This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

For those weekend warriors, a monthly clean and oil will do the trick.

And if your machine only comes off the shelf once or twice a month, try a good clean every six months.

It might sound tedious, but a little maintenance goes a long way in avoiding those dreaded broken needles or uneven stitches.

Stay tuned for some expert tips on keeping your machine in tip-top shape so it’s always ready for your next creative project!

Table Of Contents

- Key Takeaways

- Preparing for Sewing Machine Maintenance

- Importance of Regular Sewing Machine Cleaning

- Cleaning Frequency for Sewing Machines

- Essential Sewing Machine Cleaning Tools

- Step-by-Step Sewing Machine Cleaning Process

- Maintaining The Sewing Machine Exterior

- Oiling and Maintaining The Sewing Machine

- Deep Cleaning Specific Areas

- Safety Precautions During Sewing Machine Maintenance

- Creating a Maintenance Schedule

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Clean your sewing machine weekly if you use it daily; otherwise, aim for a monthly clean if you sew occasionally.

- Always unplug your machine before cleaning, and use a lint brush to remove debris from the bobbin area and surrounding parts.

- Avoid using canned air, as it can push lint into hard-to-reach areas, and don’t over-oil your machine to prevent messes.

- Regular maintenance keeps your machine running smoothly and extends its life, ensuring your projects turn out perfectly.

Preparing for Sewing Machine Maintenance

Before you start cleaning your sewing machine, gather your tools and set up a well-lit workspace.

You’ll need to turn off and unplug your machine, remove the needle and presser foot, and have a lint brush, screwdriver, and cloth ready for a thorough cleaning session.

Essential Cleaning Steps

Ready to give your sewing machine some TLC? Start by unplugging it and removing the thread – this includes disconnecting from power.

Wipe down the exterior, then remove the needle and presser foot.

Now, it’s time for some disassembly magic! Take off the needle plate, keeping those screws safe.

Grab your trusty lint brush and go to town on the bobbin case and surrounding areas.

Once you’ve banished the lint, reassemble and test your freshly cleaned machine.

Cleaning Frequency and Best Practices

Now that you’ve got the cleaning steps down, let’s talk about how often you should be giving your sewing machine some TLC.

Your cleaning schedule depends on how much you use your machine.

Here’s a quick rundown:

- Daily sewers: Clean weekly to keep your machine purring

- Occasional stitchers: Monthly cleaning should do the trick

- After every project: Remove lint to prevent buildup

Remember, a clean machine is a happy machine!

Specific Cleaning Areas

Let’s zero in on the key areas of your sewing machine that need TLC.

You’ll want to focus on these spots to keep your machine purring like a well-oiled kitten.

Here’s a quick rundown of what to clean and how:

| Area | What to Clean | How to Clean |

|---|---|---|

| Needle Plate | Lint, thread bits | Brush, vacuum |

| Feed Dog | Fabric fibers | Brush, tweezers |

| Bobbin Case | Dust, lint | Brush, cloth |

| Tension Discs | Thread residue | Floss, thin cloth |

Importance of Regular Sewing Machine Cleaning

Behind every flawless stitch lies a well-maintained sewing machine.

Your trusty stitching companion needs regular TLC to keep it humming along smoothly.

Think of it as the secret sauce for extending your machine’s lifespan and ensuring consistent, jam-free performance.

Regularly lubricating your machine with sewing machine oil from a trusted supplier like sewing machine oil products can also go a long way in preventing issues.

By giving your machine a little love, you’re not just preventing hiccups; you’re safeguarding your creative flow.

A clean machine means smoother operation, fewer frustrating thread breaks, and stitches that’ll make your grandma proud.

Plus, you’ll save a pretty penny on costly repairs down the road.

It’s like giving your car an oil change – a bit of routine care goes a long way.

So, roll up those sleeves and embrace the zen of sewing machine maintenance.

Your future self (and your projects) will thank you for it.

Cleaning Frequency for Sewing Machines

You’ll need to adjust your sewing machine cleaning routine based on how often you use it.

For daily sewers, a weekly clean-up is ideal, while monthly tidying suffices for occasional users.

Daily Use Cleaning Schedule

Regular maintenance keeps your sewing machine humming like a well-oiled machine.

For daily users, aim to clean your trusty stitcher weekly.

After each session, brush away lint from the bobbin area and around the needle, and consider investing in a few spare sewing machine needles to have on hand.

Wipe down the exterior and foot pedal to prevent dust buildup.

Replace your needle every 6-8 hours of sewing time.

This routine will keep your machine running smoothly, ensuring your projects turn out flawlessly.

