This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

I ruined my first leather belt trying to sew it on a regular machine. The needle snapped, the leather bunched up underneath, and I nearly burned out the motor forcing it through four layers of thick hide. If you’ve ever watched your domestic machine struggle with anything thicker than denim, you know exactly what I’m talking about.

Leather demands serious power, specialized needles with cutting points, and feeding systems that won’t let your material slip around like it’s got a mind of its own. The difference between a standard machine and one built for leather isn’t just about strength—it’s about whether you’ll finish your project or end up with broken equipment and a pile of frustration.

Table Of Contents

Key Takeaways

- You need a machine with at least 1/2 HP motor, all-metal construction, and specialized cutting-point needles (90/14 to 110/18) to handle leather without breaking equipment or producing skipped stitches.

- Walking feet and adjustable presser foot pressure are non-negotiable for feeding thick leather layers evenly without bunching, slippage, or ruining seams.

- Industrial models deliver continuous heavy-duty performance for serious work, while domestic heavy-duty machines like the Janome HD3000 or Singer 4423 handle occasional leather projects at a fraction of the cost.

- Proper setup matters more than the machine itself—use 2.5–3.5 mm stitch length, waxed polyester thread, higher top tension than fabric sewing, and always test on scraps before committing to your project.

Key Features of Sewing Machines for Leather

Look, not every sewing machine can handle leather—trust me, I’ve burned through enough broken needles to know. The right machine needs specific features that standard models just don’t have, and skipping these means frustration and wasted materials.

Here’s what you absolutely need to look for when you’re shopping for a leather-capable machine.

Heavy-Duty Motors and Power

You’ll need serious power to wrestle thick leather into submission. Look for machines with motors rated at least 1/2 HP—that’s your baseline for consistent stitching through heavy hides.

Here’s what separates the pretenders from the real workhorses:

- Torque Control: Industrial sewing machine motors deliver 2.5–6.0 N·m for reliable stitch formation

- Speed Regulation: Servo motors offer smoother control than older clutch systems

- Motor Efficiency: Gear reductions boost low-end torque without bogging down

- Energy Consumption: Thermal protection prevents burnout during marathon sessions

A heavy duty workhorse servo motor with a power speed reducer gives you the muscle to handle whatever project you’re tackling. When writing about these machines, it’s necessary to follow proper research paper guidelines.

Specialized Leather Needles

Power alone won’t save you if your needle can’t pierce cleanly. Leather needles feature a triangular cutting point that slices rather than pushes—sizes 90/14 through 110/18 match your hide thickness. I learned the hard way: skip the ballpoint types.

Stainless steel or carbide-tipped needles paired with bonded polyester thread (92–138 lb break strength) deliver consistent stitch formation. Swap them every 2–3 leather projects to avoid skipped stitches and thread shredding.

Adjustable Presser Foot and Walking Foot

The right needle sets you up, but presser foot pressure seals the deal. Adjustable Presser Foot lets you dial in exactly how firmly your leather feeds—too much bunches it, too little skips stitches. Pair that with a Walking Foot (even feed) and leather layers glide through without shifting, improving Leather Seam Quality on thick hides. To achieve best results, consider the importance of research methodology in sewing projects.

- Foot Pressure Control: Dial adjustments accommodate varying leather thicknesses

- Walking Foot Benefits: Alternating feed dogs advance layers evenly, preventing slippage

- Roller Foot: Teflon-coated options glide over sticky leather surfaces

- Foot Compatibility Issues: Verify shank type before swapping specialized feet

Stitch Length and Width Adjustment

Once your presser foot’s dialed, stitch control becomes your next power move. Leather Thickness demands proper Stitch Length—usually 3.0 to 4.0 mm on Heavy Duty Sewing Machines prevents perforation while maintaining Seam Integrity.

Adjust Thread Tension and test Fabric Feed on scraps before committing. Leather Sewing Machines with precise Sewing Machine Speed Control and Precision let you nail consistent stitching without bunching or skipping.

Durable, All-Metal Construction

Your machine’s skeleton matters more than you’d think. All Metal Construction—frames cast from iron or aluminum alloy—keeps your Heavy Duty Sewing Machines rigid under high torque when punching through multiple leather layers.

