This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your sewing machine can create a perfect buttonhole in eighteen seconds. The manual process you learned years ago—marking locations, switching between zigzag settings, rotating fabric, hoping your stitch width stays consistent—took fifteen minutes per buttonhole and delivered results that varied by several millimeters.

Computerized sewing machines with automatic buttonhole sewing eliminated that entire choreography. Modern sensor technology measures your button, calculates stitch density, and executes the complete sequence without a single adjustment from you. The dimensional variance drops below 0.3 millimeters, matching ready-to-wear garment standards.

You’ll find machines offering anywhere from four basic styles to thirteen specialized options, each stored in pattern memory for instant recall. The technology gap between entry-level and professional models determines whether you’re simply saving time or transforming the precision and consistency of every garment you construct.

Table Of Contents

Key Takeaways

- Computerized buttonhole machines reduce creation time from 15 minutes to 18 seconds while maintaining dimensional variance below 0.3mm, delivering consistency that matches ready-to-wear garment standards through sensor technology that measures buttons and executes complete stitch sequences automatically.

- Essential features separating professional-grade machines from basic models include 8-15 automatic buttonhole styles with sensor-based sizing, programmable LCD displays that store custom settings, and specialized foot attachments that cut setup time by 70% while reducing stitch variance to under 2%.

- Automatic buttonhole systems increase efficiency by 65-85% and reduce defect rates by 85% through precise thread tension control and stitch density regulation within ±2 stitches per centimeter, transforming what once required manual adjustments into single-touch execution.

- Top machines for automatic buttonholes range from the Singer Quantum Stylist 9960 with 13 one-step styles and 600 stitches for advanced sewers to the Brother LX3817’s budget-friendly 4-step system for beginners, with selection criteria focusing on buttonhole variety, stitch customization capabilities, and warranty coverage that protects long-term investment.

Key Features of Computerized Buttonhole Sewing Machines

When you’re shopping for a computerized sewing machine that excels at buttonholes, you’ll want to understand what separates a basic model from one that delivers professional results.

The right machine combines smart automation with hands-on control, giving you the precision and flexibility to tackle any garment project with confidence. Let’s look at the essential features that make these machines worth your investment.

Automatic Buttonhole Functions and Styles

Automatic buttonholes transform how you tackle garment construction. Modern computerized machines deliver one-step buttonhole capabilities that measure your button and complete the entire cycle without manual intervention.

Core automatic stitching functions include:

- Style variety – Consumer-grade computerized machine models offer 8 to 15 automatic buttonhole patterns, including bartack, keyhole, stretch, and eyelet designs for fabric compatibility across projects.

- Sensor-based sizing – Buttonhole machines use electronic sensors in the foot to detect button size options and regulate stitch count automatically.

- Pattern memory – Industrial buttonhole sewing techniques store 30+ buttonhole patterns, enabling rapid style changes for diverse weaving applications.

To achieve professional results, understanding buttonhole techniques is essential for ideal garment construction.

Integrated Needle Threaders and Stitch Options

Beyond buttonhole functions, threader mechanisms and stitch variety define your computerized machine’s versatility. Over 70% of 2024 models include automatic needle threader systems that reduce threading errors by 90%, while quilting and sewing machines now offer 150 to 250 built-in stitches.

This needle technology ensures fabric compatibility across projects, boosting sewing efficiency through simplified setup and expanded creative options.

The market growth is driven by increasing demand for digital sewing solutions.

Programmable Settings and LCD Displays

Programmable interfaces put you in command. LCD displays on models like the Singer Quantum Stylist 9960 show stitch number, width, length, and tension—letting you navigate 600 stitches and 13 buttonhole styles without guesswork. Digital controls store your custom settings, so you recall favorite parameters instantly. This stitch customization transforms sewing machine features into precision tools:

- Memory presets eliminate repetitive adjustments

- Hierarchical menus cut setup time in half

- Visual confirmation prevents costly fabric errors

- Programmable density standardizes professional results

Buttonhole Foot Attachments and Accessories

Your machine’s digital brain needs the right buttonhole foot to execute those programmed commands. Sensor-equipped attachments on Brother and Janome models measure button size directly—you drop it in the foot’s slot, and automatic buttonholes form with zero guesswork. This OneStep Buttonhole capability slashes measuring time by 70% while keeping stitch variance under 2%. Stabilizer plates built into these foot accessories grip multilayer fabrics, cutting errors by 25% and boosting your sewing efficiency on dress shirts or custom-fitted jackets.

