This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your sewing machine crawls along like it’s stuck in molasses, and you’re wondering if it’s finally given up the ghost. Before you panic, know this: most slowdown issues aren’t death sentences. They’re cry-for-help signals from a machine begging for basic care.

Lint buildup chokes the feed dogs, dried-out gears grind to a halt, and tangled thread turns your smooth operator into a sluggish turtle. The good news? You can fix most of these problems yourself with a cleaning brush and a drop of oil.

Sometimes, though, slow isn’t a problem—it’s exactly what you need for delicate work like appliqué or free-motion quilting. Whether you’re troubleshooting a sluggish machine or shopping for one with gentle speed control, understanding what makes your slow speed sewing machine tick (or not tick) puts you back in the driver’s seat.

Table Of Contents

- Key Takeaways

- Common Causes of Slow Sewing Machines

- Troubleshooting a Slow Sewing Machine

- Essential Maintenance for Optimal Speed

- How to Fix a Slow Sewing Machine

- Choosing The Right Sewing Machine Oil

- Slow Speed Settings and Controls

- Techniques That Benefit From Slow Sewing

- Top 3 Slow Speed Sewing Machines

- When to Seek Professional Repair Help

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Most slow sewing machine problems stem from fixable maintenance issues like lint buildup, dried-out lubrication, or thread tension problems rather than terminal mechanical failure.

- Regular cleaning every 8-10 hours of use and oiling every 6-12 months prevents the majority of speed issues by reducing friction and keeping moving parts free from debris.

- Intentional slow-speed sewing delivers superior control for precision techniques like free-motion quilting, appliqué, and buttonhole creation where accuracy trumps speed.

- Professional repair makes sense when costs exceed 50% of a replacement machine’s price, but most home sewers can resolve common slowdowns through DIY troubleshooting and basic maintenance.

Common Causes of Slow Sewing Machines

When your sewing machine starts crawling along like it’s stuck in slow motion, it’s usually trying to tell you something. The culprit could be hiding in plain sight—or lurking deep in the machine’s guts.

Let’s walk through the five most common reasons your machine has lost its zip so you can get back to stitching at full speed.

Dirt and Lint Buildup

Your slow sewing machine might be choking on lint accumulation and fabric fiber debris. Dirt removal from the feed dogs and bobbin case can instantly revive your sluggish stitcher—lint buildup clogs moving parts like dust in a vacuum.

Regular cleaning every 8–10 hours prevents slow stitching and keeps machine maintenance simple. Skip this step, and you’ll watch your machine crawl instead of purr.

Proper maintenance also involves addressing methodological flaws to guarantee peak performance.

Lack of Lubrication

Even a sparkling-clean machine can stall if you’ve skipped the oil. Without proper lubrication, metal-to-metal friction heats up gears and bearings, cutting their life by 40% and dragging your needle bar into sluggish territory.

If you notice uneven stitches or hear grinding sounds, changing a sewing machine needle and re-oiling can often fix the problem before it worsens.

A clean machine without oil still stalls—metal-on-metal friction heats gears, cuts bearing life by 40%, and drags your needle bar into sluggish territory

Apply sewing machine oil every 6–12 months to maintain friction reduction and wear prevention—old oil turns to sludge, robbing you of speed and smooth stitches.

Regular maintenance also involves checking for language related terms in the user manual to verify you’re using the correct terminology for troubleshooting.

Thread Jams and Tension Issues

Thread tension problems send your machine crawling. When upper and bobbin threads battle it out, you’ll see bird-nest jams near the needle—often triggered by a misrouted thread path or lint buildup in the bobbin area.

Many electronic sewing machine tutorials walk you through proper threading sequences and tension adjustments to prevent these tangles from happening.

Thread Breakage and Fabric Fraying scream unbalanced tension. Re-thread from scratch, clean the shuttle, and swap in the right needle to restore Tension Balancing and smooth Jam Prevention at any speed.