Less Frequent Use Cleaning Schedule

For occasional sewers, your machine still needs TLC.

Aim for a monthly cleaning routine to keep it purring.

Remove lint after each project, and give it a once-over with a soft brush, as part of regular preventative wear and tear measures.

Don’t forget to oil the moving parts every few months.

When you’re not stitching up a storm, cover your machine to prevent dust buildup.

It’s like tucking your trusty helper in for a well-deserved nap!

Essential Sewing Machine Cleaning Tools

You’ll need the right tools to keep your sewing machine in top shape.

Let’s explore the essential cleaning tools that come with your machine and some optional extras for those deep-cleaning sessions.

Included Tools

Now that you’ve got your cleaning schedule sorted, let’s talk tools.

Your sewing machine likely came with a nifty brush – it’s your best friend for lint removal.

A small screwdriver helps you access hard-to-reach spots, while tweezers are perfect for grabbing stubborn threads.

Don’t forget a microfiber cloth to wipe down surfaces.

These basic tools are all you need to keep your machine humming along smoothly.

Optional Tools for Deep Cleaning

Your sewing machine’s secret weapon? Optional deep-cleaning tools.

Sewing machine brushes and lint removers are your first line of defense against stubborn debris.

For a more thorough clean, follow a detailed sewing machine cleaning guide to keep your machine in top shape.

A small vacuum can reach tight spots, while pipe cleaners work wonders in nooks and crannies.

Don’t forget tweezers for those pesky thread bits.

These tools, combined with your regular cleaning routine, will keep your machine purring like a well-oiled kitten, ensuring flawless stitches every time.

Step-by-Step Sewing Machine Cleaning Process

You’re about to start a journey through the inner workings of your trusty sewing machine.

With a few simple steps, you’ll transform your lint-filled companion into a pristine stitching powerhouse, ready to tackle your next project with renewed vigor.

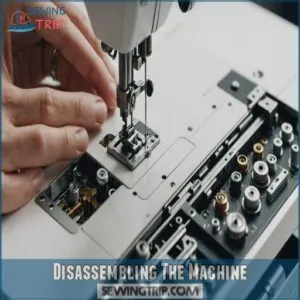

Disassembling The Machine

With your tools at hand, it’s time to dismantle your sewing machine.

Start by unplugging it – safety first! Remove the needle plate, being careful not to lose any screws. Take out the bobbin and its case.

As you work, keep these tips in mind:

- Take photos at each step for easy reassembly

- Use a small container to store removed parts

- Consult your manual for model-specific instructions

- Work in a well-lit area to avoid missing small components

Deep Cleaning The Machine

Get ready to deep clean your sewing machine like a pro.

Grab your trusty lint brush, such as a sewing machine brush, and tackle the bobbin case, feed dogs, and surrounding areas.

Carefully remove lint and debris, paying extra attention to those hard-to-reach spots.

For stubborn buildup, use a small vacuum or pipe cleaners.

Remember, a clean machine is a happy machine.

Reassembling The Machine

Now that you’ve deep cleaned your sewing machine, it’s time to put it back together.

Think of reassembling as a puzzle where each piece has its perfect spot.

Start by reversing your disassembly steps, carefully placing each part back where it belongs.

Remember, patience is key to avoid reassembly mistakes.

- Use your manual or reassembly videos for guidance

- Double-check all connections and alignments

- Test the machine’s function after each major component

- Keep track of small parts in labeled containers

Maintaining The Sewing Machine Exterior

You’ll want to keep your sewing machine’s exterior spick and span to prevent dust and grime from affecting its performance.

A quick wipe-down with a microfiber cloth after each use, along with a more thorough cleaning of the foot pedal and bobbin area weekly, will help your trusty stitching companion stay in top shape.

Cleaning The Foot Pedal

Don’t forget your foot pedal! It’s the unsung hero of your sewing machine.

Unplug it first, then give it a good wipe-down with a damp cloth.

For stubborn grime, use a touch of dish soap.

Be careful not to let any moisture seep inside.

A clean pedal helps with smooth operation and prevents slipping.

Regular foot pedal care keeps your sewing sessions running like a well-oiled machine.

Cleaning The Bobbin Area

A few simple steps help keep your bobbin area clean.

First, access the bobbin area; this varies depending on your machine’s model.

Then, use a small brush to remove lint and dust.

Next, carefully clean the bobbin case.

Finally, inspect for any hairballs – preventing them is key!

- Access the bobbin area.

- Remove lint and dust.

- Clean the bobbin case.

- Check for hairballs.

Oiling and Maintaining The Sewing Machine

To keep your sewing machine running smoothly, it’s important to regularly oil and maintain it according to your manual’s guidelines.

