This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A bobbin tension gauge, like the Towa or Tajima models, guarantees the bobbin thread plays well with the upper thread.

Screwdriver sets help fine-tune the bobbin case tension, while thread tension gauges double-check your settings.

Don’t underestimate a good cleaning kit—lint and dust love to cause chaos in tension adjustments.

Remember, the goal is for the top and bobbin threads to meet in perfect harmony, right in the fabric’s middle.

Master these tools, and you’ll stitch like a pro (no seam ripper required).

Table Of Contents

- Key Takeaways

- Sewing Machine Tension Basics

- Causes of Tension Issues

- Adjusting Sewing Machine Tension

- Top 9 Sewing Machine Tension Tools

- 1. Towa Bobbin Tension Gauge by Superior Threads

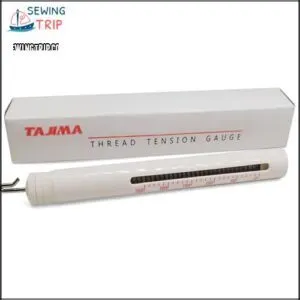

- 2. Tajima Thread Tension Gauge TTG CM76907

- 3. YICBOR Thread Tension Gauge for Embroidery Machines

- 4. Bequilter Tajima SWF Ricoma Thread Tension Gauge

- 5. LQ Industrial Sewing Machine Screwdriver Set

- 6. Sewing Machine Needle Plate Screwdriver Set

- 7. Singer 20U Industrial Sewing Machine Tension Check Spring

- 8. Industrial Sewing Machine Tension Spring

- 9. Sewing Machine Cleaning Kit 15 Piece Tool Set

- Factors Affecting Tension

- Troubleshooting Tension Issues

- Achieving Perfect Stitches

- Maintaining Optimal Tension

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- You’ll need tools like a bobbin tension gauge and thread tension gauge to measure and adjust thread tension for smooth stitching.

- Regular maintenance, like cleaning lint and replacing needles, prevents tension problems and keeps your machine running smoothly.

- Adjust the top tension dial and bobbin case screw incrementally for balanced stitches that meet in the fabric’s middle.

- Test tension settings on scrap fabric to identify and fix issues like puckering, loose threads, or uneven stitches.

Sewing Machine Tension Basics

You’ll find that getting your sewing machine’s tension right is like finding the perfect balance between your upper and lower threads, where they meet in a harmonious dance through your fabric.

When you’re working with tension settings, you’ll notice that both threads need to pull equally against each other to create those picture-perfect stitches you’re aiming for.

Importance of Balanced Tension

You’re juggling a delicate dance every time you sew – it’s all about that perfect tension control between your top and bottom threads. Think of balanced tension as your ticket to stitch quality heaven.

To achieve this balance, understanding thread tension is essential for preventing common sewing issues.

Here’s why proper thread balance matters:

- Creates professional-looking seams that’ll make your crafting buddies jealous

- Prevents fabric stretch and puckering disasters

- Guarantees your stitches hold up wash after wash

- Saves you from the heartache of ripping out wonky seams

Effects of Imbalanced Tension

Getting your tension wrong in sewing is like trying to dance with two left feet – it throws everything off balance.

When your machine’s tension is out of whack, you’ll spot some telltale signs that can make or break your project.

Understanding thread tension is essential to achieve perfect stitches and prevent common issues like loops or breaks in the thread.

| Problem | Effect |

|---|---|

| Loose Upper Thread | Loops on fabric bottom |

| Tight Upper Thread | Breaks and snaps |

| Uneven Tension | Puckered fabric surface |

| Poor Thread Quality | Inconsistent stitch quality |

| Machine Performance | Skipped or bunched stitches |

Role of Top and Bottom Threads

Regarding thread balance, your machine’s top thread and bobbin thread work together like dance partners.

The upper tension, controlled by a dial (usually set between 3-5), leads the performance, while the factory-set lower tension follows.

For perfect stitch quality, watch how these threads synchronize – they should meet right in the middle of your fabric, creating that ideal thread tension interplay, with upper tension and perfect stitch quality in mind.

Causes of Tension Issues

You’ll find that several factors can throw off your sewing machine’s tension, from a messy machine to a bent needle.

