This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your first attempt at hand sewing a straight line probably wandered across the fabric like a child’s crayon drawing. That’s normal. The difference between a crooked seam and a professional-looking stitch isn’t talent—it’s technique.

Most beginners grip the needle wrong, ignore fabric grain, and skip the setup that makes straight stitching almost automatic. You need three things: the right tools in your hands, a marked guide on your fabric, and control methods that keep each stitch exactly where you want it.

Master these fundamentals, and you’ll transform wobbly lines into precise seams that look machine-made.

Table Of Contents

- Key Takeaways

- Essential Tools for Hand Sewing a Straight Line

- Preparing Fabric and Materials

- Step-by-Step Guide to The Running Stitch

- Tips for Sewing a Consistently Straight Line

- Common Mistakes and How to Avoid Them

- Decorative and Practical Uses of Straight Stitches

- Practice Exercises for Beginners

- Top 5 Tools for Perfectly Straight Hand Sewing

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Mastering straight hand stitching requires three essentials: proper tools (right needle, matching thread, fabric markers), marked guidelines on your fabric, and controlled needle positioning with consistent tension throughout each stitch.

- The running stitch forms your foundation—start by securing thread with a knot on the fabric’s wrong side, maintain 2-4mm spacing between stitches, and finish with anchor stitches or backstitching to prevent unraveling.

- Common mistakes like crooked stitches, thread tangles, and uneven spacing stem from poor setup—pin fabric flat, cut working thread to 18-24 inches, mark your line clearly, and slow down your stitching speed to maintain control.

- Practice builds real skill by progressing from short lines on stable cotton to longer seams on varied fabrics, gradually increasing complexity from basic running stitches to decorative embroidery and repair techniques.

Essential Tools for Hand Sewing a Straight Line

You can’t sew a straight line without the right tools in your hands. The difference between frustration and control comes down to having what you need before you start.

Here’s what belongs in your sewing kit to master straight hand stitching.

Choosing The Right Needle

Your needle is your command center—get it right, and straight stitches fall into line. Match needle sizing to your fabric structure: finer numbers (9–12) for delicate silks, lower numbers (2–4) for heavyweight canvas.

Check thread compatibility by ensuring the eye accommodates your thread without friction. Needle material matters—nickel-plated steel glides smoothly.

A sharp sewing needle masters woven fabrics; use a needle threader if precision threading challenges you. For peak results, consider using the right sewing needle types to ensure a professional finish.

Selecting Appropriate Thread

Once your needle is sorted, thread selection completes your command setup. Match thread materials to your fabric matching goals: cotton threads suit natural weaving, while polyester dominates with 50% of synthetic volume for exceptional strength. Thread weight controls visibility—50-weight balances precision in straight stitch work, while 12-weight creates bold lines.

Consider these fiber types:

- Cotton (70% of natural threads)

- Polyester (chemical-resistant synthetic)

- Silk (15% natural segment)

Color selection impacts results—slightly darker hides imperfections. The sewing industry is driven by market trends analysis that influence thread choices.

Must-Have Sewing Accessories (Scissors, Thimble, Pins)

Beyond needle and thread, three tools transform hand sewing from struggle to precision. Fabric scissors stay 50% sharper when you guard them like treasure—paper is their enemy. A thimble in metal or leather shields your pushing finger through thick layers. Pins perpendicular to your stitch line anchor fabric while you work. Needle threaders and complete sewing kits simplify setup, letting you focus on mastering that straight line.

Using Fabric Markers and Rulers

A clear acrylic ruler with 1/8-inch grid markings becomes your blueprint for precision guiding. Align your ruler with the grain before drawing, then follow that guide for a ruler accuracy that keeps your straight stitch truly straight.

Choose fabric markers wisely—air-erasable ink vanishes in 24–72 hours, while permanent types need heat-setting for sewing line visibility through washes. Test each marker on scrap fabric first to confirm marker removal works.

Preparing Fabric and Materials

Before you make your first stitch, you need to set yourself up for success. The right fabric choice and proper prep work make the difference between frustration and a clean, confident line.

