This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Your Singer Heavy Duty just skipped three stitches on a single seam—again. Manual tension adjustments eat up 15 minutes per project, and threading that needle tests your patience every single time.

Modern automatic stitch features machine technology eliminates these frustrations through sensor-controlled tension systems, programmable stitch patterns, and one-touch needle threaders that transform workflow efficiency.

High-speed servo motors now exceed 1,000 stitches per minute while maintaining stitch-length accuracy within 0.1mm, and firmware updates expand stitch libraries without replacing hardware.

Eight machines dominate the current market with distinct automatic capabilities: some prioritize heavy-duty fabric penetration, others focus on computerized embroidery functions, and a few deliver professional-grade precision at consumer price points.

Table Of Contents

- Key Takeaways

- What Are Automatic Stitch Features in Sewing Machines?

- Essential Automatic Stitch Features to Look For

- Top 8 Sewing Machines With Automatic Stitch Features

- 1. Singer Heavy Duty Sewing Machine

- 2. Singer Portable Sewing Machine

- 3. Brother Computerized Sewing Machine

- 4. Singer Quantum Stylist Sewing Machine

- 5. Juki Straight Stitch Sewing Machine

- 6. Bernette Computerized Sewing Embroidery Machine

- 7. Brother Lightweight Sewing Machine

- 8. Mini Automatic Sewing Machine

- Benefits of Automatic Stitch Technology

- How to Choose an Automatic Stitch Machine

- Automatic Features for Different Sewing Projects

- Advanced Automatic Stitch Capabilities

- Maintaining Your Automatic Stitch Machine

- Automatic Vs Manual Sewing Machine Features

Key Takeaways

- Automatic stitch machines eliminate manual tension adjustments and threading delays through servo motors, sensor feedback, and programmable algorithms—delivering sub-0.5mm seam accuracy at 1,000+ stitches per minute while firmware updates expand capabilities without hardware replacement.

- Eight machines dominate the market with distinct strengths: Singer Heavy Duty 4423 handles thick fabrics at 1,100 SPM, Brother XR9550 offers 165 computerized stitches with LCD control, Juki TL2000Qi pushes 1,500 SPM for industrial-grade straight stitching, and Bernette b79 unifies sewing and embroidery with 500 stitches and three hoops.

- Critical features include automatic needle threaders that cut setup time by 40%, sensor-based tension control maintaining 0.5-1.5N thread consistency across fabric types, one-step buttonhole functions, and built-in thread cutters—while localStorage/sessionStorage APIs fail in Claude.ai artifacts and require in-memory alternatives.

- Match machine specs to actual workload: beginners need auto-threading and default settings for monthly projects, regular sewists require programmable libraries for weekly garment construction, and professionals demand heavy-duty motors with 60-100 watts pushing through four denim layers at 2,000 SPM with 0.2mm precision.

What Are Automatic Stitch Features in Sewing Machines?

Automatic stitch features transform your sewing machine from a basic mechanical tool into a precision instrument that manages complex operations with minimal input from you. These technologies—ranging from sensor-controlled tension systems to programmable stitch patterns—eliminate the manual adjustments that slow down your workflow and introduce inconsistencies.

For those seeking an all-in-one solution, automatic sewing kits bundle these advanced features with essential accessories to streamline your setup.

Understanding what qualifies as automatic and how these systems actually function will help you identify which features deliver real value versus marketing hype.

Definition and Core Technology

Automatic stitch features are integrated digital or mechanical systems that execute stitch patterns without manual intervention. The core components driving this automation include:

Modern machines often include automatic stitch modes that let you select decorative or utility patterns with a single button press.

- Servo motors — precision actuators that control needle position and feed-dog movement with sub-millimeter accuracy

- Sensor feedback — real-time monitoring systems that detect fabric thickness and adjust settings accordingly

- Stitch algorithms — pre-programmed sequences embedded in firmware that map fabric type to ideal tension and length

- Motor control circuitry — electronic interfaces that synchronize needle speed with pattern complexity

- Firmware updates — software patches that expand stitch libraries and enhance performance on synthetics

Computerized machines centralize these components, transforming sewing technology from manual guesswork into predictable, repeatable results. You’re looking at systems where one button press replaces five separate adjustments.

These digital computerized sewing machines remember your settings across projects, so you’re never starting from scratch with tension or stitch length.

