This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

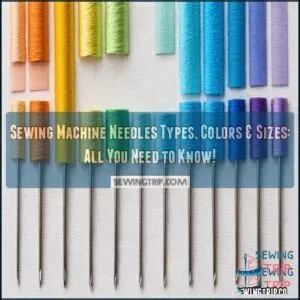

Universal needles (often yellow-banded) work for everyday sewing, while ballpoint needles (green) are perfect for knits.

Size matters—European numbers range from 60 (fine) to 120 (heavy), while American sizing uses 8-19.

These often appear together as 70/10 or 90/14 on packaging.

Colors help you quickly identify specialty needles: blue for denim, orange for leather, and purple for embroidery.

Like choosing the right key for a lock, selecting the proper needle prevents skipped stitches and broken threads that can derail your creative momentum.

Table Of Contents

- Key Takeaways

- Choosing The Right Sewing Needle

- Types of Sewing Machine Needles

- Needle Size and Color Coding

- Needle Care and Maintenance

- Needle Markings and Labeling

- Needle Compatibility and Inspection

- Needle Storage and Organization

- Needle Anatomy and Features

- Replacing and Installing Sewing Needles

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You’ll need to match needle size to fabric weight – use 60/8-70/10 for lightweight fabrics like silk, 80/12-90/14 for medium-weight cottons, and 100/16-110/18 for heavyweight fabrics like denim.

- Color coding helps you quickly identify needle types – blue bands indicate denim needles, orange for ballpoint (knits), purple for sharp/microtex, and yellow for stretch fabrics.

- You should replace your needle after 8-10 hours of sewing or when you notice skipped stitches, thread breakage, or unusual popping sounds, which are clear signs of needle wear.

- You’ll get better results by choosing specialized needles for specific fabrics – universal needles work for everyday sewing, ballpoint needles prevent runs in knits, and stretch needles have deeper scarfs to prevent skipped stitches on elastic fabrics.

Choosing The Right Sewing Needle

You’ll save yourself countless headaches by selecting the right needle for your fabric type and weight.

The perfect needle guarantees smooth stitching with minimal skipped stitches or fabric damage, while the wrong one can turn your sewing project into a frustrating mess, which is why choosing the correct one is crucial for a successful outcome with minimal skipped stitches.

Needle Size and Fabric Weight

Matching needle size to fabric weight can make or break your sewing project.

Here’s your fabric weight guide:

- Lightweight fabrics (silk, chiffon, organza): Use 60/8-70/10 needles

- Medium-weight fabrics (cotton, linen, polyester): Choose 80/12-90/14 needles

- Heavyweight fabrics (denim, canvas): Select 100/16-110/18 needles

- Very heavyweight fabrics (upholstery, leather): Use 110/18-120/19 needles

- Specialty fabrics (stretchy, metallic): Require dedicated needle types plus appropriate sizing

Always check your needle size chart before starting!

Thread Weight and Needle Compatibility

The relationship between thread weight and needle size creates the foundation for perfect stitch quality.

Your chosen needle must accommodate both your thread thickness and fabric density to prevent frustrating thread breakage and needle damage.

| Thread Weight | Recommended Needle Size | Fabric Weight | Tension Adjustment | Best For |

|---|---|---|---|---|

| Fine (50-60) | 9/70 – 11/80 | Light | Lower | Delicate silks |

| Medium (40) | 14/90 | Medium | Standard | Everyday cotton |

| Heavy (30) | 16/100 | Heavy | Higher | Denim, canvas |

| Topstitching | 18/110 | Very Heavy | Higher | Decorative work |

| Metallic | Special | Varies | Lower | Embellishments |

Remember: thicker threads need larger needle eyes to flow smoothly without fraying, which is crucial for achieving perfect stitch quality and preventing thread breakage.

Universal Needles for Woven and Knit Fabrics

Now that you know how thread weight affects your choice, let’s look at the workhorses of your sewing kit.

Universal needles offer fantastic fabric versatility, tackling both woven and knit materials without needing constant changes.

