavyweight materials.

Smaller stitches at the beginning and end create rock-solid fabric connections that’ll make your project look professional.

Practicing on Scrap Fabrics

You’ve nailed smaller stitches, but mastering thick fabric sewing demands practice.

Grab those fabric scraps and transform them into your personal testing ground.

Experiment with different needle sizes, thread tensions, and stitch lengths before tackling your main project.

Seam sampling isn’t just smart—it’s your secret weapon for avoiding costly mistakes and building confidence with challenging thick fabric sewing techniques.

Managing Fabric Bulk

When sewing thick fabrics, managing fabric bulk can make or break your project’s professional look.

You’ll want to master techniques like grading seams, using flat felled seams, and strategically trimming excess material to keep your finished piece looking sharp and clean.

Reducing Bulk in Seam Allowances

After mastering smooth sewing techniques, you’re ready to tackle fabric bulk head-on. Reducing seam allowances isn’t just about trimming—it’s an art of precision.

Here’s how to minimize bulk like a pro:

- Trim inner layers at different widths

- Stagger fabric edges strategically

- Cut diagonal corners cleanly

- Layer fabrics with surgical precision.

Understanding thick fabric types can also help in managing fabric bulk effectively. Seam grading transforms bulky constructions into sleek, professional finishes.

Using Semi-Flat Fell Seam or Flat Felled Seam

Slicing through fabric bulk becomes an art with semi-flat fell and flat felled seams.

These powerhouse techniques trim excess layers, creating clean, reinforced edges that’ll make your thick fabric projects look professional.

By carefully grading and folding seam allowances, you’ll dramatically reduce bulk while adding strength to your garment’s construction.

Bias Bound Seams and French Seams

Want to conquer bulky seams like a pro? Bias bound seams and French seams are your secret weapons for taming thick fabric edges.

Bias tape wraps raw edges cleanly, while French seams tuck messy fabric layers inside a sleek, professional fold.

These edge stabilizing techniques transform potentially lumpy seams into smooth, reinforced masterpieces that’ll make your sewing project look polished and precise.

Finishing Seams

You’ll want to master finishing seams to transform your thick fabric projects from amateur to pro-level craftsmanship.

By learning the right techniques for trimming, pressing, and securing your seams, you’ll create garments and items that look polished and professional, no matter how bulky your material.

Pressing Thick Fabric With Pressing Cloth

Pressing thick fabric isn’t just about heat—it’s about precision. Use a pressing cloth to shield your material and prevent shiny spots or heat damage.

Adjust heat settings based on fabric types; heavier fabrics need more steam. Sharp pressing techniques smooth seams effectively.

Utilizing pressing tools sewing can greatly improve the quality of your finished seams. Keep your iron clean and maintain it; buildup can ruin your textile science efforts and sewing tips.

Wide Hems With Bias Binding or Zigzag

If you’ve mastered seam pressing, it’s time to make your hems shine. Bias binding is your go-to for curved edges, while the zigzag stitch speeds up straight hems.

Both prevent fraying and add durability. Use these thick fabric sewing techniques to stabilize bulky layers and guarantee clean zigzag edges for strong, polished finishes.

For a professional finish, consider using bias tape hems on your garments. Simple, effective, and pro-worthy!

Catching Top of Hem by Hand or Machine

Hand stitching methods or machine hemming tips can add the final polish to your project.

For tough hems on thick fabric layers, use a double folded hem and secure it with neat stitches.

Sewing thick fabric tips include managing edges with precision for a clean look.

Whichever hem finishing technique you choose, focus on stable, secure hemming practices.

Troubleshooting Issues

When sewing thick fabrics, it’s easy to run into problems like skipped stitches or broken needles.

With a few quick adjustments and maintenance tips, you can tackle these issues and keep your project on track.

Resolving Stitching Problems With Thick Fabric

Stuck with uneven stitches or fabric puckering? Tackle thick seams by adjusting fabric tension and increasing stitch length.

Machine jamming or thread breakage? Swap to a heavy-duty needle and check your bobbin’s threading.

For skipping stitches, try a walking foot to steady the fabric. Troubleshooting thick fabric issues takes patience—start slow and test settings on scraps!

Fixing Skipped Stitches or Broken Needles

Skipped stitches or broken needles messing up your flow? First, check thread tension—it might be too tight.

Use heavy-duty needles and inspect for dull tips; fresh needles prevent skipped stitches.

Machine calibration is key, so adjust slowly for thick fabric sewing techniques.

Avoid fabric fraying by trimming edges smoothly.

Troubleshooting skips? Practice Stitch Recovery with scrap pieces—problems solved!

Maintaining Sewing Machine for Top Performance

Keeping your sewing machine humming smoothly is key, especially for heavy-duty fabric projects. Regular oil changes and cleaning methods prevent dust buildup and keep parts running like new. Stick to a maintenance schedule for performance optimization.

- Lubricate regularly for easier sewing machine adjustments.

- Clean lint and debris from bobbins and feed dogs.

- Check machine settings after every project for top performance.

Working With Challenging Fabrics

Tackling tricky fabrics like leather, faux fur, or thick canvas can feel intimidating, but the right approach makes it manageable.

You’ll need sturdy tools, stabilizers, and a few smart techniques to keep everything running smoothly.