For frequent sewers on the go, a portable sewing machine with reliable tension control prevents these frustrating issues from derailing your projects mid-stitch.

Motor and Electrical Problems

Your machine’s heart—the motor—can fail in sneaky ways. A worn motor reduces speed, causing uneven stitches and grinding noises.

Electrical Issues like Circuit Overloads or poor plug connections starve your motor of power. Dirty Carbon Brush contacts kill torque, while faulty Speed Regulators ignore your pedal.

Motor Failures mean sluggish stitching even at full throttle—classic signs demanding immediate machine maintenance.

Finding a certified sewing machine repair shop near you ensures proper motor diagnostics and warranty-safe fixes.

Incorrect Needle or Presser Foot Use

You’ll sabotage your speed with the wrong needle or presser foot. Here’s how mismatches kill your momentum:

The computerized sewing tools guide breaks down which foot-and-needle combos work best for different fabrics and stitch types.

- Needle Alignment off-center creates friction that slows stitch formation.

- Fabric Clearance shrinks when your needle size doesn’t match your material.

- Presser Foot Issues arise when zigzag feet meet straight-stitch programs.

- Needle Damage from worn clamps binds fabric advancement.

- Improper insertion depth hampers needle control and precision sewing.

Wrong parts mean sluggish stitches—guaranteed.

Troubleshooting a Slow Sewing Machine

So your machine’s crawling along like it’s stuck in molasses—where do you even start? The good news is most slowdowns have simple fixes you can tackle yourself in under twenty minutes.

Let’s walk through the key checks that’ll get your sewing machine back up to speed.

Inspecting for Thread Jams

Your machine’s crawling like a snail? Check your thread path first—tangled threads act like invisible brakes. Misthreading at the needle or guides creates friction that sabotages smooth stitching. Raise your handwheel slowly to catch snag points.

Peek at the bobbin area for lint accumulation around the feed dogs and tension discs. Regular cleaning and proper jam detection prevent those frustrating slow-motion moments.

Verifying Speed Control Settings

Sometimes, your sluggish stitching stems from misconfigured speed control calibration rather than mechanical wear. Check that your sewing machine settings and controls respond smoothly when you adjust the dial or lever—motor response testing reveals binding or unresponsive governors.

Most slow sewing machine issues trace back to electronic governor settings stuck at low ranges. Foot pedal adjustment and stitch speed optimization restore your machine’s purr.

Examining Foot Pedal and Electrical Cords

Your foot pedal can throttle your slow sewing machine just like a sticky gas pedal slows a car. Pedal calibration and cord inspection catch hidden culprits in speed control and motor issues before they escalate into costly foot pedal repair needs.

- Feel for intermittent resistance or sticking when you press the pedal down

- Check both cable ends for cracks, bent connectors, or corrosion buildup

- Look for cut insulation or scorch marks on your power cord

- Test another compatible pedal to pinpoint whether the fault follows your pedal or lives inside the machine

Electrical safety and power management protect you and restore smooth sewing machine maintenance routines.

Checking Belt Tension and Wear

A loose belt chokes your slow sewing machine like a slipping clutch. Press the belt’s midpoint—it should deflect just 1/4 inch. Cracks, glazing, or squealing noises signal imminent failure.

Check pulley alignment next; misalignment causes uneven wear and motor issues faster than lint buildup ever could. Proper tension adjustment and regular cleaning prevent belt replacement and restore smooth stitching speed instantly.

Essential Maintenance for Optimal Speed

Think of maintenance as your machine’s health plan—skip it, and even the best sewing machine will slow to a crawl.

A few simple habits keep your machine running smoothly and prevent most speed problems before they start.

Let’s look at the essential maintenance tasks that’ll keep your machine stitching at its best.

Regular Cleaning Routines

Want your machine purring like a kitten instead of sluggish as a snail? Regular cleaning every 8 hours of heavy use—or monthly for hobbyists—clears lint buildup from feed dogs and bobbin areas before trouble starts.

