This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

The quilting industry generates over $4 billion annually, and the machines powering this market bear little resemblance to your grandmother’s sewing setup. Today’s industrial quilting machines stitch at speeds exceeding 3,000 stitches per minute, handle throat spaces spanning 26 inches, and integrate computerized systems that transform production workflows.

Whether you’re scaling a custom bedding operation or outfitting an automotive upholstery facility, the brand you choose determines your production capacity, maintenance costs, and competitive edge. Names like Juki, Gammill, and Handi Quilter dominate professional workshops for specific reasons—their machines solve distinct production challenges through decades of engineering refinement.

Understanding what separates these manufacturers helps you match machine capabilities to your actual workload demands and growth trajectory.

Table Of Contents

- Key Takeaways

- Leading Industrial Quilting Machine Brands

- Top 10 Industrial Quilting Machines

- 1. Juki Computerized Sewing and Quilting Machine

- 2. Brother PQ1600S High Speed Sewing Machine

- 3. Singer Quantum Stylist Sewing Machine

- 4. Brother Sewing and Quilting Machine XR3774

- 5. Brother Computerized Sewing Machine

- 6. Juki TL-2000Qi Sewing Quilting Machine

- 7. Janome Sewing And Quilting Machine

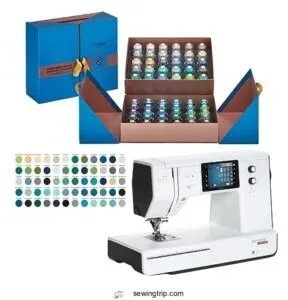

- 8. Bernette Computerized Sewing Machine Bundle

- 9. High Speed Sewing Machine Juki

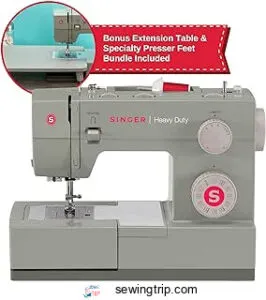

- 10. Singer Heavy Duty Sewing Machine

- Key Features of Industrial Quilting Machines

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You need machines that match your actual production volume and fabric types—industrial quilters like Juki and Gammill deliver 1,500–3,500 stitches per minute with throat spaces up to 30 inches, while brands like Handi Quilter and APQS excel at computerized precision for custom work.

- Your choice between computerized and mechanical models fundamentally changes workflow efficiency—computerized systems cut stitch variance to under 2% and boost productivity by 40% through automated features, though they cost significantly more upfront than mechanical alternatives.

- Total ownership costs extend far beyond the purchase price—factor in $100–$300 routine maintenance every few months, energy consumption differences of up to 30% between servo and induction motors, and warranty coverage that ranges from 1–10 years depending on components.

- Test-driving three machines from different price tiers under real workload conditions reveals performance gaps that spec sheets can’t capture—hands-on comparison exposes how throat space, stitch regulation, and frame ergonomics actually perform with your specific fabric handling requirements.

Leading Industrial Quilting Machine Brands

When you’re scaling up production or stepping into professional quilting, the brand behind your machine matters more than you might think. Some manufacturers have spent decades perfecting industrial-grade engineering, while others bring advanced automation to the table.

Here’s a rundown of eleven brands that consistently deliver the reliability and performance you need on the factory floor.

ABM International

ABM International stands as a powerhouse in Industrial Quilting Machines, delivering high-speed solutions for automotive upholstery, marine applications, and bedding production. With a rich ABM History in Quilting Innovations and Industrial Sewing, you’ll find their Longarm Quilting Machines engineered for demanding factory environments.

Their focus on enhanced Fabric Handling and simplified Machine Maintenance means you’re investing in equipment that won’t slow your Industrial Applications down. The company’s success is driven by the growing demand for industrial quilting technologies.

Handi Quilter

While ABM dominates factory floors, Handi Quilter connects with the Quilter Community through premium Longarm quilting machines built for serious production. You’ll appreciate their 2025 revenue of $14.4 million, backed by models like Moxie, Capri, Infinity, and Amara that deliver outstanding Stitch Quality with minimal Machine Maintenance. The company’s success can be attributed to its strong presence in the Edtech industry trends.