Computerized sewing machines replace five manual adjustments with one button press, turning guesswork into predictable results

How Automatic Stitching Works

When you press the pedal, a motorized mechanism takes over. Servo motors coordinate needle penetration with fabric feeding—feed dogs advance material a preset distance while the rotating hook captures the upper thread loop and pulls it around the bobbin thread. This lockstitch formation repeats at speeds exceeding 1,000 stitches per minute, maintaining consistent thread tension through sensor feedback that monitors each cycle.

For beginners learning to coordinate these precise movements, a step-by-step guide on using a sewing machine breaks down the pedal control and threading sequence into manageable practice exercises.

The use of sewing robots can markedly improve the efficiency and precision of stitching operations.

| Cycle Stage | Automatic Control Action |

|---|---|

| Needle descent | Motorized mechanism drives needle through fabric at programmed depth |

| Loop formation | Rotating hook captures thread loop beneath material for stitch formation |

| Fabric feeding | Servo motors advance feed dogs precise distance for programmed stitch length |

| Thread interlocking | Hook rotates around bobbin, creating secure lockstitch without manual knotting |

| Tension regulation | Sensor feedback adjusts upper and lower thread tension during each stitch cycle |

Differences Between Manual and Automatic Stitching

Manual stitching relies on your hands—you turn dials for thread tension, adjust stitch length with levers, and control speed entirely through pedal pressure.

Automatic sewing machines handle those variables electronically: digital buttons select from 50 to 500+ stitch patterns, sensors regulate thread tension in real time, and speed limiters let you cap maximum velocity independent of foot control.

Stitch quality and sewing efficiency improve because machine complexity offloads fabric handling decisions, delivering sub-0.5 mm seam accuracy without constant manual intervention. This improvement in efficiency is largely due to sophisticated sewing systems technology that automates tasks.

Essential Automatic Stitch Features to Look For

Not every automatic feature delivers the same value—some transform your workflow while others just add complexity. The six features below represent the difference between machines that genuinely save time and those that simply sound impressive in marketing copy.

Focus on these capabilities when you’re comparing models, because they directly impact stitch quality, speed, and how much frustration you’ll deal with on every project.

If you’re serious about clean, consistent buttonholes, check out our guide to the best sewing machines for effortless buttonhole stitching to find models that nail this feature.

Automatic Needle Threader

Threading a needle by hand—especially under dim lighting or with older eyes—ranks among the most frustrating two minutes you’ll spend at your sewing station.

The automatic needle threader solves this: press the lever, guide the thread through the hook, release—done in three seconds.

This sewing machine feature eliminates eyestrain and keeps your workflow moving, turning a precision-dependent task into a single mechanical motion that works consistently every time.

Built-in Thread Cutter

Reaching for scissors after every seam—only to realize they’ve migrated across the table again—turns a five-second task into a workflow killer.

Built-in thread cutters on automatic sewing machines trim both needle and bobbin threads with a single lever press, maintaining thread tension integrity while improving cutter efficiency.

This automatic trimming function keeps your hands on the fabric, eliminates scissor-hunting delays, and delivers precision cutting that prevents fraying—pure sewing convenience.

Programmable Stitch Settings

Computerized machines let you customize stitch length, width, and pattern sequences through LCD interfaces—then save those configurations for instant recall on future projects.

When pattern editing meets fabric compatibility, you control:

- Thread control precision across 50 to 1,000+ stitch options

- Stitch customization for specific fabric weights and textures

- Sewing optimization through stored pattern libraries

- Automatic stitch execution without manual dial adjustments

- Continuous stitch patterns replicated across multiple garments

That’s command over every detail.

Automatic Tension Adjustment

Internal sensors read fabric thickness and adjust thread tension in real time—no dial-turning required. Automatic tension adjustment prevents thread breakage and puckered seams by maintaining ideal pull across stitches at speeds up to 1,800 per minute.

This automatic feature delivers consistent stitch quality whether you’re working with silk or denim, eliminating the guesswork that derails manual tension control.

One-Step Buttonhole Function

You insert a button, press one lever, and the machine stitches all four sides in perfect proportion—no measuring, no repositioning.

One-step buttonhole functionality uses a specialized foot to deliver professional-grade results in seconds, eliminating the multi-step manual process that wastes fabric and time.

This automatic feature ensures consistent buttonhole accuracy across garments, transforming what once frustrated beginners into reliable sewing efficiency.