These all-purpose sewing machine needles deliver:

- Superior stitch quality across multiple fabric types

- Reduced fabric damage with their slightly rounded points

- Impressive needle longevity compared to specialized options

- Better cost comparison since you’ll need fewer specialty needles

- Simplified selection process when you’re unsure about exact fabric composition

Keep universal needles in sizes 70/10, 80/12, and 90/14 for best practices in everyday sewing.

Types of Sewing Machine Needles

You’ll need to choose from several specialized needle types, including universal, ballpoint, stretch, and denim, each designed for specific fabric properties and sewing tasks.

The right needle choice guarantees smooth stitching, prevents fabric damage, and helps you achieve professional-looking results without frustrating thread breaks or skipped stitches.

Sharp Needles for Tightly Woven Fabrics

Sharp needles slice through densely woven fabrics like a hot knife through butter.

When working with silk, chiffon, or microfiber materials, these precision needles create clean piercing points that prevent fabric damage.

Microtex needles, a popular sharp needle variety, feature an extra-fine point ideal for straight stitching on delicate fabrics.

- Available in sizes from delicate 60/8 to medium 90/14 to match fabric weight

- Distinguished by their purple color band for easy identification

- Create smaller holes than universal needles, perfect for silk and chiffon

- Reduce puckering and fabric distortion during detailed work

- Excel at precision topstitching and microstitching techniques

- Require more frequent replacement as fine points dull faster

Choose sharps whenever fabric density demands precision and clean penetration.

Ballpoint Needles for Knit Fabrics

Knit fabrics can be temperamental under the wrong needle.

Ballpoint needles feature rounded tips specifically designed to glide between knit fabric types rather than piercing through them.

This gentle approach prevents runs and needlepoint damage that often plague knit projects. When selecting ballpoint needles, consider both your fabric and thread weight.

Lightweight jerseys work best with 70/10 or 80/12 sizes, while thicker sweater knits require 90/14 needles to prevent looping issues. The rounded tip pushes fibers aside instead of breaking them, maintaining the fabric’s natural stretch.

You’ll recognize ballpoint needles by their orange band in most best brands like Schmetz and Organ. Regular needle changes are essential—a dulled point can cause skipped stitches and fabric distortion.

For particularly stretchy materials, consider graduating to stretch needles, though ballpoint needles handle most standard knits beautifully. Your knit fabrics will thank you with smooth, even stitches and maintained elasticity.

Stretch Needles for Elastic Fabrics

While ballpoint needles work with regular knits, stretch needles excel with highly elastic fabrics.

These specialized needles feature:

- A medium ballpoint tip that slides between fibers without snagging

- A deeper scarf to prevent skipped stitches on Lycra and Spandex

- A special coating that reduces friction and heat buildup

- A slender eye that minimizes fabric damage

Identifiable by their yellow band, stretch needles (sizes 75/11-90/14) guarantee your elastic garments maintain their recovery properties while creating perfect seams.

For superior results, consider using polyester thread for stretchy fabrics.

Denim Needles for Heavy Fabrics

Power through heavyweight fabrics with specially reinforced denim needles, engineered with a medium-sharp point and optimized blade that glides through tough materials with minimal deflection. These workhorses feature SCHMETZ exclusive advanced point design perfect for penetrating extra thick fabrics.

- Blue-coded needles available in sizes 90/14 for regular denim up to 110/18 for heavyweight applications

- Large eye accommodates thicker threads typically needed for heavy fabrics

- Extra sturdy shaft reduces breakage when crossing thick seams

- Superior performance on denim, quilts, and upholstery compared to universal needles of same size

For professional results, match your needle size to your fabric weight and always use proper thread tension. These needles are designed for heavyweight fabrics, making them ideal for working with tough materials and ensuring minimal deflection.

Needle Size and Color Coding

You’ll quickly identify the right needle for your project by understanding the color coding and sizing systems that manufacturers use to distinguish between types.

Needle sizes feature two numbers (like 80/12) that represent European and American measurements, while color bands on the shank indicate specific needle types such as blue for denim or yellow for stretch fabrics.

Understanding European and American Sizing Systems

Now that we’ve explored various needle types, let’s reveal the mystery of needle sizing systems.

Sewing machine needles use two numbering systems side by side. European sizes directly reflect needle diameter in millimeters (100 equals 1mm), while American sizes range from 8 (finest) to 18 (thickest). You’ll see these written as 70/10 or 90/14.