Their strengths include:

- Intuitive controls for mastering sophisticated Quilting Techniques

- Sturdy construction ensuring consistent performance across fabric types

- Extensive training resources supporting smart Fabric Selection

- Reliable customer support minimizing downtime

- Proven track record among Industrial longarm quilting machines

Innova

You’ll find Innova Models deliver outstanding Stitch Quality through powerful motors that reach 3,000 stitches per minute across their Longarm quilting machines. Their Industrial quilting machine manufacturing focuses on low Machine Maintenance requirements with US-made construction and extensive 5-year warranties.

INNOVA Longarm Quilting Systems include the 18″, M20, and Classic 22″ models, each designed to advance your Quilting Techniques while maximizing Longarm Features for consistent production reliability.

Nolting

When you’re ready for custom-built reliability, Nolting brings over 40 years of Nolting History to Industrial quilting machine manufacturing. Their Longarm quilting machines—from Fun Quilter through Diamond Project models—give you flexible Fabric Selection paired with precise Stitch Patterns.

You’ll master sophisticated Quilting Tips through modular design that simplifies Machine Maintenance. Nolting stands among proven Longarm quilting machine brands and Quilting machine brands delivering customized production solutions.

Gammill

With over 40 years of Gammill History, you’ll find four decades of Quilting Techniques refinement in every Industrial Quilting Machine. Your Longarm quilting machines gain peerless Stitch Quality through:

- Statler computerized precision across production runs

- Enhance models delivering consistent Fabric Selection handling

- Vision 2.0 advancing automated pattern execution

- Simplified Machine Maintenance protocols across Longarm quilting machine models

Gammill earned $8.9 million in 2025, solidifying its position among elite Quilting Machine Brands.

APQS

Precision-driven manufacturing distinguishes APQS among Longarm quilting machine brands. Your Industrial quilting machines access computerized control through Millie, Millie 30, Freddie, and Lucey configurations, each optimizing Stitch Quality for demanding production schedules.

| APQS Models | Quilting Techniques | Machine Maintenance |

|---|---|---|

| Millie | Edge-to-edge precision | Simplified protocols |

| Millie 30 | Extended throat workflows | Modular components |

| Freddie | Multi-layer handling | Quick-access systems |

| Lucey | Pattern automation | Integrated diagnostics |

APQS Accessories improve Longarm quilting machines through standardized mounting systems supporting your evolving Quilting machine models requirements.

Brother Industries

Brother Industries anchors your Textile Manufacturing workflows through Sewing Innovation proven across Industrial Applications. The Brother PQ1600S delivers Machine Reliability at production scale, complementing broader Industrial Quilting Machines portfolios.

Your Sewing Machines integrate Quilting Accessories through standardized mounting, extending Quilting Machines capability beyond conventional parameters.

This multinational footprint ensures consistent performance across diversified manufacturing environments requiring adaptable equipment solutions.

Bernina International AG

Swiss Engineering meets quilting mastery when you explore Bernina International AG’s legacy. This brand’s Textile Expertise spans generations, delivering Sewing Precision that professional quilters demand in industrial quilting environments.

Bernina’s history showcases relentless Quilting Innovations, from computerized quilting systems to longarm quilting machines. Your production workflows gain reliability through their methodical approach to equipment design, where each stitch reflects decades of manufacturing refinement within competitive European textile markets.

Juki Corporation

When you demand speed without sacrificing stitch quality, Juki Corporation delivers Industrial Quilting Machines engineered through rigorous Manufacturing Process standards. Their Juki History in Industrial Applications places them as pioneers in Sewing Technology innovation.

- The Juki 2010q and Juki HZLF600 exemplify their Quilting Innovations for professional environments

- High-speed capabilities reach industrial-grade performance thresholds

- Your production demands meet machines built for continuous operation

- Sewing Machine durability reflects decades of Japanese manufacturing expertise

Pfaff Industrial

Pfaff History brings German precision engineering to Industrial Quilting Machines designed for uncompromising production demands. Your Quilting Machine expectations meet Industrial Sewing standards refined across decades of Fabric Handling innovation.