Let’s walk through the essential steps to get your materials ready.

Selecting Fabric Types for Beginners

Your fabric selection sets the foundation for mastering straight hand sewing. Start with plain-weave cotton—quilting cotton, poplin, or chambray—because these stable, non-stretch textiles won’t shift or distort while you stitch. Medium-weight options around 120–200 g/m² give you enough body without fighting the needle.

- Cotton poplin: crisp, minimal fraying

- Quilting cotton: affordable, widely available

- Cotton chambray: breathable, predictable behavior

Prewash your fabric to prevent shrinkage after you’ve sewn those perfect lines.

Cutting and Measuring Fabric Accurately

Precision separates confident sewers from those who constantly rework seams. Cut your fabric with sharp scissors along a ruler or measuring tape—industry data shows even small cutting errors can produce 10–20% fabric waste and dimensional tolerances beyond the acceptable ±0.5–1.0 cm range.

Accurate measuring tools make the most of every inch, reduce costly mistakes, and deliver the cutting precision your straight stitch techniques demand for professional results.

Marking a Straight Line With Tools

You can’t control your needle if you can’t see where you’re headed. Lay a ruler along your fabric and trace with fabric markers—tailor’s chalk for thick weaves, water-soluble pens for smoother cotton or linen.

Sewing mats with printed grids give you perpendicular reference lines, so your seam guide stays locked. Pick high-contrast marking tools that vanish after you’ve sewn your straight stitch.

Threading and Knotting Techniques

Thread tension and knot security are crucial—your straight stitch won’t hold if the foundation fails. Here’s how you can master needle threading and knotting with hand dexterity that improves your sewing efficiency:

- Cut 18–30 inches of thread for ideal control and fewer tangles

- Use a wire-loop threader to thread your needle in one motion instead of several attempts

- Tie with 3 newtons of force—firm enough to grip, not so tight you weaken the thread

- Pull slowly until the knot catches on the fabric’s wrong side, securing your hand sewing techniques for every running stitch

Step-by-Step Guide to The Running Stitch

The running stitch is your foundation for hand sewing straight lines. You’ll start by securing your thread, keep your stitches even as you work across the fabric, and finish with a knot that won’t unravel.

Master these three steps and you’ll have the control to tackle any hand-sewn seam with confidence.

Starting The First Stitch Correctly

Your very first move with the sewing needle sets everything in motion—get it wrong, and your entire seam unravels.

Start by pushing the threaded needle up from the fabric’s wrong side, pulling slowly until your knot catches firmly underneath. Knot security and proper stitch anchoring prevent gaps right where your straight stitch begins.

A tiny backward stitch through both layers locks your thread tension before you continue with hand stitching forward.

Maintaining Even Stitch Length

Your rhythm matters more than speed—consistent spacing separates messy stitching from polished needlework. Aim for 2 to 4 millimeters per straight stitch, using your fingernail width as a physical guide for stitch length control.

Thread tension management demands slow, steady pulls to prevent puckering, while ergonomic sewing tips like relaxed shoulders improve stitch consistency techniques.

Fabric choice considerations also matter—stiffer weaves help you nail uniform hand stitching faster.

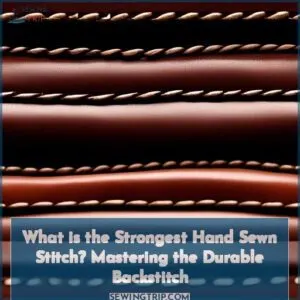

Securing The End of Your Line

Once you’ve nailed even spacing, lock your work in place—unraveling seams kill confidence fast. Master these end securing methods:

- Knotting techniques: Form a tiny loop on the wrong side, pass your sewing needle through twice, then snug it within 2 millimeters of your final straight stitch.

- Anchor stitches: Sew 2–3 overlapping stitches in place to flatten bulk.

- Backstitching: Reverse-stitch 3–4 millimeters over your last stitches for military-grade thread tension control.