When matching fabric to needles, consider:

- Lightweight fabrics: 60-70 European/8-10 American

- Medium fabrics: 80-90 European/12-14 American

- Heavy fabrics: 100-110 European/16-18 American

This metric conversion evolved historically, with each sizing system reflecting regional manufacturing standards.

Color Bands on Needle Packaging

Dozens of needle color codes simplify your sewing experience, turning needle identification into a straightforward process. Those colorful bands on packaging serve as your visual guide to needle types and sizes.

While brand variations exist, most manufacturers maintain color consistency for user accessibility.

Here’s your needle types guide:

- Blue bands typically indicate denim/jeans needles for heavy fabrics

- Yellow bands mark stretch needles for elastic materials

- Red bands often signify embroidery needles for decorative work

- Green bands usually denote microtex/sharp needles for precision sewing

Band placement matters—check both the package and needle shank for these helpful identifiers.

Needle Size and Thread Weight Compatibility

Now that you understand color coding, let’s match your needle size with thread weight for perfect stitches.

The rule is simple: your needle eye should be at least 40% larger than your thread diameter.

For medium-weight threads (40 wt), choose 80/12 to 90/14 needles. Heavier decorative threads need larger eyes—a 30 wt thread pairs with #100/16 needles.

Always select your thread based on your fabric type and project needs first, then find a compatible needle size. This approach prevents needle damage and maintains tension balance, ensuring your stitch quality remains consistent regardless of fabric weight.

A needle size chart is your best friend!

Universal Needle Colors and Sizes

Now that you’ve matched thread weight to needles, let’s look at universal needle colors and sizes.

Those colored bands on your needles aren’t just decorative—they’re a practical coding system that saves you time.

A needle color chart helps you quickly identify universal needle sizes and their ideal applications. Brand variations exist, but most follow similar patterns.

- Yellow bands typically indicate universal 80/12 needles for medium-weight fabrics

- Blue bands often mark heavier 90/14 needles perfect for denim

- Red bands usually denote finer 70/10 needles for delicate fabric pairing

Needle Care and Maintenance

You’ll extend your sewing machine needle‘s lifespan and maintain superior stitch quality by implementing proper care techniques, just as a mechanic maintains precision tools.

Your needles require regular inspection for signs of wear such as bent tips or burrs, and should be replaced after approximately eight hours of active sewing time to prevent fabric damage and thread breakage, which is crucial for maintaining the overall health of your sewing machine and ensuring proper care.

Proper Storage and Handling

Now that you’ve mastered needle sizes, let’s talk about keeping those tiny tools in tip-top shape. Proper needle storage isn’t just about organization—it’s essential for extending needle lifespan and preventing accidents.

Store your needles in their original packaging, specialized needle cases, or on magnetic strips to prevent damage. Keep them away from moisture and direct sunlight, which can cause corrosion or warping. A dedicated storage solution helps maintain needle integrity.

Consider these needle organization methods:

Storage Method Benefit

Signs of a Worn Needle

Struggling with your sewing projects? Recognizing the signs of a worn needle can save you hours of frustration.

Watch for these telltale signs:

- Thread breakage occurring frequently, leaving your project in disarray

- Skipped stitches creating uneven seams and compromising your work’s integrity

- Unusual popping sounds during sewing, indicating needle dullness or bending

A worn needle with a dull point causes fabric puckering and damages delicate materials.

Bent needles create inconsistent stitch patterns and may lead to needle breakage inside your machine.

A good way to avoid this is to replace worn needles.

Replace your needle after 8-10 hours of sewing to prevent fabric damage and maintain stitch quality.

Cleaning and Inspecting Needles

Once wear becomes noticeable, proper needle maintenance becomes your next priority.

Regular cleaning and inspecting needles extends their life and improves your sewing results.

Wipe needles with a lint-free cloth dampened with cleaning solvents to remove lint and adhesive residue.

For best cleaning, consider using specialized cleaning products.

Check for microscopic flaws by holding against light – bent needles, burred eyes, and tiny burrs can cause major problems.

Establish a weekly inspection frequency to catch issues before they damage your fabric, ensuring proper maintenance of your sewing tools.