Metal Chassis Design means less flex, quieter operation, and Metal Frame Benefits like easier repairs down the road.

Industrial Sewing Machine builders know Durable Machine Parts outlast plastic every time.

Types of Leather Sewing Machines

Not all leather sewing machines are built the same, and picking the wrong type can leave you frustrated or flat-out unable to finish your project. The choice between domestic and industrial models, flatbed versus cylinder-arm designs, and mechanical versus computerized controls makes a real difference in what you can create.

Let’s break down the main types so you know exactly what fits your leather work.

Domestic Heavy-Duty Vs. Industrial Models

When you’re choosing between domestic heavy-duty and industrial sewing machines for leather, the motor comparison comes down to horsepower and duty cycle. Industrial models feature all-metal frame durability that manages continuous heavy-duty sewing, while domestic machines work for occasional projects.

Yes, maintenance costs run higher on industrial sewing machines, but the ownership benefits—like greater power for thick leather—often justify the investment.

Flatbed Vs. Cylinder-Arm Machines

Your workspace and project shape determine whether you need a flatbed or cylinder-arm leather sewing machine. Flatbed configurations give you a large horizontal surface, perfect for handling big panels like upholstery pieces and bags. Cylinder-arm types excel when you’re tackling tubular shapes—sleeves, pockets, curved seams.

- Flatbeds stabilize wide leather panels for even feeding across the work surface

- Cylinder arms navigate around curves and tight spots you can’t reach otherwise

- Heavy duty flatbed models dominate leather sewing for most craftspeople

- Industrial sewing machine cylinder arms shine on boots and cylindrical accessories

Both machine configurations handle thick leather, but flatbeds suit most sewing techniques and fabric handling needs.

Mechanical Vs. Computerized Options

You’ll face a real fork in the road when shopping for a leather sewing machine: mechanical models rely on gears and cams with straightforward hands-on control, while computerized options bring automation benefits like programmable stitch memory and tension regulation.

Cost analysis shows mechanical heavy-duty sewing machines cost less upfront, but computerized industrial sewing machine models deliver consistent results across projects through their user interface—though maintenance costs run higher for electronics.

Applications: Garments, Upholstery, Accessories

Your leather sewing machine choice depends heavily on what you’re actually building. Each application demands specific sewing techniques and heavy-duty sewing capabilities to handle unique challenges in leather crafting, upholstery tips, and accessory making.

Here’s how garment construction and leather sewing machines align with different projects:

- Garments: Need flexible stitch quality, 90–110 needles, smooth curved seams

- Upholstery: Require walking feet, 3–4 mm stitch length, large panel feeding

- Accessories: Demand tight stitches, reinforced stress points, precision presser feet

- Hardware Integration: Compatible feet for grommets, rivets in sewing leather

- Edge Finishing: Post-stitch burnishing, edge paint for professional results

Top 5 Sewing Machines for Leather

After years of breaking needles on my regular machine, I learned the hard way that not all “heavy-duty” models can actually handle leather. The right machine makes all the difference between smooth, professional seams and a frustrating pile of skipped stitches.

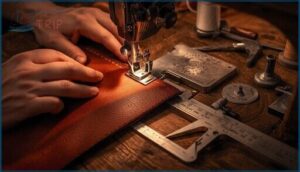

The right sewing machine transforms leather work from frustrating skipped stitches into smooth, professional seams

Here are five machines I trust for leather work, from beginner-friendly options to serious workhorses.

1. Janome Heavy Duty Sewing Machine

View On Amazon

View On Amazon You won’t find a better match of power and control than the Janome HD3000. This heavy-duty sewing machine punches through thick leather like it’s canvas, thanks to a motor that pulls around 1000–1200 watts.

The all-metal frame keeps vibrations down when you’re stacking multiple leather layers, and the sewing speed hits roughly 900–1,000 stitches per minute.

