This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You’ve just watched thousands of dollars’ worth of sewing equipment vanish into the baggage handler’s world, and there’s nothing you can do but hope for the best. That familiar knot in your stomach isn’t paranoia—it’s the reality of transporting delicate machinery through airports, car trunks, and hotel lobbies.

Your machine’s tension assembly, timing gears, and needle bar can shift or break with a single hard jostle, turning your creative retreat or teaching gig into an expensive repair nightmare.

Smart sewing machine carrying tips go beyond tossing your equipment in any available bag. You need strategic packing, protective cases that actually work, and a clear understanding of what security screeners allow through checkpoints.

Table Of Contents

Key Takeaways

- The right protective case makes the difference between a smooth trip and a repair nightmare—look for hard-shell options with at least 1.5 pounds per cubic foot foam density, rolling trolleys with 15cm wheels, and modular dividers that keep your machine from shifting during transit.

- Before you pack, secure the presser foot on scrap fabric, remove the needle entirely, extract all bobbins and accessories, and use original packaging or custom-cut foam that eliminates internal movement to prevent timing misalignment and broken parts.

- TSA allows sewing machines in carry-on and checked bags, but you’ll face airline-specific size limits (typically 22×14×9 inches), weight caps ranging from 15 pounds to unlimited, and blade restrictions requiring scissors under 4 inches and rotary cutters in checked luggage only.

- Car travel gives you control over placement and vibration exposure while carry-on airplane transport avoids the 0.58% baggage mishandling risk—either way, label everything inside and out, add insurance beyond standard liability limits, and run quick maintenance checks before and after every trip to catch damage early.

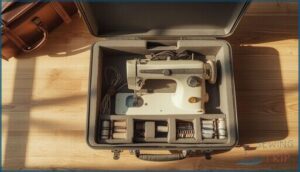

Choosing The Best Sewing Machine Case

Your sewing machine deserves better protection than a pillowcase and a prayer. The right case shields your equipment from drops, moisture, and the chaos of baggage handling while keeping accessories organized and within reach.

Your sewing machine deserves better protection than a pillowcase and a prayer—the right case shields it from drops, moisture, and baggage chaos

Let’s look at the key features that separate a smart investment from a flimsy disappointment.

Hard-shell Vs. Soft-shell Cases

For machine protection, hard shell cases deliver greater impact resistance and weather protection that soft-sided travel cases can’t match. You’ll appreciate the added weight that comes with a hardshell case—it’s the price you pay for long-term case longevity and security features like tamper-resistant locks.

Soft-sided protective case options work well for quick trips, but they won’t shield your investment from rough baggage handlers or unexpected spills.

Hard shell luggage provides high durability, making it a worthwhile investment for protecting your sewing machine.

Shock Absorption and Padding Features

But even the sturdiest case construction fails without proper shock absorption inside. Look for foam density above 1.5 pounds per cubic foot—it’s your frontline defense against impact attenuation during baggage handling.

Custom padding shaped to your machine’s contours beats generic inserts every time, because vibration isolation depends on consistent contact between foam and metal. For the best possible protection, consider investing in custom foam inserts.

Machine stability under travel stress requires at least one inch of padding thickness surrounding all critical components.

Rolling Trolleys and Telescopic Grips

Padding alone won’t help if you can’t move your machine comfortably through an airport. Rolling trolleys with telescopic grips eliminate arm fatigue—especially important when consumer-grade cases support 30 to 60 pounds. Proper ergonomic handle height keeps your arm slightly bent, reducing shoulder strain and injury risk reduction greatly.

- Larger wheel size impact matters: 15 cm wheels reduce physical stress compared to 8 cm versions

- Four-wheel designs improve stability and maneuverability in tight spaces

- Load capacity limits must match your machine’s weight plus accessories

Modular Storage and Adjustable Dividers

Once you’ve got wheels sorted, you’ll want a machine travel case with customizable compartments. Adjustable padded dividers using hook-and-loop fasteners let you create snug cells for each item—your machine, foam inserts, and zippered pouches for packing sewing supplies.

This adaptable layout delivers impact protection by preventing internal collisions during transit. Market adoption shows these modular systems now dominate craft storage, offering organization benefits through reconfigurable spaces.

| Feature | Benefit |

|---|---|

| Hook-and-loop dividers | Quick layout changes |

| Padded compartments | Prevents scratches |

| Adjustable grids | Fits varying item sizes |

| Multiple tray levels | Maximizes vertical space |

| Removable sections | Adapts as gear changes |

Comfortable Handles and Ergonomic Design

Your wrists and arms shouldn’t ache after hauling gear through airports. Handle ergonomics matter—look for these travel bag features on your Rolling Machine Tote:

- Telescopic grips with smooth extension mechanisms that lock at multiple heights, reducing musculoskeletal risk

- Cushioned grips with rubberized overlays for enhanced pressure distribution across your palm

- Reinforced frames combining grip durability with anti-slip textures

These design elements transform portable sewing machines from awkward loads into easy companions for machine portability.

