This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Most quilters don’t realize their domestic machine is holding them back until they watch an industrial model power through twelve layers of batting without breaking a sweat. Industrial sewing machines transform quilting from a slow, careful process into a high-speed craft where thick materials and large projects become manageable instead of intimidating.

The throat space alone—often three times larger than domestic machines—lets you manipulate king-size quilts without wrestling bunched fabric through a cramped opening.

Once you understand the right setup, from selecting walking foot mechanisms to dialing in thread tension for heavy materials, industrial sewing machine quilting projects open up possibilities that simply weren’t practical before.

Table Of Contents

- Key Takeaways

- Choosing The Right Industrial Quilting Machine

- Essential Setup for Industrial Machine Quilting

- Needle and Thread Selection for Quilting

- Quilting Techniques on Industrial Machines

- Top 10 Industrial Sewing Machines and Tools for Quilting

- 1. Brother PQ1600S High Speed Quilting Machine

- 2. Juki Heavy Duty Sewing Machine

- 3. CKPSMS Seam Guide Gauge Quilting Tool

- 4. Magnetic Seam Guide Sewing Machine Attachment

- 5. Industrial Sewing Machine Set Motor

- 6. Industrial Leather Hand Crank Sewing Machine

- 7. Meander Quilting Template Free Motion Ruler

- 8. Juki TL 18QVP COL Platinum Sewing

- 9. Industrial Heavy Duty Sewing Machine

- 10. Industrial Sewing Machine Needles Size 22

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Industrial sewing machines deliver ten times the power of domestic models with 550-750 watt motors and throat spaces up to 26 inches, making thick layers and king-size quilts manageable without constant fabric wrestling.

- Choosing between walking foot and compound feed machines depends on your budget and project complexity, while flatbed models suit piecing work and longarms excel at large-scale quilting with dramatically improved workflow.

- Proper setup requires matching needle size to fabric thickness (80/12 for standard cotton, 100/16 for heavy batting), balancing thread tension between 4-6, and adding extension tables to support quilt weight and reduce physical strain.

- Servo motors cut energy use by 60-80% compared to clutch motors while delivering full torque at low speeds, giving you precise control from 50 to 3,000 stitches per minute for both detailed ruler work and high-speed piecing.

Choosing The Right Industrial Quilting Machine

Picking the right industrial quilting machine can feel like standing at a crossroads, especially when you’re ready to move beyond home models. The right choice depends on your quilting style, project size, and the features that’ll support your creative vision.

Let’s break down the key factors that’ll help you find your perfect match.

Walking Foot Vs. Compound Feed Machines

When you’re choosing between a walking foot and a compound feed machine for industrial machine quilting, understanding the feeding mechanism makes all the difference. Walking foot machines excel at preventing fabric slippage through thick layers, offering strong sewing efficiency and an accessible experience.

Different machines use varied methods for fabric movement, impacting their suitability for specific tasks.

Compound feed machines provide excellent durability and precision but come at a higher cost. Your choice depends on budget and project complexity.

Flatbed Vs. Longarm Industrial Machines

Your decision between a flatbed industrial machine and a longarm quilting machine hinges on throat space, workflow ergonomics, and cost analysis.

Flatbeds offer 8–10 inches of throat space and machine versatility for piecing and construction, but pushing large quilts through that opening becomes a physical struggle.

Longarm quilting machines provide 18–26 inch throats, dramatically improving project throughput by letting you quilt king-size tops without constant repositioning—though they’ll cost you considerably more upfront. Many longarm machines also include a helpful stitch regulator for consistent stitches.

Power and Motor Strength Considerations

Once you’ve settled on throat space, turn your attention to motor power—it’s the difference between smooth quilting and a machine that stalls mid-seam. Industrial machines pack 550–750 watt motors with serious torque control, giving you ten times the punching power of domestic models.

Industrial machines deliver ten times the punching power of domestic models with 550–750 watt motors that prevent mid-seam stalls

Servo motors deliver energy efficiency around 95%, maintaining strong motor performance at low speeds for precise work. Match motor wattage to your fabric layers: 90 watts is suitable for duvets, but thick batting demands that industrial-grade strength.

Key Features for Quilting (Throat Space, Speed, Stitch Control)

With power sorted, three features determine whether you’ll breeze through bed-sized quilts or wrestle them into submission:

- Throat Space Benefits: Domestic machines offer 7–8 inches; longarms extend beyond 18 inches, letting you tackle queen-size projects with fewer stops and less fabric wrestling.

