This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You reach for what looks like the right presser foot, attach it to your machine, and three stitches later you realize something’s wrong. The fabric puckers, the seam wanders, or worse—the foot won’t even snap into place. Most sewers own a collection of mysterious metal attachments they’ve never actually used, simply because they can’t tell which foot does what.

Here’s the truth: identifying presser feet isn’t about memorizing catalogs or guessing based on vague similarities. Each foot has distinct visual markers—from the width of its opening to the presence of guide plates or rollers—that reveal its purpose. Once you know what to look for, you’ll match the right foot to any project in seconds.

Table Of Contents

Key Takeaways

- Each presser foot has distinct visual markers like opening width, guide plates, or rollers that reveal its specific purpose, making identification possible in seconds once you know what to look for.

- Attachment systems fall into two main categories—snap-on feet for quick changes and screw-on feet for stability—and you must match your machine’s shank type (low, high, or slant) to ensure compatibility.

- Specialty feet multiply your machine’s capabilities by solving specific fabric challenges: walking feet prevent layer shifting, Teflon feet glide over sticky materials, and zipper feet enable close-to-seam precision.

- Matching the right foot to your fabric type and stitch technique directly impacts seam quality and prevents common problems like puckering, wandering seams, or uneven tension.

What Are Sewing Machine Presser Feet?

Presser feet are the unsung heroes of your sewing machine—those small attachments that snap or screw onto the needle bar to hold fabric steady while you stitch. Without them, your fabric would bunch, slip, and generally refuse to cooperate.

Most home machines come with a basic set of feet for straight stitching, zippers, and buttonholes—like those included with the Brother XL-3750 sewing machine.

Let’s break down what they’re, how they work, and why they’re built the way they’re.

Industrial walking foot machines use a synchronized presser foot and feed dog system to move thick layers evenly—check out this complete guide to industrial walking foot sewing for details on models and features.

Definition and Purpose of Presser Feet

A presser foot is a metal or plastic attachment that clamps fabric flat against your machine’s feed dogs during stitching. It’s essential for fabric control and sewing precision—without it, you’d struggle to maintain stitch quality.

Most machines include a general-purpose foot, but specialized options like zipper, buttonhole, and walking feet tackle specific tasks—check out this complete guide to sewing machine presser feet to find the right one for your project.

Different presser foot types handle specific tasks by changing how the attachment systems interact with feed dogs. Think of sewing machine presser feet as specialized tools: each one transforms your machine’s capabilities for particular techniques.

Before investing in specialty feet, check reliable sewing machine reviews to ensure your model supports the attachments you need.

Think of presser feet as specialized tools—each one transforms your sewing machine’s capabilities for specific techniques

How Presser Feet Enhance Sewing Functions

These attachments multiply your machine’s capabilities by stabilizing fabric movement and enabling precision techniques. Specialty presser feet improve sewing efficiency through targeted designs—walking feet prevent slippage on layered materials, while quarter-inch feet guarantee consistent seam allowances. Here’s how presser foot types boost machine versatility:

- Reduce fabric shifting for better stitch precision

- Guide accurate seam measurements with built-in markings

- Minimize friction on delicate or sticky materials

- Enable professional techniques like invisible zippers

- Maintain consistent fabric control across different weights

Common Materials and Construction

Most manufacturers build these tools from stainless steel or aluminum for foot durability, while thermoplastics like polypropylene keep costs down without sacrificing strength. Construction methods vary—metal feet handle high-speed stitching better, and surface coatings like Teflon help you glide over sticky vinyl or leather.

Material selection directly impacts sewing machine compatibility and how long your sewing machine feet and accessories last through heavy use.

How Do Presser Feet Attach to Machines?

Before you can swap presser feet like a pro, you need to understand how they actually connect to your machine. There are two main attachment systems, plus different shank sizes that affect which feet will work with your setup.

Let’s break down the mechanics so you can confidently match any foot to your machine.

Snap-on Vs. Screw-on Feet

You’ll find two main attachment methods for sewing machine presser feet: snap-on and screw-on systems. Snap-on feet click into place without tools, making foot changes quick and boosting sewing efficiency. Screw-on feet thread onto the shank with a screw, delivering enhanced foot stability on heavy fabrics.

Pairing the right foot with the right stitch becomes easier once you explore sewing stitch tutorial videos that demonstrate how each combination works in action.

Each sewing machine foot type has trade-offs—snap-on means convenience, while screw-on ensures rock-solid hold, though compatibility issues can arise across different shank systems.

Identifying Shank Types (Low, High, Slant)

Your sewing machine presser feet snap onto one of three shank types: low, high, or slant. Low shank sits close to the needle plate with a short presser bar, while high shank extends higher with more clearance. Slant shank angles forward on older machines.

Check your manual for shank height specs—this determines foot compatibility and ensures your snap-on foot locks securely every time.