Changing Needles for Different Fabrics

Now that your needles are clean, let’s talk about swapping them for different fabrics.

Selecting the right needle types prevents needle damage and maintains perfect stitch quality. Think of it as matching your screwdriver to the screw—precision matters!

For ideal fabric compatibility and thread tension:

- Lightweight silks: Use size 60-70/8-10 needles for tear-free results

- Medium cottons: Choose 80-90/12-14 universal needles

- Heavy denim: Install 100-110/16-18 jeans needles at the correct needle angle

- Stretchy knits: Select ballpoint needles to prevent runs

Needle Markings and Labeling

You’ll find that sewing machine needles feature specific markings and color codes that reveal their type, size, and intended use at a glance.

These visual indicators, from manufacturer logos to color bands, help you quickly select the perfect needle for your project without squinting at tiny print on packaging, which is a key factor in choosing the right tool for your needs, and thus, the intended use.

Manufacturer Logos and Branding

When you’ve wrapped up needle maintenance, it’s time to think about who made your needles.

The manufacturer logos on sewing machine needles aren’t just fancy decoration—they’re your quality guarantee.

Brand recognition matters in the sewing world, with each logo representing different strengths:

- Schmetz: German engineering with exceptional durability and precision

- Singer: Time-tested reliability that matches their machine quality

- Janome: Japanese craftsmanship known for smooth fabric penetration

These logos help protect you from counterfeit needles that can damage your machine and projects.

Quality assurance is built into reputable brands, which is why experienced sewists develop brand loyalty after comparing needle performance across different materials.

Needle Size Numbering Systems

After logos help identify quality brands, you’ll need to decode those mysterious numbers on your sewing needles.

European sizing (60-120) directly reflects needle diameter in millimeters, while American sizing (8-18) uses a different scale.

The two systems always appear together (like 90/14) on your needle size chart. Remember: smaller numbers mean finer needles for delicate fabrics, larger numbers for heavier materials.

Selecting needles requires understanding imperial and metric measurements.

Color Coding on Needle Packages

After mastering needle sizes, let’s look at how manufacturers make selection easier with visual cues.

Decoding Colors on needle packages simplifies your shopping experience.

Each color code indicates both type and size at a glance:

- Universal needles: Typically marked with yellow bands for quick selection

- Denim/Jean needles: Blue bands signal strength for heavy fabrics

- Stretch needles: Gold bands identify elasticity-friendly options

- Embroidery needles: Red bands highlight decorative specialists

- Quilting needles: Green bands denote multi-layer capabilities

Brand variations exist, so keep a needle color chart handy!

Specialty Needle Labels

Examining specialty needle labels reveals essential information for your sewing success.

These tiny identifiers use consistent needle color codes, clear font legibility, and recognizable brand recognition to help you make perfect matches.

You’ll find needle types and sizes prominently displayed, with regulatory compliance information tucked into packaging corners.

A quick glance at the label accuracy tells you everything—from fabric compatibility to thread requirements—making specialty needles easier to select for your specific projects.

Needle Compatibility and Inspection

You’ll need to verify your needle’s compatibility with your sewing machine before each project, checking for any bends, burrs, or dull points that could damage your fabric or cause skipped stitches.

A quick inspection under good lighting will save you hours of frustration and help guarantee professional-looking results every time, ensuring that you achieve the desired outcome with minimal effort.

Standardized Needle Sizing

Sewing machine needle sizing follows two standardized systems that work together like a well-oiled machine.

European sizing uses metric measurements (needle diameter in 0.1mm), while American sizing uses a numerical scale.

- European size 70 = 0.7mm diameter = American size 10

- Universal size format displays both: 70/10

Understanding this dual-system helps you select the perfect needle for any fabric weight—preventing thread breakage and ensuring clean stitches every time.

Matching Needles to Sewing Machines

When selecting sewing machine needles, compatibility is vital for superior performance.

Every machine has specific requirements for shank compatibility and needle sizes that vary across different machine models.

Check your manual for brand specifics and system variations that match your needle bar.

Properly matched needles prevent skipped stitches, maintain thread tension, and guarantee appropriate fabric handling.