Longarm quilting machines from Pfaff deliver reliability where Sewing Machine performance directly impacts profitability.

| Feature | Specification | Application |

|---|---|---|

| Speed Range | 1,500–2,800 SPM | High-volume production |

| Throat Space | 10–18 inches | Commercial projects |

| Machine Maintenance | Minimal lubrication | Extended uptime |

| Quilting Techniques | Multi-pattern capability | Decorative & structural |

Aisin Seiki Co., Ltd

Aisin History traces Japanese Innovation from Automotive Solutions into textile machinery, where Co Ltd engineering transforms Industrial Sewing expectations.

Your Quilting Machine needs meet precision standards forged in automotive manufacturing—Seiki Products apply that same exacting methodology to Longarm quilting machines.

The Quilting industry gains access to Sewing Machines built with tolerances usually reserved for engine components, delivering unequalled consistency across production runs.

Top 10 Industrial Quilting Machines

You need machines built to handle production volume without breaking down mid-shift. The right equipment balances speed, precision, and durability while fitting your workflow requirements.

Here are ten industrial quilting machines that deliver consistent performance across various manufacturing applications.

1. Juki Computerized Sewing and Quilting Machine

The Juki DX-2000QVP stands as a powerhouse in computerized sewing and quilting machine design, delivering 1,050 stitches per minute for serious production work. With 287 stitch patterns and four fonts built-in, it offers creative flexibility across diverse quilting techniques.

This industrial machine features 8 inches of workspace and programmable foot control accessing seven functions, managing everything from straight-line precision to complex fabric compatibility challenges.

The automatic needle threader and jam-resistant build minimize downtime, though proper machine maintenance ensures long-term reliability. Juki models consistently deliver the sewing speed professionals demand.

Best For: Experienced sewers and quilters who need a reliable, high-speed machine for both creative projects and production work, especially those working with large quilts or multiple fabric types.

- Impressive 1,050 stitches per minute with 287 stitch patterns and 4 fonts, giving you serious creative range and speed for complex quilting projects.

- 8 inches of workspace to the right of the needle and programmable foot control with 7 functions make handling large quilts and detailed work much easier.

- Automatic needle threader and jam-resistant design cut down on frustration and keep you sewing instead of troubleshooting.

- Some users report the automatic needle threader and bobbin winder can be finicky or stop working properly over time.

- Not ideal for very heavy or thick fabrics—it handles thin to medium-weight materials best, which limits certain project types.

- The computerized functions and settings take some practice to master, so beginners might feel overwhelmed at first.

2. Brother PQ1600S High Speed Sewing Machine

Brother’s PQ1600S accelerates your workflow with 1,500 stitches per minute—outpacing most semi-industrial machines you’ll encounter. The 5.7 x 8.6-inch throat space accommodates bulky quilt sandwiches, while the extension table stretches to 11.1 x 23.3 inches for precise fabric management on large-scale projects.

You’ll master complex quilting techniques using the adjustable pin-feed mechanism and knee lifter for hands-free control. Thread management stays consistent through the manual tension dial and built-in cone stand, though regular machine maintenance at 500-hour intervals keeps this high-speed sewing machine delivering commercial-grade performance across thick materials.

Best For: Quilters and sewists handling high-volume projects who need commercial-grade speed and a large workspace for thick fabrics and intricate stitching.

- Blazing 1,500 stitches per minute with an extra-large workspace (5.7 x 8.6-inch throat, 11.1 x 23.3-inch extension table) makes quick work of bulky quilts and multi-layer projects.

- Hands-free knee lifter and adjustable pin-feed mechanism give you precise control over fabric movement, especially helpful for free-motion quilting and complex patterns.

- Solid 25-year chassis warranty and metal construction mean this machine can handle heavy daily use without breaking down.

- Threading the machine can be tricky, and the side-loading bobbin won’t always warn you when thread runs out.

- Runs loud at top speed, and the top thread tension dial is positioned awkwardly, making quick adjustments harder than they should be.

- Pin feed mechanism and needle threader may wear out or feel clunky with extended use, requiring periodic maintenance or workarounds.

3. Singer Quantum Stylist Sewing Machine

When sewing machine reviews highlight 850 stitches per minute alongside 600 built-in patterns, Singer’s 9960 model stands out for its computerized precision rather than raw speed. This $330–$400 Singer quilting machine bridges desktop versatility with production-grade automation, requiring standard sewing machine maintenance every 100 hours under heavy use.

