This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

First, double-check your threading – both the upper thread tension and bobbin case.

A bent or damaged needle could also be the culprit, so replace it with the correct type for your fabric.

Make sure you’re using compatible thread weights too.

Built-up lint and debris often cause jams, so give your machine a thorough cleaning.

If mechanical issues persist, consult your manual for timing adjustments or replace worn parts.

With a little troubleshooting, you’ll soon be stitching smoothly again – and the next steps may provide the solution you need.

Table Of Contents

Key Takeaways

- Sewing machine jams can feel like hitting a brick wall, but don’t throw in the towel just yet! With some nifty troubleshooting tricks up your sleeve, you’ll be back on the straight and narrow in no time.

- It’s often the little things that trip us up – a bent needle, tangled threads, or a stubborn tension knob can quickly turn your sewing session into a royal mess. But fear not, these pesky culprits are easy to tame once you know where to look.

- Just like a well-oiled machine, keeping your trusty sewing companion in tip-top shape is key to avoiding frustrating jams. Regular cleaning and maintenance are like a breath of fresh air, preventing lint and debris from throwing a wrench into your stitching plans.

- If all else fails and your machine still insists on playing hard to get, it might be time to call in the big guns. Sometimes, worn-out parts or timing issues require a professional’s touch to get your sewing mojo back on track.

Incorrect Threading

One of the most common causes of sewing machine jams is incorrect threading, either due to issues with the upper thread tension or problems with how the bobbin is threaded. You’ll want to carefully examine the threading paths and make certain both the upper thread and bobbin are properly inserted according to your machine’s instructions.

Upper Thread Tension Issues

You’re likely experiencing jamming due to incorrect upper thread tension. Check that tension adjustment knob and verify the thread is catching between the tension discs. Too loose, and the thread won’t catch properly, causing tangles and jams. Too tight restricts thread flow. Gently tug the top thread – you want slight resistance. Adjust as needed.

Bobbin Threading Problems

You may also face bobbin threading problems. Check that the bobbin case is properly aligned and seated, with the correct tension. Use the recommended bobbin thread type and wind it evenly to the right length. Poor-quality thread, improper winding, or the wrong bobbin can lead to jamming issues depending on your fabric type.

Needle Issues

A bent or damaged needle can absolutely wreak havoc on your sewing machine, causing constant jamming issues. Using the incorrect needle type for your fabric is another common culprit – needles are designed for specific fabrics, so be sure to match the right needle to your project.

Bent or Damaged Needle

You may be using a bent or damaged needle, causing your sewing machine to jam. Here’s what to do:

- Check the needle for bends, burrs, or other damage.

- Replace the needle if it’s damaged – use a new, high-quality needle.

- Make sure the needle is properly inserted and aligned.

- Lubricate the needle with a small drop of sewing machine oil.

A bent or dull needle can snag fabric, break threads, and cause frustrating jams. Stay on top of needle quality for smooth sewing.

Incorrect Needle Type

Aside from bent needles, using the wrong needle type can cause jams too. Different fabrics need specific needles – knits need ballpoint, while wovens need sharp points. The needle’s thickness matters too:

| Fabric Weight | Needle Size |

|---|---|

| Lightweight | 9/70 – 11/80 |

| Medium | 11/80 – 14/90 |

| Heavy | 16/100+ |

Not matching the needle to your fabric? That’s a recipe for constant jams and skipped stitches!

Fabric and Thread Compatibility

A mismatch between the weight of your fabric and the weight of your thread can lead to jamming. You’ll want to verify you’re using an appropriate thread weight for the thickness of your fabric. Heavier fabrics require a sturdier thread, while lightweight fabrics call for a finer thread.

Additionally, avoid bargain-bin threads, as low-quality threads are more prone to fraying, snagging, and causing jams.

Fabric Weight and Thread Weight Mismatch

If you’ve matched the wrong fabric weight with an incompatible thread weight, jams can happen. To prevent this:

- Use lighter thread weights for delicate fabrics

- Pair heavier threads with thicker, sturdier fabrics

- Check the needle position – it should align with the fabric’s thickness

- Consider the fabric texture and choose the right needle gauge

Pairing the right fabric, needle, and thread is essential for smooth sewing. A mismatch can quickly lead to frustrating snags and jams.

Thread Quality Issues

Inferior thread quality can wreak havoc, leading to sewing mayhem. Cheap, poor-quality thread is prone to breakage, fraying, and inconsistent tension. Invest in high-quality thread from reputable brands to guarantee smooth sailing. Consider the following thread factors:

| Thread Factor | Description |

|---|---|

| Thread Type | Cotton, polyester, etc. Match thread to fabric. |

| Thread Weight | Thin, thick. Match weight to fabric weight. |

| Thread Storage | Store properly to prevent tangling, dust. |

Skimping on thread is a surefire recipe for jamming disasters. Quality thread = happy stitching.