So, let’s look at some common culprits and how you can easily fix them.

Bobbin Thread Issues

So, your bobbin – that tiny thread spool – can be a real troublemaker!

Bobbin thread issues like fraying, knots, or tangles create tension imbalance, leading to thread breakage and uneven stitches.

Sometimes, your bobbin won’t unwind smoothly from its case, causing further headaches.

A tangled bobbin or incorrect bobbin tension can feel like battling a tiny, thread-wrapped gremlin.

Check your bobbin for fray and confirm it spins freely – a happy bobbin means happy stitches!

Needle Condition

Beyond bobbin woes, your needle’s condition is key. A dull needle, like a blunt knife, struggles to pierce fabric cleanly, leading to thread breakage and fabric damage.

Mismatched needle size or a damaged needle creates similar havoc. Needle sharpness affects needle thread tension and stitch quality.

Regular needle replacement prevents these issues. Inspect your needle; if it’s bent or dull, it’s time for a swap. Proper maintenance of the needle plate problems is also important to prevent unnecessary thread breakage and guarantee smooth sewing operations.

Machine Cleanliness

A bent needle isn’t the only culprit behind tension troubles.

Dust bunnies and lint can sabotage your stitches too.

Regular machine cleaning, including dust removal, filter cleaning, and debris clearance with a brush, keeps your machine humming.

Proper oil application and dirt in machine parts removal prevent costly sewing machine repairs.

Think of it as a spa day for your sewing machine—and your sanity!

Adjusting Sewing Machine Tension

You’ll learn to fine-tune your sewing machine’s tension, balancing the top and bobbin threads for perfect stitches.

This involves adjusting both the top tension dial and the bobbin tension screw, and we’ll guide you through it step by step.

Step-by-Step Adjustment Guide

Now that you know what causes tension headaches for your machine, let’s fix them!

Here’s your step-by-step Machine Calibration guide:

- Grab some scrap fabric.

- Thread your machine.

- Adjust your Tension Settings.

- Test your Thread Control with a few stitches.

- Repeat steps 3 & 4 until your stitches look like a sewing ninja’s work. This Adjustment Process is key for any Sewing Techniques. Don’t forget your sewing machine tension tools!

Bobbin Thread Tension Adjustment

Bobbin tension is usually factory-set, but occasional tweaking might be needed.

For bobbin thread tension adjustment, locate the small screw on your bobbin case.

Using a tiny screwdriver from your sewing machine tension tools, carefully turn the screw.

Clockwise increases tension; counterclockwise decreases it.

Tiny tweaks are key!

To achieve ideal results, utilizing a tension gauge tool is essential for precise adjustments.

Test your sewing machine tension adjustment on scrap fabric after each adjustment using a thread tension meter for sewing machine calibration.

Bobbin case maintenance and bobbin screw adjustment are important for perfect stitches.

Top 9 Sewing Machine Tension Tools

You’re about to discover nine essential tools that’ll help you conquer sewing machine tension like a pro, banishing frustrating puckers and messy stitches forever.

These gadgets will make adjusting your tension easier and more precise, so you can achieve perfectly balanced stitches every time.

1. Towa Bobbin Tension Gauge by Superior Threads

The Towa Bobbin Tension Gauge is your precision instrument for perfect stitches.

This nifty gadget measures your bobbin’s tension, giving you a number to dial in that "just right" feel.

It works with L-style bobbins, making it a breeze to use with your long-arm quilting or embroidery machine.

No more guessing games – just accurate tension and flawless results, every single time.

This little tool might just become your new best friend!

Best For: Quilters and embroiderers using long-arm machines with L-style bobbins who want to achieve precise bobbin tension.

- Accurate tension measurement eliminates guesswork.

- Easy to use with no setup required.

- Compatible with L-style bobbins and popular long-arm machines.

- Some users find the price point high.

- Not compatible with M-style bobbins.

- Requires understanding of bobbin tension principles for optimal use.

2. Tajima Thread Tension Gauge TTG CM76907

Want to tame unruly top thread tension on your embroidery machine? The Tajima Thread Tension Gauge TTG CM76907 is your trusty sidekick.