For serious leather stitching without industrial price tags, Janome’s heavy-duty sewing delivers exactly what leather sewing machines should: zero compromise.

| Best For | Sewers who need a reliable machine that can handle heavy fabrics like leather, denim, and canvas without breaking the bank on industrial equipment. |

|---|---|

| Built-in Stitches | 14 |

| Material Construction | Aluminum/Metal |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | 4-step |

| Free Arm | Yes |

| Weight | 23 lbs |

| Additional Features |

|

- Powerful 1000–1200W motor tackles thick leather layers and heavy-duty materials that would stall weaker machines

- All-metal frame construction keeps the machine stable and reduces vibration when working with dense fabrics

- Fast stitching speed of 900–1,000 stitches per minute lets you finish projects quickly without sacrificing control

- Only 14 built-in stitches, which is limiting if you want decorative options beyond basic utility stitches

- Weighs 23 pounds, making it awkward to move around or store if you don’t have a dedicated sewing space

- No automatic tension adjustment means you’ll need to dial it in manually for different fabric weights

2. Singer Commercial Sewing Machine Model

View On Amazon

View On Amazon If you want industrial-grade motor power without the industrial price tag, the Singer 4423 Heavy Duty sewing machine delivers 1,100 stitches per minute through leather that would choke lesser models. Machine durability matters when you’re pushing seams through garment-weight leather day after day, and Singer’s heavy-duty construction manages it.

You’ll appreciate the stainless steel bed plate—it doesn’t warp when you’re feeding thick hides for hours. The four-step buttonhole might seem basic, but leather sewing machine reviews consistently praise its reliability over fancier computerized options.

| Best For | Sewers who need to tackle heavy fabrics like leather and denim regularly without spending thousands on a true industrial machine. |

|---|---|

| Built-in Stitches | 18 |

| Material Construction | Stainless Steel |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | 4-step |

| Free Arm | Not specified |

| Weight | Not specified |

| Additional Features |

|

- Blazing fast at 1,100 stitches per minute with enough motor power to handle thick leather layers consistently

- Stainless steel bed plate stays flat and smooth even during long sessions with heavy materials

- Drop feed capability lets you switch to free motion work for quilting or creative leather projects

- Gets pretty loud at high speeds and vibrates noticeably when pushing through thick fabric

- Only 90 days of warranty coverage on parts feels short for a machine marketed as heavy-duty

- Cramped needle insertion area and weak lighting make threading and setup harder than it should be

3. Toyota Heavy Duty Sewing Machine

View On Amazon

View On Amazon Toyota’s heavy duty platform brings that 15-pound all-metal frame you’ll lean on during heavy duty sewing sessions. When machine comparison matters, you’re looking at adjustable stitch width and length controls that handle everything from thin suede to thick belt leather—no plastic drive gears giving out mid-project like cheaper models.

The walking foot compatibility matters for leather projects, especially when you’re tackling upholstery corners. Just know their customer service trails Singer’s, so stock up on leather sewing machine needles and maintain it yourself following basic maintenance tips.

| Best For | Sewers who need a sturdy machine that can handle both heavy-duty leather projects and delicate fabrics without switching equipment. |

|---|---|

| Built-in Stitches | Multiple options |

| Material Construction | Metal |

| Automatic Needle Threader | No |

| Buttonhole Feature | Available |

| Free Arm | Not specified |

| Weight | 15.1 lbs |

| Additional Features |

|

- 15-pound all-metal frame provides excellent stability when working with thick materials like denim and leather

- Adjustable stitch width and length controls let you customize settings for different fabric weights, from thin chiffon to heavy belt leather

- Walking foot compatibility makes it easier to feed leather evenly through the machine, especially useful for upholstery work

- Stitch selector knob has a tendency to break or become loose with regular use

- Plastic drive gear raises durability concerns for frequent or heavy-duty projects

- Customer service from the manufacturer (Aisin) is often unresponsive, so you’ll likely need to handle maintenance and repairs yourself

4. Singer Heavy Duty Sewing Machine

View On Amazon

View On Amazon Singer’s Heavy Duty 4432 hits 1,100 stitches per minute, which matters when you’re cranking out leather projects on deadline. That metal frame won’t vibrate across your worktable like plastic housings do during heavy-duty sewing.

