This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your vintage Singer won’t thread itself, and the instruction manual that came with it probably disappeared decades ago. That thin metal loop you’re staring at? It’s a thread guide, and there are usually five or six of them hiding along the path between your spool and needle.

Miss even one, and you’ll end up with tangled messes, skipped stitches, or thread that snaps mid-seam. The good news: once you understand how each guide works and where your thread needs to go, threading becomes muscle memory.

These machines were built when easy to use meant rock-solid construction, not straightforward design—but that durability is exactly why your Singer still runs smoothly after 50, 70, or even 100 years.

Table Of Contents

Key Takeaways

- Your vintage Singer uses five or six thread guides along a specific path from spool to needle, and missing even one causes tangled thread, skipped stitches, or mid-seam breaks that wreck your sewing.

- The tension discs need thread seated between them with the presser foot raised, while the take-up lever must be threaded at its highest point—these two steps control whether your stitches balance or fall apart.

- Regular maintenance means brushing lint from guides, flossing between tension discs with thick thread, and applying one tiny drop of proper machine oil to pivot points without over-lubricating.

- When replacing worn guides, verify your exact Singer model number first and check that new parts match the original bend, screw size, and SIMANCO number to maintain proper thread flow and tension control.

Key Components of Vintage Singer Thread Guides

Your vintage Singer relies on a network of parts to guide thread from spool to stitch. Each component plays a specific role in keeping tension consistent and preventing those frustrating tangles or skipped stitches.

Following a clear threading guide for your Singer sewing machine ensures each part works together seamlessly to deliver smooth, professional results.

Let’s look at the four key thread guides you’ll work with every time you thread your machine.

Spool Pin and Upper Thread Guide

The spool pin on your vintage Singer sewing machine holds the thread and usually stands upright on the machine’s head. Most classic models—like the Singer 15, 66, or 99—use a metal drive-in pin about 60–65 mm long.

Right below it, you’ll find the upper thread guide, a small metal hook or eye that keeps the thread aligned and prevents it from swinging off the spool pin during sewing.

You can find information on different spool pin types and finishes to guarantee compatibility with your specific vintage model.

Tension Discs and Tension Spring

Just beneath that upper guide, your vintage Singer’s tension discs—two or three hardened steel or brass-faced washers—grip the thread between smooth surfaces. A spring-loaded arm presses them together, creating steady drag that balances your stitches. When you raise the presser foot, a release pin separates the discs so you can slide thread in or out easily.

Here’s what you need to know:

- Tension Disc Function: The discs clamp thread to control feed speed, usually with 30–40 grams of force.

- Spring Adjustment: Turn the tension knob clockwise to tighten, counterclockwise to loosen—about 1/16-turn at a time.

- Disc Material: Worn discs show grooves; lightly smooth with emery cloth or replace matched pairs for Singer 66, 99, or 201 models.

A set of original tension discs is available for replacement and is designed specifically for vintage Singer machines.

Quick tip: Oil or lint between the discs masks true tension, so always clean before adjusting your thread tension settings.

Take-Up Lever and Needle Bar Guide

After thread passes the tension discs, it climbs to the take-up lever—a pivoting arm that pulls slack tight after each stitch. Thread it right-to-left through the lever’s eye when it’s at its highest point.

Then guide the thread down to the needle bar guide, a tiny hook near the needle clamp. This small metal loop keeps your thread aligned straight into the needle eye, preventing fraying and skipped stitches on your Singer sewing machine.

Bobbin Winder Thread Guide

Your Singer sewing machine has one more thread guide you’ll use often: the bobbins winder thread guide. This small spring or bent wire sits near the handwheel, keeping thread stable as it leaves the spool during bobbin winding. Proper thread alignment through this guide ensures smooth winder mechanics and bobbin quality every time.

Here’s why this vintage Singer thread guide matters:

- Controls thread path to prevent whipping at high speeds

- Creates evenly packed bobbins with level layers

- Protects moving parts by keeping thread close to the machine

Most models like the Singer 66, 99, and 15-30 use the same coil spring design—about three-eighths inch diameter. When thread passes cleanly through this guide and into the tension control disc, your bobbin winds perfectly without manual fussing.

If you’re still learning the full path from spool to needle, this guide to threading a Singer sewing machine walks through each checkpoint step-by-step.