You’ll manage quilting fabric selection through the LCD panel’s real-time stitch adjustments, while automatic stitch modes simplify pattern switching across the 6.5-inch throat space. Thread tension control operates automatically, though the quilter community support forums recommend manual calibration for specialty projects.

Best For: Quilters and experienced sewers who want computerized precision with a wide variety of stitch options for both decorative projects and fast-paced production work.

- Fast stitching speed of 850 stitches per minute with 600 built-in patterns and automatic features like needle threading and tension control that save time on setup and adjustments.

- Comprehensive accessory package worth $350 includes 18 presser feet, extension table, and specialty tools that cover most quilting and garment-making needs right out of the box.

- LCD panel provides real-time stitch information and easy pattern selection, making it simple to switch between techniques without constant manual reference.

- The 6.5-inch throat space may feel limiting for larger quilting projects compared to dedicated long-arm machines.

- At 20 pounds, the machine is heavy and not easily portable for classes or sewing groups.

- Some users report inconsistent stitch quality and issues with the needle threader and feed dogs that may require troubleshooting or manual adjustments.

4. Brother Sewing and Quilting Machine XR3774

When Quilting Machine Reviews feature a sub-$170 model delivering 37 stitches plus 800 stitches per minute, the XR3774 proves that budget constraints don’t eliminate quilting capability. Thread Management simplifies through the automatic threader and top drop-in bobbin system.

You’ll execute Sewing and Quilting Techniques across its wide extension table, though expect vibration during high-speed work—unlike the Brother PQ1600S’s industrial-grade stability. This Sewing Machine demands minimal Machine Maintenance beyond regular cleaning, while its included walking foot accommodates layered Fabric Selection for Quilt Patterns.

Best For: Beginners and intermediate sewers who want an affordable, feature-packed machine for everyday projects and quilting without breaking the bank.

- You get 37 built-in stitches and speeds up to 800 stitches per minute, plus helpful features like an automatic needle threader and quick drop-in bobbin that make setup genuinely easy.

- The wide extension table and eight included feet (walking, quilting, buttonhole, and more) give you serious quilting capability right out of the box.

- At under $170 with a 25-year limited warranty, it’s one of the best values in entry-level quilting machines—proven by years of reliable service from long-term users.

- The machine vibrates and can shift around during high-speed sewing on heavy projects, and the bottom grips don’t hold it steady like more expensive models.

- It’s not quiet, so expect some noise during operation compared to higher-end machines.

- The automatic needle threader can be finicky to use, and the extension table sometimes comes loose when you’re working on larger quilting projects.

5. Brother Computerized Sewing Machine

Precision meets versatility in the Brother Computerized Sewing Machine. You’ll appreciate the LCD interface for easy stitch selection and real-time Thread Management, while the sophisticated needle threader streamlines Machine Maintenance.

Whether you’re tackling intricate Quilting Patterns or basic Sewing Techniques, the wide table assists efficient Fabric Handling. Unlike the industrial Brother PQ1600S, this model excels in intuitive Computerized Sewing for creative projects.

For anyone seeking a reliable entry in the Quilting Machines category, this Sewing Machine Guide delivers both innovation and practical value.

Best For: Home sewers and quilters who want computerized precision and creative flexibility without the complexity or cost of industrial machines.

- 185 built-in stitches including 55 alphanumeric options and 8 auto-size buttonholes give you serious creative range for everything from quilting to monogramming.

- LCD screen and advanced needle threader make stitch selection and setup genuinely painless, even if you’re just getting started.

- Comes loaded with accessories—wide table, 8 presser feet, and instructional DVD—so you’re ready to tackle different projects right out of the box.

- Lightweight design might feel too flimsy for heavy-duty projects or thick fabric layers compared to sturdier industrial models.

- Only works with 120V AC and is sold for US use only, so international buyers are out of luck even with adapters.

- Some users may need time to adjust settings and get comfortable with the computerized features before achieving consistent results.

6. Juki TL-2000Qi Sewing Quilting Machine

When industrial-grade performance fits on your worktable, the Juki TL-2000Qi delivers. This Sewing Machine harnesses 1,500 stitches per minute—Sewing Speed that rivals dedicated Industrial Machines—yet remains portable enough for home studios.