- Unplug first: Safety isn’t optional when you’re digging into delicate parts.

- Brush gently: Compressed air or small brushes dislodge lint without scratching metal.

- Log it: Maintenance logs track cleaning schedules and support warranties down the road.

Proper Lubrication Techniques

After regular cleaning, lubrication keeps metal parts gliding smoothly. Apply one drop of manufacturer-recommended sewing machine oil to pivot points—needle bar, shuttle race, feed mechanism—then wipe away excess to avoid fabric stains. Synthetic oils suit high-speed models; light, pure lubricant works for most domestics.

Follow your maintenance schedules: over-lubricating attracts lint, while skipping oil invites squeaks and sluggish stitching.

Replacing Needles and Worn Parts

Swap your needle after every project or eight hours of stitching—dull needles snag fabric and skip stitches. Fresh needles prevent slow sewing machine hiccups before they start.

Inspect timing belts, feed dogs, and needle bar bushings yearly for looseness or visible wear. Use manufacturer parts for safe, precise fit.

Match needle type to fabric weight; the wrong size bends metal and ruins seams.

Cleaning Bobbin Area and Feed Dogs

After swapping needles and worn parts, turn your attention to the bobbin area—lint buildup here chokes your machine like dust in your lungs.

Unplug first, then pop out the bobbin case and brush away every fiber hiding in the housing and between feed dog teeth. A lint-free cloth with cleaning solution finishes the job.

Test on scrap fabric to confirm smooth feeding and proper thread tension.

How to Fix a Slow Sewing Machine

Your machine’s crawling along like molasses, and you’ve already cleaned and oiled it—so what’s next? Sometimes the fix goes deeper than routine maintenance, involving adjustments to pressure, tension, or even worn-out parts.

Let’s walk through the troubleshooting steps that’ll get your machine back up to speed.

Step-by-Step Troubleshooting Guide

Think of machine troubleshooting like solving a puzzle—you’ll uncover the issue by checking each piece. Start with these Troubleshooting Steps to diagnose your slow sewing machine:

- Verify your speed control settings and foot pedal position

- Check for thread jams in the bobbin area and needle plate

- Inspect the drive belt for looseness or wear

- Test the pedal for dirt buildup or obstruction

- Consult your manual’s Error Detection guide for specific diagnostic tools

Adjusting Presser Foot Pressure

Pressure Adjustment makes all the difference when your slow sewing machine drags through thick layers or skips stitches. You’ll find the dial or screw near the top of your machine—twist it to match your fabric weight.

Proper Foot Calibration keeps your presser foot balanced against the feed dogs, ensuring smooth Fabric Guidance without distortion.

| Fabric Type | Pressure Setting |

|---|---|

| Light (silk, chiffon) | Low pressure |

| Medium (cotton, blends) | Mid-range |

| Heavy (denim, canvas) | High pressure |

| Multiple layers | Increased pressure |

Test on scrap fabric first for perfect Stitch Regulation every time.

Correcting Thread Path and Tension

Thread Alignment and Tension Adjustment turn a sluggish slow sewing machine into a dream. Start by rethreading from scratch—every guide, every turn, every disc—with your presser foot raised so the thread seats perfectly.

- Check Needle Seating to confirm the needle is fully inserted and threaded correctly

- Inspect Bobbin Winding for even tension and proper insertion direction

- Test Stitch Quality on scrap fabric and adjust upper or bobbin tension accordingly

- Clean the bobbin area with sewing machine oil to reduce friction

- Compare your thread path against the manual to catch hidden routing errors

Proper sewing machine maintenance keeps tension smooth and stitches consistent.

When to Replace Belts or Motor Parts

Timing matters when parts fail. Cracks, glazing, or missing ribs on your belt mean it’s time to swap. If your motor overheats, smells burnt, or stalls under light loads, those are classic Motor Wear Signs pointing to failing components.

| Warning Sign | Action Needed |

|---|---|

| Belt slipping or cracking | Belt Replacement |

| Motor overheating or burning smell | Inspect motor parts |

| Delayed pedal response | Check Speed Control Issues and motor speed |

Ignoring these Part Inspection clues raises Repair Costs down the road.