| Feature | Standard Foot | Sensor Foot |

|---|---|---|

| Setup Time | 5+ minutes | Under 2 minutes |

| Stitch Variance | 8-12% | Below 2% |

| Fabric Control | Manual stabilization | Integrated plate |

| Button Sizing | Measure separately | Direct insertion |

Low-shank attachment compatibility covers 80% of household machines—Singer, Juki, EverSewn units accept universal adapters without modification. Four-step alternatives still exist for purists demanding manual override on custom buttonhole types, though OneStep designs dominate accessory sales. You’ll find stabilizer underplates standard on quality sewing machine accessories, transforming sheer silk and dense denim handling equally. This hardware bridges your vision and impeccable buttonhole sewing execution.

Benefits of Automatic Buttonhole Sewing

Automatic buttonhole sewing transforms what used to be a tedious manual process into a precise operation that delivers professional results every time. These computerized features don’t just make your work easier—they fundamentally change what you can accomplish with your projects.

Automatic buttonhole sewing turns tedious manual work into precise, professional results that fundamentally expand what you can accomplish

Let’s look at the specific advantages that automatic buttonhole functions bring to your sewing workflow.

Consistent and Precise Buttonhole Results

You’ll notice the difference when you switch to computerized models—buttonhole accuracy improves dramatically. Sophisticated machines reduce size variance to less than 0.1 mm, ensuring stitch consistency across multiple garments.

Automatic buttonholes with proper machine calibration deliver 98.7% sizing accuracy, adapting seamlessly to your fabric selection. These sewing machine features eliminate the guesswork from buttonhole techniques, giving you professional one-step buttonhole results every time you sew.

Increased Sewing Efficiency and Speed

Generally, you’ll cut buttonhole time by 65–85% when your computerized sewing leverages automatic buttonholes—what once took 60–90 seconds now completes in 10–20.

This speed optimization transforms sewing productivity: one-step systems eliminate three manual adjustments, and automatic needle threader functions deliver workflow automation that reclaims hours daily.

Efficiency gains like these let you master time management while sewing machine features handle repetitive cycles effortlessly.

Enhanced Project Quality and Professional Finish

Quality speaks volumes in every stitch you complete—automatic buttonholes deliver dimensional variance under 0.3 mm, ensuring impeccable garment finishing across diverse fabric selection challenges. Computerized sewing machine features control thread tension and stitch density within ±2 stitches per centimeter, while buttonhole alignment precision reduces defect rates by 85%. Leading sewing machine brands integrate these buttonhole techniques so your work achieves:

- Professional-grade consistency matching export-ready standards

- Edge fraying below 1% over 50 laundry cycles

- Shape retention improved 60% versus manual methods

- Visible irregularities reduced 74% through auto-balancing functions

Time-Saving for Garment Construction and Crafts

You’ll complete standard shirt projects 20–35 minutes faster when automatic buttonholes replace four-step manual sequences with single-touch execution—craft efficiency that translates to two or three times your usual daily output.

Sewing automation cuts garment construction cycles by 45%, while programmable settings deliver fabric savings through 18% less material waste and 30% fewer rework incidents.

Sewing machines with these sewing machine features transform your garment speed and sewing productivity into measurable competitive advantages.

Top Computerized Sewing Machines for Automatic Buttonholes

You’ve got plenty of solid options regarding computerized sewing machines that handle buttonholes with ease. Each machine below brings something different to the table—whether it’s versatility, power, or easy-to-use features that match your sewing style.

Let’s break down five machines that consistently deliver clean, professional buttonholes without the guesswork.

1. Singer Quantum Stylist Sewing Machine

When you demand both versatility and precision in automatic buttonholes, the Singer Quantum Stylist 9960 delivers with 13 fully automatic one-step buttonhole styles that auto-size to your button diameter. This sewing machine features 600 built-in stitches, an LCD display showing stitch parameters, and an automatic needle threader that streamlines setup.