- Speed vs. Control: Semi-industrial models hit 1,500 stitches per minute, while longarms reach 2,200–3,500 spm for serious productivity enhancements.

- Stitch Regulation Types: Regulated modes adjust machine speed to your hand movement, keeping stitches even whether you’re crawling around tight curves or racing across open workspace.

Essential Setup for Industrial Machine Quilting

Getting your industrial machine ready for quilting isn’t as complicated as it might seem. The right setup makes all the difference between a smooth quilting experience and one that leaves you frustrated.

Let’s walk through the essential adjustments and preparations you’ll need to tackle any quilting project with confidence.

Selecting The Right Quilting Foot

Your quilting foot is the handshake between machine and fabric—get it wrong, and you’ll wrestle every seam. Start by checking your shank height; most industrial machines use high-shank feet that won’t swap with domestic low-shank accessories.

Match the feed mechanism to your project: a walking foot synchronizes layers for straight-line work, while a freemotion foot lets you dance curves with design visibility and adjustable foot pressure.

| Foot Type | Best For |

|---|---|

| Walking Foot | Straight-line quilting, binding, layer control on thick batting |

| Freemotion Quilting Foot | Curved designs, echo quilting, 360° visibility with marking guides |

| Patchwork/Quarter-Inch Foot | Precise ¼” seams for piecing quilt blocks before quilting |

Adjusting Machine Settings for Quilting

Before you stitch a single line, balance your thread tension between 4 and 6—start at the factory default of 4.5 and test on scrap layers. Set stitch length to 2.5-3.0 mm (about 10 stitches per inch) for even quilting thread coverage.

Adjust presser foot pressure to middle settings, raise feed dogs for straight lines, and cap speed control at 50-75% until your needle size and batting thickness sync perfectly.

Workspace Optimization and Quilt Weight Management

Beyond your machine bed, generous workspace ergonomics transform quilt handling. Add extension tables flush with the bed to reduce drag, then position support surfaces on all sides—that way quilt weight never pulls against your shoulders.

Set your table at 89 cm for standing or adjust your chair so your elbows hit 90 degrees.

Alternate tasks and take breaks every 30–60 minutes to reset posture and reduce fatigue.

Maintenance and Longevity Tips

A clean machine is a reliable machine—daily lint removal from your bobbin case and feed dogs cuts thread breakage by half in high-volume work.

- Oiling practices: Run oil through marked ports for 3–5 minutes without thread to protect bushings and extend component life

- Needle management: Swap needles twice yearly to prevent skipped stitches

- Motor care: Power down between sessions to reduce clutch wear

- Climate control: Use dust covers in humid spaces to stop rust

Professional service every two years or 10 million stitches keeps timing sharp and tension calibrated, delivering durable stitches that reflect industrial-grade reliability.

Needle and Thread Selection for Quilting

Getting the right needle and thread combination is like finding the perfect dance partner—they need to work together smoothly, or your quilting project will fall apart. Your industrial machine can handle thick layers and long hours, but only if you’re using tools that match the job.

Let’s walk through what you need to know about sizing, quality, and pairing to keep your stitches clean and your projects moving forward.

Recommended Needle Sizes and Types

You’ll need to match your needle selection to the quilt thickness you’re tackling. For standard quilting cotton and medium batting, reach for a size 80/12 or 90/14—they’re your workhorses on an industrial machine. When you’re working with heavier layers, bump up to a 100/16 to prevent skipped stitches.

System compatibility matters too: most walking-foot machines use 135×17 needles. Don’t forget needle wear—swap them out every eight hours of quilting to maintain clean penetration and thread compatibility.

Choosing High-Quality Quilting Threads

When you’re choosing thread for industrial quilting, thread fiber makes all the difference. Polyester delivers about 30% stronger tensile strength than cotton—meaning fewer breaks at high speeds—while long-staple cotton produces less lint to clog your machine.

Look for 40 wt or 50 wt thread weights depending on how bold you want your stitching line. Thread finishes and colorfastness matter too, especially for quilts you’ll wash frequently.

Matching Needle and Thread to Fabric

Your fabric weight determines everything—pair Tex 27–40 thread with size 75/11 or 80/12 needles for medium-weight quilting cotton, then scale up to 90/14 or 100/16 when you’re sewing through heavy batting or canvas backings.