You’ll master sophisticated Quilting Techniques through its straight-stitch precision and automatic thread trimmer, tools usually reserved for Longarm Quilting Machines. The aluminum die-cast frame ensures minimal vibration during Fabric Handling, while the knee lifter and LED lighting simplify Thread Management.

With a 5-year mechanical warranty, Machine Maintenance stays straightforward, making this powerhouse ideal for professionals demanding reliability without compromise.

Best For: Quilters and sewers who need industrial-level speed and precision for thick fabrics, large projects, and free-motion work but want a machine that fits in a home studio.

- Blazing 1,500 stitches per minute with rock-solid aluminum construction means you can power through king-size quilts and heavy materials like denim without the machine vibrating across your table.

- Automatic thread cutter and knee lifter let you keep both hands on your work, making it way easier to tackle detailed quilting without constantly stopping to snip threads or wrestle with the presser foot.

- Five-year mechanical warranty and straightforward maintenance give you peace of mind that this workhorse will keep running, plus it uses common needles and accepts industrial presser feet for serious versatility.

- Straight stitch only, so if you’re looking for decorative stitches or zigzag options, you’ll need a different machine for those jobs.

- The automatic needle threader can be finicky and might need tweaking, and the bobbin area is a bit awkward to reach if you’ve got arthritis or larger hands.

- At 25 pounds and requiring a voltage converter outside North America, it’s not the most portable or plug-and-play option if you travel or live abroad.

7. Janome Sewing And Quilting Machine

When 170 stitches meet 1,000 SPM velocity, you’re commanding one of Janome’s most multifaceted Quilting Machines—the Memory Craft series delivers Computerized Sewing precision without sacrificing raw throughput.

Your Fabric Selection expands through automatic thread cutters and drop-feed capability, while the 10-inch flatbed rivals Longarm Quilting workspace on a compact frame.

Janome Models like this balance sophisticated Quilting Techniques with straightforward Machine Maintenance, backed by durable construction that withstands industrial-level demands.

For Sewing Speed that conforms to intricate piecing or production runs, this Sewing Machine proves flexibility drives mastery.

Best For: Quilters and experienced sewists who need a fast, feature-rich machine with professional workspace and automatic conveniences for tackling both intricate piecing and high-volume projects.

- 170 stitches plus dual alphabets and 1,000 SPM speed give you serious creative range and productivity without compromising precision on detailed work.

- 10-inch seamless flatbed and one-push needle plate conversion let you switch between quilting and standard sewing without cramping your project space.

- Automatic thread cutter, superior needle threader, and memorized needle up/down cut down on repetitive tasks so you can focus on the actual sewing.

- Some users report skipped stitches or thread cutter malfunctions, suggesting quality control inconsistencies that may require service calls.

- The instruction booklet leaves gaps, so you might spend extra time troubleshooting features or hunting down tutorials online.

- At $1,999, it’s a significant investment, and Janome’s recent financials show declining profits—raising questions about long-term support and parts availability.

8. Bernette Computerized Sewing Machine Bundle

At 394 stitches backed by 820 SPM, you’re unlocking the Bernette Bundle’s creative range without sacrificing Computerized Sewing precision. Eight presser feet and a 170 mm free arm transform your Quilting Techniques from concept to finished quilt top.

This Sewing Machine package delivers Sewing Accessories valued at $249, automatic thread cutters, and memory storage for pattern recall, positioning it as a cost-effective alternative to dedicated Longarm Quilting frames.

User Experience centers on minimal Machine Maintenance and straightforward digital controls, proving Bernina’s sister brand understands production flexibility.

Best For: Sewers and quilters who want a feature-packed machine with hundreds of stitches and automated functions without spending over $1,000.

- 394 built-in stitches with memory storage let you save custom patterns and switch between projects quickly, plus the 820 stitches-per-minute speed keeps production moving.

- Bundle includes $249 worth of accessories like eight presser feet, bobbins, and needles, so you’re not buying extras separately right after unboxing.

- Automatic thread cutter and needle threader reduce setup time and hand strain, especially helpful during long quilting sessions.

- No automatic tension adjustment means you’ll dial it in manually when switching between fabric types, which adds a learning curve for beginners.