Keep a needle selection chart nearby for quick reference when switching between projects to ensure superior performance.

Visual Examination of Needles

When your stitches start looking shabby, a careful visual examination of your sewing machine needles might reveal the culprit. Checking your needles regularly prevents frustrating sewing issues.

Here’s what to inspect:

- Point Condition – dull points tear fabric instead of piercing it cleanly

- Eye Integrity – damaged eyes fray and break threads

- Shank Shape – bent shanks cause erratic stitching

- Groove Visibility – worn grooves lead to thread jams

- Needle Markings – faded color coding makes identification difficult

Roll the needle on a flat surface to check for bends, and examine the eye under good lighting. A magnifying glass helps spot minor defects before they become major problems. This process ensures that you can identify and replace damaged needles, which is crucial for maintaining good sewing machine performance and preventing frustrating issues.

Magnification Tools for Needle Inspection

Tiny needle defects often hide in plain sight.

Proper magnification tools reveal what your eyes miss.

| Magnifier Type | Image Clarity | Best For |

|---|---|---|

| Needle Loupes | High Detail | Tip Inspection |

| LED Magnifiers | Excellent | Defect Detection |

| Smartphone Lenses | Convenient | Quick Checks |

When examining sewing machine needles, good lighting options matter as much as magnification.

Position your ergonomic magnifier under natural light or use an LED lamp to spot bent tips, burrs, or dulled points before they cause stitch problems.

Needle Storage and Organization

You’ll save precious sewing time and prevent needle damage by implementing an effective storage system for your various needle types and sizes.

Magnetic strips, labeled cases, and original packaging can transform your sewing area from a frustrating needle hunt into an organized workspace where you’ll always find exactly what you need, making it an essential part of having an effective storage system.

Original Packaging and Pincushions

After unpacking your new needles, preserve their original packaging for smart organization.

Factory cases clearly display needle sizes, colors, and brands—information you’ll need later.

For convenient storage, consider these options:

- Vintage packaging often features collectible designs that double as storage

- DIY pincushions made from dense fabrics prevent needle dulling

- Needle organization by type in labeled cases saves time

- Storage solutions with compartments keep different needle brands separate

To further optimize, consider using a needle organizer with pockets.

Magnetic Strips and Cases

While pincushions serve their purpose, magnetic strips and cases offer next-level organization for your sewing machine needles.

These magnetic storage solutions keep needles visible and secure, preventing those frustrating "where did it go?" moments.

Portable cases made from various materials protect your different needle types and sizes during travel, and magnetic strip organization systems allow you to arrange needles by color codes or markings for quick identification.

For safety and convenience, these storage options beat rummaging through drawers any day, and some cases even include labels to help you track needle sizes at a glance.

Needle Sizers and Gauges

Needle sizers and gauges are essential tools for identifying unmarked needles in your collection.

These handy devices feature precision-cut slots that match standard needle sizes, eliminating guesswork when your needle size chart isn’t available.

Simply slide your needle through until you find the perfect fit, using either digital gauges for enhanced accuracy, or DIY alternatives that can be crafted from sturdy materials when commercial options aren’t available.

Downloadable Needle Guides

You’ll frequently find downloadable needle guides invaluable for organized sewing projects.

These detailed references explain machine needle types and sizes in easy-to-access formats.

- PDF needle size charts with color-coding systems for quick visual identification

- Mobile-friendly guides offering instant access to needle/fabric compatibility when shopping

- Laminated printouts with update frequency information to keep by your sewing machine

Access these guides digitally or print them for convenient reference whenever you’re selecting the perfect needle.

Needle Anatomy and Features

You’ll discover that every sewing machine needle has specific parts including the shank, shaft, eye, point, and scarf that work together to create perfect stitches.

Each component serves a vital function, from the butt that attaches to your machine to the precisely engineered tip that pierces fabric with minimal damage.

Needle Point Styles and Shaft Thickness

Understanding different needle point styles and shaft thickness substantially affects your sewing results.

Sharp points precisely pierce woven fabrics, while ballpoints gently push between knit fibers.

The shaft strength directly relates to needle deflection when sewing thick materials.

Fine-diameter shafts work beautifully on silks, while robust shafts prevent bending on denim.