Checking Compatibility With Your Machine

Before you buy any presser foot, grab your machine’s manual and flip to the compatibility chart. Match the foot shank types and attachment methods to your model’s specifications.

You can also verify on the manufacturer’s website or contact support with your serial number.

Always test a new snap-on foot on scrap fabric to confirm smooth sewing machine presser feet performance and proper needle clearance.

Key Types of Sewing Machine Feet Explained

Now that you know how feet attach to your machine, let’s look at the most common types you’ll encounter. Each foot is designed for a specific task, and recognizing them saves you time and frustration.

We’ll cover the essential ones first, then move into specialty feet that handle trickier fabrics and techniques.

All-Purpose/Standard Foot

Your sewing machine’s all-purpose foot is the workhorse you’ll use for about 80% of your projects. This flat-bottomed presser foot attachment manages standard stitching on woven fabrics and lightweight to medium materials with consistent fabric compatibility.

Here’s what makes it essential for sewing machine calibration and presser foot alignment:

- Snap-on or screw-on mounting fits most low-shank machines perfectly

- Simple profile accommodates straight and zigzag stitches without fuss

- Metal or durable plastic construction ensures reliable foot maintenance

- Works beautifully for topstitching and basic seam construction tasks

Zipper Foot (Regular and Invisible)

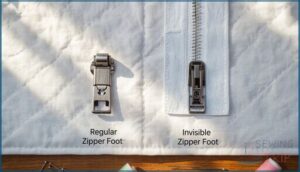

When you’re tackling zippers, the right presser foot makes zipper installation feel like a breeze. Regular zipper feet sit flush against teeth for standard applications, while invisible zipper feet include a raised guide channel that aligns fabric edges perfectly.

Here’s your quick foot comparison for zipper alignment:

| Feature | Regular Zipper Foot | Invisible Zipper Foot |

|---|---|---|

| Toe Profile | Flat, single-row design | Grooved or ridged center |

| Needle Position | 6–8 mm from toe edge | Offset to far side |

| Best For | Standard zippers, piping | Hidden seams, formal wear |

| Stitch Visibility | Visible topstitching | Concealed within fold |

| Attachment | Snap-on or screw-on | Snap-on or screw-on |

You’ll recognize these sewing machine feet instantly—regular versions stay flat, invisible types show that telltale ridge. Both sewing machine accessories attach via your machine’s standard shank system, so switching between sewing techniques takes seconds.

Test your adjustable zipper foot on scrap fabric first to confirm your presser foot delivers clean zipper alignment every time.

Buttonhole Foot

You’ll spot a buttonhole foot by its rectangular toe and that signature vertical slot down the center—it’s your go-to presser foot for perfect buttonhole alignment. This sewing machine accessory guides fabric through the stitch sequence, keeping button size consistent and sewing accuracy sharp.

- Metal versions handle heavy fabrics with zero flex

- Adjustable guides let you dial in stitch density precisely

- Snap-on shanks guarantee instant foot compatibility across most sewing machines

Always test on scrap first.

Blind Hem Foot

Your blind hem foot transforms invisible hems from impossible to achievable with its clever adjustable guide plate and staggered blind hem stitch pattern. You’ll recognize it by the narrow groove running along one side—it folds fabric precisely before stitching.

| Feature | Purpose |

|---|---|

| Adjustable Guide | Controls fabric fold distance |

| Narrow Groove | Aligns fabric edge perfectly |

| Staggered Stitch | Creates invisible hemming techniques |

| Metal/Plastic Plate | Guides delicates smoothly |

| Shank Compatibility | Ensures proper foot adjustment |

Check your shank type before buying—correct alignment makes all the difference with this presser foot on your sewing machine.

Walking Foot

Your walking foot handles thick quilts and slippery fabrics with dual feed mechanisms that grip both layers simultaneously—no more shifting or puckering. You’ll spot its distinctive raised bar across the presser foot surface.

This quilting feet essential works on most low-shank sewing machine presser feet systems, though you’ll want to verify compatibility.

Master fabric control and stitch regulation for professional quilting methods with proper foot maintenance.

Specialty Feet (e.g., Teflon, Roller, Embroidery)

Beyond everyday sewing machine presser feet, specialty feet solve tricky fabric challenges you’ll face with leather sewing, embroidery, and delicate materials.

- Teflon feet glide over sticky vinyl and leather without snagging, preventing heat buildup

- Roller feet feature small wheels that feed bulky or slippery fabrics evenly

- Embroidery feet include adjustable guides for precise design positioning

- Nonstick feet resist adhesive backings during appliqué work

- Always verify compatibility with your machine’s shank system before purchasing

Visual and Functional Identification Tips

You don’t need a magnifying glass to figure out which presser foot is which. Each foot has visual clues—like its shape, openings, and sometimes tiny markings—that tell you exactly what it does.