Choosing The Right Sewing Machine Oil

Not all oils are created equal—some can actually gum up your machine and make it slower. The right oil keeps your machine purring like a kitten, while the wrong kind turns it sluggish as molasses.

Let’s look at the types of oil you should use, how they impact speed, and the best way to apply them.

Types of Sewing Machine Oil

You’ve got several good choices for sewing machine oil. Mineral oils are your workhorse—reliable for most household machines and easy on the wallet. Synthetic lubricants last longer between applications, especially if you’re running high-volume projects.

Pay attention to oil viscosity and machine compatibility, though. Not every lubricant brand plays nice with every model, so check your manual before you pour.

How Oil Affects Sewing Speed

Think of oil viscosity as your machine’s throttle control—thicker oil increases friction, while thin mineral or synthetic lubrication types slice through drag and boost motor performance.

Proper sewing machine oil application cuts resistance in your needle bar and shuttle, letting you hit faster speeds without overheating. Skip it, and slow sewing becomes your new normal.

Regular sewing machine maintenance with the right lubrication keeps motor issues at bay.

Application Tips for Slow Machines

Want your slow stitching to stay smooth instead of sluggish? Here’s how to oil your machine for precision sewing without the mess:

- Apply 1–2 drops to moving metal parts, never over-lubricate or you’ll attract lint

- Clean the bobbin area before oiling to prevent residue interference at low speeds

- Use manufacturer-recommended oil for reliable thread tension and pedal control

- Test speed calibration on scrap fabric after lubrication

- Schedule maintenance after defined slow sewing hours

Slow Speed Settings and Controls

Controlling your machine’s speed isn’t just about pressing a pedal—most machines give you multiple ways to dial in the perfect pace. Whether you’re using a classic lever, tweaking pedal sensitivity, or tapping into programmable features, the right settings make all the difference.

Let’s walk through the three main controls that put you in the driver’s seat.

Using Speed Dials and Levers

Most modern sewing machines give you two main speed control options: a speed dial that caps your maximum stitch rate and a lever that switches between preset ranges—low, medium, high. The speed dial works independently of how hard you press the pedal, so you can’t accidentally zoom past your comfort zone. Think of it as a built-in safety net for slow sewing.

Here’s how these controls stack up:

| Control Type | How It Works | Best For |

|---|---|---|

| Speed Dial | Sets fixed maximum RPM; pedal stays within that ceiling | Quilting, delicate fabrics, beginners |

| Lever Adjustment | Toggles between stepped speed ranges (binary or multi-step) | Quick switches between project types |

| Electronic Clutch | Translates dial position into precise motor response via microcontroller | High-end machines needing fine-tuned sewing speed control |

| Speed Lock Feature | Temporarily fixes speed to prevent accidental changes | Precision work like buttonholes |

| Programmable Presets | Saves custom speeds for specific stitch types | Repetitive tasks requiring consistent slow sewing |

Check your dial calibration if the displayed setting doesn’t match actual sewing machine settings and controls. Dirt around the dial can gum up movement and throw off lever adjustment accuracy. Power down before inspecting—your fingers will thank you. Test on scrap fabric after any motor response tweaks to confirm the speed dial delivers what you expect.

Adjusting Foot Pedal Sensitivity

Your foot pedal isn’t just an on-off switch—it’s a finely tuned speed regulator. Sensitivity settings let you control how much pressure triggers a given stitch rate. Higher sensitivity means shorter pedal travel for the same speed, giving you smoother slow sewing control. Lower sensitivity prevents accidental overspeed when you’re nervous.

Check your electronic controls menu for pedal calibration options, or consult your manual for foot pedal adjustments that match your comfort level.