Preparing Your Sewing Machine for Transport

Before you zip up that case and head out the door, you need to prep your machine so it arrives in one piece. A few simple steps can mean the difference between showing up ready to sew and dealing with a repair bill.

Here’s what you need to do to get your machine travel-ready.

Securing The Presser Foot and Needle

Before you tuck your sewing machine into its case, think of the presser foot and needle as the most vulnerable parts that need your attention. Lowering the presser foot onto a scrap of fabric stabilizes the foot assembly and prevents the needle from bouncing against the feed dogs during transport. Many sewists choose complete needle removal to eliminate breakage risk—simply raise the needle to its highest position, loosen the clamp screw, and slide the needle out. This extra step protects the needle bar from side impacts that could bend or misalign delicate hardware.

| Transport Step | Why It Matters |

|---|---|

| Lower presser foot on fabric | Reduces strain on tension springs and limits vertical movement |

| Remove needle entirely | Prevents bending, breakage, or gouging of the needle plate |

| Check clamp security | Stops presser feet from detaching inside the case during jolts |

| Verify alignment after travel | Confirms needle passes centrally and foot tracks straight for clean stitches |

Once you arrive, take a moment for alignment checks—run a test seam on scrap fabric to confirm your needle still passes through the plate opening cleanly and your presser foot tracks straight. Protecting sewing machines during travel isn’t just about cushioning; it’s about securing every moving part so you can stitch with confidence the moment you unpack.

Removing Accessories and Bobbins

Before your machine hits the road, pull out all loose accessories and bobbins to prevent internal damage. Protruding bobbin winders and auxiliary pins break easily under side pressure, while loose bobbins can shift and gouge the hook mechanism if your machine tips during transit.

- Unthread completely to prevent tension spring deformation and imprinting on guides

- Remove presser feet to eliminate snag points and reduce impact damage during handling

- Extract bobbin and bobbin case to stop thread nests and misalignment in the hook race

- Store small parts separately in labeled zippered pouches so nothing gets left behind

- Unplug and remove needles to protect yourself and prevent bent needle bars during lifting

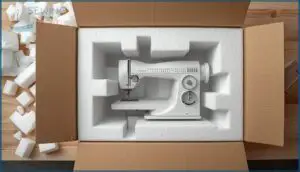

Using Original Packaging and Foam Inserts

Nothing beats the original box with its molded foam inserts when you’re packing a sewing machine. Those factory forms cut shock transmission by 40–60% during packaging drop tests, protecting vulnerable corners and controls from baggage handlers.

If you’ve tossed that box, invest in custom-cut foam that immobilizes your machine completely—carrier standards require zero internal movement to meet damage claims, and vibration dampening protects delicate alignment during transport.

| Foam Insert Types | Protection Benefit |

|---|---|

| High-density polyurethane | Reduces shock 40–60% in drop tests |

| Multi-layer soft + firm | Extends absorption distance by 50% |

| Custom-cut forms | Limits internal movement to under 5 mm |

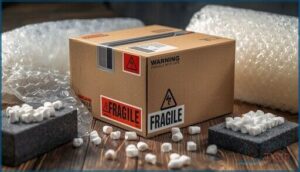

Marking The Machine as Fragile

Bright “FRAGILE” labels on at least three sides of your box cut visible damage claims by 13% across electronics shipments. High-contrast orange or red designs grab handler attention on conveyor belts, discouraging careless stacking that cracks delicate components.

While fragile items benefit from these markings, pair your label visibility with dense padding—carrier options like USPS Special Handling offer segregated transport for maximum damage prevention when protecting sewing machine shipments.

Packing Essential Sewing Supplies for Travel

Your sewing machine is safely packed, but don’t forget the smaller items that make your work possible. A forgotten bobbin case or missing power cord can turn your travel plans into a frustrating scramble at your destination.

Here’s what you need to bring along to keep your sewing sessions running smoothly, no matter where you’re headed.

Thread Snips, Needles, and Seam Rippers

When traveling with sewing accessories, sharps injury risk demands attention. Magnetic storage containers securely hold needles and prevent punctures, while compact solutions like pencil-case pouches keep snips and seam rippers organized.

To navigate TSA and airport security smoothly, pack travel kits carefully:

- Store needles in rigid, puncture-resistant containers

- Place seam rippers in checked baggage when possible

- Use zippered pouches to prevent shifting during carry-on transport

Organizing Bobbins and Presser Feet

After securing your cutting tools, turn your attention to bobbins and presser feet—small parts that vanish faster than thread through a needle. Commercial bobbin storage boxes with individual slots keep extra bobbins tangle-free, while repurposed ice cube trays offer segmented compartments for budget-conscious sewers.