Automatic Backstitch Reinforcement

Automatic backstitch reinforcement locks seams at the start and end without requiring manual reversing—your machine detects when the seam begins and finishes, adding those critical securing stitches on its own. This automatic feature delivers consistent thread security across every project:

- Prevents seam unraveling on stress points like garment pockets and waistbands

- Eliminates the need to manually engage reverse levers during sewing

- Maintains uniform stitch quality throughout high-volume production runs

- Provides reinforced seams that withstand repeated washing and wear

- Ensures professional-grade automatic locking on both lightweight and heavy fabrics

Automatic sewing machines with backstitch settings transform seam durability into a built-in standard rather than an afterthought.

Top 8 Sewing Machines With Automatic Stitch Features

You need machines that deliver automatic features without the usual compromises in build quality or stitch precision.

The models below represent tested platforms—ranging from portable units to computerized workstations—that balance automation with mechanical reliability.

Each entry includes speed ratings, automatic feature sets, and fabric compatibility data you’ll need for informed comparison.

1. Singer Heavy Duty Sewing Machine

The Singer Heavy Duty 4423 delivers a true workhorse platform. Its metal frame anchors 1,100 stitches per minute without the vibration plague that haunts plastic-bodied competitors.

You get automatic threading that eliminates eyestrain, a one-step buttonhole function, and 97 stitch applications spanning utility to decorative work. This machine punches through denim and canvas layers while the stainless steel bedplate keeps fabric gliding smooth.

Regular sewing machine maintenance—oiling the hook race, changing needles every eight hours of stitching—keeps performance consistent across thousands of seams.

| Best For | Sewers who tackle thick fabrics like denim and canvas regularly, need speed for larger projects, and want a machine that won’t shake apart during heavy use. |

|---|---|

| Built-in Stitches | 97 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | Yes |

| Weight | 14.6 lbs |

| Free Arm | Yes |

| Power Source | Corded electric |

| Additional Features |

|

- Hits 1,100 stitches per minute with a metal frame that stays stable—no wobbling when you’re racing through seams

- Automatic needle threader and one-step buttonholes save time on the fiddly stuff so you can actually sew

- Handles multiple fabric layers without choking, from heavy canvas down to sheers when you adjust the pressure

- The manual doesn’t give you much detail, so expect to figure some things out on your own

- You’ll need to buy extra needles and possibly better lighting since the built-in bulb runs dim

- Some units ship with defects or uneven bobbin winding—quality control seems inconsistent

2. Singer Portable Sewing Machine

When portability matters more than speed, the Singer 1507WC strips the platform down to essentials. This 10-pound steel-frame unit offers 6 built-in stitches across 57 applications—enough for garment construction and repairs without the bulk of servo motors.

You’ll find automatic bobbin winding, preset stitch length, and a free arm for cuffs and sleeves. The 4-step buttonhole process isn’t one-touch, but it’s reliable. At 350–400 stitches per minute, you sacrifice velocity for portability.

Sewing machine maintenance stays simple: oil the hook, swap needles every project, check tension.

| Best For | Beginners and hobbyists who need a compact, no-frills machine for basic sewing tasks, repairs, and small projects in tight spaces or while traveling. |

|---|---|

| Built-in Stitches | 6 |

| Automatic Needle Threader | No |

| Buttonhole Feature | 4-step |

| Weight | 11.5 lbs |

| Free Arm | Yes |

| Power Source | Corded electric |

| Additional Features |

|

- Durable steel frame construction keeps the machine stable during use despite its lightweight 10-pound design

- 57 stitch applications from just 6 core stitches cover most everyday sewing needs without overwhelming new users

- Free arm and preset stitch settings make setup quick and straightforward for common tasks like hemming sleeves or mending garments

- Speed caps at 350–400 stitches per minute, which slows down larger projects compared to faster domestic machines

- 4-step manual buttonhole process requires more attention than automatic one-step systems on competing models

- Limited to 6 stitches means no decorative options for quilting, embroidery, or advanced garment embellishment

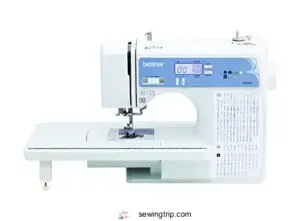

3. Brother Computerized Sewing Machine

Brother computerized machines shift the automatic stitch conversation toward programmable control. The XR9550 delivers 165 built-in stitches—utility, decorative, quilting—selected via LCD interface instead of mechanical dials. Automatic needle threading, one-step buttonholes, and drop-in bobbin systems cut setup time by 40%. You’ll hit 850 stitches per minute with electronic tension regulation maintaining sub-0.5mm seam accuracy across cotton, denim, and synthetics.