Programmable Speed Features on Modern Machines

Today’s computerized machines go beyond the old speed dial. You’ll find electronic interfaces that store your favorite limits, so even full-pedal pressure won’t outrun your comfort zone. Adjustable acceleration smooths the jump from zero to full steam, while motor drivers enforce programmable limits on every stitch. It’s speed control that remembers what you need.

- Speed-range sliders cap maximum stitches-per-minute regardless of pedal input

- Start-up profiles let seams begin slowly before accelerating to your target pace

- Stitch-by-stitch modes deliver supreme precision at crawling speeds

- Software menus reassign physical controls to width or other functions

- Memory storage saves your preferred slow-sewing settings between sessions

Techniques That Benefit From Slow Sewing

Slowing down your machine isn’t just for troubleshooting—it’s actually the secret weapon for tackling some of the trickiest sewing tasks out there. When you dial back the speed, you gain the control and precision needed for techniques that demand a steady hand and sharp eye.

Let’s look at three specific projects where slow stitching makes all the difference.

Free-Motion Quilting Precision

Quilting accuracy depends on your hand-fabric coordination. When you’re doing Free Motion Quilting, slow speed gives you the breathing room to match hand movement with needle speed—aim for 10 to 12 stitches per inch. Jerky hands make wobbly lines, so smooth gliding wins every time. Lower your machine speed to 50-75% max. Your precision sewing will thank you.

| Speed Factor | Impact on Stitch Control | Recommended Action |

|---|---|---|

| Machine calibration | Prevents racing or stalling | Set limiter 50-75% max |

| Hand movement | Controls path accuracy | Glide smoothly, pause at turns |

| Thread visibility | Shows stitch formation | Use 50-weight cotton thread |

| Fabric handling | Reduces distortion | Wear quilting gloves for grip |

Appliqué and Intricate Stitching

Appliqué demands patience—you can’t rush those tight curves. Drop your speed to 25–30% of max when stitching intricate details or edge finishing around motifs. Use a clear appliqué foot for visibility, pair it with a 75/11 needle, and keep stitch length short (1.5–2.5 mm) for smooth sewing curves. Add stabilizer under your fabric to prevent puckering. Precision sewing starts with slow, deliberate control.

Buttonhole Creation and Finishing Touches

Buttonhole stitches need slow, steady control—rushing causes uneven edges and weak bar tacks. Drop to 600 SPM for consistent stitch density and clean reinforcement techniques.

Fabric preparation matters: stabilize first, mark accurately, then stitch. Edge finishing depends on uniform speed around the entire opening.

Test your stitch quality on scrap fabric before tackling garments. Precision sewing pays off when buttons slide through effortlessly without fabric stabilization issues.

Top 3 Slow Speed Sewing Machines

Now that you know when slow stitching makes all the difference, let’s talk hardware. Some machines are built from the ground up to handle delicate, controlled work without fighting you every step of the way.

Here are three portable options that give you the slow-speed precision you need without breaking the bank.

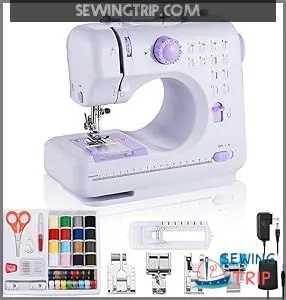

1. Rxmeili Portable Electric Sewing Machine

If you’re hunting for a truly compact sewing machine with gentle speed control, the Rxmeili Portable Electric Sewing Machine (model RXM001) checks all the boxes. Weighing just under five pounds and offering 12 built-in stitches, this mini marvel runs on either AC power or four AA batteries—perfect for dorm rooms or travel.

Its low-high speed switch and foot pedal give you precise control for slow sewing on delicate fabrics. The portable design includes an accessory drawer and built-in light, making sewing accuracy easier.