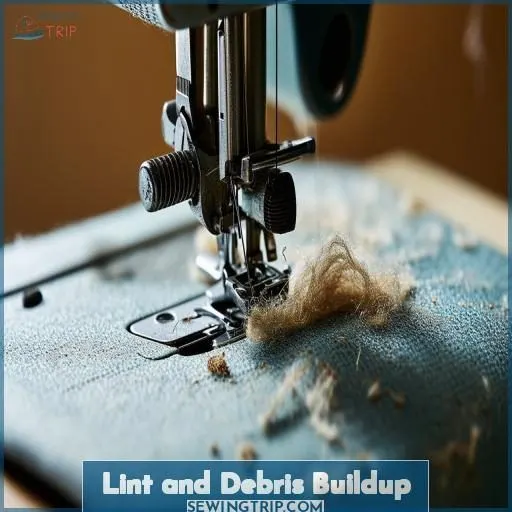

Lint and Debris Buildup

Lint and debris buildup in the bobbin area and tension discs is a common culprit for sewing machine jams. Regularly cleaning these sections by using a small brush or compressed air can prevent material from accumulating, causing tension issues and stoppages.

Cleaning the Bobbin Area

Don’t overlook the bobbin area when cleaning your machine! Built-up lint and debris can easily lead to tension issues and jams. Follow these steps:

- Remove the bobbin case and use a small brush to clear lint accumulation.

- Check the bobbin case positioning is correct and aligned properly.

- Make certain you’re using the right bobbin type and winding evenly.

A clean bobbin area promotes smooth stitching and prevents frustrating snags.

Cleaning the Tension Discs

Another area that collects lint and debris is the tension discs. You’ll want to clean these regularly, as a buildup can cause the thread to catch and jam. Here’s a quick guide:

| Step | Action |

|---|---|

| 1 | Refer to your machine’s manual |

| 2 | Locate the tension discs |

| 3 | Use a small brush to gently clean |

| 4 | Check for any damage or misalignment |

| 5 | Consider lubricating or replacing if needed |

Keeping those tension discs in tip-top shape is key to preventing frustrating jams.

Mechanical Problems

If your sewing machine continues to jam despite your efforts to address issues like incorrect threading, needle problems, and fabric/thread compatibility, there may be underlying mechanical problems causing the jams. Timing issues or worn-out parts within the machine’s internal mechanisms could be the culprit, requiring professional servicing or repair to resolve the persistent jamming.

Timing Issues

Another issue could be incorrect timing. You might need to check your machine’s timing mechanism:

- Look for timing marks on the handwheel and stitch plate

- Verify that the needle is properly aligned with these markings

- Consult your manual for specific timing diagnostics

- Consider a timing adjustment or timing belt replacement

Proper timing is essential for smooth operation and preventing jams.

Worn-Out Parts

If timing issues aren’t the culprit, worn-out parts could be jamming your machine. Over time, components like gears, bearings, belts, bobbin cases, and tension discs can wear down, leading to snags and jams. Here’s a handy guide to identifying worn parts:

| Part | Signs of Wear | Replacement Frequency |

|---|---|---|

| Gears | Stripping, cracking | Every 5-7 years |

| Bearings | Grinding noises, stiffness | Every 3-5 years |

| Belts | Cracking, stretching | Annually |

Don’t let worn parts slow you down – replace them promptly for smooth sewing.

Frequently Asked Questions (FAQs)

Why does my sewing machine keep jamming underneath?

A clogged machine or tangled threads beneath the fabric may cause jamming underneath. Check for fabric or thread buildup below the needle plate and clear any obstructions carefully.

Why does my sewing machine keep knotting underneath?

You’re likely facing knotted threads underneath because of incorrect threading, tension issues, or bobbin problems. Carefully rethread the machine, check tensions, and inspect the bobbin area for tangles or debris.

What are the 7 common sewing machine troubles?

Like a well-oiled machine, avoid common troubles by mastering thread tension, threading, bobbins, needles, fabric pairing, maintenance, and presser foot height. Troubleshoot skillfully for seamless sewing.

Why does my sewing machine keep bunching the thread?

Bunching threads are often caused by improper tension settings or a damaged needle. Check your top and bobbin tension, and replace your needle if it’s bent, dull, or the wrong type for your fabric.

How do I disengage the clutch for rethreading?

Like a key to open a secret, disengaging the clutch reveals the path to smooth rethreading. Lift the presser foot, then turn the handwheel in your direction—the needle will rise, allowing effortless threading.

What stitch length is most jam-resistant?

For jam-resistant stitching, use a moderate 5-5mm stitch length. Shorter stitches can cause fabric puckering and jamming, while longer ones may skip stitches and loop excess thread. Aim for balanced tension and precise fabric feeding.

Are industrial machines more prone to jamming?

Picture an industrial machine whirring non-stop, churning out fabric. Surprisingly, they’re less prone to jams than home models. Their sturdy components and rigorous maintenance create smooth, consistent stitching—a workhorse’s advantage.

Do computerized models reduce jamming incidents?

Yes, computerized sewing machines often reduce jamming incidents. With precise tension control and automatic settings, you’re less likely to experience threading issues that lead to jams. However, proper maintenance and setting adjustments are still essential for best performance.

How often should bobbin tension be adjusted?

Monitor bobbin tension during long projects; adjust as needed when thread begins tangling or developing uneven stitches. In general, adjust tension if stitch quality deteriorates, but avoid excess tinkering.

Conclusion

Troubleshooting a sewing machine that keeps jamming is like unraveling a tangled thread – patience and a systematic approach are key.

By addressing potential issues with threading, needles, fabric and thread compatibility, lint buildup, and mechanical problems, you’ll soon have your machine humming smoothly again.

Stay diligent, follow the guidance outlined, and you’ll overcome this frustrating hurdle, stitching seamlessly on your next project.