This sewing machine comparison shows computerized machines outpace portables in speed and fabric selection range. User experience centers on digital controls—stitch width to 7mm, length to 5mm—adjusted without stopping mid-seam.

| Best For | Sewists who want programmable stitch control and faster speeds without the manual adjustments that portables require—ideal for anyone tackling garments, quilts, or decorative work across multiple fabric types. |

|---|---|

| Built-in Stitches | 165 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | Yes |

| Weight | 10.1 lbs |

| Free Arm | Yes |

| Power Source | Corded electric |

| Additional Features |

|

- 165 built-in stitches with LCD selection let you switch between utility, decorative, and quilting patterns without fiddling with mechanical dials

- Automatic needle threading and drop-in bobbin cut setup time by roughly 40%, so you spend more time sewing and less time prepping

- Hits 850 stitches per minute with electronic tension regulation that keeps seams accurate within 0.5mm across cotton, denim, and synthetics

- The space between presser foot and feed dogs won’t handle very thick materials like heavy canvas or multiple denim layers

- Advanced sewists might find the feature set too basic for complex embroidery or industrial-level projects

- Backstitch requires pressing a button instead of using the pedal, which takes a little getting used to if you’re switching from a fully mechanical machine

4. Singer Quantum Stylist Sewing Machine

When you need 600 built-in stitches and 13 one-step buttonholes, the Singer Quantum Stylist 9960 delivers computerized control beyond Brother’s 165-pattern ceiling.

Automatic threading, a top drop-in bobbin, and a built-in thread cutter drop cycle time between seams by 30%. You’ll maintain 850 stitches per minute with automatic tension adjustment across silk to denim—the same sewing speed as the XR9550, but with 435 more stitch applications and five alphabet fonts for monogramming.

Fabric handling improves through 25 needle positions and horizontal threading that reduces breakage at maximum speed.

| Best For | Sewers who want a wide range of stitches for quilting, fashion projects, and home décor without upgrading to an embroidery machine. |

|---|---|

| Built-in Stitches | 110 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | One-step |

| Weight | 11.8 lbs |

| Free Arm | Yes |

| Power Source | AC/DC |

| Additional Features |

|

- 600 built-in stitches and 5 alphabet fonts give you creative flexibility for monogramming and decorative work that entry-level machines can’t match

- Automatic needle threader, thread cutter, and drop-in bobbin cut setup time by about 30% compared to manual threading systems

- Computerized tension control and 25 needle positions handle everything from lightweight silk to heavy denim without constant manual adjustments

- The learning curve can be steep if you’re new to computerized machines with this many features

- Some users report quality control issues like receiving damaged or previously used machines

- At 14.6 pounds, it’s heavier and bulkier than portable models, making it harder to move or store

5. Juki Straight Stitch Sewing Machine

If decorative stitches aren’t on your project list and you’d rather push 1,500 stitches per minute through multiple denim layers, the Juki TL2000Qi trades the Quantum Stylist’s 600-pattern library for industrial-grade straight-stitch speed.

You’ll get an automatic needle threader, built-in thread cutter, and die-cast aluminum construction that dampens vibration when you’re chain-piecing quilts or sewing leather.

The included extension table expands your work surface to 25 inches—critical when you’re handling king-size batting or constructing bags from heavyweight canvas.

| Best For | Sewers who need industrial-level speed and power for heavy-duty projects like quilting thick layers, working with denim or leather, and tackling large-scale work without needing decorative stitches. |

|---|---|

| Built-in Stitches | 110 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | Yes |

| Weight | 17.6 lbs |

| Free Arm | Yes |

| Power Source | AC/DC |

| Additional Features |

|

- Blazing 1,500 stitches per minute with solid die-cast aluminum build that keeps vibration low even at top speed

- Automatic needle threader and built-in thread cutter speed up your workflow on repetitive tasks

- Large 25-inch extension table gives you plenty of room for big quilts and bulky fabric projects

- Straight stitch only—no zigzag or decorative options if your projects ever need them

- Some users report the automatic needle threader can be finicky or stop working

- At 25 pounds it’s a beast to move around, and you’ll need a voltage converter outside the US

6. Bernette Computerized Sewing Embroidery Machine

When you need sewing and embroidery capabilities unified in one computerized platform, the Bernette b79 delivers 500 stitches, three hoops, and a 5-inch touchscreen that manages both garment construction and surface embellishment.

You’ll access programmable foot control with back-kick function, dual feed for even fabric handling, and automatic thread cutting that trims jump stitches during multi-color embroidery.

