This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

First, check your presser foot pressure; too tight can snap threads, while too loose makes fabric slip and tangle.

Next, thread your machine carefully, following the manual—don’t skip those guides, and keep your machine clean and lubricated since lint build-up is the sneaky culprit behind many breakages.

Use high-quality thread (avoid the cheap stuff that frays) and match it to your fabric.

Table Of Contents

Key Takeaways

- Regularly clean your sewing machine to remove lint and debris, and keep it well-lubricated to ensure smooth operation and prevent thread breakage.

- Match your needle and thread to your fabric type, and replace dull or bent needles to maintain proper stitching and reduce breakages.

- Check and adjust thread tension carefully—too tight can cause snapping, and too loose results in uneven stitches.

- Always use high-quality thread that suits your fabric, and avoid cheap or brittle threads that are more prone to fraying and breaking.

Machine Setup Essentials

If your sewing machine isn’t set up right, thread breakage can turn your project into a frustrating mess.

From adjusting the presser foot to proper threading and cleaning, a few simple tweaks can make all the difference.

Presser Foot Pressure Adjustment

When your presser foot pressure’s off, it’s like driving with a flat tire—nothing works right.

Too loose? Your fabric slides everywhere. Too tight? It puckers and pulls, and guess what? Thread snaps.

Adjust foot pressure to match fabric weight for smooth sewing.

For a detailed guide, explore adjusting presser foot pressure techniques for various fabrics and sewing tasks. A quick tweak can save you heaps of frustration and boosts sewing accuracy—thread breakage prevention at its finest!

Threading Machine Correctly

Threading your machine right is like setting the table before a feast—it’s essential.

Follow the threading order in your manual, looping through all thread guides and tension control areas.

Check bobbin alignment, and don’t rush, as skipping one tiny step can wreak havoc on your sewing machine threading.

Master these threading tips, and you’ll dodge thread tension tantrums effortlessly!

Regular Cleaning and Maintenance

Neglecting sewing hygiene is asking for trouble.

Dust removal is your first defense—lint loves to jam up bobby care and thread tension control.

Swipe the needle plate, clean the bobbin case, and oil with machine oil sparingly.

Don’t skip filter cleaning either! Regular sewing machine cleaning stops most thread breakage causes, making sewing machine maintenance a game-changer for smooth stitching.

Thread Quality Matters

Your thread matters more than you think, and low-quality thread is often the sneaky culprit behind constant breakage.

Stick with strong, smooth thread that suits your fabric, and you’ll save yourself a lot of frustration.

Choosing Right Thread Type

If your sewing thread keeps snapping, it might be time to rethink your thread type selection.

Match thread material to your fabric—cotton for cotton, polyester for synthetics.

Pay attention to thread weight selection; lightweight cotton needs finer yarn.

Don’t underestimate color choice, either—blending makes repairs invisible.

Oh, and skip the bargain-bin threads; quality saves sanity.

To achieve maximum sewing results, consider learning about thread selection tips to guarantee the best thread for your project.

Storing Thread Properly

Don’t toss threads into a drawer and call it a day—good thread storage tips go a long way.

Store spools in airtight storage containers to keep dust away, and manage humidity control by avoiding damp areas.

Climate conditions matter, too—dry, cool spaces help thread condition.

Organize by color or type for better thread handling tips and effortless thread management.

Thread Material Selection

Picking the right thread material is like choosing the perfect dance partner—it just clicks.

Cotton threads are great for natural fabrics, while synthetic fibers work wonders with stretchy or heavy materials.

Pay attention to thread weights and fiber blends for smooth stitches.

Avoid cheap sewing threads; they fray fast.

Matching your sewing thread to your fabric guarantees quality results.

To achieve superior sewing performance, understanding the sewing machine threading process is essential for preventing thread breakage and guaranteeing a smooth sewing experience.

Needle and Bobbin Issues

Your needle and bobbin might seem like tiny parts, but they can cause big headaches if they’re bent, dull, or dirty.

Keep them in top shape, and you’ll save yourself a ton of frustration—and maybe a few broken threads!

Bent or Dull Needle Problems

A bent or dull needle causes thread fray, fabric damage, and all sorts of sewing errors.

If stitches skip or threads snap, it’s time for a sewing machine needle replacement.

Regular needle inspection and maintenance matter—look for bends or dull tips.

Needle selection is key too; match the size to your fabric.

Trust me, fresh needles save headaches!

Damaged Bobbin Causes

A damaged bobbin case can turn sewing into a headache fast.

Scratches cause thread snags, warping messes with the bobbinn thread, and poor bobbinn management leads to uneven tension.

If you’ve ever cursed at random fabric tears, check for bobbinn friction or misalignment.