- Thread cutter sometimes snips too close to the needle, forcing you to rethread more often than you’d like mid-project.

- Some users report motor issues and slow customer support response times, which could leave you stuck if the machine needs repairs.

9. High Speed Sewing Machine Juki

When you’re chasing 5,500 stitches per minute, the High Speed Juki 2010Q Semi-Industrial Machine redefines your workflow. This straight-stitch powerhouse merges Machine Durability with an all-metal frame, delivering consistent Fabric Handling across heavy quilts and multi-layer textiles.

Sewing Speed reaches commercial thresholds without computerized complexity, letting you focus on sophisticated Quilting Techniques. Juki Maintenance requires regular oiling, yet user reports confirm 15+ year service lives.

At 37.8 pounds and with automatic needle threading, the Juki Sewing Machine anchors your production line with reliable, no-frills muscle.

Best For: Quilters and garment makers who need a fast, durable workhorse for straight-stitch projects and can handle regular maintenance.

- Blazing speed of 5,500 stitches per minute cuts production time significantly while handling thick fabrics and multiple layers without hesitation.

- All-metal construction and automatic lubrication system deliver 15 year lifespans, making it a solid long-term investment for serious sewers.

- Automatic needle threader and even feed foot compatibility streamline setup so you spend more time sewing and less time fussing with adjustments.

- Regular oiling and cleaning are mandatory, which adds maintenance tasks compared to modern low-maintenance machines.

- Straight stitch only means no decorative stitches or computerized features, limiting creative flexibility for varied projects.

- Threading technique differs from standard machines and some users report early mechanical failures, requiring a learning curve and potential troubleshooting.

10. Singer Heavy Duty Sewing Machine

While Juki delivers raw speed, your Singer Heavy Duty 4423 counters with 1,100 stitches per minute and a motor 60% stronger than domestic units—critical when Heavy Duty Fabrics like 12 oz denim test your production line.

At $249.99, this Semi-Industrial Machine balances Industrial Sewing power with accessible Sewing Machine Maintenance: regular oiling and a metal frame guarantee decades of service.

Built-in needle threaders and 23 stitches support varied Quilting Techniques, while consistent Thread Management keeps jams minimal. For small-scale Industrial Machines needs, the SINGER Heavy Duty remains your cost-effective workhorse.

Best For: Small business owners, home sewers tackling upholstery or denim projects, and anyone needing reliable heavy-duty stitching without the price tag of full industrial equipment.

- Motor is 60% stronger than standard machines, handling 12 oz denim and multiple fabric layers with a top speed of 1,100 stitches per minute.

- Metal frame construction and simple mechanical design make maintenance straightforward—regular oiling keeps it running for years.

- At $249.99, you get semi-industrial power with 23 built-in stitches and a built-in needle threader, making it accessible for both beginners and pros.

- Single-speed operation can feel too fast for delicate work or beginners still learning control.

- Upright spool pin design occasionally causes thread to jump and wrap, leading to frustrating jams mid-project.

- Some users report motor issues and thread breakage, and you may need extra accessories like small screwdrivers for adjustments and repairs.

Key Features of Industrial Quilting Machines

When you’re shopping for an industrial quilting machine, knowing which features matter most can save you from costly mistakes down the road. The difference between a machine that keeps up with production demands and one that becomes a bottleneck often comes down to a handful of critical specifications.

Let’s break down the key features you need to evaluate before making your investment.

Workspace and Throat Space

Throat space defines your creative reach. For longarm quilting machines, models like Handi Quilter Infinity deliver 26 inches, while Gammill’s Optimum stretches to 30 inches—critical for king-size projects.

Workspace ergonomics matter: shorter operators struggle with oversized frames, and inadequate clearance forces constant repositioning.

Industrial machines demand smart frame size selection; a 24-inch throat usually satisfies professional versatility without sacrificing sewing comfort or quilt maneuverability.

Sewing Speed and Stitches Per Minute

Speed optimization separates hobby machines from production powerhouses. Industrial models like APQS reach 3,500 stitches per minute, while Gammill tops 2,700—dwarfing domestic units capped near 800.