Specialty points like wedge tips for leather offer unique fabric piercing capabilities.

Remember, point geometry and shaft elements aren’t just technical terms—they’re key to achieving professional results without damaging your fabric or breaking needles.

Eye Shape and Size

Looking beyond shaft thickness, the eye of your sewing machine needle plays a critical role in stitch quality. This small opening determines thread compatibility and can substantially impact your sewing results.

Larger eyes accommodate thicker specialty threads used in decorative work, while smaller eyes guide fine threads with precision. Your thread should pass through the needle eye with minimal resistance—like threading a bead onto a string.

- Thread breakage often signals a mismatch between your thread and needle eye size.

For specialty needles like embroidery types, the enlarged eye prevents friction and damage to delicate threads. When working with metallic or decorative threads, always opt for needles with wider eyes to avoid frustrating breakage issues.

Matching eye size to your fabric types guarantees smoother stitching and professional results.

Needle Materials and Coatings

Three key coatings transform your sewing machine needle’s performance.

The steel composition forms the foundation, while specialized coatings enhance durability.

Titanium nitride, a ceramic coating nearly as hard as diamond, extends needle life 3-5 times longer than standard needles.

Note how needle point changes fabric penetration.

| Coating Type | Benefits | Best Uses |

|---|---|---|

| Hard Chrome | Corrosion protection, friction control | General sewing |

| Titanium Nitride | Extreme abrasion resistance, maintains shape | High stitch count, dense fabrics |

| Nonstick | Prevents thread tearing, reduces adhesion | Delicate fabrics |

| Ceramic | Superior needle hardness, reduced needle temperature | Heavy-duty projects |

| PD Coating | Maximum coating durability | Large embroidery patterns |

The coatings provide distinct benefits, including corrosion protection, friction control, and extreme abrasion resistance, making them suitable for various sewing tasks, such as general sewing, high stitch count, and heavy-duty projects.

Specialty Needle Features

The sphere of specialty needles offers remarkable features suited to specific sewing challenges.

Each needle’s design incorporates unique elements that optimize performance:

- Twin Needles: Feature two parallel shafts with a single shank, creating perfectly even double stitches for decorative work.

- Titanium-Coated Needles: Enhanced with durable coating types that resist wear and heat, extending needle life up to five times longer.

- Wing Needles: Distinctive blade extensions create decorative holes in fabric, perfect for heirloom sewing techniques.

Point design, eye shape, and groove depth vary across specialty needles to match specific fabric needs.

Replacing and Installing Sewing Needles

You’ll need to master the art of replacing your sewing machine needle correctly to prevent skipped stitches and fabric damage.

Knowing when and how to install a fresh needle will substantially improve your sewing results, just like changing a dull kitchen knife transforms your cooking experience, which is a key concept in achieving professional-looking sewing results.

Frequency of Needle Replacement

After examining the intricate details of needle anatomy, let’s focus on when to replace those tiny workhorses in your machine.

Your needle’s lifespan directly impacts stitch quality and project success. Just like changing your car’s oil, preventative maintenance through regular needle replacement keeps everything running smoothly.

| Project Type | Fabric Type | Usage Hours |

|---|---|---|

| Everyday Sewing | Cotton/Linen | 8-10 hours |

| Heavy Duty | Denim/Canvas | 6-8 hours |

| Delicate Work | Silk/Chiffon | 10+ hours |

Most sewing machine needles should be replaced after 8-10 hours of active sewing time. Heavy fabrics like denim accelerate needle wear, requiring more frequent changes. Meanwhile, lightweight projects extend needle longevity slightly.

Don’t wait for obvious needle damage to appear—your projects deserve fresh, sharp needles that guarantee perfect stitches every time.

Signs of Wear and Damage

Your sewing machine needle silently deteriorates with use.

Watch for bent needles, burred points, or uneven shafts that signal imminent failure. When thread breaks frequently or skipped stitches appear, needle damage is likely the culprit.

Fabric damage—like snags or holes—indicates needle wear has progressed too far. Listen for unusual sounds during sewing, as they often precede needle breakage.

Replace needles at the first sign of trouble to prevent project-ruining needle issues.