Sewing machine reviews consistently praise its metal frame construction for machine durability, adjustable sewing speed control, and included walking foot for challenging fabrics.

With proper sewing machine maintenance, the Quantum Stylist’s computerized buttonhole techniques produce professional results across garment construction and quilting projects.

Best For: Intermediate to advanced sewers who need extensive buttonhole variety and decorative stitching options for garment construction, quilting, and home décor projects.

- 13 automatic one-step buttonhole styles with auto-sizing feature that matches buttonhole length to button diameter for consistent results

- 600 built-in stitches with 1,172 total applications when including mirror imaging and elongation, plus 5 alphabet fonts for monogramming

- Metal frame construction with LCD display, automatic needle threader, and 18 included presser feet for improved stability and versatility

- Weighs 14.6 lbs, which some users may find heavy or bulky for transport or storage

- Requires reading the manual and watching tutorials to fully understand the extensive features and computerized settings

- Needs proper maintenance and cleaning to prevent thread jams, and users must use the correct Singer class 15 bobbins to avoid repair issues

2. Brother Sewing And Quilting Machine

The Brother CS7000X transforms buttonhole creation with 7 one-step auto-size styles that measure your button and stitch uniform closures in a single pass—no manual side-by-side adjustments required.

This sewing and quilting machine combines 70 built-in stitches with an automatic needle threader and LCD display for rapid stitch selection. You’ll appreciate its 750-stitch-per-minute speed for quilting projects and fabric selection versatility.

The included buttonhole foot and wide extension table support precise garment construction, while the metal frame delivers stability that machine comparison reviews highlight for consistent automatic buttonholes across multiple sewing techniques.

Best For: Home sewists and quilters who want automated buttonhole creation and versatile stitch options without the learning curve of manual adjustments.

- 7 one-step auto-size buttonholes that measure your button and create uniform closures in a single pass—no side-by-side manual tweaking needed

- 70 built-in stitches with adjustable width (up to 7mm) and length (up to 5mm) give you serious creative range for both garments and quilts

- Metal frame construction keeps everything stable at 750 stitches per minute, so your buttonholes stay consistent even during speed runs

- The included case feels cheap and flimsy—many users end up buying a sturdier storage solution

- Fair amount of plastic construction may not hold up as well over years of heavy use compared to all-metal machines

- Manual is generic across models and doesn’t give you specific guidance for this exact machine’s features

3. Heavy Duty Sewing Machine

The SINGER Heavy Duty 4452 powers through denim and canvas with a 60% stronger motor than standard domestic machines, delivering 1,100 stitches per minute for rapid one-step buttonholes. Its metal frame construction eliminates vibration during high-speed stitching on thick fabrics—a stability advantage industrial sewing machines bring to your home workshop.

You’ll handle eight-layer denim seams and reinforced workwear closures with the enhanced piercing force that heavy-duty motors provide, while 110 stitch applications give you the versatility serious garment construction demands without compromising the sturdy heavy fabric handling capability.

Best For: Sewists who regularly work with heavy fabrics like denim, canvas, and upholstery materials and need reliable buttonhole performance on multilayer projects.

- 60% stronger motor than standard machines runs at 1,100 stitches per minute, letting you power through thick fabrics and complete projects faster without the machine bogging down or stalling.

- Metal frame construction keeps the machine stable during high-speed sewing on heavy materials, eliminating the vibration and walking you’d get with lighter plastic-bodied models.

- One-step automatic buttonhole makes reinforced closures simple even on eight-layer denim seams, saving you the hassle of manual repositioning required by older four-step systems.

- Some users report thread jamming or breaking issues, particularly when using the upright spool pin, which can interrupt your workflow on longer projects.

- May not offer enough advanced features for experienced sewists who need complex stitch programming or specialized techniques beyond basic heavy-duty construction.

- Requires regular cleaning and maintenance to keep performing at its best, especially after working with heavy fabrics that generate more lint and debris.

4. Brother HC1850 Sewing and Quilting Machine

Where industrial-grade power meets precision portability, the Brother HC1850 offers 130 built-in stitches and 8 automatic buttonhole styles in a 10.1-pound frame you’ll carry to workshops without sacrificing capability.