For a detailed guide to troubleshooting, explore common sewing machine bobbin problems.

Regular bobbinn maintenance, like smoothing rough spots and using the correct bobbin type, saves you trouble.

Lint Buildup Prevention

A dirty bobbin case is like a dust bunny trap, waiting to mess with your stitches.

Lint buildup sneaks in from fabric and threads, causing thread breakage and tension headaches.

Keep things smooth with regular lint removal and machine cleaning.

Grab a soft brush or vacuum attachment, clear debris, and watch your sewing machine thread management improve.

Clean machine, happy stitches!

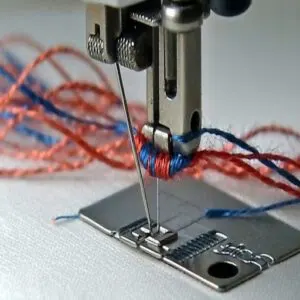

Threading and Tension Tips

If your sewing machine isn’t threaded right or the tension’s off, you’re asking for trouble (and snapped thread).

Don’t worry, though—small tweaks, like rethreading carefully or adjusting the tension dial, can make a world of difference, with actions like rethreading being crucial.

Correct Threading Technique

Getting the thread path just right can feel like threading a needle—literally, which requires sewing machine needle threading tips to avoid common errors.

Always follow your machine’s threading tips from the manual—every guide matters, as this is crucial for smooth sewing machine thread management.

For more in-depth guidance, explore these sewing machine needle threading tips, which can provide detailed advice on how to thread your sewing machine correctly.

- Make certain your thread flows smoothly through the thread path for better tension control and fewer snags.

- Don’t skip bobbin threading—it’s key for machine calibration and smooth sewing machine thread management.

Adjusting Tension Settings

Tension control can feel like a tug-of-war sometimes.

Start by tweaking your top thread tension dial—too tight, and threads snap; too loose, stitches sag.

Adjust for fabric thickness and sewing speed, testing on scraps first.

For specific tension-related products, explore these sewing machine tension products.

Don’t ignore the bobbins tension spring; lint loves to sneak in.

Proper machine calibration makes thread tension settings your ultimate breakage solution.

Balancing Top and Bobbin Thread

Balanced stitches start with thread synchronization.

If your top thread’s pulling too tight or the bobbin’s slacking, chaos follows.

Check thread tension settings:

- Match thread types: Use similar top and bobbin threads for balance.

- Test tension: Scraps are your best friend—sew and adjust.

- Inspect bobbin spring: A lint-packed bobbin tension spring spells trouble.

Nail it, avoid thread breakage!

Top 5 Thread Breakage Solutions

Thread breakage can make you want to throw your machine out the window, but don’t worry, I’ve got you covered.

These five practical solutions will keep your thread running smoothly and your sewing frustrations in check.

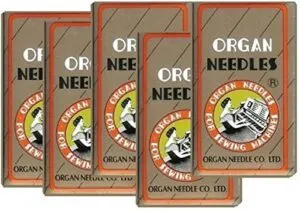

1. Sewing Machine Needles Assorted Sizes

Regarding solving thread breakage, having assorted needle sizes is like having the right tool for every job.

Different fabrics need different needle sizes—thicker fabrics love larger needles, while delicate ones demand finer points.

Universal needles are a safe bet for most projects, whether you’re working on wovens or knits.

Switch needles every few hours or when your stitches start misbehaving (hello, skipped stitches or popping sounds!).

Trust me, a sharp, properly sized needle is your sewing ally!

Understanding the various sewing machine needles types is essential for achieving professional results and preventing common issues like thread breakage.

Best For: Hobbyists and professionals looking for reliable and affordable needles for general-purpose sewing on a variety of fabrics.

- Compatible with various sewing machine brands.

- High-quality needles offering durability and smooth stitching.

- Affordable pack with multiple sizes for diverse sewing needs.

- Assorted sizes may include needles not frequently used by everyone.

- Not specifically tailored for heavy-duty or specialty fabrics.

- Requires regular replacement for optimal performance.

2. Sewing Machine Needles Assortment Pack

Sometimes, you need a little help to tackle that never-ending thread breakage, and that’s where assortment packs shine.

They’re like a toolbox for your sewing machine—giving you needles in various sizes to match different fabrics.

The SCHMETZ or Singer packs, for example, work with most machines, so no guessing games.

Plus, they’re perfect for experimenting when you’re unsure which needle suits your project.

A well-stocked pack means fewer headaches, more sewing success, and smoother stitches, especially on tricky fabrics!

Best For: Sewing enthusiasts looking for a versatile and affordable assortment of needles compatible with a variety of machines and fabrics.