Hook it onto the top thread, give a gentle tug, and the gauge reveals the tension in grams. This helps you fine-tune tension for different thread types (polyester needs more oomph than rayon) and stitch types, preventing thread breaks and looping stitches.

No more bobbin thread showing on top – just smooth, professional embroidery.

Best For: Embroiderers looking to achieve perfect top thread tension on their home or commercial machines.

- Measures top thread tension in grams for precise adjustments.

- Helps eliminate common embroidery issues like thread breaks and looping stitches.

- Works with various thread types and stitch types.

- Requires a separate purchase for bobbin tension.

- May involve a learning curve for users unfamiliar with tension gauges.

- Not specifically designed for regular sewing machines.

3. YICBOR Thread Tension Gauge for Embroidery Machines

Need a tension fix for your embroidery? The YICBOR Thread Tension Gauge, similar to the CKPSMS gauge, offers a pencil-style design for precise top thread tension setting on TAJIMA, SWF, and Ricoma machines.

Wrap the thread, check the needle’s reading, and adjust accordingly. While an analog gauge, it gets the job done, although a digital option might offer easier readability.

Just be aware the printed markings might wear over time, which could affect the TAJIMA, SWF, and Ricoma machines’ performance.

Best For: Embroiderers using TAJIMA, SWF, or Ricoma commercial machines who need a hands-on way to measure and adjust top thread tension.

- Simple, pencil-style design for easy tension checks.

- Compatible with popular commercial embroidery machines (TAJIMA, SWF, Ricoma).

- Affordable way to maintain consistent thread tension.

- Analog display may be less precise than digital alternatives.

- Printed markings might wear off over time.

- Requires manual interpretation of the tension reading.

4. Bequilter Tajima SWF Ricoma Thread Tension Gauge

The Bequilter Tajima SWF Ricoma Thread Tension Gauge is your go-to for commercial embroidery machines, especially Tajima, SWF, and Ricoma.

This pencil-style gauge helps you nail the top thread tension. Its hook and slide guide set the top layer thread’s tension, while the spring-loaded slider needle alerts you to needed adjustments.

Expect top thread tensions to vary, sometimes by 5 to 10 gf. This handy tool guarantees consistent tension and ideal embroidery quality. It’s like having a tiny tension whisperer right in your sewing kit!

Best For: Embroiderers using Tajima, SWF, or Ricoma commercial machines who need precise top thread tension control.

- Easy to use, pencil-style design for quick tension checks.

- Compatible with popular commercial embroidery machine brands.

- Helps maintain consistent thread tension for optimal embroidery quality.

- Specific tension recommendations for different thread types may require additional research.

- May not be compatible with all commercial embroidery machines.

- Requires some practice to master the technique of using the gauge effectively.

5. LQ Industrial Sewing Machine Screwdriver Set

Fine-tune your bobbin case tension like a pro with the LQ Industrial Sewing Machine Screwdriver Set.

This five-piece stainless steel set is your trusty sidekick for tackling tension tweaks on various machines, including Singer models.

Say goodbye to rust and hello to smooth adjustments. Its compact size makes it perfect for small spaces, but be mindful of the small parts – you don’t want them playing hide-and-seek.

Some users have noted the Phillips head can be a bit delicate, so treat it with care.

Best For: Sewing enthusiasts and professionals working with Singer, Pfaff, Euro, and Eversewn machines who need a precise tool for bobbin case tension adjustments.

- Convenient and compact for small workspaces and easy storage.

- Rust-proof and corrosion-resistant stainless steel construction for durability.

- Specifically designed for adjusting bobbin case tension, improving sewing machine performance.

- Small parts can be easily lost if not carefully stored.

- Phillips head may be prone to bending with excessive force.

- May not fit perfectly under all sewing machine arms due to its size.

6. Sewing Machine Needle Plate Screwdriver Set

Needle-plate screwdrivers are essential for adjusting needle plates, tension mechanisms, and other sewing machine components.

This specialized screwdriver set simplifies accessing and adjusting those tiny screws holding everything together. Think of them as the perfect wrench in your sewing toolkit, allowing precise adjustments for ideal tension and smooth stitching.

No more struggling with ill-fitting tools! This set guarantees you have the right tool for the job, making maintenance a breeze and keeping your machine humming happily.