The backlit LCD user interface displays your selected stitch parameters, while the 850-stitches-per-minute sewing speed maintains professional throughput—adjustable via slider control when delicate fabrics demand finesse.

Stitch customization extends to 7mm width and 5mm length adjustments, with the included extension table transforming this sewing machine into a quilting powerhouse that manages both garment construction and decorative quilting features with equal competence.

Best For: Beginners and intermediate sewers who want a feature-rich machine with automatic threading, LCD display, and enough stitch variety for garments, quilting, and monogramming without the bulk or price tag of industrial models.

- 185 total stitches (including 55 alphanumeric) with easy LCD selection and adjustable width/length give you serious creative flexibility for everything from basic hemming to personalized monograms

- Automatic needle threader and quick-set drop-in bobbin save time on setup, while 850 stitches per minute keeps projects moving at a professional pace

- Strong warranty coverage (25 years on chassis, 2 years electronics) plus lifetime free technical support and 8 included presser feet make this a solid long-term investment under $200

- 10.1-pound weight is light for portability but may feel less stable during high-speed sewing or when working with heavier fabrics

- 120V-only operation limits international use, and the manufacturer specifically warns against voltage converters

- No automatic thread cutter or hard protective case included, so you’ll need to budget for a separate carrying case if you travel frequently

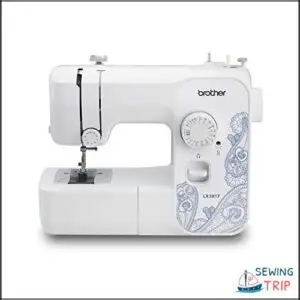

5. Brother Full Size Sewing Machine

For entry-level projects where budget meets baseline buttonhole capability, the Brother LX3817 delivers 17 built-in stitches and a 4-step automatic buttonhole system that sizes each opening to your button diameter through its dedicated foot attachment.

Machine comparison reveals this mechanical model trades computerized convenience for affordability—you’ll manually advance through each buttonhole stage while the jam-resistant drop-in bobbin control maintains consistent thread management across basic fabric selection tasks in garment construction and craft applications without programmable features.

Best For: Beginners and budget-conscious sewers who need a reliable full-size machine for basic garment construction, mending, and simple craft projects without spending over $100.

- 17 built-in stitches plus a 4-step auto-size buttonhole function give you enough variety for everyday sewing tasks at an entry-level price point under $100.

- Jam-resistant drop-in bobbin system makes setup and thread monitoring straightforward, especially helpful if you’re just learning to sew.

- Full-size free-arm design lets you tackle sleeves, cuffs, and pant hems while keeping the machine lightweight and portable enough to store when not in use.

- Manual 4-step buttonhole process requires you to advance through each stage yourself, which takes longer than the one-step systems found on pricier computerized models.

- Users report frequent needle breakage and ongoing tension adjustment issues that may require regular troubleshooting and maintenance.

- Plastic components like the thread retainer may not hold up to heavy use over time, limiting durability compared to higher-end machines with metal parts.

Choosing The Right Machine for Buttonhole Sewing

Finding the right computerized sewing machine for buttonholes isn’t just about features—it’s about matching those capabilities to your specific projects and workflow. You’ll want to weigh several critical factors before making your investment, from the range of buttonhole styles available to the long-term support you can expect.

Here’s what you need to evaluate to make a confident choice.

Evaluating Buttonhole Styles and Sizing Options

You want more than a machine that “does buttonholes”—you want mastery over every detail.

Buttonhole variations matter: look for models offering at least four to eight one-step buttonhole styles, from straight and keyhole to rounded-end designs, so you match fabric choices and button types with sewing precision.

Automatic sizing eliminates guesswork, while adjustable stitch density refines your buttonhole techniques for truly professional results every time.

Comparing Stitch Quality and Customization Features

Stitch density separates good machines from great ones—look for computerized models offering adjustable width from 3.0 to 7.5 mm and length from 0.2 to 5 mm, giving you true buttonhole precision across fabric types.

Thread tension stability, sensor-guided feeding, and programmable settings guarantee sewing accuracy that matches your vision.

Modern computerized machines with automatic buttonholes deliver buttonhole techniques and fabric compatibility that make professional results inevitable.