Group presser feet by function—patchwork, walking, and zipper feet travel best in labeled zippered pouches, preventing mix-ups when you’re assembling your travel sewing kit.

Power Cords, Bobbin Cases, and Extra Accessories

Your power cord and foot pedal don’t belong tangled at the bottom of a tote. Multi-compartment organizers generally include two to four dedicated pockets for cord tangle prevention and easy trip-readiness.

Remove your bobbin case from the machine before travel—bobbin case safety matters, since loose metal parts shift and jam mechanisms. Pack extra bobbins alongside machine-specific presser feet in separate zippered pouches.

Accessory modularity keeps packing essentials organized and prevents the “left it in the hotel room” panic.

Stackable Bins and Zippered Pouches

Your thread collection and notions need homes that won’t spill mid-flight. Stackable bins separate thread from tools, cutting lost-item frustrations by 71%. Pair those with zippered pouches—small ones measure 2.75 x 5.25 inches for needles, while large 5.25 x 10.5-inch versions handle presser feet.

- Stack bins three high for safe, space-efficient packing

- Choose clear plastic for instant color identification

- Use foam inserts between layers for shock protection

Portable Sewing Tables and Extension Cords

A portable sewing table measuring 87 by 48 cm gives you a stable workspace at workshops, with an ergonomic height of around 76 cm to keep your posture comfortable.

Most machines draw just 100 watts, so a 16 AWG extension cord rated for 13 amps meets power needs safely.

Pack both for true portability—your machine deserves a dedicated setup wherever creativity strikes.

Navigating Airline and Security Regulations

Flying with your sewing machine doesn’t have to feel like working through a maze of red tape. The Transportation Security Administration has clear guidelines, but every airline adds its own twist to size limits, weight caps, and what you can actually bring through security.

Here’s what you need to know before you head to the airport, so your machine makes it to your destination without a hitch.

TSA Guidelines for Sewing Machines

The Transportation Security Administration explicitly permits sewing machines in both carry-on allowance and checked baggage, but officer discretion at the checkpoint determines final approval.

Keep in mind:

- Your machine undergoes X-ray screening and may require manual inspection if internal components obscure the image

- Sharp objects like rotary cutters must travel in checked baggage, while needles under 4 inches can stay with you

- Lithium batteries follow strict airline travel regulations requiring cabin placement

- Airport security guidelines let officers swab your machine for explosive traces

- TSA’s online database offers item-specific clarification before carrying sewing machines on planes

Carry-on Size and Weight Restrictions

Most U.S. airlines converge on 22 x 14 x 9 inches for carry-on luggage, but weight limit variance runs from strict 15-pound caps to no limit at all. Regional policy differences matter—Asia-Pacific carriers routinely enforce 7-kilogram rules, while North American airlines rarely weigh cabin bags.

Machine dimension implications become critical when your 20-inch-wide case plus padding approaches that size limit enforcement threshold, so compare airline policy before booking.

Declaring Needles and Scissors at Security

How do you breeze past the checkpoint without losing your favorite embroidery scissors? TSA allows needles in carry-on baggage, but blade length limits matter—scissors must measure 4 inches or less from the pivot point.

Wrap sharp tools in protective sheaths and place them in a labeled pouch for quick inspection.

International regulations often cap blades at 6 cm, raising your risk of confiscation on connecting flights.

International Airline Policies

Crossing borders with your machine? Each country writes its own rules. EVA Air caps cabin items at 125 cm total dimensions and 7 kg, while Australian carriers often allow 7–10 kg for compact gear.

Japan bans most scissors in carry-on but permits machines if they meet size limits.

If your model includes lithium batteries, pack spares in your carry-on—checked baggage won’t cut it under international travel restrictions.

Checked Vs. Carry-on Baggage Considerations

Should you tuck your machine in the overhead bin or send it below? Carry-on luggage keeps you in control during security screening and eliminates that 0.58% mishandled baggage risk U.S. carriers posted in 2023. Yet size limits matter—most airlines cap carry-on baggage at 22×14×9 inches.

Checked baggage suits heavier models, but airline regulations often cap liability for damage, leaving you vulnerable despite fragile labels.

Tips for Safe and Stress-Free Transport

Getting your sewing machine from point A to point B doesn’t have to feel like a high-stakes mission. A few smart precautions can save you from heartbreak when you unpack at your destination.

Here’s how to keep your machine safe, your supplies organized, and your stress levels in check.