Best For: Sewers of all levels looking to maintain, repair, or adjust their sewing machines with precision.

- Designed specifically for sewing machine screws, ensuring a perfect fit.

- Makes adjusting needle plates, tension mechanisms, and other components easier.

- Simplifies maintenance and keeps your sewing machine running smoothly.

- May not be necessary for users who never adjust their sewing machines.

- Might be redundant if you already own a comprehensive set of small screwdrivers.

- Quality can vary between brands, so it’s important to choose a reputable set.

7. Singer 20U Industrial Sewing Machine Tension Check Spring

Restore your Singer 20U’s tension harmony with the Singer 20U Industrial Sewing Machine Tension Check Spring.

This small but mighty spring is a cost-effective fix for tension woes, especially bottom loop mysteries.

Compatible with similar machines like Consew, Rex, Tacsew, and Yamata, it’s easy to install and adjust, getting you back to sewing frustration-free.

It’s like giving your machine a tiny tune-up!

Available on Amazon for about $8, this spring is a small investment for big improvements.

Best For: People with Singer 20U class sewing machines (or similar models like Consew, Rex, Tacsew, and Yamata) experiencing tension problems, especially bottom looping.

- Cost-effective solution for tension issues.

- Easy installation and adjustment.

- Compatible with various machine brands.

- Requires careful disassembly of the machine.

- Potential for bending the spring during installation.

- May not solve all tension-related problems.

8. Industrial Sewing Machine Tension Spring

Like a tiny guardian of stitch perfection, the Industrial Sewing Machine Tension Spring keeps your threads in line.

Compatible with Brother, Juki, Singer, Janome, and more, this spring is essential for balanced tension.

Remember, proper assembly is key to avoid frustrating mishaps. Check compatibility with your specific model, especially if you have a Singer 15, as some users have reported fit issues.

This small but mighty spring is a game-changer for consistent, trouble-free stitching.

Best For: Industrial sewing machine owners using Brother, Juki, Singer, Janome, and similar machines who need a replacement or spare tension spring.

- Compatible with a wide range of industrial sewing machine brands.

- Essential for maintaining balanced thread tension and achieving consistent stitches.

- Small and affordable, making it a cost-effective solution for tension issues.

- May not be compatible with all Singer models, particularly the Singer 15.

- Requires proper assembly to avoid potential damage or malfunctions.

- Some users have reported fit issues with specific machines.

9. Sewing Machine Cleaning Kit 15 Piece Tool Set

Finally, a clean machine is a happy machine! This 15-piece cleaning kit is your sewing machine’s new best friend.

It tackles dust bunnies and thread snarls with tweezers, lint brushes, and screwdrivers. Keeping your machine spotless prevents tension headaches down the road.

Plus, the handy storage bag keeps everything organized. For under $6, it’s a steal – a small price to pay for perfectly balanced stitches.

Best For: Anyone who wants to keep their sewing machine in tip-top shape without breaking the bank.

- Comprehensive set of tools for various cleaning and repair tasks.

- Affordable price point for essential sewing machine maintenance.

- Convenient storage bag for organization and portability.

- Some users might find the tools to be of basic quality.

- The kit may not include specialized tools for advanced repairs.

- Durability of the tools might be a concern for frequent users.

Factors Affecting Tension

You’ll find that your fabric type and thread choice play a big role in achieving perfect tension, so let’s explore how these factors, along with your machine’s settings, can make or break your stitches.

Proper maintenance also keeps your machine stitching smoothly, preventing tension troubles down the road.

Fabric Type and Thread Quality

Beyond the right tools, your fabric and thread are key players in tension.

Fabric density, from airy chiffon to sturdy denim, demands different thread weights and sewing machine tension settings.

Match fiber types (cotton, silk, polyester) and weave patterns for a smooth ride.

Don’t forget yarn textures—a chunky yarn needs a looser tension than a sleek one.

Mastering these combos achieves perfect stitches!

Needle Size and Type

The right needle size and type can make or break your stitch quality. Keep these in mind: Understanding needle sizes is essential for best results.

- Needle Materials: Use stainless steel for longevity or titanium for high-speed sewing.