- Includes a wide range of sizes (65/9 to 110/18) for different fabric types.

- Compatible with popular sewing machine brands like Janome, Brother, and Singer.

- Offers excellent value for money with sharp, durable needles.

- May not work seamlessly with all fabric types or machine models.

- Some customers report occasional bending or durability issues.

- Lacks a robust storage solution for better needle organization.

3. Prewound Bobbins for Sewing Machines

Ever feel like you’re on a roll, and then bam—thread breaks mid-project?

Prewound bobbins can save the day, these ready-to-go lifesavers hold more thread than self-wound ones and are wound evenly by machines, cutting down on tangles and tension problems.

Whether you’re quilting or tackling embroidery, they’re a game-changer.

Just double-check compatibility with your machine—brands like Brother and Janome play nice.

Bonus: no more stopping to wind bobbins mid-stitch, trust me, they’ll make sewing smoother and a lot less stressful.

Best For: Beginners and experienced sewists looking for a convenient, time-saving option for embroidery, quilting, and regular sewing projects.

- Ready-to-use bobbins save time and eliminate the hassle of self-winding.

- Smooth thread winding reduces tangles and tension issues.

- Compatible with a wide range of machine brands like Brother, Janome, and Singer.

- Limited to white thread, not ideal for projects needing various thread colors.

- Made of plastic, which might not suit eco-conscious users.

- Not compatible with older machine models requiring tension-adjustable bobbins.

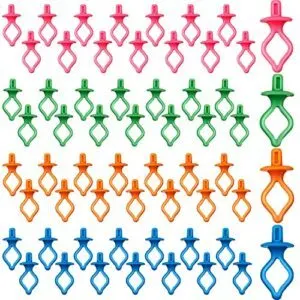

4. Bobbin Thread Spool Matching Set 20 Pieces

Ever spent more time untangling a thread mess than actually sewing?

The Bobbin Thread Spool Matching Set (20 pieces) is your new best friend.

It keeps your bobbin and thread together—no more mismatched colors or wild goose chases in your sewing drawer.

Flexible and easy to use, it’s great for travel or tight crafting spaces, plus the bright colors make finding what you need a breeze.

Just squeeze the ends to lock everything in place—simple, handy, and honestly, life-changing for sewing enthusiasts!

Best For: Sewing enthusiasts looking to keep their bobbins and thread spools organized, especially in small spaces or while traveling.

- Keeps bobbins and spools matched and organized.

- Bright colors make it easy to identify threads.

- Flexible and simple design that’s easy to use.

- Not compatible with pegged thread holders.

- May not fit well with smaller thread spools.

- Can interfere with storage pins or pegs.

5. WILLBOND Bobbin Holders Thread Spool Clips Sewing

Keeping thread and bobbins organized can feel like herding cats, but WILLBOND Bobbin Holders make it a breeze.

They clip bobbins right on top of your thread spools, saving you time and sanity.

No more digging through bins or chasing runaway bobbins.

Made from durable silicone, they fit most spool sizes and keep thread tangles at bay.

While some larger brands mightn’t fit perfectly, their compact, colorful design is a game-changer for sewing enthusiasts looking to keep their workspace tidy, using durable silicone.

Best For: Sewing enthusiasts who want an affordable, colorful, and compact solution to organize thread and bobbins efficiently.

- Keeps thread and bobbins securely together to prevent tangling and save time.

- Made from durable silicone, lightweight, and easy to store.

- Fits most spool sizes and comes in vibrant, assorted colors for easy sorting.

- May not fit perfectly on larger spools or specific brands like Aurifil and Gutterman.

- Slight size variations due to manual measurement.

- Colors may appear slightly different from screens, which might bother some users.

Troubleshooting Common Issues

When your thread keeps snapping, it’s easy to feel like your machine is working against you.

Don’t worry—by checking tension, threading, and needles, you’ll get those stitches running smoothly again in no time.

Identifying Thread Breakage Causes

Figuring out why thread keeps snapping can test your patience, but don’t worry—you’ve got this.

Look for the usual suspects:

- Thread Fraying Factors: Cheap, old, or mismatched threads.

- Fabric Thickness: Too thick? Switch techniques.

- Machine Vibration: Is your machine jiggling too much?

- Needle Problems: Bent or dull needles ruin stitches.

- Threading Path Issues: Missed a guide? Double-check!

Resolving Tension Problems

Feeling like your thread has trust issues? It’s probably your sewing machine tension.

Test on scrap fabric first—too tight, and the thread snaps; too loose, and there’s a spaghetti mess underneath.

Adjust top tension gradually, check the bobbin tension spring for lint, and match thread to fabric thickness for perfect thread balance. Machine calibration saves headaches!