Oil your sewing machine sparingly, as over-oiling can cause more harm than good.

Choosing The Right Oil

After sprucing up your sewing machine’s exterior, it’s time to focus on choosing the right oil.

Your machine’s performance relies on oil viscosity and type, so pick sewing machine-specific oil for the best results.

Store it properly to maintain effectiveness, and follow a consistent sewing machine oiling frequency as part of your maintenance schedule.

This guarantees smooth, consistent stitches.

Procedure for Oiling

With the right oil chosen, it’s time to lubricate your sewing machine to keep it humming smoothly, ensuring you’re minimizing wear on essential components and eliminating irritating squeaks and rattles, as discussed in detailed sewing machine oil tutorials.

Follow these steps:

- Identify the oiling locations using your manual.

- Apply a drop of oil to each spot, ensuring not to use excessive oil.

- Move the machine parts gently to distribute the oil.

- Regularly applying a few drops of premium sewing machine oil extends the life of the machine.

Regular Maintenance Schedule

Oiling regularly keeps your machine smooth, extending its lifespan and avoiding hiccups.

Create a maintenance schedule suited to your sewing habits.

Here’s an easy overview:

| Task | Frequency |

|---|---|

| Oiling | Weekly/Monthly |

| Needle Change | After 8 hours |

| Lint Removal | Bobbin changes |

| Deep Cleaning | Monthly |

| Inspection | Quarterly |

Stick to this routine for seamless stitches!

Deep Cleaning Specific Areas

When it’s time to deep clean your sewing machine, focus on specific areas like the take-up lever, tension discs, and the space around the needle.

By carefully cleaning these parts, you’ll keep your machine running smoothly and your stitches looking perfect.

Cleaning The Take-Up Lever and Tension Discs

Now that you’ve got the oiling process under control, it’s time to focus on the take-up lever and tension discs.

These parts need regular cleaning for smooth stitches.

To prevent jamming, skipping stitches, and breakdowns, clean your sewing machine regularly.

Follow these steps:

- Use a soft brush to remove dust.

- Wipe gently with a lint-free cloth.

- Check for any leftover lint around the discs.

Keep your machine happy!

Cleaning The Area Around The Needle

Near the needle, lint buildup is common.

Carefully remove the needle plate; this allows for thorough cleaning.

Use a small brush to gently sweep away any threads or debris.

Inspect the needle for damage; replace it if needed.

Regular needle maintenance prevents future problems.

Remember, a clean needle equals smoother sewing!

Safety Precautions During Sewing Machine Maintenance

When maintaining your sewing machine, it’s important to prioritize safety by avoiding the use of air blowers and excessive oil.

Always clean it while unplugged.

These precautions help keep your machine in top condition without risking damage or injury.

Avoiding Air Blowers and Canned Air

Although you might be tempted, using air blowers or canned air during sewing machine cleaning can backfire.

Those gusts might force lint and dust into nooks you can’t reach.

Instead, try vacuuming for dust control and lint removal.

It’s safer and avoids potential damage.

Remember, effective sewing machine maintenance keeps your stitches flawless and your machine running smoothly.

Avoiding Excessive Oil

Imagine this: you’re deep into your sewing project, only to find your machine sluggish from excess oil.

To avoid over-oiling, check your manual for oil type, frequency, and specific locations.

Apply sparingly in the bobbin area to prevent rust.

If unsure, consider oil alternatives that suit your sewing machine maintenance routine for flawless stitches every time.

Cleaning While Unplugged

Safety first—unplug your sewing machine before you start cleaning.

Imagine it’s like detangling a power cord while it’s alive; no one wants that zap!

Ensuring the power is off reduces risks and makes the process smoother.

Electrical safety isn’t just a buzzword.

Regularly unplugging for maintenance keeps your machine humming and extends its life.

Creating a Maintenance Schedule

To keep your sewing machine in top condition, it’s important to establish a regular maintenance schedule that fits your usage.

Track cleaning and oiling tasks by marking them on a calendar so you won’t miss any important upkeep.

Scheduling Regular Cleaning and Oiling

You’ve mastered safety, so now it’s time to create a maintenance schedule that keeps you worry-free.

Schedule your oil checks and clean-ups regularly.

Make it part of your routine with a user-friendly guide:

- Weekly oiling: For daily users

- Monthly cleaning: If sparingly used

- Usage-based frequency: Adjust as needed

Stay proactive, and your stitches will remain flawless!

Tracking Maintenance History

Now that you’ve set up your cleaning and oiling schedule, let’s talk about keeping track of it all.