- Fabric Density: Thicker fabrics like denim need larger needles.

- Thread Compatibility: Match the needle thread to your project.

- Needle Condition: Replace dull needles regularly to prevent skipped stitches.

Machine Settings and Maintenance

Proper machine settings and maintenance aren’t just chores—they’re your secret weapon for sewing success.

Regularly check your sewing machine tension dial, tension meters, and alignment with scheduled upkeep. Dust and grime can throw off thread monitoring and tension adjustment faster than spilled coffee.

Follow this quick guide to stay on top of it all:

| Task | Frequency |

|---|---|

| Clean tension discs | Weekly |

| Check sewing alignment | Monthly |

| Adjust settings | As needed |

| Monitor thread quality | Per project |

| Service your machine | Annually |

Troubleshooting Tension Issues

Is your fabric puckering or your thread snapping? Let’s troubleshoot those tension troubles and get your stitches looking smooth again.

Identifying Common Tension Problems

So, your fabric and thread choices are sorted. Great!

Now, let’s play detective with your sewing machine tension problems. Notice any thread breakage? Are your stitches uneven or is the fabric puckering?

These are common tension indicators, often caused by thread issues or fabric problems. Don’t worry, troubleshooting these sewing machine tension problems is easier than you think.

Identifying these stitch quality red flags is the first step on the path to perfect seams.

Checking Threading and Bobbin Winding

Scrutinize your threading and bobbin winding like a detective on a case. Is the thread tension happy? Is your bobbin winding tight and even, not a tangled mess?

A smooth, balanced bobbin thread tension is key. Understanding bobbin tension problems is essential for achieving perfect stitches.

Double-check these three common culprits:

1.Correct threading path,

2.Even bobbin winding, and 3. Secure bobbin placement. If these sewing machine tension tools and techniques are off, your stitches will be wonky.

Adjusting Tension for Specific Fabrics

Getting the tension right for different fabric types is like finding the sweet spot with Goldilocks—you need settings that aren’t too tight or too loose.

Heavier fabrics demand higher sewing machine tension settings, while delicate ones need gentler pressure.

Use tools like tension meters and test stitches to adjust thread tension for perfect stitch balance, whatever the fabric density.

Achieving Perfect Stitches

You can’t achieve perfect stitches without consistent tension, the right needle, and a thread that works seamlessly with your fabric.

It’s like baking cookies—if one ingredient’s off, the results just won’t come together!

Importance of Consistent Tension

Consistent tension makes or breaks your sewing projects.

Without proper thread balance, expect puckered fabric or uneven stitches. Tension control keeps stitches smooth and aligned, ensuring sewing precision every time.

Think of it as a tightrope act—too tight, and it snaps; too loose, and it sags. Using sewing machine tension tools helps maintain stitch quality and flawless fabric tension.

Selecting The Right Needle and Thread

Perfect stitches start with the right needle and thread.

Match the needle size and type to your fabric choice—delicate fabrics need finer needles, while heavier materials call for thicker ones.

Pair your needle with thread types and weights that match both fabric and project needs.

High thread quality guarantees even stitch balance and prevents frustration over skipped stitches or breakages.

Choosing The Right Stitch Type

Choosing the right stitch type is like finding the perfect dance partner—it depends on rhythm, fabric, and purpose. Analyze your fabric and match it with the ideal stitch for durability and style:

- Straight stitch: Best for seams and hems.

- Zigzag stitch: Great for stretchy fabrics.

- Overlock stitch: Prevents fraying.

- Decorative stitch: Adds flair.

Understanding the thread types is essential for achieving perfect stitches, as different threads work better with specific stitch types and fabrics.

Always check tension, stitch length, and width!

Maintaining Optimal Tension

You can’t stitch perfectly if your machine isn’t well-maintained, plain and simple.

Regular cleaning, oiling, and proper storage keep your tension balanced and your stitches smooth, saving you hours of frustration.

Regular Machine Maintenance

Keeping stitches flawless starts with regular sewing machine maintenance. Think of it as your machine’s “spa day.”

Daily checks, like clearing lint and inspecting threads, prevent costly sewing machine repair.

Stick to an oil change schedule outlined in your manual, replace worn parts, and use proper sewing machine tools.