Preparing Your Vintage Singer for Threading

Before you thread a single guide, your vintage Singer needs a bit of prep work to run smoothly. Think of this step like setting the table before a meal—everything needs to be clean, positioned right, and ready to go.

Let’s walk through the quick checks and setup moves that’ll save you frustration down the road.

Cleaning and Inspecting The Machine

Before anything else, wipe away lint from every visible surface using a soft brush or cotton swab—especially around the spool pin, thread path, and tension area. A barely damp cloth with mild soap removes grime from the vintage Singer sewing machine body without harming decals.

Then inspect each thread guide for bends or damage, turn the handwheel slowly, and apply one drop of oil at designated points only.

Unlocking The Hand-Crank Mechanism

⚠️ Before you thread, turn the stop motion screw counterclockwise about a quarter turn to disengage the needle bar—this frees the hand crank for bobbin winding and prevents damage during threading preparation.

Hold the balance wheel steady, then rotate the center knob toward you until you feel the clutch washer release. If the mechanism won’t budge, old oil may have gummed up the clutch; apply a drop of penetrating oil around the screw, let it soak five minutes, then try again with gentle pressure.

Gathering Essential Supplies

✅ Before you start, lay out your supplies—you’ll save time and avoid stopping mid-thread. Thread quality matters; all-purpose polyester pairs well with standard needle types like 11/80 or 14/90.

Grab these essentials:

- Fresh machine oils for lubricating moving parts around the thread guide posts

- A small brush to clear lint from vintage Singer thread guides and tension discs

- Quality sewing notions including a needle threader and tweezers for tight spaces

Step-by-Step Threading Process

Threading your vintage Singer isn’t complicated once you know the exact route the thread needs to follow. You’ll move through four distinct stages, starting with the upper path and ending with a properly wound bobbin.

Each step builds on the last, so taking them in order makes the whole process smoother and gets your machine ready to sew.

Threading The Upper Path

Raise your presser foot first. That single move opens the tension discs so your thread seats correctly. Start at the spool pin, lead your thread through the first upper guide, then slip it between the tension discs—right to left works on most vintage Singers. Thread the take-up lever when it’s at the top, guiding thread through its eye for smooth flow.

| Starting Point | Tension Zone | Lever & Needle |

|---|---|---|

| Spool pin holds thread | Thread enters tension discs | Take-up lever pulls thread |

| Upper guide aligns path | Check spring controls slack | Final guide stabilizes flow |

| Thread unwinds smoothly | Presser foot must be raised | Needle alignment matters |

| No jerking or snagging | Thread seats between discs | Threading direction varies |

Pro tip: Turn your handwheel toward you to raise the take-up lever into view—it makes threading that eye much easier and keeps your upper thread Singer path locked in place for balanced stitches.

Navigating Each Thread Guide

Each guide on your Singer sewing machine acts like a checkpoint—skip one and your stitches fall apart. Thread routing matters for tension control and proper stitch formation, so let’s walk through it.

- Upper guide after the spool pin controls the first direction change in your threading path

- Tension discs need thread slipped sideways, right to left, so it seats fully between the plates

- Take-up lever pulls slack at the top of each stroke; thread it right to left when raised

- Faceplate guides direct thread down toward the needle bar, keeping alignment tight

- Side guide near the needle clamp holds thread in the correct plane as the bar moves

Turn your handwheel slowly after threading each guide—watch for snagging or jumping, which signals the thread is riding on top instead of sitting inside. Guide alignment and Singer thread guides maintenance prevent most threading headaches.

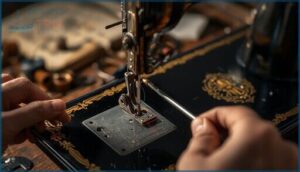

Threading The Needle Correctly

Your needle orientation is the final handshake between thread and fabric—get the orientation wrong and stitch formation crumbles. On most vintage Singer sewing machine models, thread the needle from left to right so thread sits in the long groove during penetration. ✅ Check needle alignment by feeling for the flat side facing left or forward (model-dependent).

Thread tension relies on correct needle threading; skip this detail and you’ll chase thread guide springs and fabric selection issues forever.

Winding and Inserting The Bobbin

With the needle dressed, bobbin winding comes next. Loosen the stop-motion knob on your handwheel so the needle bar stays still.