Just remember: it’s built for light repairs and beginner projects, not heavy-duty work.

| Best For | Beginners, students, and anyone tackling light repairs or small sewing projects in tight spaces who need something portable and easy to use. |

|---|---|

| Built-in Stitches | 12 stitches |

| Speed Control | Single speed |

| Power Source | AC/Battery |

| Built-in Light | Yes |

| Storage | Storage drawer |

| Weight | 4.98 lbs |

| Additional Features |

|

- Dual power options (AC adapter or batteries) make it super portable for travel, dorms, or sewing on the go

- 12 built-in stitches with adjustable speed control give you flexibility for different fabrics and skill levels

- Compact and lightweight design (under 5 pounds) with built-in light and storage drawer keeps everything organized

- Not built for heavy-duty fabrics or advanced sewing projects—strictly light to medium weight materials

- Some users report quality control issues, including defective units or machines that stop working after limited use

- Can’t run on battery and AC power simultaneously, and incorrect operation may cause jams or broken needles

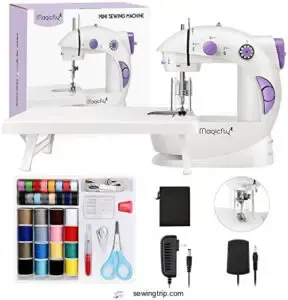

2. Magicfly Mini Portable Sewing Machine

The Magicfly Mini Portable Sewing Machine brings dual power flexibility—plug into AC or pop in four AA batteries for cordless freedom. Its compact design fits tight spaces, while 12 built-in stitches and an L-H speed control button let you dial down for slow sewing on silk or speed up for heavier cotton.

The extension table, LED work light, and safety needle guard make this mini powerhouse beginner-friendly. Just be warned: tension adjustment can be finicky, and it’s not built for marathon denim marathons or heavy-duty repairs.

| Best For | Beginners and occasional sewers who need a portable, budget-friendly machine for light repairs, small projects, and basic stitching on thin to medium fabrics. |

|---|---|

| Built-in Stitches | Fixed stitch |

| Speed Control | Dual-speed |

| Power Source | AC/DC/Battery |

| Built-in Light | LED lamp |

| Storage | Extension table |

| Weight | 1 kg (2.2 lbs) |

| Additional Features |

|

- Dual power options (AC adapter or four AA batteries) let you sew anywhere, even without an outlet nearby.

- 12 built-in stitches and adjustable speed give you enough variety for basic projects without overwhelming complexity.

- Compact size with an extension table, LED light, and safety needle guard makes it easy to store and beginner-friendly.

- Tension adjustment is tricky and requires patience to dial in correctly for consistent stitches.

- Not reliable for heavy-duty sewing—struggles with thick fabrics like denim and may fail after light use based on user reports.

- No backstitch function and a reputation for inconsistent performance, with some units breaking down within days.

3. Portable Mini Electric Sewing Machine

Looking for the ideal lightweight companion? This portable mini electric sewing machine weighs just 1.1 to 2.5 kg—half what most full-size machines lug around—and tucks neatly into cramped apartments or travel bags.

You’ll get 12 to 38 built-in stitches at a gentle 350 to 400 stitches per minute, perfect for slow-speed stitching on delicate fabrics. Dual power (AC or four AA batteries) means you can sew anywhere.

Just remember: compact design benefits come with trade-offs—this isn’t your denim-layer workhorse, but for quick repairs and light garments, it’s gold.

| Best For | Beginners, students, and casual sewers who need a portable machine for quick repairs, light alterations, and simple craft projects in small spaces. |

|---|---|

| Built-in Stitches | 12 stitches |

| Speed Control | 2-speed control |

| Power Source | AC only |

| Built-in Light | LED light |

| Storage | Storage drawer |

| Weight | 5 lbs |

| Additional Features |

|

- Ultra-lightweight at 1.1 to 2.5 kg and compact footprint (around 12-13 inches) makes it easy to store and carry anywhere you need it.

- Dual power options (AC adapter or four AA batteries) let you sew at home or on the go without hunting for an outlet.

- Includes 12 to 38 built-in stitches and beginner-friendly features like threading marks and dual control options (foot pedal or button switch).

