This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

This guide demystifies the selection process, from simple to compound feed machines, and highlights the unmatched benefits of the latter.

Whether you’re a beginner or aiming to elevate your craft, understanding the nuances of walking foot machines will empower your upholstery projects with innovation and mastery.

Table Of Contents

Key Takeaways

- Walking foot machines enhance ease of use and work quality in upholstery by effectively handling multiple fabric layers and maintaining consistent stitch length.

- Compound feed walking foot machines, which combine feed dog and needle feed, are particularly beneficial for upholstery projects to ensure precision stitching and even seams on long runs.

- When selecting a walking foot machine for upholstery, considerations should include price, power, and precision requirements, features such as the walking foot attachment and sewing speed control, and choosing from reputable brands like Sailrite, Consew, and Adler.

- Practical tips for successful upholstery sewing with a walking foot machine include correct machine setup, using the appropriate presser foot and needle, employing pneumatic staplers for tough spots, and regularly maintaining the machine by oiling moving parts and replacing the needle after 7-8 hours of use.

Walking Foot Essentials for Upholstery

You’ll find that a walking foot significantly enhances ease of use and the quality of your upholstery work.

It’s designed to handle multiple fabric layers and maintain a consistent stitch length, ensuring your projects look professional.

Ease of Use and Quality of Work

Diving into upholstery? A walking foot sewing machine is your ally, blending ease of use with top-notch quality.

Despite its cost and maintenance, the needle feed ensures every stitch is a step towards perfection.

Handling Multiple Fabric Layers

Continuing from the ease of use, your walking foot’s compound feed tackles multiple fabric layers like a champ.

- Compound feed grips heavy-weight fabrics firmly.

- Needle feed ensures even stitching.

- Presser feet handle varied fabric types.

- Double needle options offer reinforced seams.

Consistent Stitch Length

When you’re powering through upholstery work, a walking foot ensures your seams stay even on long runs.

The Consew 206RB-5, with its needle feed, delivers uniform stitches that scream dependability and control.

Types of Walking Foot Machines

When choosing a walking foot machine for upholstery, understanding the difference between simple and compound feed is crucial. This knowledge ensures you select a machine that offers needle movement and stitch consistency, matching your project needs.

Simple Vs. Compound Feed

Transitioning from the basics, let’s dive into the nuts and bolts of walking foot machines.

- Simple feed relies solely on the feed dog.

- Compound feed adds needle feed, enhancing fabric control.

- Upholstery thrives with compound feed for even stitches.

- Industrial sewing machines like the Singer 206RB5 excel with compound feed.

Needle Movement and Stitch Consistency

As you transition from simple to compound feed walking foot machines, you’ll notice the needle movement is key to maintaining stitch length.

It’s like having cruise control for your upholstery projects—steady and reliable, without the hiccups.

Your walking foot is your trusty co-pilot, steering through layers with finesse.

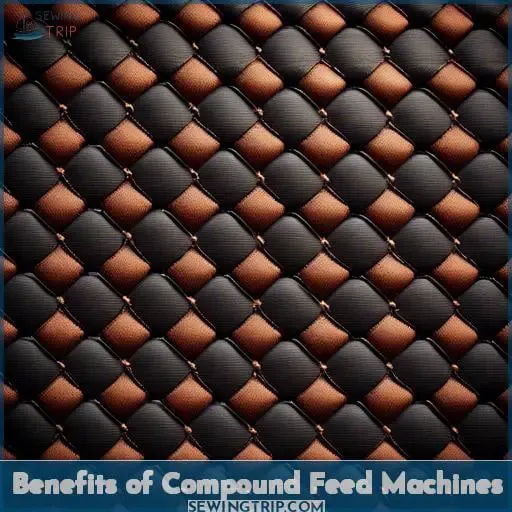

Benefits of Compound Feed Machines

Choosing a compound feed machine for your upholstery projects means you’re opting for a model that outperforms those without needle feed in precision and capability.

However, it’s important to understand their limitations to ensure they align with your sewing needs.

Superiority Over Non-Needle Feed Models

When tackling upholstery, a needle feed walking foot sewing machine is your secret weapon. It delivers even seams, especially on long runs, and climbs layers like a champ.

You’ll marvel at the consistent stitch quality, even with the thickest upholstery fabrics and threads.