Trim tails to 5 millimeters—never flush.

Tips for Sewing a Consistently Straight Line

Knowing the running stitch is one thing—keeping it perfectly straight is another.

Your line stays true when you combine smart positioning with a few simple control techniques.

Here’s how you master the straightness that separates beginner work from professional results.

Using Guides and Marked Lines

Precision is your secret weapon when you want to sew straight lines consistently. Fabric markers and straight edges take the guesswork out of every stitch. Draw your guideline with a water-erasable marker or tailor’s chalk before you begin. Then, match each straight stitch to that marked line.

Here’s a quick comparison of marking tools and sewing guides:

| Tool Type | Best For |

|---|---|

| Water-erasable markers | Temporary lines that disappear quickly |

| Tailor’s chalk | Visible markings on various fabrics |

| Clear acrylic rulers | Drawing precise straight edges |

| Quilting rulers with grids | Maintaining consistent seam guide measurements |

| Magnetic seam guides | Holding fabric steady while you sew straight |

Choose ruler techniques that suit your fabric. Transparent gridded rulers help you align edges perfectly. Mark the beginning, middle, and end points of your line for maximum accuracy. These simple marking tools transform shaky stitches into professional straight lines every time.

Hand Positioning and Needle Control

Once you’ve marked your line, your hands become precision instruments. Hold the needle between your thumb and index finger while your middle finger—ideally with a thimble—pushes from behind. This three-finger grip gives you serious finger dexterity and needle guidance.

Keep your wrist in neutral alignment, not bent, and maintain hand ergonomics by working at elbow height. A needle threader simplifies setup so you can focus entirely on hand sewing techniques that deliver straight lines.

Adjusting Stitch Tension

Tension control makes or breaks your straight line. Pull each stitch until the thread sits flush with the fabric—taut but not tight enough to pucker or stretch the material. If you see tiny wrinkles forming along your seam, you’re overdoing it. Loose stitches leave visible loops that catch and unravel.

Adjust thread tension based on fabric weight: lighter materials need a gentler hand sewing technique than denim or canvas.

Common Mistakes and How to Avoid Them

Even experienced sewers hit bumps when they’re learning to hand sew a straight line. The good news is that most mistakes follow predictable patterns, and you can fix them once you know what to watch for.

Let’s look at the three most common problems and how to tackle them head-on.

Preventing Thread Tangles

Controlling your thread stops tangles before they start. Cut working lengths between 18 and 24 inches—anything longer twists and loops as you stitch.

Run the thread through beeswax or conditioner to reduce friction and static. Let your threaded needle hang freely every few stitches so gravity untwists the fibers.

Slow, steady pulls keep loops from tightening into knots.

Avoiding Crooked Stitches

Your straight stitch drifts when fabric shifts or your needle control falters. Pin layers flat before you start—no bunching means no crookedness. Mark your straight line with a ruler and fabric pen, then guide your needle along that path.

Match your needle size to fabric weight so it doesn’t deflect. Slow down, keep consistent hand positioning, and let proper stitch tension prevent wavering seams.

Fixing Uneven Stitch Lengths

Inconsistency ruins hand sewing when you rush or grip your needle wrong. Master stitch length control by marking 2.5 to 3 mm intervals—that’s roughly 8 stitches per inch. Adjust thread tension so it doesn’t pucker or sag.

Match needle selection to fabric weight, keep steady sewing posture, and practice fabric handling without stretching. Your straight line depends on deliberate sewing technique, not speed.

Decorative and Practical Uses of Straight Stitches

The straight stitch isn’t just a building block—it’s a workhorse you’ll rely on for everything from quick fixes to expressive embroidery. Once you master the basics, you can put this simple stitch to work in dozens of practical and creative ways.

Let’s look at three core applications that show exactly why the straight stitch earns its place as the foundation of hand sewing.

Basting and Seam Construction

Basting is the workhorse of seam construction—it’s your temporary straight-line insurance policy before committing to permanent stitches. This hand sewing technique holds fabric layers exactly where you want them, preventing shifts that sabotage seam accuracy.