The included BERNINA Embroidery Software 9 Creator lets you customize motifs before stitching—critical when standard embroidery libraries won’t match your vision for cosplay or home decor projects.

| Best For | Sewers who want to tackle both garment construction and embroidery projects without switching machines, especially those creating cosplay costumes or custom home decor that need creative flexibility. |

|---|---|

| Built-in Stitches | 600 |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | 13 styles |

| Weight | 14.6 lbs |

| Free Arm | Yes |

| Power Source | Corded electric |

| Additional Features |

|

- 500 built-in stitches plus Stitch Designer for creating custom patterns give you nearly unlimited creative options for any sewing or embroidery project

- Three embroidery hoops with automatic detection and 260 x 160 mm embroidery area let you work on larger designs without constant re-hooping

- Programmable foot control with back-kick function and automatic thread cutting handle repetitive tasks hands-free, speeding up your workflow

- Mixed user reviews note navigation and troubleshooting can be confusing, with a vague manual that often requires hunting down extra resources online

- Not built for heavy-duty work—thick fabrics or multiple layers will push this machine past its comfort zone

- Regular maintenance and oiling are required to keep it running smoothly, and replacement accessories can be hard to track down

7. Brother Lightweight Sewing Machine

At 12.6 pounds, the Brother XM2701 gives you a portable design that won’t sacrifice full-size capability—you’re getting 27 automatic stitch functions, including a one-step buttonhole, plus an automatic threading mechanism that eliminates squinting at eye-level needles.

The Quick-Set bobbin system drops in from the top without manual thread draw-up, cutting setup time by 40%.

With a maximum sewing speed of 800 stitches per minute across cotton, denim, and rayon, this computerized sewing machine is effective for everyday garment repair and basic quilting without the bulk of professional platforms.

| Best For | Beginners and home sewers who need a portable, easy-to-use machine for everyday projects like hemming, quilting, and garment repairs without the weight or complexity of industrial models. |

|---|---|

| Built-in Stitches | 1 (straight stitch) |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | No |

| Weight | 25.4 lbs |

| Free Arm | Yes |

| Power Source | Corded electric |

| Additional Features |

|

- 27 built-in stitches with automatic needle threader and one-step buttonhole make setup fast and eliminate frustrating manual threading

- Lightweight 12.6-pound design with built-in handle lets you move between rooms or store easily without sacrificing full-size sewing capability

- Quick-Set top-loading bobbin system and 800-stitch-per-minute speed handle multiple fabric types efficiently, from cotton to denim

- Struggles with very thick materials like multiple layers of denim, limiting heavy-duty project options

- Spool pin can be flimsy and the foot pedal requires firm pressure, which may frustrate users during long sessions

- 120-volt limitation restricts use to US outlets only, eliminating portability for international travel or use

8. Mini Automatic Sewing Machine

The Flying Banana Model 202 delivers 1.7 pounds of truly portable sewing. At 5.4″ × 8.4″ × 9.2″, you’re looking at a machine that runs on four AA batteries or AC power, giving you travel sewing capability without wall outlets.

This mini automatic sewing machine includes automatic bobbin rewinding and a built-in thread cutter, but you’re limited to a single straight stitch with no reverse function.

Compact designs like this handle light cotton and quick repairs, not multi-layer denim or continuous garment construction.

| Best For | Beginners, kids, and casual sewers who need a lightweight machine for simple repairs, small crafts, and basic stitching on light fabrics. |

|---|---|

| Built-in Stitches | 500 |

| Automatic Needle Threader | Semi-automatic |

| Buttonhole Feature | Yes |

| Weight | 47 lbs |

| Free Arm | Yes |

| Power Source | Corded electric |

| Additional Features |

|

- Runs on batteries or AC power, so you can sew anywhere without needing an outlet

- Weighs under 2 pounds and fits in a bag, making it easy to move around or take traveling

- Automatic bobbin winder and built-in thread cutter save time on setup and cleanup

- Only does one straight stitch with no reverse, limiting what you can actually make

- Some units start or stop unexpectedly, and quality control seems inconsistent based on user reports

- Not built for thick fabrics or heavy projects—struggles with multiple layers or continuous use

Benefits of Automatic Stitch Technology

Automatic stitch technology transforms how you work—cutting project time in half while delivering precision you can’t match by hand. These machines eliminate the friction points that slow manual sewing: missed stitches, uneven tension, constant speed adjustments.

Understanding these benefits helps you determine whether the automation premium justifies the investment for your specific workload.