⚠️ Place an empty bobbin on the small spindle, route thread through the S-shaped bobbin winder guide for proper tension, then hand-wrap five clockwise turns to anchor. Engage the winder against the handwheel’s rubber tire, treadle gently until the bobbin fills firm and smooth—stop before thread reaches the rim.

Troubleshooting Common Thread Guide Issues

Even a perfectly threaded Singer can act up if something along the thread path isn’t quite right.

You might notice skipped stitches, constant breakage, or thread that won’t stay put in the guides.

Let’s walk through the most common thread guide problems and how to fix them so your machine runs smoothly again.

Identifying Incorrect Threading Paths

Spotting thread path errors on your Singer sewing machine starts with a visual sweep. Check if your thread follows a smooth S-shaped route from spool pin to needle—any floating sections or skipped guides signal trouble.

Bird nests under the fabric, uneven stitches, or puckered seams point to guide misalignment. Compare your threading to your model’s diagram to catch mistakes before stitch quality suffers. ✅

Adjusting Thread Tension

Once you’ve confirmed the thread follows the right path, it’s time to dial in the sweet spot on that upper tension control. Most vintage Singers use numbered settings from 0 to 9—start around 4 for medium cotton, then test on scrap fabric to see if threads lock in the middle of the layers.

Key tension adjustments for better stitch quality:

- Raise the presser foot when threading so tension discs open fully

- Turn the dial higher if bobbin thread shows on top (tighten upper tension)

- Turn the dial lower if top thread loops underneath (loosen upper tension)

- Adjust for fabric thickness—thicker layers need slightly looser settings

- Clean between tension discs with soft fleece if thread balance feels inconsistent

Pro tip: Leave bobbin tension alone unless absolutely necessary—most sewing machine thread and tension fixes happen with the upper dial. Test every change on a scrap strip before returning to your project.

Preventing Thread Breakage and Snarls

Even perfect tension control won’t help if your thread quality or needle size is off.

Old cotton thread snaps easily, especially if it’s been sitting in sunlight or damp storage. Match your needle to thread weight—size 12 or 14 for standard cottons—and check thread routing for tiny burrs on metal guides that scrape the coating and cause mid-stitch breaks.

Checking for Worn or Missing Guides

⚠️ Guide Inspection is your first line of defense against Sewing Issues. Run a finger along each metal surface—grooves or sharp edges mean wear. Compare your Thread Path to factory diagrams for Vintage Models to spot missing pieces.

A flashlight reveals bent ears near the needle bar. These Maintenance Tips keep your Singer sewing machine running smoothly, protecting Thread Guide Springs and other vintage sewing machine parts from damage.

Maintaining and Replacing Thread Guides

Your thread guides work hard with every pass of fabric, and over time they can wear down or break. Keeping them clean and catching damage early will save you from skipped stitches and frayed thread down the road.

Here’s how to maintain your guides and swap in new ones when the old parts finally call it quits.

Cleaning and Lubricating Guides

A clean thread guide is like a clear highway—your thread glides instead of snagging. Regular thread guide maintenance keeps your Singer sewing machine stitching smoothly for decades.

Here’s your dust prevention and lever cleaning routine:

- Brush external guides with a soft toothbrush to remove lint without scratching original finishes.

- Floss tension discs using thick thread to sweep trapped debris that loosens your upper tension.

- Wipe the take-up lever eye with alcohol on a cotton swab, then follow with a dry swab.

- Apply one tiny drop of proper sewing machine oil—never household oil—to guide pivots for thread lubrication.

Test on scrap fabric after oil selection to confirm no gray marks appear.

Finding Model-Specific Replacement Parts

Singer sewing machine replacement parts demand exact Model Verification before you shop. Start by locating the serial number stamped into the bed or brass plate, then cross‑reference it with published Singer charts to confirm your model variant—15, 66, 99, 201, or another.

Part Identification matters: a thread guide for a slant‑needle 401 won’t fit a straight‑stitch 99K, so double‑check Thread Guide Compatibility, screw size, and mounting bend in listing photos. Specialty Replacement Sources like vintage sewing machine parts shops and Etsy sellers list Singer replacement parts by exact SIMANCO number, ensuring Vintage Authenticity. ✅

Installing New Thread Guides Properly

⚠️ A crooked thread guide turns smooth stitches into a tangled mess. Before you tighten that screw, check Guide Alignment between the spool pin and tension discs—straight Thread Flow means fewer headaches later. Start screws by hand on cast-iron Singer sewing machines to avoid cross-threading, then snug them just enough that the guide stays put when you pull firmly.