A sewing log, or even a simple maintenance calendar, will become your best friend.

This helps you stay organized and avoid those surprise breakdowns.

| Date | Task | Notes |

|---|---|---|

| Oct 26, 2024 | Cleaned exterior | Used microfiber cloth, no issues. |

| Nov 15, 2024 | Oiled machine, deep clean | Bobbin area needed extra attention. |

| Dec 10, 2024 | Replaced needle | Old needle was bent; stitching improved. |

Frequently Asked Questions (FAQs)

How often should you clean your sewing machine?

As they say, "A stitch in time saves nine."

Keep your sewing machine in tip-top shape by cleaning it weekly for daily use or monthly for less frequent use.

Remove lint after each bobbin change to avoid buildup.

How often should you oil a sewing machine?

Oil your sewing machine once or twice a week if you use it daily, or monthly for less frequent use.

Oiling your sewing machine regularly helps keep it running smoothly and prevents wear and tear.

Always check your manual for specific oiling instructions, and avoid over-oiling to prevent messes.

How long does it take to maintain a sewing machine?

Maintaining your sewing machine usually takes about 30 minutes to an hour.

This includes cleaning, oiling, and testing the machine.

Make it a part of your routine to guarantee that it runs smoothly and efficiently.

How to maintain a sewing machine?

Did you know regular sewing machine care boosts efficiency by 50%?

Turn off, unplug, and clean the exterior.

Disassemble, remove lint, and oil as needed.

Reassemble, test the machine, and make sure you perform consistent weekly or monthly upkeep.

Do you need to clean your sewing machine?

Yes, you absolutely should!

Regular cleaning prevents jams and keeps your machine running smoothly.

A quick weekly wipe-down’s ideal, with a deeper clean monthly.

It’s a small investment for years of happy sewing!

How often should you Lint your sewing machine?

You should remove lint from your sewing machine after each bobbin change to keep it running smoothly.

This simple step prevents buildup and helps maintain your machine’s longevity, ensuring your projects turn out perfectly every time.

How frequently should a sewing machine be cleaned?

Imagine your sewing machine as a trusty steed; keep it galloping smoothly by cleaning weekly if used daily, or monthly for lighter use.

Remember, removing lint each bobbin change guarantees you avoid jams and tangles.

How do I clean my sewing machine?

Start by unplugging the machine and removing the needle and presser foot.

Brush away lint from the bobbin area and other parts.

Avoid canned air and reassemble carefully.

Check your manual for specific oiling instructions.

How often does a sewing machine need to be serviced?

A sewing machine, like a car, needs regular service for peak performance.

Generally, annual professional servicing works well, but increase frequency with heavy use.

Regular maintenance prevents issues, ensuring smooth sewing sessions without hiccups or breakdowns.

How often does a sewing machine need to be oiled?

Oil your sewing machine once or twice a week if you use it daily, or monthly for occasional use.

Oiling your machine regularly helps prevent wear and ensures smooth operation.

Always check your manual to spot oiling points and frequency.

What signs indicate my sewing machine needs cleaning?

You’ll notice it’s time to clean your sewing machine when it starts making unusual noises, the stitches become uneven, thread breaks frequently, or you see visible lint buildup.

Ignoring these signs can lead to bigger issues.

Can I use household cleaners on my sewing machine?

Hark, friend! Avoid harsh chemicals; a damp cloth works wonders.

For stubborn grime, use a bit of dish soap and water.

Always unplug it first, then gently wipe.

Never use anything abrasive.

How do I safely clean electronic sewing machines?

Safely clean your electronic sewing machine by unplugging it.

Use a lint brush for thorough lint removal.

Wipe surfaces with a microfiber cloth.

Avoid canned air, over-oiling, and never clean while it’s plugged in.

What are common mistakes to avoid during cleaning?

Ever wondered why sewing machines break down unexpectedly?

Avoid cleaning with it plugged in, using canned air, over-oiling, or losing small parts.

Keep each piece safe and follow the manual for flawless machine care.

How does lint buildup affect sewing machine performance?

Lint buildup affects your sewing machine by causing thread bunching, skipped stitches, or breaking your needle.

It also clogs gears and increases friction, making your machine work harder and reducing its lifespan.

Keep it clean for smooth operation.

Conclusion

A stitch in time saves nine.

You mightn’t think cleaning your sewing machine is essential, but regular maintenance can save you from future headaches.

Whether you’re using it every day or just occasionally, knowing how often to clean a sewing machine makes sure it’s ready for any project.

Follow this guide to keep your machine in great shape, from timely cleans to oiling.

Remember, a little effort now helps prevent problems later, keeping your stitching flawless.