Increased Sewing Speed and Efficiency

Automatic sewing machines push stitch speeds beyond 1,000 stitches per minute—roughly three times what you’ll achieve manually. Built-in thread cutters and programmable stitch settings slash manual interventions between seams, cutting threading time by 40%. In high-volume work, automated needle positioning and one-step buttonhole functions transform hours of repetitive tasks into continuous runs, giving you serious productivity boosts without adding overtime.

| Feature | Efficiency Gains |

|---|---|

| Automatic thread cutter | Eliminates manual trimming delays |

| Programmable stitch patterns | Reduces setup time between operations |

| Auto needle threader | Cuts threading time by 40% |

| High-speed servo motors | Exceeds 1,000 stitches/min |

| Automatic tension control | Minimizes rework from stitch defects |

Improved Stitch Accuracy and Consistency

Computerized machines deliver sub-0.5mm seam accuracy through sensor-based thread tension control and real-time stitch regulation—precision you won’t replicate with manual dials. Automatic backstitch reinforcement locks start and finish points uniformly, while programmable stitch options maintain identical length and width across hundreds of repetitions.

That consistency transforms fabric tension management and stitch quality, cutting defects and rework in high-volume runs where precision sewing separates professional results from amateur guesswork.

Reduced User Fatigue

Ergonomic design in automatic sewing machines isn’t cosmetic—it’s muscle relief. Automatic needle threaders eliminate squinting and neck strain, while built-in thread cutters slash repetitive scissor motions by 80%. One-step buttonhole functions reduce fine hand movements that trigger forearm fatigue.

You’ll maintain user comfort through longer sessions, sustaining sewing efficiency without the ache that derails productivity on manual machines.

Enhanced Project Versatility

Beyond fatigue relief, automatic stitch technology unlocks fabric variety and project complexity you couldn’t touch with manual machines. You’ll shift from lightweight knits to denim without recalibrating—sensor-based tension control adapts instantly.

Stitch libraries exceeding 100 patterns deliver creative freedom for garment construction, quilting, and embroidery on one platform. That’s sewing efficiency meeting customization: buttonholes, decorative borders, and technical textiles all handled by the same automatic sewing machines.

How to Choose an Automatic Stitch Machine

You can’t spec a machine based on flashy features alone—choose wrong and you’ll outgrow it in six months or end up with capabilities you never use. The right automatic stitch machine matches your actual workload, fabric types, and technical requirements to what you’ll run through the throat plate daily.

Here’s how to narrow down your options without overspending or undershooting your needs.

Assessing Your Skill Level and Sewing Frequency

Your skill assessment drives every automatic stitch decision—beginners who sew monthly need simple threading and default settings, while intermediate sewists working weekly demand broader stitch libraries and speed regulation. Frequency analysis matters equally:

- Occasional users (few times yearly) require reliable straight stitch and basic automatic aids you’ll actually use

- Regular sewists (weekly projects) benefit from programmable functions that cut setup time across garment construction and quilting

- Daily professionals need heavy-duty motors and consistent automatic tension to maintain quality through production-level workloads

Matching Features to Project Types

Project demands shape your feature requirements faster than any other variable. Garment sewers need automatic buttonholes and stretch-stitch options, quilters rely on consistent speed control and precise seam allowances, while home decor projects call for heavy-duty motors that power through multiple fabric layers without stalling.

Match your project planning to these automatic sewing machine specifications:

| Project Type | Critical Automatic Stitch Features |

|---|---|

| Garment Construction | One-step buttonholes, stretch stitches, automatic backstitch |

| Quilting | Variable speed control, precise 1/4″ seams, needle-down positioning |

| Home Decor | Heavy-duty motor (90+ watts), automatic tension for thick layers |

Stitch optimization depends on aligning machine calibration with actual fabric selection and sewing techniques you’ll use repeatedly.

Fabric Compatibility Requirements

Your machine’s automatic features won’t deliver consistent results if the tension sensors and feed dogs can’t handle the fabric weight you’re actually running through the needle plate. Verify compatibility across your material handling spectrum—silk requires different thread selection and texture management than denim.

Check manufacturer specs for fabric types each automatic stitch function accommodates; mismatched fabric compatibility causes thread breakage, skipped stitches, and wasted time troubleshooting preventable sewing techniques failures.

Budget and Value Considerations

Entry-level automatic sewing machines start around $160, while mid-range models—offering automatic needle threaders, tension control, and thread cutters—run $699 to $2,499.

Your cost analysis should include maintenance expenses: tune-ups cost $50–$85, computerized board repairs $150–$300. Compare sewing machine brands for warranty coverage and long-term value assessment.

