This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A properly oiled machine glides through fabric like butter. A neglected one fights you every stitch. The difference comes down to about five minutes of maintenance and three drops of the right oil. You don’t need a technician to do this. You just need to know where to put the oil, what type to use, and how often your particular model needs attention.

Table Of Contents

Key Takeaways

- Most sewing problems like skipped stitches and puckered seams come from a dry hook race, not tension or needle issues, and proper oiling with 2–3 drops of light synthetic oil at designated points solves these problems in about five minutes.

- You must clean all lint and debris from the bobbin area, feed dogs, and hook race before applying oil, because oil sticks to dust and creates gummy buildup that causes more jams and mechanical problems.

- Over-oiling damages your machine by attracting lint, staining fabric, and contaminating moving parts—always wipe away excess oil with a lint-free cloth and test-stitch on scrap fabric before starting your project.

- Oiling frequency depends on your usage: light sewers need maintenance every six months, moderate users every three months, and heavy users weekly, while many modern Brother models have sealed bearings that don’t require user oiling at all.

Safety Steps Before Oiling a Brother Sewing Machine

Before you put a single drop of oil in your Brother sewing machine, you need to prepare it properly.

Taking the right safety steps protects both you and your machine from damage. Here’s what you’ll need to do first.

Unplugging and Powering Down The Machine

Before you begin machine maintenance on your Brother sewing machine, turn the power switch to “O” (off). Then unplug the machine by gripping the power supply plug—never yank the cord itself. This prevents cord damage and reduces electrical shock risks.

Remember to consult the Brother operation manual for safety information. Check the outlet for safety issues before reconnecting later. If you spot frayed wires or damage, contact a Brother service center before proceeding.

Removing The Needle, Presser Foot, and Bobbin

Once the machine is off and unplugged, place fabric or paper over the needle plate to catch small parts. Raise the needle using its button, then loosen the needle clamp screw at least 1.5 turns with a screwdriver. Orient the flat side toward the back when inspecting needle condition.

Lift the presser foot lever, press the black release button behind the presser foot holder, and lift out the bobbin. Brother machines benefit from regular bobbin maintenance.

Detaching The Needle Plate and Covers

After removing the bobbin, you’re ready to access the machine’s interior. About 70% of Brother models use two screws to secure the needle plate. Use your screwdriver to loosen them completely:

- Slide the plastic plate toward you after loosening

- Lift from the back notch once screws are removed

- Set screws aside for quick-release reassembly

- Remove any covers hiding mechanical access points

This creates cleaning access for proper oiling.

Cleaning The Machine Prior to Oiling

Before you apply any oil, you need to clear out the dust and lint that’s built up inside your machine. Oil sticks to debris like a magnet, so a dirty machine will just trap more gunk and cause problems down the road.

Let’s walk through the cleaning steps to get your Brother ready for proper lubrication.

Removing Dust and Lint With a Brush

Lint buildup in the bobbin race is like sawdust in a workshop—it grinds things to a halt. Use a soft cleaning brush (the one that came with your machine works well) to sweep dust from the feed dogs and bobbin area.

Clean weekly for regular sewing, or twice daily with fleece or velvet. Brushes won’t push debris deeper like compressed air can.

Using Tweezers for Stubborn Debris

When thread bits wedge behind the bobbin case, tweezers shine where brushes can’t reach. Long, fine-point precision tweezing removes stubborn fiber from hook driver cams—cutting thread jam reduction incidents by 78% during monthly cleaning routines.

- Grip tangled threads gently without scratching delicate machine parts

- Extract debris from tight corners inaccessible to brushes

- Protect components better than needles or scissors

- Prevent skipped stitches by removing hidden accumulations

Cleaning The Feed Dogs and Bobbin Area

Between the feed dogs, lint buildup hides where you can’t see it. Remove the needle plate and reach deep into the bobbin area with your brush.

Cleaning frequency matters—every two to three bobbin changes prevents jams and tension problems. Neglecting cleaning pushes the needle plate upward, reducing feed dog grip by half.

Clean the bobbin case thoroughly to avoid skipped stitches.

Identifying Oiling Points on Brother Machines

Before you add a single drop of oil, you need to know where it goes. Not every Brother machine oils the same way, and some models don’t need oiling at all.

Your user manual holds the map, but there are a few common spots worth checking first.