Sewing With Leather or Faux Fur

Sewing leather or faux fur needs finesse.

Use sharp scissors for thick material cutting, and opt for heavy-duty thread and leather needles.

Faux fur handling improves if you trim seams and sew slowly.

A Teflon presser foot prevents sticking while stitching luxury textiles like leather.

For synthetic fabric care, practice on scraps to perfect thick fabric sewing techniques.

Using Stabilizers for Difficult Fabrics

Tackling difficult fabrics like leather or faux fur often calls for stabilizers.

These sewing aids give extra fabric support and prevent slipping or warping.

Use tear-away or fusible interfacing types depending on your project.

Stabilizer materials work wonders with thick fabric sewing techniques, especially when sewing multiple layers fabric.

Combine this with strong thread thick fabric for clean, reliable results.

Tips for Topstitching Thick Fabric

Slow your sewing speed and adjust fabric tension for easier topstitching on thick fabric. Use strong thread designed for thick material, and always test on scraps.

A longer stitch length helps handle those thick seams like a pro.

Keep it smooth by pressing before stitching and using a walking foot as part of your thick fabric sewing techniques.

Preventing Common Mistakes

When sewing thick fabric, skipping the right stitch type or neglecting needle care can lead to frustration—and ruined projects.

By slowing down, adjusting your machine settings, and staying mindful of these details, you’ll avoid headaches and create smoother finishes.

Avoiding Wrong Stitch Type for Thick Fabric

Choosing the wrong stitch for thick fabric can mess with seam strength and cause thread breakage.

Keep it smooth with these tips:

- Match stitch length to fabric density; longer stitches handle bulk better.

- Opt for low stitch density to prevent puckering.

- Test tension control on scraps before sewing.

- Slow sewing speed avoids skipped stitches.

Neglecting Needle Care and Maintenance

Skipping needle care isn’t a small mistake—it’s a fast track to needle breakage, fabric tears, and sewing errors.

Dull needles can wreak havoc, causing skipped stitches and even machine damage.

Regularly replace needles, match needle size to fabric, and use high-quality thread.

To prevent such issues, understanding Sewing Machine types is essential.

Proper needle care and sewing machine maintenance keep projects smoother and prevent costly fixes.

Rushing Through Projects and Failing to Adjust Machine Settings

Rushing through projects often backfires, especially with thick fabrics. Adjusting machine settings is non-negotiable for success. Slow it down and focus on precision to avoid frustration.

- Calibrate your machine: Adjust thread tension and stitch length for smooth sewing.

- Warm up first: Practice calibration on fabric scraps.

- Control speed: Stick to sewing speed limits for accuracy.

- Prioritize fabric tension control: Prevent skipped stitches or damage.

Frequently Asked Questions (FAQs)

What is the best stitch setting for thick fabric?

Did you know a longer stitch length, around 3-4mm, makes thick fabric easier to sew?

Pair it with tension set between 4-6 for smooth, even stitches.

Test first—your machine’s quirks matter!

How to sew very thick fabric?

Use a heavy-duty needle, strong thread, and a walking foot.

Increase stitch length, adjust tension, and sew slowly for control.

Clip layers instead of pinning and trim seam allowances to reduce bulk for smooth results.

Which presser foot for thick fabric?

Over 70% of sewing challenges with thick fabric come from poor feeding.

A walking foot prevents slipping layers, while a Teflon foot reduces drag.

Both guarantee smooth movement, making tricky jobs much easier and stress-free.

What is the best needle to sew through thick fabric?

The best needle for thick fabrics is a heavy-duty needle, sizes 16- For denim or canvas, go with denim needles (90/14, 100/16, or 110/18). Stretch needles (90/14 or 100/16) suit thick knits.

How to create clean buttonholes on thick fabric?

Buttonholes on thick fabric can be tricky—think wrestling a bear.

Use a sharp buttonhole cutter, increase stitch length, stabilize with interfacing, and sew slowly in small increments for precision.

Practice on scraps to perfect.

What are tips for topstitching thick materials?

Use a longer stitch length for better penetration, and a walking foot to keep layers moving evenly.

Heavy-duty thread adds durability, while pressing seams beforehand guarantees smoother topstitching.

Test settings on scrap fabric first.

How to prevent skipped stitches on corners?

Hold the fabric taut as you sew, and slow down to maintain control.

Pivot carefully, using the handwheel to guide the needle manually at tricky corners.

A sharp needle avoids slips and missed stitches.

Best ways to reinforce seams for durability?

Strong seams start with sturdy thread and a longer stitch length.

Secure the beginning and end with backstitching.

For heavy-duty durability, try flat-felled seams or add a second row of stitching parallel to the first.

How to handle layering thick fabrics smoothly?

Did you know denim weighs up to 14 ounces per yard?

To layer thick fabric seamlessly, clip pieces firmly, use a walking foot for even feeding, and adjust stitch length to avoid bunching.

Conclusion

They say, "A stitch in time saves nine," and with these sewing thick fabric methods, you’ll tackle heavy materials like a pro.

Use the right tools—heavy-duty needles, sturdy threads, and sharp threads—for clean, precise results.

Adjust your machine settings carefully and don’t skip practicing on scraps to avoid frustration.

Managing bulk with flat-felled or bound seams guarantees durability.

Stick to these tips, stay patient, and every challenging project will soon feel like second nature!