Fixing Needle and Bobbin Issues

A misaligned needle or dirty bobbin case can feel like sewing sabotage.

Double-check your needle alignment—it should face the right way, not be bent or dull, and explore bobbin cleaning to nix hidden thread tangles.

Slow your sewing speed if fabric friction builds up, as needle maintenance and bobbin care are thread breakage solutions you’ll want to master.

Preventing Future Breakage

You don’t have to keep battling thread breakage with every project.

Stick to regular machine maintenance, use good-quality threads and needles, and adjust your sewing speed to keep things running smoothly.

Regular Machine Maintenance

Let’s face it—ignoring Machine Cleaning is like driving without an oil change.

Regular sewing machine maintenance tips, like clearing lint from the bobbin case and throat plate, checking filters, or applying lubrication tips, keep things running smoothly.

Replace worn parts pronto, and consider a little thread conditioner, paired with consistent bobbins maintenance, which spells fewer breaks and happier sewing.

Using Quality Threads and Needles

The wrong thread or a dull needle can wreck your sewing vibe.

Stick to high sewing thread quality—fresh, smooth thread that’s the right thickness for your fabric.

Match thread material to fabric, like cotton for cotton or polyester for stretch.

And needle sharpness? It’s key! Switch needles often and choose sewing needle types that match your project.

Quality control matters!

Adjusting Sewing Speed and Technique

Rushing through sewing? Slow it down! Speed control and steady fabric handling make a huge difference.

- Control sewing speed: Go slow for thick fabrics or tricky areas.

- Mind your stitch length: Longer stitches can ease thread tension.

- Calibrate your machine: Double-check for smooth thread flow.

- Practice sewing techniques: Relax with firm fabric grip.

- Pause to troubleshoot: Small tweaks prevent thread breakage.

Frequently Asked Questions (FAQs)

How to prevent thread breakage on a sewing machine?

Did you know 80% of thread breaks come from tension issues?

Double-check your threading, clean out lint, and match thread and needle to your project.

Keep tension balanced—like a good coffee-to-cream ratio!

How do you prevent a sewing machine from breaking?

Don’t underestimate maintenance—clean out lint, use fresh needles, and check thread quality.

Double-check your threading, tweak tension for balance, and use the right needle for your fabric.

A little care prevents big headaches!

Why is my sewing machine thread breaking?

Thread breaks like a bad surprise at the worst moment.

Check for a dull needle, bad tension, dusty bobbin case, or cheap thread.

Wrong threading’s often the culprit—give your machine a quick rethread.

What are the best sewing machine thread quality tips?

Fresh thread works wonders—ditch that old, brittle stuff that snaps faster than you blink.

Match thread type to fabric, pick high-quality brands, and store it dry.

Your stitches will thank you, trust me.

How do you prevent a thread break?

Picture a dance where every step clicks—your machine needs that harmony.

Use quality thread, match it to fabric, clean often, and tweak tension.

Oh, and replace dull needles—they’re the clumsy dancers breaking your thread rhythm!

How do I fix a high thread tension on my sewing machine?

Crank down the top thread tension dial a notch or two, then test on scrap fabric.

If the thread’s still tight, check the bobbin tension or rethread everything—machines love acting up for no reason sometimes!

What is the best way to sew stretchy fabrics?

Stretchy fabrics can be tricky, but you’ve got this.

Use a ballpoint needle, polyester thread, and a zigzag stitch.

Don’t pull the fabric—let the machine feed it.

A walking foot helps tons too!

How does humidity affect sewing thread performance?

Humidity’s like a sneaky villain—it makes threads swell or weaken.

Too much dampness, and threads snap or tangle; too dry, they fray.

Keep your sewing room balanced with a dehumidifier or humidifier for smoother stitching.

Can sewing speed impact thread durability?

Who knew speed demons could ruin thread.

Sewing too fast heats up the needle, frays the thread, and snaps it.

Slow your pace, let the machine work smoothly, and your thread will thank you.

What are common issues with metallic threads?

Metallic threads can be a diva—they snag easily, fray like crazy, and need special care.

Use a metallic needle, loosen the tension, slow down, and add a thread lubricant.

Patience is your best friend here!

Conclusion

Think of your sewing machine like a trusty car—it needs the right fuel, regular tune-ups, and careful driving to avoid breakdowns.

By tweaking tension, keeping it clean, and using quality thread and needles, you’ll master these preventing sewing machine thread breakage techniques in no time.

Don’t let thread trouble ruin your projects—stay patient, troubleshoot those little quirks, and stick to these tips.

Sewing’s an art, but with the right care, it won’t drive you nuts!