- Slower stitch speed (350-400 stitches per minute) and limited motor power mean it struggles with thick fabrics like heavy denim or leather.

- Basic tension and length adjustments are coarser than full-size machines, making precision work harder to dial in.

- Not designed for continuous heavy use or high-volume projects—best as a secondary machine for occasional light tasks.

When to Seek Professional Repair Help

Sometimes your best troubleshooting efforts won’t bring your machine back to life, and that’s okay. Knowing when to call in a pro can save you time, money, and a whole lot of frustration.

Let’s look at the warning signs that say it’s time to get expert help, how to find the right technician, and whether fixing or replacing makes the most sense for you.

Signs of Major Motor or Electrical Issues

When your slow sewing machine suddenly stops mid-stitch or you catch a burning smell near the motor, you’re facing serious trouble. Motor failure shows up as grinding noises or zero needle movement despite power flowing.

Electrical overload causes intermittent power loss and flickering lights. Faulty wiring triggers overheating you can’t ignore.

These motor issues demand professional attention—don’t risk further damage.

Finding Qualified Sewing Machine Technicians

You need a technician with real training, not just a toolbox. Check for sewing machine repair and service credentials from programs like Sewing Doc Academy. Verify technician certification before handing over your machine for sewing machine maintenance and repair.

Scan repair shop reviews on Yelp for red flags. Ask about machine specialist training—vintage versus computerized models require different expertise.

Local service center locations in Ashburn or Sterling offer quick estimates.

Weighing Repair Versus Replacement Options

Once you’ve found your qualified technician, get an honest repair estimate. If the quote exceeds 50% of a new machine’s cost, replacement decisions make more sense—especially for entry-level models past their prime.

Minor fixes like tension adjustments run $50–$100, but motor issues or timing repairs climb higher fast. Weigh repair thresholds against your machine’s age and how many good years it has left.

Frequently Asked Questions (FAQs)

What fabrics work best at slow speeds?

Woven cottons like quilting cotton and chambray feed smoothly without slipping, making them perfect for controlled fabric selection at reduced speeds.

Natural fibers such as linen and hemp also handle slow stitching beautifully.

Can slow sewing reduce thread breakage issues?

Like driving too fast over potholes, rushing through fabric stresses threads to the breaking point.

Slow sewing reduces thread breakage by minimizing needle alignment issues, maintaining stitch consistency, and preventing fabric tension spikes that snap delicate fibers mid-stitch.

How does slow stitching affect seam strength?

Slow stitching won’t weaken your seams if you match stitch density and thread interaction to your fabric tension.

Material durability stays solid when you control sewing speed and maintain consistent stitch length for quality seam elongation.

Are computerized machines better for speed control?

Yes—computerized sewing machines excel at speed control. Electronic controls deliver programmable settings and speed consistency that manual pedals can’t match.

Motor efficiency stays steady across fabric types, giving you reliable, repeatable results every time.

Does slow sewing consume less electricity overall?

Not really. Your machine pulls roughly the same wattage whether you’re stitching fast or slow. But slower work takes longer, so you’re actually using more total electricity to finish the same project.

Conclusion

A slow speed sewing machine doesn’t have to mean game over—it means you’ve got choices. Clean out that lint tornado, drop in some oil, and watch your machine bounce back like new.

Master those speed controls for detailed work, or grab a machine built for gentle precision. You’re not just fixing a problem; you’re taking charge of every stitch. Now get in there and show that machine who’s boss.

- https://www.justanswer.com/appliance/ndhks-model-7360-singer-sewing-machine-begun.html

- https://www.seamwork.com/issues/2020/05/sewing-machine-care-tips

- https://sewingmachinetalk.com/sewing-machine-motor-problems-2/

- https://www.assembil.com/how-to-start-sewing-exercise-14-01-adjusting-thread-tension-presser-foot-pressure/

- https://en.wikipedia.org/wiki/Sewing_machine