Proper Needle Installation

Properly installing sewing machine needles is essential for achieving flawless stitches.

First, gently loosen the needle clamp screw and remove the old needle.

Insert the new needle with the flat side facing the back, pushing it up to the proper needle depth.

Pay attention to needle orientation—incorrect alignment causes skipped stitches and fabric damage.

Use installation tools if available, especially for delicate needle types.

Secure placement requires just enough tightness on the screw—overdoing it can strip threads.

Before threading, double-check your work against your machine’s manual to confirm the threading sequence flows smoothly, ensuring a successful installation with proper needle depth.

Troubleshooting Needle Issues

Nearly all needle issues stem from simple problems you can fix yourself.

When your project isn’t cooperating, check for these common troublemakers:

- Skipped stitches often indicate a dull needle that’s pushing fabric down rather than piercing it cleanly.

- Thread breaks typically occur when your needle eye is too small or has rough edges from wear.

- Fabric puckers usually mean you’re using a needle that’s too thick for your material.

- Needle snapping happens when the needle hits something it shouldn’t, like pins or a needle plate.

Match your needle to both fabric and thread weight.

Even the right needle wears out—change it after every 8-10 hours of sewing or sooner if you notice bent needles, strange noises, or thread breakage.

A fresh needle prevents fabric damage and saves hours of needle troubleshooting.

Frequently Asked Questions (FAQs)

What is the Best Way to Store My Sewing Machine Needles?

Your delicate threaded soldiers need a proper home.

Store needles in labeled containers, magnetic holders, or pin cushions.

Keep them dry and away from children.

You’ll extend their life and find them easily.

How Can I Tell When It’s Time to Replace My Sewing Needle?

Replace your needle when you notice bent tips, burrs, dull points, skipped stitches, unusual sounds, fabric damage, or after 8-10 hours of sewing.

Don’t wait until your projects suffer from needle fatigue.

How Do I Safely Dispose of Used and Damaged Sewing Needles?

I was shocked when I found my son playing with my old needles.

Place used sewing needles in a rigid container like a medicine bottle, and seal it before throwing it in the trash.

Are There Any Tricks for Threading the Eye of a Sewing Needle More Easily?

Use a needle threader tool, moisten the thread end, cut it at an angle, or stiffen with hairspray.

Working in good lighting with contrasting thread colors also makes threading much easier.

What do the different colors on sewing machine needles mean?

Did you know that 85% of sewers rely on color-coded needles?

The colors on your sewing machine needles indicate their type: yellow for universal, blue for denim, purple for sharps, and orange for ballpoint.

What are the 7 different types of sewing needles?

The seven primary sewing machine needles include universal, sharp, ballpoint, stretch, denim, quilting, and leather types. You’ll choose different needles based on your fabric type and specific project requirements.

What is the color code for needle size?

Sewing machine needle sizes follow color coding: green for size 70 (extra fine), orange for 80/12, blue for 90/14, and red for 100/ You’ll find these colors on both needle packages and shanks.

Which needle is smaller, 80 12 or 90 14?

Like comparing dress sizes, smaller numbers mean smaller needles. The 80/12 needle is thinner than the 90/14 needle. You’ll want to use 80/12 for lighter fabrics and 90/14 for medium-weight materials.

What colors are sewing machine needles?

Most sewing machine needles use color bands to indicate type and size.

You’ll find universal (no color/yellow), microtex (purple), ballpoint (orange), stretch (yellow), jeans (blue), and green for extra fine fabrics, which are all clearly indicated by these color bands.

What are the 7 types of sewing needles?

You’ll need to know these main sewing needle types: universal, ballpoint, sharp, stretch, denim, quilting, and leather.

Each type is designed for specific fabrics and projects, ensuring your stitches stay perfect.

Conclusion

Picture yourself smoothly completing every sewing project with confidence—that’s the power of understanding sewing machine needles types, colors, and sizes.

You’ll save time and frustration by selecting the right needle for each fabric.

Remember, it’s not just a small metal piece; it’s the critical connection between your machine, thread, and fabric.

Keep this guide handy, and you’ll never second-guess your needle choice again, which will make your sewing machine thank you, and give you the confidence to complete projects smoothly.