Utilizing tension gauge tools is essential for maintaining ideal machine performance.

These simple Machine Cleaning Tips keep tension balanced and costs down.

Cleaning and Oiling The Machine

A well-maintained machine runs like a dream. Regular cleaning and oiling extend its life and keep tension smooth.

Here’s how:

- Brush lint off the bobbin case and feed dogs.

- Use cleaning solutions sparingly to remove grime.

- Apply the right oil types per your sewing machine manual.

- Follow maintenance schedules religiously.

- Keep sewing machine tension tools clean for accurate adjustments.

Proper sewing machine maintenance is key to achieving peak performance and extending the lifespan of your machine.

Storing The Machine and Accessories Properly

Dust’s your machine’s worst enemy, so cover it up! Use dust protection and storage containers for sewing machine tension tools, manuals, and cleaning supplies to avoid chaos.

Keep the sewing machine tension disc, spring, and assembly clean by organizing accessories nearby. A dedicated spot saves effort and prevents frustration—because who wants to hunt for that tiny screwdriver mid-project, and maintain cleaning supplies nearby.

Frequently Asked Questions (FAQs)

What Happens if I Don’t Adjust the Tension?

Skipping tension adjustments is like driving a car with flat tires—you’ll get nowhere fast.

Expect puckered seams, loose threads, uneven stitches, and plenty of frustration.

Adjusting tension keeps your machine’s “sweet spot” intact.

How Do I Know if My Tension is Too Tight or Too Loose?

If stitches bunch up or fabric puckers, your tension’s too tight.

Loose, gappy stitches? It’s too loose.

Test on scrap fabric—always a stitch-saver.

Balanced tension gives smooth, clean stitches without snags or gaps!

What Can I Do if My Tension is Still Not Correct After Adjusting It?

Still wrestling with bad stitches? Double-check your machine’s threading, clean the bobbin case, or switch to a fresh needle.

Sometimes stubborn issues need a pro’s touch—don’t hesitate to call a technician for help!

What is the Best Way to Test My Tension?

Grab some scrap fabric and sew a few test stitches.

Check for even, balanced stitches—no loops or puckers.

Adjust tension gradually based on the results. It’s like fine-tuning an instrument—small tweaks matter!

What Are the Most Common Causes of Sewing Machine Tension Problems?

Did you know improper threading causes 80% of tension problems?

Other culprits include mismatched or poor-quality thread, bent needles, dirty bobbin cases, and incorrect tension settings.

Regular maintenance and precision threading keep your stitches on point.

How do I adjust the tension on my sewing machine?

Turn the top tension dial to tighten or loosen the thread, adjusting slowly.

Test on scrap fabric to spot issues.

For bobbin tension, tweak the tiny screw on the bobbin case—small turns deliver big changes!

How to know what tension to use when sewing?

Don’t let tension drive you nuts—test on scrap fabric first.

Use lighter tension for delicate fabrics and heavier for thick ones.

Aim for balanced stitches where threads lock in the fabric’s middle, not visible loops, with balanced stitches being the goal.

How do you fix loose thread tension?

Loose thread tension feels like trying to zip up a jacket with a broken zipper.

Check threading, clean the machine, adjust the tension dial incrementally, and test on scrap fabric until stitches lie balanced and smooth.

What controls the tightness of the top thread?

Think of the tension dial like your sewing machine’s “volume knob.”

It controls how tightly the top thread is pulled through the machine, balancing it against the bobbin thread for smooth, even stitches.

What tools help measure thread tension precisely?

You can use thread tension gauges or tension test devices to measure thread tension precisely.

These handy tools clip onto the thread path and display tension levels, helping you adjust for smoother, more balanced stitching.

Conclusion

Did you know nearly 80% of stitch issues stem from improper tension?

With the right sewing machine tension tools, like a bobbin tension gauge or thread tension gauge, you can eliminate the guesswork.

Mastering these gadgets guarantees smooth, balanced stitches every time—no surprises or frustrating thread tangles.

Regular maintenance and cleaning keep things running smoothly, so you can focus on creating.

Invest in these tools, fine-tune your machine, and watch your sewing projects come together perfectly with the right sewing machine.