Limitations and Capabilities

After highlighting the edge compound feed machines have, let’s dive into their capabilities and limits.

- Zig zag stitch adaptability, especially with the Adler 867 Mtype.

- Double needle machines excel in upholstery precision.

- Walking foot/zig zag machines balance stretch and strength in sails.

- Yet, the quest for the perfect presser foot continues.

Considerations for Machine Selection

When selecting a sewing machine for upholstery, it’s crucial to consider both the price and the specific features that will meet your needs.

Look for models from reputable brands that offer the necessary power and precision for handling heavy fabrics and multiple layers.

Price and Availability

When eyeing the perfect walking foot machine, your wallet and patience play big roles.

| Feature | Consideration | Impact |

|---|---|---|

| Pricing strategies | Singer 20U | Competitive edge |

| Geographical distribution | Consew 206RB5 | Location matters |

| Wait time analysis | Consew 206RB-4 | Patience is a virtue |

| Market competition | Top stitch feet | Shop around |

| Shipping costs | Zipper feet | Adds up |

Machine Features for Upholstery

After considering price and availability, focus on these key features for your upholstery masterpiece:

- Walking foot attachment for seamless fabric handling.

- Juki-grade durability for relentless marine work.

- Sewing speed control for precision in every stitch.

Recommended Brands and Models

After diving into the nuts and bolts of what makes a great upholstery machine, let’s zero in on the crème de la crème of brands and models that’ll make your sewing dreams a reality.

| Brand | Model | Specialty |

|---|---|---|

| Sailrite | LSZ-1 | Walking foot zig zag for sails and seam construction |

| Consew | 146 | Double needle machines for upholstery |

| Adler | 867 Mtype | Heavy duty sewing machine with zig zag capability |

Practical Tips for Upholstery Sewing

When tackling upholstery projects, it’s crucial to set up your machine correctly and understand the techniques for sewing heavy fabrics.

You’ll also benefit from having the right tools on hand to streamline the process and ensure a professional finish.

Machine Setup and Maintenance

Setting up your upholstery beast? Remember, the right foot presser and needle selection are your best pals.

Keep that bobbin winding tight and thread tension just right.

And don’t skimp on oil lubrication—your machine will thank you.

Sewing Techniques for Heavy Fabrics

After mastering your machine setup, dive into sewing techniques for heavy fabrics.

Your walking foot guide becomes your bible, ensuring smooth sailing through thick layers.

Keep your Consew CP206RL or Sailrite LS-1 humming with precision.

Don’t forget the value of pneumatic staplers for those tough spots.

Additional Tools for Upholstery

In upholstery, your sewing table’s pedal position can make or break your workflow.

Opt for pneumatic staplers and stainless steel staples for durability.

Stuck? Online resources are a goldmine for troubleshooting with your walking foot.

Frequently Asked Questions (FAQs)

How do I maintain my walking foot’s performance?

To keep your walking foot sewing smoothly, regularly oil the moving parts.

Replace the needle after 7-8 hours of use.

Clean lint from the bobbin area after each session.

Can a walking foot sew delicate fabrics like silk?

Navigating silk with a walking foot is like steering a yacht through calm seas—it’s smooth sailing. This tool ensures your delicate fabrics glide under the needle without a hitch, making every stitch a masterpiece.

What’s the difference between a walking foot and a dual feed?

A walking foot moves all fabric layers in unison, ideal for quilting and bulky materials.

Dual feed only advances the top layer, better for lighter projects with less bulk.

How do I troubleshoot a walking foot that skips stitches?

To fix a skipping walking foot:

Change your needle.

Check bobbin tension.

Ensure proper threading.

If the issue persists:

Slow down your sewing speed.

Verify the foot is securely attached.

Are there eco-friendly walking foot options available?

Currently, there aren’t specific eco-friendly walking foot options highlighted in the sources provided.

However, choosing brands committed to sustainability in their manufacturing processes can be a step in the right direction.

Conclusion

Rome wasn’t built in a day, and neither is mastery in upholstery.

Choosing the right walking foot machine is crucial for ensuring ease of use, quality, and consistency in your projects.

Whether you opt for a simple or compound feed machine, remember that a walking foot is essential for handling multiple fabric layers with precision.

By considering machine features, price, and recommended brands, you’ll set yourself up for success.

Follow these practical tips, and your upholstery work will truly stand out.