You’ll master fabric stability with these basting techniques:

- Use longer stitches (6-20mm) for quick thread selection and removal

- Control curved seams with shorter, even stitches

- Secure collars and sleeves before final stitching

- Remove basting only after verifying fit

Gathering and Basic Repairs

You’ll transform loose fabric into controlled gathers using parallel rows of running stitches—the same straight line technique that closes torn seams and reattaches buttons. For gathering, sew two rows 1/8 inch apart, leaving long thread tails to draw up fullness.

Your hand stitching repairs extend garment life dramatically, with studies showing mending displaces 82% of new clothing purchases while mastering essential textile mending skills.

Mending your clothes isn’t just frugal—it displaces 82% of new purchases while teaching you textile repair skills that last a lifetime

Straight Stitch Hand Embroidery

Your hand stitching becomes art when you master straight stitch embroidery. Build botanical designs by radiating stitches outward for petals or cluster them to form pine needles and grass textures.

Thread colors and fabric choices define your visual impact—contrasting hues add definition along leaf veins. Keep stitch lengths under 1 inch to prevent snagging, and practice consistent stitch tension on scrap fabric first for smooth embroidery designs.

Practice Exercises for Beginners

You won’t master the straight stitch by reading alone—you need to put needle to thread and start sewing. The best way to build confidence is through targeted practice that starts simple and gradually challenges your growing skills.

Here are three exercises designed to take you from shaky beginner to steady hand.

Sewing Short and Long Straight Lines

Start with short lines—three to four inches—to master stitch length control and hand-eye coordination. Short segments let you focus on precision guidance without fatigue. Once you sew straight consistently, scale up to twelve-inch lines. Longer runs test fabric tension and sewing speed while building confidence.

Each hand sewing exercise sharpens your straight stitch technique and sewing tips that keep every line ruler-perfect.

Using Different Fabrics for Practice

Once you conquer short and long straight lines, switch up your fabric selection to build real hand sewing mastery.

Start with cotton muslin—its stable weave shows every stitch clearly and won’t shift under your sewing needle. Then try cotton/polyester blends for different thread tension, flannel for thicker sewing surfaces, and linen to feel how material stretch and fiber blends challenge your control.

Gradually Increasing Stitch Complexity

After you’re comfortable with basic fabric changes, push your hand sewing skills forward by increasing stitch complexity along each straight line.

Follow this stitch progression to build seam strength and control:

- Master running stitch density at 5–6 stitches per inch, then work toward backstitch’s 18–19 stitches per inch for stronger permanent seams.

- Add edge finishing with overcast stitches on raw fabric edges to prevent fraying.

- Practice concealed stitches like blind-hem for invisible finishes.

- Mix embroidery techniques into your straight lines for decorative effects.

Top 5 Tools for Perfectly Straight Hand Sewing

You’ve practiced your stitches and built your confidence—now it’s time to level up with the right tools. The best hand sewers know that a few strategic accessories can transform your straight lines from “good enough” to genuinely impressive.

Here are five game-changing tools that’ll give you the precision and control you’ve been working toward.

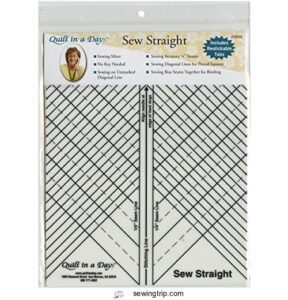

1. Sew Straight Quilting Guide Tool

You know that moment when you think you’ve nailed a quarter-inch seam, only to discover your blocks are shrinking? The Sew Straight quilting guide tool solves that frustration with clear acrylic precision.

This lightweight seam guide attaches to your machine without permanent changes, letting you align fabric edges consistently for straight stitch mastery. At around $12, it’s a breakthrough for quilting accuracy and fabric alignment.

Set it once with a quilting ruler, and watch your quilting efficiency soar as crooked seams become ancient history.