Needle and thread pairing affects both visual effects and durability factors: lighter needles prevent visible holes in delicate fabrics, while heavier combinations deliver thread strength for utility quilts that’ll see hard use.

Adjusting Thread Tension for Thick Materials

Once you’ve paired needle and thread to fabric, tension troubleshooting becomes your next challenge. Start with factory mid-range settings—around 3 to 4 on most dials—then test on a scrap quilt sandwich matching your batting thickness.

Loose upper tension prevents puckering through thick materials, while small bobbin adjustments (quarter-turns only) balance stitch quality without causing needle deflection or breakage across bulky seams.

Quilting Techniques on Industrial Machines

Once you’ve got your machine set up and your needles and thread sorted, it’s time to put everything into action. Industrial machines give you the power and control to handle different quilting techniques, from simple straight lines to more creative free-motion designs.

Let’s look at the main approaches you’ll use to bring your quilting projects to life.

Straight-Line and Free-Motion Quilting Methods

When you’re working on industrial quilting machines, mastering both straight stitch and freemotion quilting techniques opens up endless design applications. Straight-line methods rely on a walking foot and moderate speed control to maintain even layers, while freemotion techniques require lowered feed dogs and a hopping foot so you can guide the fabric freely.

Stitch regulation helps match needle speed to your hand movement, and proper ergonomics—like supporting large quilts—prevents strain during long sessions and keeps your stitches smooth.

Using Quilting Templates and Rulers

Templates and quilting rulers turn abstract quilting designs into precise motifs on industrial quilting machines. Ruler thickness matters: 1/4 inch acrylic is ideal for material safety and technique accuracy at high speeds.

To nail it:

- Adjust ruler foot height so it barely clears your quilt sandwich—better stitch formation, less drag

- Add silicone grip dots under rulers to prevent micro-slippage during workspace setup

- Keep rulers close to the needle to reduce leverage and improve risk mitigation

Light pressure beats clamping down every time.

Stabilization Techniques for Large Projects

When large projects shift under your needle, you lose hours to seam-ripping. Basting density every 3–5 inches stabilizes fabric layers and batting in the quilt sandwich, keeping your workspace support solid.

Managing bulk through accordion-pleating—not tight rolling—gives you layer stability and structural stability at the throat. Roll only what enters the machine, puddle the rest, and let adjacent surfaces carry the weight.

Marking and Planning Quilt Designs

Mapping your quilt design before you sew prevents costly errors and keeps patterns aligned across industrial throat plates. Choose your marking method based on fabric weight, project timeline, and equipment capabilities.

- Digital Patterning – Import CAD files into CNC systems for 360-degree rotational freedom and multi-axis precision at speeds reaching 3,000 stitches per minute.

- Manual Marking – Use Hera markers, masking tape, or freezer paper templates for chemical-free pattern transfer with positioning accuracy on light to medium fabrics.

- Chemical Markers – Apply water-soluble pens like Sewline or Dritz disappearing ink for ultra-thin lines that erase completely after light water application or spritzing.

- Tailors Chalk and Disappearing Ink – Mark dark fabrics with Clover water-soluble pencils that rub away with damp cloth before heat setting locks marks permanently.

- Ruler Specifications and Design Accuracy – Verify straightness using 8.5-inch by 24-inch acrylic rulers with angle guides, or rely on computerized systems that eliminate drafting errors through grid overlay features.

Top 10 Industrial Sewing Machines and Tools for Quilting

Now that you’ve mastered the techniques, it’s time to talk about the tools that’ll make your quilting life easier. The right machine or accessory can transform how you work, whether you’re stitching straight lines or tackling intricate free-motion designs.

Here are ten machines and tools that quilters rely on for professional results.

1. Brother PQ1600S High Speed Quilting Machine

You won’t find many high-speed sewing machines that match the Brother PQ1600S‘s impressive 1,500 stitches per minute—a major advantage for serious quilters. This powerhouse among industrial quilting machines combines outstanding sewing machine features like a flexible presser foot and pin-feed system for perfect fabric control.

The included accessories, from seven specialized feet to a built-in knee lifter, make setup simple. User feedback consistently praises its sewing machine durability, backed by 25-year warranty coverage on the chassis. It’s quilting machine features designed with your workflow in mind.

Best For: Serious quilters and sewing professionals who need a high-speed, straight-stitch workhorse for large-scale projects and can work without zigzag or decorative stitches.