Locating The Hook Race and Needle Bar

The hook race sits below the bobbin case—open the hook cover and lift out the bobbin to expose it. Turn your handwheel about 50 degrees to see the circular track where the hook rotates.

For the needle bar, you’ll need to remove the face plate. Look for the felt washer on the lower needle bar, just above the needle clamp. Your service manual shows exact locations.

Checking for Sealed Bearings or No Oiling Models

Some Brother machines don’t need oiling at all. Models like the Brother 270D or CS6000i often have sealed bearings or plastic gears pre-lubricated from the factory. If your manual says “no oiling required,” trust it—adding sewing machine oil to sealed components attracts lint and causes jams.

Look for shielded bearing covers or check for oil port instructions to identify low-maintenance machines with sealed component care.

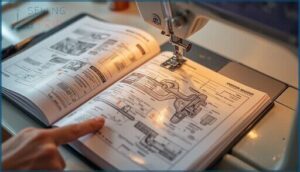

Referencing The User Manual for Oiling Locations

Your owner’s manual is the most reliable source for machine-specific Maintenance Tips and Lubrication Points. Brother manuals generally show where to apply sewing machine oil—often the hook race (daily) or needle bar felt washer (every 40–50 hours). Follow these manual guidance references to avoid guesswork:

- Check labeled diagrams for exact oiling schedules

- Note if your model prohibits user oiling

- Identify hook race and needle bar locations

- Confirm recommended sewing machine oil type

- Review warnings about over-oiling fabric stains

How to Oil a Brother Sewing Machine

Once you’ve identified where your Brother machine needs oil, the actual oiling process is straightforward. You’ll need the right oil, a steady hand, and a clean cloth to catch any drips.

Follow these steps to keep your machine running smoothly without making a mess.

Choosing The Correct Sewing Machine Oil

You can’t just reach for any bottle on the shelf. Light, clear sewing machine oil—never household lubricants—protects your Brother machine. Synthetic oils with SAE 5–10 viscosity offer excellent machine lubrication and won’t stain fabric. Avoid oils with additives or detectable color.

Tri-Flow works well for industrial models, while Singer All-Purpose suits domestic machines. Machine compatibility matters, so check your manual before oiling.

Applying 2–3 Drops at Designated Points

Once you’ve selected the right oil, apply exactly 2–3 drops per designated oiling point. Focus on the hook race and bobbin area—these spots need precise lubrication techniques for peak sewing performance. Use a fine-tip bottle for oil drop precision. After applying oil, turn the handwheel 5–10 times to distribute lubrication across moving parts.

Machine longevity depends on proper machine oil application:

- 2–3 drops reduce friction by 35–45%, protecting internal components

- Correct oiling frequency cuts skipped stitches by 60%

- Over-oiling attracts dust and lint, shortening machine lifespan

- Precision application prevents thread breakage and needle jams

- Proper sewing machine oiling extends your machine’s life by years

Wiping Away Excess Oil to Prevent Stains

After applying oil, wipe metal surfaces with a lint-free cloth—microfiber removes 99% of residues that could stain your fabric. Run the handwheel several times, then check for visible droplets under direct light.

Test-stitch scrap fabric before your project. Excess oil causes 60% of streaks on light-colored fabrics.

Proper residue management and fabric stain prevention keep your work clean and professional-looking.

Reassembling The Machine After Oiling

Once your cloth shows no oil residue, replace the needle plate and tighten its screws to 3–5 kgf·cm for proper needle alignment. Reinsert the bobbin with thread oriented correctly—95% of jams stem from improper bobbin placement.

Clip the presser foot back and adjust its height. Run the machine without thread for five minutes to complete final calibration and distribute machine oil evenly through lubricated components.

Maintenance Frequency and Troubleshooting Tips

Knowing when and how often to oil your Brother sewing machine keeps it running smoothly and prevents costly repairs down the road. You’ll also want to recognize the warning signs that your machine needs attention before small issues turn into big problems.

Let’s cover the maintenance schedule that works for your sewing habits, red flags to watch for, and mistakes that can damage your machine.

Oiling Schedules for Different Usage Levels

Your sewing frequency determines how often you need to maintain your machine. Light users (under 3 hours weekly) should oil every six months. Moderate sewers (3–7 hours weekly) benefit from quarterly oiling schedules. Heavy users (8+ hours weekly) need weekly machine oil application.