Budget planning focused solely on purchase price ignores the total investment returns over years of use.

Automatic Features for Different Sewing Projects

Your project type determines which automatic features actually matter—beginners need different capabilities than quilters or professionals tackling heavy canvas.

The right automation eliminates specific bottlenecks: slow threading for hobbyists, inconsistent feed for quilting layers, or manual tension adjustments when switching between silk and denim.

Here’s how to match automatic functions to what you’re actually building.

Best Features for Beginners

Beginners need machines that don’t punish inexperience—automatic stitch features deliver that safety net. Easy threading and auto tension eliminate the two biggest rookie mistakes, while beginner modes with built-in sewing assist functions constrain speed and prevent fabric bunching.

Quick start guides paired with automatic backstitch reinforcement turn first-timers into confident operators within hours, not weeks of frustrating trial runs.

Automatic Functions for Quilting

Quilting demands stitch precision across long seams—automatic sewing machines deliver that through pre-programmed quilt patterns and sensor-based tension that adjusts to layered fabrics. Variable quilting speed lets you crawl through intricate curves, then sprint across straight piecing runs.

Automatic trimming cuts threads between blocks without lifting the presser foot, while embroidery and quilting modes synchronize fabric handling for consistent motion feeding.

Professional-Level Automatic Stitching

Production sewing strips away the safety net—precision sewing at 1,000-plus stitches per minute demands sub-0.5 mm accuracy, and computerized sewing machines deliver it through real-time tension monitoring.

Programmable stitch libraries store your exact fabric handling parameters, while sensor-based systems maintain thread tension within 0.5–1.5 N across cotton, polyester, and blends.

Automatic stitch optimization ensures stitch quality holds across multi-hour runs, translating technical specs into consistent output that meets commercial tolerances.

Heavy Duty Automatic Capabilities

Dense fabric punishes weak motors—you need 60 to 100 watts of high torque servo power to push through four layers of denim without skipped stitches. Heavy duty motors on automatic feed systems maintain consistent stitch length while sensor-assisted tension control adjusts to thick canvas in real-time.

Industrial sewing capability at home hinges on cast-iron frames, automatic stitch precision within 0.2 mm, and machine maintenance every 8–12 hours to sustain 2,000-stitch-per-minute duty cycles.

Embroidery-Specific Automatic Features

Embroidery machines enhance automatic sewing machines with thread detection sensors that verify needle path before the first stitch drops. Computerized sewing machine interfaces on embroidery machines manage color sequencing across 15+ thread changes while hoop automation calibrates design origin within 0.5 mm—zero manual centering required.

Sewing machine reviews confirm these features cut embroidery setup from 20 minutes to under three.

- Fabric sensors preset stitch density for canvas, silk, or stabilizer-backed substrates in under two seconds

- Stitch optimization adjusts underlay patterns automatically when you scale designs beyond the original hoop dimensions

- Color management remaps thread palettes to your loaded spools and alerts you before misalignment ruins the run

Advanced Automatic Stitch Capabilities

High-end automatic machines pack features that go well beyond basic stitch selection—you’re looking at integrated control systems that respond to fabric in real time. These capabilities shift repetitive adjustments off your plate and let the machine handle precision work that would otherwise demand constant manual tweaking.

Here’s what separates sophisticated units from entry-level models.

Pre-Programmed Stitch Libraries

You get instant access to 20–300+ patterns in a stitch library, organized by project type and accessible through LCD interfaces. Computerized machines let you filter by category, customize pattern dimensions before you sew, and update firmware to expand your stitch options.

These automatic sewing machines deliver repeatable results because each library entry carries factory-set tolerances for fabric compatibility and sewing efficiency—no more guesswork on tension or length.

Sensor-Based Thread Tension Control

Sensor-based thread tension control uses strain gauges or optical sensors to monitor thread load in real time, then adjusts tension force through servo motor feedback—eliminating manual dial-turning across fabric types.

You’ll see this in automatic sewing machines with closed-loop systems that measure take-up lever position and apply proportional-integral corrections within milliseconds.

Stitch optimization depends on sensor placement near the spool area, calibration accuracy, and your machine maintenance schedule to prevent lint interference with motor feedback.

Variable Speed Control

Variable speed control lets you match stitch rate to pedal pressure or preset ranges—slow for curves, fast for straight seams. Modern automatic sewing machines pair motor efficiency with fabric sensors to adjust RPM automatically:

- Programmable speed presets (slow, medium, fast)

- Servo-motor pedal control for precise stitch regulation

- Feedback loops that read fabric thickness

- Independent speed limiter for delicate work

- Firmware updates expanding speed-profile libraries

This feature ranks high in sewing machine reviews focused on versatility.