- Blazing fast 1,500 stitches per minute with excellent control for high-volume quilting

- Smart fabric handling with pin-feed mechanism and adjustable feed dogs that prevent puckering on thick layers

- Impressive 25-year warranty on chassis plus tons of included accessories like knee lifter and seven specialty feet

- Straight stitch only—no zigzag or decorative options limits versatility

- Steep learning curve makes it tough for beginners to master threading and high-speed operation

- Thread cutter can snip threads too short if you don’t dial in the settings just right

2. Juki Heavy Duty Sewing Machine

When you’re ready to step up your quilting game, the Juki TL series delivers the heavy-duty features serious quilters need. The Juki TL2010Q stands out among industrial quilting machines with speeds up to 1,500 stitches per minute—double what most domestic models offer.

You’ll appreciate the 9-inch throat space for managing larger projects and the knee lifter that frees your hands during free-motion work.

This industrial machine combines reliable speed and performance with a usability workflow that makes sense, positioning it perfectly for quilters moving up to heavy-duty sewing without the full industrial price tag.

Best For: Serious quilters and small studio owners who need industrial-level speed and power for handling thick layers and large projects without investing in a full factory machine.

- Runs at 1,500 stitches per minute—twice as fast as most home machines—so you can finish quilts and heavy projects much quicker.

- The 9-inch throat space and knee lifter give you room to maneuver big quilts and keep your hands free for precise free-motion work.

- Built with an aluminum die-cast frame and mostly metal parts, so it stays stable at high speeds and holds up through years of heavy use.

- Assembly can be tricky since the table and machine ship separately, and some users report missing parts or unclear instructions.

- It’s a straight-stitch-only machine, so you won’t get any decorative stitches or utility functions beyond basic sewing.

- The price sits around $900–1,100, which is a significant jump from entry-level machines and may require budgeting for accessories or professional setup.

3. CKPSMS Seam Guide Gauge Quilting Tool

When seam accuracy makes or breaks a pieced block, the CKPSMS Seam Guide Gauge becomes your precision partner on industrial machines. This screw-on metal guide attaches directly to your presser foot bar, giving you a rigid edge to run fabric against—no slipping like tape or magnets on aluminum plates.

You’ll maintain quarter-inch seams across long quilting lines and pieced units without constantly watching needle markings. Installation takes minutes, and the slotted mounting hole lets you fine-tune placement.

It’s particularly valuable for straight-line quilting techniques and repetitive piecing where consistency directly impacts your finished quilt dimensions.

Best For: Quilters working on industrial or heavy-duty machines who need repeatable seam accuracy for piecing and straight-line quilting without relying on magnetic guides or tape.

- Screw-on design stays put on aluminum and non-ferrous plates where magnets won’t work, maintaining stability even at high speeds

- Adjustable mounting slot lets you dial in exact seam allowances and lock them in for consistent quarter-inch seams across multiple blocks

- Works as a physical fence you can feel, reducing the need to constantly watch needle markings during long quilting runs

- Installation and adjustment can be fiddly, especially finding the right positioning on machines with limited presser bar clearance

- Won’t fit every machine model—some Brother and Singer machines require different presser feet or have incompatible bar configurations

- May not mount high enough on certain presser foot bars if the screw hole sits too far up the bar

4. Magnetic Seam Guide Sewing Machine Attachment

If your needle plate is ferromagnetic steel, this stainless steel magnetic seam guide snaps on instantly for guide accuracy across straight or curved stitching. Its magnetic strength is secure on most industrial machines with metal plates, though it won’t work on aluminum surfaces or computerized models where magnets risk electronic interference.

Market overview shows these sell for around five dollars, making them accessible for any quilter.

Usage tips: clean the plate regularly to maintain hold, test on scrap sandwiches first, and verify machine compatibility before relying on it for precision piecing.

Best For: Quilters and sewers working with mechanical machines who want consistent seam allowances without repeatedly measuring or switching specialty presser feet.

- Snaps on instantly to metal needle plates and repositions quickly for different seam widths, so you can switch from quarter-inch piecing to wider allowances in seconds.

- Costs around five dollars, making it one of the most affordable ways to improve stitching accuracy for both beginners and experienced sewers.

- Provides a solid physical edge that’s easier to follow than etched plate markings, helping you maintain straight lines through long quilting runs.