Once you learn what to look for, matching the right foot to your project becomes second nature.

Recognizing Foot Shape and Markings

You’ll find that presser foot shapes and marking symbols tell you exactly what each attachment does. Look for notches or molded letters—like “S” or “M”—that signal stitch guidance and fabric compatibility.

Most feet use a standard C-shaped snap-on shank, making identification straightforward. Check for foot alignment marks on the surface; they’re your roadmap to consistent seams with any zipper foot or all-purpose foot.

Matching Feet to Stitch Type and Fabric

Once you’ve spotted the shape and markings, your next move is matching presser foot to fabric stretch and stitch optimization. Woven cottons pair beautifully with a straight stitch and standard foot for precise seam allowance. Stretchy knits demand a zig zag or dual-feed setup to prevent fabric distortion. Zipper foot compatibility depends on your sewing machine shank—always confirm before you start.

- Woven fabrics need stable feet for accurate straight-stitch seam allowance control

- Stretch fabrics require walking or dual-feed feet to minimize fabric distortion

- Zipper and buttonhole applications demand specialized feet for clean, aligned finishes

- Foot compatibility hinges on shank type—check your manual or manufacturer’s list

- Fabric selection drives presser foot choice, ensuring stitch optimization on every project

Choosing The Right Presser Foot for Projects

Once you know what each foot does, the real skill is matching it to the work in front of you. Your project dictates the foot, not the other way around, and choosing correctly saves time and frustration.

Let’s walk through how to pick the right foot, keep your collection organized, and track down extras when you need them.

Selecting Feet Based on Sewing Techniques

Technique matching starts with your project’s demands—choose feet that mirror your stitch goals. For zipper foot work, you’ll get close-to-seam precision on both visible and invisible installations. A gathering foot simplifies fabric handling when you’re creating ruffles or attaching gathered edges.

Here’s your quick reference for stitch optimization:

| Sewing Technique | Recommended Presser Foot |

|---|---|

| Zipper insertion | Zipper Foot |

| Gathering fabric | Gathering Foot |

| Seam finishing | Blind Hem Foot |

| Heavy fabric layers | Walking Foot |

Match your sewing machine’s foot calibration to the task, and you’ll notice better seam finishing every time.

Tips for Organizing and Storing Feet

A labeled storage bin keeps your presser foot collection organized and accessible. Use stackable sewing accessory boxes with compartments for each foot type—you’ll find what you need faster. Presser foot cases with clear labels prevent mix-ups and protect delicate attachments.

Keep frequently used feet within arm’s reach of your sewing machine. Regular audits help you spot worn pieces and maintain an efficient foot storage system.

Where to Find Additional or Replacement Feet

Your sewing machine manufacturer’s website lists compatible presser feet by model number—that’s your first stop for genuine parts.

Authorized dealers and online retailers stock both OEM and aftermarket options with detailed foot compatibility charts.

Local sewing accessory stores let you examine replacement guides in person, while sewing communities share trusted sources for hard-to-find sewing machine parts and specialty presser foot attachments.

Frequently Asked Questions (FAQs)

Can I use feet from different machine brands?

Most presser feet aren’t interchangeable across brands due to shank variations and proprietary designs. Adapter usage can bridge some gaps, but always verify foot interchange compatibility through your sewing machine presser feet guide before purchasing.

How do I clean and maintain presser feet?

Ironically, the tools that keep fabric spotless need cleaning too.

Remove your foot, brush away lint with a cotton swab, wash with mild soap, dry completely, and store labeled to prevent rust—simple daily maintenance pays off.

What causes presser feet to break or malfunction?

Most breakage comes from material fatigue, repeated drops, or using incompatible feet on your machine.

Wear patterns from heavy fabrics, needle strikes, and skipped maintenance also shorten presser foot durability markedly.

Are vintage presser feet compatible with modern machines?

Most low-shank vintage presser feet snap right onto modern sewing machines thanks to standardized shank interfaces.

High-shank or slant-shank vintage foot geometry needs shank conversion adapters—compatibility charts confirm era-specific feet matches before purchasing.

Do presser feet affect stitch quality or tension?

Yes, absolutely. Your foot choice directly impacts fabric feed and tension control. Wrong feet cause skipped stitches or uneven seam formation. Proper presser foot adjustment and needle clearance guarantee stitch consistency across all sewing techniques.

Conclusion

You’ve just saved yourself from plenty of “why isn’t this working?” moments. Learning how to identify types of sewing machine feet means your projects run smoother, your fabric behaves, and you stop second-guessing every attachment.

Keep your feet organized, label anything unfamiliar, and refer back to visual markers when you’re unsure. The right foot transforms tricky techniques into straightforward tasks—so use this knowledge every time you sit down to sew.