Best For: Quilters who want consistent quarter-inch seams without constantly checking their needle position, especially beginners still building muscle memory for accurate piecing.

- Keeps your seam allowances spot-on without pre-marking fabric, so you spend more time sewing and less time measuring or ripping out wonky seams.

- Lightweight acrylic design lets you see through it while you work, and it won’t mess with computerized machines like magnetic guides can.

- Costs around $12, which is pretty reasonable compared to what you’d spend on specialty feet or dealing with blocks that don’t fit together right.

- You’ll need to remove it every time you refill your bobbin, which can get annoying if you’re in the zone.

- The sticky pads can lose their grip over time, so you might need replacements or find yourself readjusting it more often than you’d like.

- Takes some careful setup with a ruler to get the alignment right at first—if you rush it, you might end up with seams that are still off.

2. Free Motion Quilting Slider Mat

Your fabric fights you with every stitch when friction takes over. The Top Slider free motion quilting mat changes that battle with its Teflon surface—100% PTFE that drops resistance below 0.1.

At roughly $30 for an 8 by 11.75 inch mat, you get a tacky pink backing that grips your machine bed while fabric glides effortlessly across.

Align the needle opening correctly, and watch your straight lines and free motion tips transform as the slider benefits kick in during complex quilting techniques and precise fabric manipulation.

Best For: Quilters who struggle with fabric drag during free motion work and want smoother movement across the machine bed without constantly repositioning their quilt sandwich.

- PTFE surface drops friction below 0.1, letting you glide fabric in any direction with way less hand pressure than a bare metal bed

- Tacky backing sticks to your machine without tape but peels off cleanly when you’re done, so you can reuse it across multiple projects

- Works great with grip gloves or handles to give you better control on curves and dense fills where you’re changing direction constantly

- At $30 for the standard size, it’s pricier than DIY Teflon sheet options you could cut yourself

- The 8 by 11.75 inch mat only covers smaller machine beds, so you’ll need the king size version if you have a big extension table

- Grid markings get hidden under your quilt layers during stitching, which limits their usefulness compared to mats designed specifically for alignment

3. Sewing Machine Seam Guide Tape

With precision sewing on your side, HONEYSEW’s diagonal seam guide tape delivers four washi paper rolls at $7.99. This seam guide puts a red center line right under your needle with blue markers exactly 1/4 inch out—perfect for quilting half square triangles and straight lines without chalk.

The low-tack adhesive peels clean from your machine bed, though adhesive durability varies with use. Align the center thread with your needle position, and watch those consistent seams appear across every project, matching different seam guide types and machine compatibility needs.

Best For: Quilters and sewists who need consistent 1/4 inch seams for piecing projects like half square triangles without marking fabric every time.

- Clear visual guides with a red center line and blue 1/4 inch markers make it easy to sew accurate seams without constantly measuring

- Washi paper adhesive removes cleanly from your machine bed without leaving sticky residue behind

- Four rolls for under eight bucks gives you plenty of tape to reapply as needed across multiple projects

- Adhesive can lose its stick fairly quickly, so you’ll need to replace strips more often than you’d probably like

- Some users report the markings aren’t always precisely 1/4 inch, which defeats the purpose if you’re working on projects where accuracy really matters

- Edges can peel up during use, interrupting your sewing flow when you have to stop and press them back down

4. Sewing Machine Seam Guide Ruler

At $13.99, the Madam Sew seam guide ruler transforms your machine sewing accuracy with 16 precision holes measuring seam allowances from 1/8 to 2 inches. This green plastic sewing tool clips onto your machine bed, giving you straight lines without guesswork.

The magnetic guide holds firm for long seams, while the 45-degree line trims half-square triangles clean. Quilting ruler benefits meet practical sewing machine accessories in one compact 2.5″ x 5.5″ design, making precision stitching aids accessible for every straight stitch you master.

Best For: Quilters and sewists who want consistent seam allowances without eyeballing measurements every time.