- Won’t work on computerized sewing machines because the magnetic field can interfere with electronics, and won’t stick to aluminum needle plates.

- Magnet strength can weaken if lint builds up on the plate, causing the guide to shift during sewing and throwing off your seam width.

- Limited to a specific seam range (up to about 3cm), so it’s not ideal if you regularly work with very wide or specialized seam allowances.

5. Industrial Sewing Machine Set Motor

Beyond accessories, your machine’s heart—the motor—makes or breaks your quilting flow. Modern servo motors slice energy use by sixty to eighty percent compared to clutch motors, running quiet at idle and delivering full torque even at crawling speeds for dense stitch work.

You’ll appreciate the fine control from fifty up to three thousand stitches per minute, perfect for ruler work or highspeed piecing. Direct-drive systems drop belt losses entirely, boosting efficiency.

Regular motor maintenance extends your industrial machine’s lifespan while keeping sewing speed consistent and motor torque reliable through every quilt.

Best For: Tailors, fashion designers, and upholstery shops running long production hours who need quiet operation, precise speed control for detailed work, and lower energy bills.

- Cuts electricity consumption by 60–80% compared to clutch motors, staying silent at idle instead of drawing power continuously.

- Adjustable speed from 50 to 3,500 stitches per minute with full torque at low speeds, so you can creep through thick layers or fly through straight seams without losing needle power.

- Runs quieter and cooler than traditional motors, reducing fatigue and heat buildup during all-day sewing sessions.

- Requires assembly out of the box and ships with a Chinese manual, so setup may take extra effort if you’re not mechanically inclined.

- Weighs 86 pounds for the machine alone (plus 44 pounds for the table stand), making it tough to move or reposition solo.

- May need periodic lubricating oil top-ups and regular maintenance to keep the servo motor running at peak performance over time.

6. Industrial Leather Hand Crank Sewing Machine

Hand-crank sewing machines deliver stitch control you won’t find in electric models, especially when you’re sewing thick leather up to three-quarters of an inch. Manual operation lets you place each needle entry exactly where you want it, essential for holsters, saddles, and belts.

These industrial machines weigh around twenty-one pounds, balancing portability with durability. You’ll appreciate the cylinder bed design for curved projects and the quiet workspace—no motor hum interrupting your focus on leather sewing projects.

Best For: Leatherworkers and DIY enthusiasts who need precise control when sewing thick materials like saddles, holsters, and belts without relying on electricity.

- Manual hand-crank operation gives you exact stitch placement and works anywhere without power, making it perfect for workshops or remote locations.

- Handles seriously thick materials up to 3/4 inch, including leather, canvas, and rubber, with a durable cast iron or aluminum construction built to last.

- Cylinder bed design makes curved projects like boots and bags much easier, while the quiet operation lets you focus without motor noise.

- Requires manual lubrication before each use and careful handling (handwheel positioning, needle groove direction) to avoid damage or thread breakage.

- Some models don’t include a table stand or motor, and shipping damage has been reported by customers due to the machine’s weight.

- Slower sewing speed compared to electric machines since you’re controlling each stitch by hand, which might not suit large production runs.

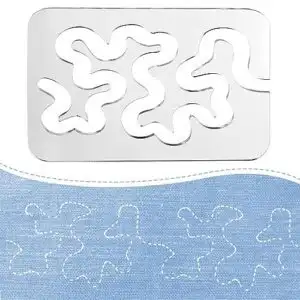

7. Meander Quilting Template Free Motion Ruler

After manual control comes guided freedom. Meander quilting templates made from clear acrylic—usually three to five millimeters thick—transform FMQ from intimidating to approachable. You’ll guide this transparent ruler alongside your ruler foot, creating flowing meander patterns without pre-marking your quilt top.

The template material withstands repeated passes under industrial machines, while foot compatibility depends on your shank height. Design applications range from baby quilts to handbags, and usage techniques emphasize balancing hand speed with needle movement.

Expect to invest around twenty-seven dollars for quality free-motion quilting templates that build your confidence in this essential quilting technique.

Best For: Beginner and intermediate quilters who want to master free-motion meandering with guided curves instead of going completely freehand.