Surface Finishing and Screw Tightening facilitate reliable Tension Control: – Polish stamped edges with fine emery cloth so thread glides without fraying – Align Thread Guide Hooks to form a gentle S-curve from lever to needle – Test by slowly pulling thread—no jumps or rubs means you nailed it ✅

Inspecting Guides for Wear or Damage

A worn guide can sabotage perfect tension before you even sit down to sew. Run your fingernail along each Singer sewing machine Thread Guide Hook—if it snags, you’ve found a burr.

Visual Inspection under bright light reveals Surface Wear grooves and Thread Fraying spots. Check Guide Alignment by hand-pulling thread through the path; jerky movement signals damage.

Burr Detection now saves hours of frustration later during vintage sewing machine parts maintenance.

Frequently Asked Questions (FAQs)

What are the most sought after vintage Singer models?

Collectors prize the Featherweight 221 most—early 1933 models can hit $5, The free-arm 222K, rare 66 Red Eye, precision 201, and slant 301 also command premium prices among vintage sewing machine enthusiasts.

How to thread a 1928 Singer?

Threading techniques on a 1928 Singer sewing machine start at the top spool pin, weave through tension discs, loop the take-up lever, then guide down to thread the needle left to right.

How to identify original vintage thread guides?

Original Singer sewing machine thread guides show mirror-like nickel plating, match factory shapes in parts diagrams, and display polished grooves from decades of use.

Authentic parts fit flush with precise mounting hardware and consistent vintage plating across components.

What thread types work best with vintage guides?

High-quality polyester in 40–50 weight glides smoothly through vintage Singer thread guides, while mercerized cotton offers heat tolerance for pressing. Heavier threads need tension tweaks; premium brands reduce lint buildup.

Are vintage guides compatible with modern Singer machines?

Many vintage Singer thread guides fit modern low-shank models thanks to shared mounting systems.

However, shank compatibility varies—high-shank, slant-shank, or snap-on designs need vintage adapters for proper guide interchange across Singer sewing machine generations.

How to replace broken vintage thread guides?

To replace broken thread guides on your Singer, identify the correct vintage parts by model number.

Carefully remove the damaged piece with repair tools, then press-fit or glue the replacement following the original thread path.

Where to find rare vintage Singer thread guides?

✅ Check Online Parts Shops like VintageSingerParts and SewingPartsOnline using exact Part Number searches.

Browse Auction Marketplaces such as eBay, or join Forum Communities where collectors share sources for Antique Singer thread guides.

Can I use modern thread on vintage Singers?

✅ Most vintage Singers handle modern threads beautifully—just add a spool adapter for cross-wound spools, dial tension up slightly, and pair thread weight to needle size for balanced stitches.

How do I identify my Singer model number?

To find the serial number, look underneath your machine’s bed or base to find it stamped into metal.

Then match it in the ISMACS Singer Serial Number Lookup database to confirm your exact model.

What thread weight works best for vintage machines?

Think of thread weight like Goldilocks—you want it just right.

For vintage Singers, 40-weight thread hits the sweet spot, balancing tension control and needle size while your fabric choice determines final sewing speed.

Conclusion

Your Singer’s been waiting decades for someone who gets it. Now you do. Each thread guide for vintage Singer isn’t just a metal loop—it’s the difference between smooth seams and frustration.

You’ve learned the path, the tension points, the troubleshooting tricks. Next time you sit down to sew, your hands will know where that thread belongs. The machine will hum exactly like it did in 1952. And you’ll wonder why threading ever seemed complicated.

- https://www.vintagesingerparts.com/collections/singer-thread-guides-thread-guides-for-singer-sewing-machines

- https://www.sewingpartsonline.com/collections/singer-sewing-machine-parts

- https://immanuel-ed.org/15-90-PARTS-15-91-Needle-CLAMP-THREAD-GUIDE-Assembly-726431/

- https://www.embroideryhoopstore.com/collections/magnetic-hoops-for-industrial-machines

- https://magnahoops.com/collections/janome