- 16 different seam measurements from 1/8″ to 2″ give you options for any project

- Magnetic guide stays put during long seams so you’re not constantly adjusting

- Works with most sewing machines right out of the box

- The 1/4″ hole runs too large for some needles, which defeats the purpose for precision piecing

- Strong magnet can lift throat plates on certain machines or make repositioning frustrating

- Not compatible with single-hole throat plates, limiting use on some equipment

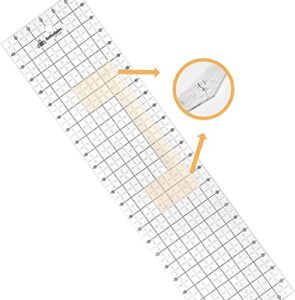

5. Clear Acrylic Quilting Ruler Tool

Your fabric won’t lie about crooked cuts. The Beehive Clear Acrylic Quilting Ruler (14″ x 6″) gives you cutting accuracy through 3mm acrylic thickness that won’t flex under your rotary blade. Edge stability keeps your seam lines true, while dual-scale measurement markings in contrasting yellow read clean on any fabric.

This ruler material lets you see grain lines and patterns while you work, making quilting and sewing straight lines dependable. At around $20, it’s among essential sewing tools that improve your hand-sewing precision.

Best For: Quilters and sewers who need dependable straight cuts and accurate measurements for piecing blocks and cutting fabric strips.

- Rigid 3mm acrylic stays flat during rotary cutting, preventing the flex that causes crooked cuts and wasted fabric.

- High-contrast yellow markings stay visible on light and dark fabrics, making it easier to line up measurements quickly.

- Clear material lets you see fabric patterns and grain lines underneath, so you can align cuts without guessing.

- Some users find the price steep compared to basic quilting rulers.

- The clear design can be harder to see on certain dark fabrics despite the yellow markings.

- A few customers reported packaging problems and occasional quality control issues like cracked rulers on arrival.

Frequently Asked Questions (FAQs)

How do you sew a straight line?

You push your threaded needle up through fabric, then down again at a short distance.

Repeat this basic motion evenly, keeping consistent spacing and tension while guiding your stitches along a marked line.

How do I learn to hand sew?

Start with hand sewing tutorials and online lessons covering sewing basics. Beginner lessons build your skills through repetition and guidance from experienced sewers.

Join a sewing community for tips and tricks. Practice sewing fundamentals regularly.

How do I choose the right sewing needle?

Match your needle to your fabric weight and thread compatibility. Choose finer needles for delicate fabrics, thicker ones for heavy materials. Check eye size and needle finish to prevent thread shredding and improve your sewing skills.

How do you hand sew curved lines smoothly?

Some folks think curved stitching is straight-line sewing gone rogue. It’s not.

Use backstitch or stem stitch, shorten stitch length on tight curves, mark your fabric guidance line clearly, and control thread tension for smooth curve methods.

What fabrics are hardest for straight line sewing?

Slippery fabrics like chiffon and satin are notoriously difficult because layers slide against each other. Stretchy materials, thick textiles like velvet, and delicate lace also challenge your control, making accurate stitching harder than stable cottons.

How do you remove visible marking lines later?

Wondering if those guide lines will haunt your fabric forever? Water-soluble fabric marking dissolves with full immersion, chalk brushes away, and heat-erasable Frixion Pens vanish under iron pressure—preventing ghosting along every seam.

When should you switch from hand to machine?

Switch to a sewing machine when project size exceeds small repairs, fabric type demands durability, or you need consistent stitch quality and faster sewing speed.

Machines reduce production costs and physical strain on repetitive straight seams.

Conclusion

A straight line is your foundation—the wall you build everything else upon. Without it, every seam collapses under scrutiny.

You now hold the blueprint: proper tools, marked guides, controlled needle movement. Hand sewing a straight line isn’t about flawlessness on your first attempt. It’s about deliberate practice with each stitch.

Pick up your needle. Mark your fabric. Start stitching. That crooked beginner’s line transforms into professional work through repetition, not luck. Your hands already know what to do.