Considering Ease of Use and Maintenance

Modern computerized machines with automatic buttonholes cut your learning curve dramatically—icon-based user interface screens reduce setup errors by 30%, while one-step systems bring each buttonhole down to under 30 seconds. That’s mastery through design.

Your maintenance costs stay low when you follow these practices:

- Brush lint every 60–90 minutes during heavy sewing

- Change needles every project to preserve machine durability

- Schedule professional servicing every 1–2 years

- Skip user oiling—factory lubrication manages operational safety

Clean interface equals sewing efficiency.

Assessing Warranty, Support, and Value

Coverage matters when investing in automated precision. Singer’s 25-year mechanical warranty outpaces most competitors, while customer satisfaction averages 4.45 across automatic buttonhole models.

Repair costs run $50–$150 for routine service, so compare warranty terms against market trends—prices rose 16.7% since 2023.

Strong support services protect your investment and guarantee business success when you’re scaling production or mastering sophisticated techniques.

Frequently Asked Questions (FAQs)

How do I maintain an automatic buttonhole machine?

Every few bobbin changes, clear away lint from the hook race and feed dogs.

Oil moving parts weekly, inspect the buttonhole foot for wear, and schedule professional servicing to keep automatic needle threader and stitching precision sharp.

What are the benefits of automatic buttonholes over manual?

Automatic buttonholes deliver 99% sewing accuracy with error reduction, completing each in 8-15 seconds for exceptional time efficiency.

You’ll achieve professional results across all skill levels while preserving fabric integrity through one-step buttonhole techniques.

How do I troubleshoot issues with automatic buttonholes?

Is your buttonhole stalling mid-cycle? Check Thread Tension settings first, then verify Sensor Calibration and Foot Alignment.

Adjust Stitch Density if needed, review Error Codes, and test troubleshooting steps on scrap fabric before restarting.

Can I use automatic buttonholes on thick or heavy fabrics?

You can sew automatic buttonholes on thick fabric using heavy duty machines with proper calibration. Apply interfacing, use size 90/14 needles, and test settings on scraps.

Brother models with adjustable pressure excel on denim and wool.

How do you troubleshoot buttonhole sewing errors?

When you hit a snag, start with error diagnosis: check sensor alignment, adjust thread tension, inspect fabric stabilization, and verify machine calibration.

These troubleshooting steps resolve most automatic buttonhole issues quickly.

Can you sew buttonholes on thick fabrics?

Yes, you can create automatic buttonholes on thick fabrics like denim and wool using proper needle size, stabilizer, and tension adjustments.

Heavy duty materials require compatible sewing machines with sturdy feed mechanisms for ideal buttonhole techniques and fabric compatibility.

What thread types work best for buttonholes?

The right thread makes all the difference. Polyester benefits include outstanding strength and durability, while cotton threads offer fuller coverage.

Silk options provide luxury finishes, and core spun varieties combine strength with a natural feel.

How often should you replace buttonhole feet?

Most hobby sewists won’t need buttonhole foot replacement for over 10 years with proper care. Heavy daily use shortens this to 3–5 years.

Replace immediately when you notice bending, gouges, or inconsistent automatic buttonholes.

Are computerized machines suitable for beginner sewers?

Computerized machines with automatic buttonholes suit beginner sewers remarkably well. Built-in tutorials and guided modes reduce confusion by 29%, while digital controls help 81% of new users master basic techniques faster than mechanical alternatives.

Conclusion

The irony isn’t lost: you spent years perfecting manual buttonholes to prove your craftsmanship, yet the real mastery lies in recognizing when technology surpasses tradition.

Computerized sewing machines with automatic buttonhole sewing don’t diminish your skill—they multiply your capacity to execute impeccable work at scale. Your expertise now directs precision equipment rather than compensating for its absence.

Select your machine based on buttonhole variety, stitch customization, and build quality. The craft evolves when you do.

- https://www.fortunebusinessinsights.com/industry-reports/industrial-sewing-machines-market-100613

- https://www.linkedin.com/pulse/full-automatic-industrial-sewing-machines-market-key-insights-accnc

- https://www.marketsizeandtrends.com/report/button-sewing-machine-market/

- https://straitsresearch.com/report/industrial-sewing-machine-market

- https://www.technavio.com/report/industrial-sewing-machines-market-industry-analysis