For sealed bearing models, professional maintenance every 12–18 months manages machine part lubrication without owner intervention, protecting machine longevity.

Signs Your Machine Needs Oiling

Listen for unusual machine noise—grinding or squeaking means your Brother needs attention. Watch for skipped stitches or uneven stitch quality, which signal friction inside. If your handwheel feels stiff or fabric feed slows down, those are red flags.

Check oil levels at lubrication points; visible dust buildup without clean oil residue tells you it’s time for sewing machine maintenance to prevent mechanical issues.

When to Contact Brother Service Centers

Contact Brother Customer Support when your machine refuses to run after oiling or shows visible damage to motors and circuit boards. Warranty claims require proof of purchase and your serial number.

Use the Brother Authorized Service Center Locator to find certified repairs—non-authorized work voids coverage.

Service costs average $75–$100, with annual maintenance plans recommended for heavy users.

Avoiding Over-Oiling and Common Mistakes

Most repairs stem from applying more than 2–3 drops at any single point, which contaminates fabric and attracts lint into moving parts. Over-oiling shortens machine longevity instead of protecting it.

Follow these lubrication techniques to avoid costly troubleshooting:

- Use only synthetic oils approved by Brother—never WD-40 or household substitutes

- Apply one drop per point after 8–10 sewing hours, not after every use

- Wipe excess oil immediately to prevent stains and residue buildup

- Clean all lint before oiling to stop gummy deposits

- Stick to maintenance schedules in your manual—more oil doesn’t compensate for skipped cleaning

Frequently Asked Questions (FAQs)

Can I use WD-40 instead of sewing machine oil?

While WD-40 might seem like a slick shortcut, it’s not a substitute for sewing machine oil.

WD-40 evaporates quickly and attracts dirt, causing gumming and mechanical failure in precision parts over time.

How do I fix a squeaky sewing machine after oiling?

If your noisy machine keeps squeaking after oiling, check for lint buildup, worn belts, or missed lubrication spots.

Squeak Diagnosis and proper Oil Application at key points boost Machine Lubrication, Noise Reduction, and align with smart Maintenance Schedules.

Is it safe to oil a computerized Brother sewing machine?

Your computerized Brother sewing machine might be better off without extra attention. Most modern models feature sealed bearings and self-lubricating parts—oiling risks oil damage, warranty void, and electronic faults.

Always follow expert advice and your manual.

What happens if I accidentally over-oil my Brother sewing machine?

Over-oiling causes oil leaks, fabric staining, and dust buildup that damages gears. You’ll notice performance issues within weeks.

Wipe excess oil immediately with a soft cloth to prevent contamination and preserve proper machine maintenance and cleaning.

How do I store my sewing machine long-term?

Like tucking away a cherished heirloom, proper storage protects your investment. Store your machine in climate control between 68–77°F with humidity levels at 40–60%.

Use protective covers, storage containers, and maintenance schedules including regular cleaning and oiling to prevent rust.

What causes my machine to skip stitches suddenly?

Skipped stitches usually happen from needle damage, thread breakage, or bobbin issues. Check fabric tension and machine timing too.

If troubleshooting sewing machine problems doesn’t help, try sewing machine repair or fresh machine oil.

Should I oil vintage Brother machines differently?

Think of your vintage Brother as a classic car—its metal heart needs the right fuel.

Use light, paraffin-based sewing machine oil on exposed metal points, avoiding petroleum products that crack nylon parts.

Does thread quality affect how often I oil?

Yes, thread quality affects oiling frequency. Low-quality threads produce more lint accumulation in Brother sewing machines, increasing friction and requiring more frequent oil application.

High-quality synthetic threads create less debris, reducing your maintenance needs.

Conclusion

Like a well-tuned engine, your Brother machine runs best when friction doesn’t fight every motion. Three drops in the right spots will save you from skipped stitches and tension headaches. Now you know how to oil a Brother sewing machine—where the oil goes, how much to use, and when it’s time.

Make oiling part of your routine. Your machine will thank you with smooth seams and years of reliable service.

- https://www.brother-usa.com/contact-us

- https://download.brother.com/welcome/doch000266/bm35002600ug01en.pdf

- https://manuals.plus/brother/brother-sewing-and-mending-machine-operation-manual

- https://nickleelectrical.com/electrical-safety-statistics/

- https://www.esfi.org/workplace-safety/workplace-injury-fatality-statistics/