- Clear acrylic lets you see your fabric underneath, so you can line up patterns with seams and design elements as you stitch

- Durable enough for repeated use on both domestic and industrial machines, with thickness designed to work safely with ruler feet

- Takes the guesswork out of spacing and flow, helping you avoid common mistakes like overlapping lines or awkward gaps

- Won’t fit every machine setup—you need to match the template thickness with your shank type and ruler foot height or risk jamming

- Can slide around during use, so you’ll need to press firmly or use grip aids to keep curves smooth and consistent

- Limited coverage area means you have to stop, reposition, and restart frequently when working across larger quilt tops

8. Juki TL 18QVP COL Platinum Sewing

If your quilting demands match the TL-18QVP’s capabilities, you’re looking at an investment-grade machine. This Collector’s Edition features a Micro-Lifter Function that floats your presser foot over thick seams—think six denim layers without drama. Speed Control maxes at 1,500 stitches per minute, while that 8.5-inch throat space accommodates quilts up to 92 inches square.

Build Quality centers on aluminum die-casting, and Quilting Accuracy holds true through quarter-inch seam allowances. Industrial quilting machine reviews compare it favorably against the Juki 2010, though sewing machine portability takes a hit at thirty pounds. Quilting machine accessories expand functionality further.

Best For: Serious quilters and garment makers who work with multiple fabric layers and need industrial-grade precision for haute couture projects, free-motion quilting, or bespoke handbag creation.

- Micro-lifter float function handles up to 6 layers of denim smoothly, eliminating skipped stitches when crossing thick seams

- 8.5-inch throat space and 1,500 stitches per minute maximum speed let you tackle large quilts (up to 92 inches) quickly without sacrificing accuracy

- Automatic thread trimmer and needle threader save time on repetitive tasks, while the quarter-inch foot delivers consistent seam allowances

- $1,899 price point puts it out of reach for casual sewers or beginners just getting into quilting

- 30-pound weight makes it essentially a stationary machine—you won’t be taking this to sewing classes or retreats

- Limited Collector’s Edition availability means you might struggle to find one in stock, and replacement parts could be harder to source down the line

9. Industrial Heavy Duty Sewing Machine

You’ll find industrial sewing machines deliver ten times the power of domestic models through 550-750 watt motors that handle heavy fabrics without hesitation. These workhorses maintain stitch speed up to 5,000 stitches per minute, while frame durability ensures years of reliable service.

Material thickness capacity reaches 9mm on quality units—essential when you’re layering batting and backing. Ergonomic features like knee lifters reduce fatigue during marathon quilting sessions.

Industrial machines transform thick materials into finished quilts faster than you’d manage with standard equipment, especially on commercial-scale projects.

Best For: Professional quilters and commercial sewing operations that need to handle thick, layered materials at high speeds for large-scale production work.

- Powerful 550W motor handles up to 9mm of material thickness and runs at 5,000 stitches per minute, making quick work of heavy quilts and upholstery projects

- Built with industrial-grade components and heavy-duty frames that stand up to continuous daily use without breaking down

- Features like knee lifters and walking foot mechanisms reduce hand fatigue and help you manage multiple fabric layers smoothly

- Assembly can be tricky and might need professional help to get everything set up correctly

- Some users report customer service issues and occasional shipping damage like broken wheels

- Instructions aren’t always clear, so you may need to do extra research or reach out for support to figure things out

10. Industrial Sewing Machine Needles Size 22

When you’re tackling thick materials and multiple fabric layers on your industrial machine, size 22 needles (marked 140/22) become essential tools for maintaining stitch quality and fabric integrity. These heavy-duty needles pair perfectly with bonded thread sizes V92 and V138, penetrating dense quilt sandwiches without breaking.

Thread pairing matters—match your needle size to thread weight for smooth machine setup and reliable tension control. Though they’ll leave larger holes than standard quilting needles, size 22 needles excel in material applications requiring strength, like multi-layer quilts with heavy batting or functional quilted upholstery projects.

Best For: Industrial sewers working with thick, multi-layer materials like heavy quilts, leather, canvas, or dense upholstery who need durable needles that can handle heavy-duty threads without breaking.

- Strong iron alloy construction keeps the needle sharp and resistant to bending even when pushing through multiple fabric layers or tough materials like denim and leather

- Works seamlessly with heavy bonded threads (V92 and V138) for secure, high-strength seams that won’t skip or break during industrial sewing runs

- Comes in a 30-piece pack so you’ve got plenty of replacements on hand for extended projects or commercial work

- Leaves noticeably larger needle holes in fabric compared to standard sewing needles, which can be visible in tightly woven or delicate quilting projects

- Only compatible with industrial lockstitch machines, so you can’t use these with home sewing machines or other industrial machine types

- No warranty or return policy information provided, and quality might vary between different batches based on user reviews

Frequently Asked Questions (FAQs)

What is the best industrial sewing machine for quilting?