Your motor performance directly impacts quilting efficiency: Juki’s TL-2000Qi adjusts from 200 to 1,500 stitches per minute for precision control. Semi-industrial machines consistently deliver 1,500 stitches per minute, cutting completion time nearly in half on high-volume runs.

Stitch Variety and Regulation

Modern industrial quilting machines offer 8 to 30 programmable stitch types—lockstitch, chainstitch, zigzag, and specialized patterns—giving you precise fabric handling control.

Computerized quilting systems like Nolting’s IntelliStitch regulate stitch length regardless of movement, reducing errors by 90% during free-motion work.

Longarm quilting machines with optical sensors adjust thread tension and needle control in real time, ensuring quilting patterns maintain consistency across complex designs.

Durability and Construction

Industrial quilting machine durability hinges on three core elements:

- Frame Materials: Over 85% of leading models use cast aluminum or heavy-duty steel frames, delivering exceptional vibration resistance and structural integrity during high-speed operation.

- Metal Gears: All-metal gear assemblies extend operational lifespan by 60% compared to plastic-metal hybrids.

- Throat Space: Longarm quilting machines feature 10–15 inch throat clearances, preventing fabric distortion in heavy-duty quilting applications.

Computerized Vs. Mechanical Models

Choosing between a computerized quilting machine and a mechanical model fundamentally reshapes your production approach. Computerized quilting systems offer 50–500+ stitches versus 10–30 on mechanical units, with precision stitching variance under 2% compared to 5%+. Automated cutting, fabric sensors, and quilting software with machine learning capabilities increase productivity by 40% across longarm quilting machines and industrial machines.

| Feature | Computerized Models | Mechanical Models |

|---|---|---|

| Stitch Options | 50–500+ built-in patterns with digital libraries | 10–30 basic stitches, manual dial selection |

| Precision | Machine learning now cuts material waste by 17% and boosts stitch accuracy by 22% in real-time quilting operations |

Predictive Analytics embedded in longarm quilting machine features enable self-correcting automation systems that reduce operator intervention by 40%.

Intelligent Stitching powered by cuttingedge technology and Data Optimization ensures your automation trends deliver consistent quality across diverse fabrics.

Smart Manufacturing Adaptations

Robotics Integration has pushed throughput 45% higher since 2022, while digital twin simulations and augmented reality modules let you visualize quilt patterns before production begins. Computerized quilting systems now leverage predictive maintenance to optimize uptime across industrial machines.

- Multi-needle automation systems command over $320 million globally, projected to hit $550 million by 2028

- Cybersecurity measures protect longarm quilting machine data in connected factory environments

- Supply chain optimization through blockchain trials ensures authenticity verification for high-value custom quilts

Cuttingedge technology drives an 8% market CAGR through 2028.

Frequently Asked Questions (FAQs)

How often do industrial quilting machines need maintenance?

Daily cleaning prevents buildup, while weekly lubrication every 7-8 hours maintains performance.

Monthly inspections address wear on longarm quilting machine parts.

Annual professional servicing ensures industrial machines achieve maximum durability through preventive measures and usage tracking.

Can industrial machines handle specialty or unconventional fabrics?

You might think industrial machines choke on specialty fabrics—but they don’t. With needle innovation, material adaptation systems, and stitch optimization, these quilting machinery powerhouses tackle everything from stretchy synthetics to abrasive technical textiles with precision.

What training is required to operate these machines?

You’ll need structured training covering safety protocols, machine setup, quilting techniques, and industrial maintenance. Many brands offer free training through instructional DVDs, video tutorials, and customer service support.

Longarm quilting machine training often includes operator certification programs for thorough skill development.

Are replacement parts readily available for older models?

Replacement parts for older quilting machine models become increasingly scarce after 15-20 years, driving up repair costs and lead times.

Part availability declines as manufacturers discontinue production, though some support critical components longer.

Conclusion

You’ve discovered that choosing industrial quilting machine brands isn’t about chasing the most expensive nameplate—it’s about matching horsepower to your actual production rhythm.

The 11 manufacturers and 10 models detailed here give you the technical vocabulary to negotiate confidently and the specification benchmarks to sidestep costly mismatches.

Your next move? Test-drive three machines from different tiers under real workload conditions. That hands-on comparison reveals what spec sheets never will.