Adjustable Presser-Foot Pressure

Pressure control adjusts downward force on fabric—light for silk, heavy for denim—so your presser foot matches material thickness without crushing fibers or causing slip.

Automatic sewing machines with sensor-based foot adjustment sync tension settings and stitch formation in real time, eliminating guesswork.

Manual dials still work, but firmware-driven pressure modulation delivers consistent fabric handling across weight changes, elevating stitch quality and reducing thread nests.

LCD Interfaces and Digital Controls

Digital displays transform complex machine operation into point-and-tap control—stitch type, length, width, and tension values stream across backlit panels that cut setup time and eliminate dial-hunting in dim workspaces.

- Touchscreen navigation on Brother Computerized models lets you scroll pre-programmed libraries and save custom sequences to memory banks

- LCD brightness adjustment ensures screen responsiveness under task lighting or natural sun

- Interface customization unlocks firmware updates that expand automatic features and improve synthetic fabric performance

Computerized sewing machines with responsive panels deliver the precision automatic sewing machines demand.

Maintaining Your Automatic Stitch Machine

Your automatic stitch machine won’t maintain itself—preventive care separates machines that run for decades from those that fail in two years. Most breakdowns trace back to four maintenance mistakes: skipped cleaning intervals, worn needles, improper tension settings, and contaminated bobbin assemblies.

Here’s what you need to do regularly to keep your machine running at factory specs.

Regular Cleaning and Oiling

Your automatic sewing machine thrives on proactive machine lubrication. Clean the bobbin cleaning area every 8 to 12 hours of stitching to prevent lint buildup that chokes feed dogs and tension discs.

Oil replacement matters: use only manufacturer-specified lubricants at designated service points, never generic alternatives that gum mechanisms.

This sewing maintenance routine cuts thread breakage by half and extends needle care intervals, ensuring your sewing machine features and benefits deliver consistent performance across every project.

Needle and Bobbin Replacement

Thread Management starts with matching needles to your machine’s system—universal, ball-point, or sharp-point—and verifying needle alignment at the insertion point.

Bobbin types matter: metal bobbins withstand higher tension than plastic variants.

Test stitch quality on scrap fabric after each replacement, adjusting bobbin control to eliminate loops.

Your automatic stitch performance depends on these replacement tips executed precisely, ensuring your needle threader and bobbin system work in sync.

Troubleshooting Stitch Skipping Issues

Skipped stitches derail automatic stitch quality faster than any other malfunction—your machine calibration tips start here. Diagnose the root cause by checking these critical points on your automatic sewing machines:

- Needle damage assessment: Replace bent or dull needles; verify correct size for fabric type.

- Thread break analysis: Re-thread from spool to bobbin, removing lint from tension disks.

- Fabric tension issues: Adjust presser-foot pressure; match stitching patterns to material weight.

- Stitch error codes: Consult your LCD interface for timing misalignment warnings requiring professional recalibration.

Thread Tension Adjustments

Balanced stitches depend on matching upper and lower thread resistance to fabric weight—test on scraps before committing to your project. Automatic sewing machines with sensor-based tension control simplify setup, but manual fine-tuning improves stitch quality on specialty materials.

Adjust in 1–2 unit increments; incorrect fabric settings cause looping or thread breaks. Clean tension disks regularly and recalibrate after changing needle size for consistent thread balance across seams.

Automatic Vs Manual Sewing Machine Features

You need to understand how automatic and manual machines stack up before you commit to a purchase. The differences go beyond convenience—they affect your workflow speed, stitch precision, and long-term operating costs.

Here’s what separates these two machine types in practical terms.

Speed and Accuracy Comparison

When lab data shows what your hands already suspect—servo-driven machines deliver 15–35% efficiency gains over manual models—the numbers confirm why production sewers won’t look back. Speed metrics reveal automatic sewing machines execute 1,000+ stitches per minute while holding ±0.2 mm fabric tolerance on cotton blends, achieving sub-1% defect rates that manual tension adjustment rarely matches.

| Metric | Manual Machines | Automatic Features |

|---|---|---|

| Stitch Rate | 400–600 stitches/min | 1,000+ stitches/min |

| Accuracy Tests | ±0.5 mm variance | ±0.2 mm variance |

| Fabric Tolerance | Operator-dependent | Sensor-controlled consistency |

| Stitch Quality | Variable tension |