Using Cushioned Padding to Prevent Damage

Your machine deserves protection that actually works—not just any foam will do. Proper cushion curve design ensures impact resistance without bottoming out, and vibration damping foams guard against hidden transit stress that leads to machine damage prevention failures.

Follow this padding thickness guide:

- Wrap your machine in closed-cell foam at least 3 centimeters thick on all sides

- Add extra cushioning to the base where shock absorption matters most

- Use foam density between 30-180 kg/m³ for best support

- Fill empty spaces to prevent shifting during transport

- Test compression—foam should bounce back, never flatten completely

The economic impact of skimping on padding shows up in repair bills and shipping insurance hikes. Protecting sewing machine components means choosing materials proven to handle drops and road vibration, not just grabbing whatever’s handy.

Labeling and Insuring Your Machine

Padding won’t help if your machine vanishes. Owner ID tags—both inside and on the External Labeling of your case—turn searches into reunions.

Understanding Liability Limits matters: airlines cap domestic losses at $4,700, international at roughly $2,175. Declared Value coverage through shipping carriers protects beyond the default $100. Insurance Options like travel insurance or home policies close gaps, keeping machine damage prevention from becoming a financial nightmare during safe transport.

Car Travel Vs. Airplane Travel Strategies

Your mode of transportation shapes damage risk more than you might expect. Car travel with a sewing machine lets you control placement—wedge yours in the rear footwell, snug between seats, to minimize vibration exposure during sudden stops.

Airplane travel demands a carry-on strategy when possible; checked bags face stacking pressure and drops from conveyor heights. For frequent flights, trip insurance offsets the 0.6% mishandling rate and protects the safe transport of sewing machines.

Preventing Lost or Forgotten Items

Beyond physical damage, lost bobbins and forgotten foot pedals derail entire travel sessions. Packing checklists cut forgotten items by nearly 40%, according to travel research.

Store all essential sewing supplies—machine manual, power cord, presser feet—in dedicated storage compartments, then add labeling luggage tags with contact details. Minimizing items reduces clutter, while your travel checklist confirms you’ve packed everything before departure. That’s your insurance against missing the one tool you’ll actually need.

Quick Maintenance Checks Before and After Travel

Even with careful packing, your machine needs a quick once-over before and after every trip. A five-minute exterior damage check catches loose knobs or cracks that could worsen under vibration. Then inspect needle and foot alignment, remove lint buildup around the bobbin area, and run tension testing on scrap fabric. These tune-ups prevent in-use malfunctions by 20–30%, keeping your machine transport worry-free.

- Check for visible cracks, loose components, or oil leaks on the exterior casing

- Remove or verify needle condition; confirm presser foot hasn’t bent during handling

- Clear lint and dust from the throat plate, hook, and tension disks

- Test-stitch at different lengths to make certain timing and feed remain stable

- Retighten screws and fasteners loosened by transport vibration

Frequently Asked Questions (FAQs)

How do I clean my machine before traveling?

Before sewing machine transport, unplug your machine and brush lint from the bobbin area, under the needle plate, and around feed dogs using a soft brush.

Avoid compressed air—it pushes debris deeper inside during machine maintenance tune ups.

What should I do if my case breaks?

If your transport luggage breaks, immediate protection comes first—wrap your machine in towels or foam.

Assess repairability, check warranty options, document damage for insurance claims, then explore replacement options for future sewing machine travel.

Can I ship my sewing machine instead of flying?

Yes, you can ship your sewing machine instead of flying. Shipping with insurance offers better protection for high-value machines, especially when you double-box and use professional packing to prevent damage during transportation.

How do I protect electronic or computerized features?

Temperature extremes and humidity control matter most for computerized sewing machines. Avoid storage below 5°C or above 35°C, use surge protection against voltage spikes, and prevent static discharge by maintaining 45–85% relative humidity during operation.

Whats the best way to store thread spools?

Think of thread spools as fine wine—they need the right environment to stay vibrant. Store them in climate-controlled bins with humidity between 40-60%, away from sunlight, to prevent fading and tangling while preserving fiber strength.

Conclusion

A single bump can turn your cherished machine into a pile of misaligned parts—but it doesn’t have to. These sewing machine carrying tips give you the armor your equipment deserves, whether you’re boarding a plane or loading a car.

Protective cases, strategic packing, and pre-travel checks transform anxiety into confidence. Your machine has carried you through countless projects; now you know how to return the favor every time you hit the road.

- https://csews.com/sewing-2/taking-a-sewing-machine-on-a-plane

- https://www.explore.com/1989636/sewing-machine-tsa-approved-unexpected-item-carry-on-plane/

- https://www.aircanada.com/ca/en/aco/home/plan/baggage/carry-on.html

- https://www.highspeedtraining.co.uk/hub/manual-handling-weight-limits/

- https://oem.bmj.com/content/79/9/618