You’d think bigger means better, but the best quilting machine depends on your project size and technique. Expert opinions favor the Janome Continental M8 for versatility across industrial machines.

Is a quilting machine a sewing machine?

Yes, a quilting machine is a specialized sewing machine. Both use lockstitch principles to join layers, but quilting machines offer enhanced features like extended throat space, walking feet, and better layer management for handling thick quilt assemblies.

Do I need a different sewing machine to quilt on?

You won’t need a completely different sewing machine to quilt on, especially if you’re working on smaller projects. Your current machine, whether domestic or industrial, can handle quilting with the right setup—proper foot, needles, and thread selection make all the difference.

That said, project size and skill level matter. If you’re tackling king-size quilts regularly, a dedicated longarm machine offers clear industrial machine advantages: massive throat space, power to handle thick layers, and speed that cuts hours off your work. Budget considerations play a big role here. Walking foot or compound feed industrial machines deliver professional results without the premium price tag of specialized quilting equipment.

For beginners or occasional quilters, quilting alternatives like adding a walking foot attachment to your existing sewing machine work beautifully. Machine necessity really comes down to what you’re making and how often you’re making it—quilting on industrial machines shines for large-scale or commercial work, but standard machines absolutely get the job done for most home quilters.

Which sewing and quilting machine should I buy?

Your sewing machine selection depends on budget considerations, quilting frequency, project size, and space requirements.

Heavy-duty sewing machines with easy-to-use features suit frequent quilters, while automation needs determine whether industrial sewing machines are necessary.

What is the best automatic controlled sewing machine for quilting?

Like choosing the right GPS for a road trip, picking an automatic quilting machine depends on your destination.

The Bernina 770QE Plus delivers impressive quilting precision and automation benefits, while the Juki TL-18QVP offers impressive speed at 1,500 stitches per minute for serious quilters.

Which hybrid machine is best for sewing & quilting?

The Janome Horizon Memory Craft 9480QC offers outstanding stitch versatility with 400 built-in stitches and excellent workspace considerations.

For budget analysis, the Brother SE600 provides solid embroidery capabilities under $500, making hybrid machine comparison straightforward.

Can industrial machines handle curved quilting designs?

Can machines truly master curves? Yes, industrial machines handle curved quilting designs effectively using free motion quilting techniques (FMQ).

Curve stitching precision depends on fabric feed systems, speed control impact, and operator skill influence handling design complexity limits.

What stitch patterns work best for industrial quilting?

Straight stitches, meanders, and grid quilting designs deliver durable stitches on industrial machines. Pattern density, batting choice, and stitch length around 10–11 per inch guarantee stitch quality, while free-motion and template designs increase versatility.

How do you prevent fabric puckering on industrial machines?

You’ll prevent puckering by lowering thread tension to the lightest balanced setting, reducing presser foot pressure on thick fabric layers, and adjusting stitch length to 0–5 mm while guiding—not pulling—material through feed dogs.

What safety precautions are needed for industrial quilting machines?

Nearly 70% of sewing station accidents involve needle-stick injuries. Proper machine guarding, ergonomic controls, and routine industrial machine maintenance prevent injury patterns.

Monitor noise exposure, secure barriers around moving parts, and maintain neutral posture during quilting.

Conclusion

Think of your quilting journey like building a bridge: domestic machines got you across the creek, but industrial sewing machine quilting projects let you span the canyon.

You’ve now got the blueprint—machine selection, setup fundamentals, needle-thread pairings, and techniques that turn intimidating layer stacks into manageable work. The tools exist, the methods are proven, and your next king-size quilt won’t require compromise. What once seemed impossible now sits within reach.

- https://www.gminsights.com/industry-analysis/industrial-sewing-machine-market

- https://straitsresearch.com/report/industrial-sewing-machine-market/united-states

- https://www.archivemarketresearch.com/reports/industrial-quilting-machine-455893

- https://craftindustryalliance.org/the-size-of-the-quilting-market-quilting-trends-survey-results-2025/

- https://www.proficientmarketinsights.com/market-reports/sewing-and-quilting-market-3650