You’ll work with 110/18 needle compatibility for thick hides, though tension adjustments take some trial runs on scrap leather. The Singer Machine manages multiple layers without stalling, but that sensitive foot pedal gets touchy during slow, controlled leather sewing when precision matters most.

| Best For | Sewers who need speed and power for tackling thick fabrics and leather projects without spending industrial-machine money. |

|---|---|

| Built-in Stitches | 97 |

| Material Construction | Metal frame |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | One-step |

| Free Arm | Not specified |

| Weight | 17.1 lbs |

| Additional Features |

|

- Blazing 1,100 stitches per minute with a metal frame that stays put during heavy work

- Handles thick leather and multiple layers with needle compatibility up to 110/18

- Automatic needle threader and 97 stitch options make it versatile for different projects

- Foot pedal sensitivity makes slow, controlled stitching tricky on leather

- Thread tension and bobbin jams reported by multiple users

- Instruction manual lacks detail, especially for leather-specific techniques

5. Brother Heavy Duty Sewing Machine

View On Amazon

View On Amazon Brother’s ST371HD runs 800 stitches per minute with enough torque for garment leather and accessory work, though it lags behind higher-speed options for production leather stitching. That metal needle plate manages heavy-duty motors without flex, and the automatic threader saves frustration during long leather crafting sessions.

You’ll find 37 stitch options excessive for leather sewing—straight stitches do most work—but the free arm helps with bag construction. Regular machine maintenance and proper needle selection keep this workhorse reliable for midweight projects without industrial price tags.

| Best For | Sewers who tackle garment leather, accessories, and thick fabrics but don’t need industrial-level speed or advanced features. |

|---|---|

| Built-in Stitches | 37 |

| Material Construction | Metal |

| Automatic Needle Threader | Yes |

| Buttonhole Feature | Auto-size |

| Free Arm | Yes |

| Weight | 18.4 lbs |

| Additional Features |

|

- Metal construction and 800 SPM motor handle leather, denim, and heavy fabrics without bogging down

- Automatic needle threader and drop-in bobbin cut setup time on multi-hour leather projects

- Free arm design simplifies bag construction and cylindrical leather pieces like cuffs

- 37 stitches feel redundant when leather work relies almost entirely on straight stitching

- Non-interchangeable bobbins with other Brother models force you to stock separate supplies

- Some users report pedal overheating issues and limited customer support responsiveness

Essential Tips for Sewing Leather

You’ve got your machine, but here’s the thing—sewing leather isn’t the same as stitching cotton. The right needle, thread, and tension settings make the difference between a project that holds up for years and one that falls apart in weeks.

Let me walk you through the essentials that’ll save you from costly mistakes and keep your machine running strong.

Choosing The Right Needle and Thread

Your needle selection makes or breaks leather sewing. I always reach for leather needles sized 90 to 110—tapered or wedge points slice through without tearing.

Match your leather thread thickness to the hide: 0.9–1.2 mm waxed polyester gives you strength and fabric compatibility. Test on scraps first to nail stitch tension before committing to your project.

Adjusting Tension and Stitch Settings

Balance your tension between needle and bobbin—that’s where leather sewing precision starts.

I crank top tension higher than for woven fabrics and set stitch length between 2.5 and 3.5 mm depending on leather thickness.

Test on scraps, adjust in tiny steps, and watch for flat backstitches. If threads loop on top, tighten; if they show underneath, loosen slightly.

Using Walking or Teflon Feet

Switching to a walking foot or Teflon foot transforms how you sew leather—no more wrestling with sticky surfaces or puckered seams.

Here’s what these attachments fix:

- Walking mechanism feeds top and bottom layers at the same rate, eliminating slippage on belts and upholstery.

- Nonstick surfaces prevent leather from dragging or sticking during stitching.

- Reduced foot pressure keeps delicate exotic leathers from scuffing.

- Smoother leather feed through multiple thick layers without bunching.

- Leather foot sets offer specialized options for different project types and thicknesses.

Maintenance and Care for Longevity

Your machine won’t last without consistent care—leather dust and debris kill motors faster than you’d think. Oil mechanical parts every 8–12 hours of use, replace needles after each project, and wipe down feed dogs weekly.

Thread selection matters too; synthetic options reduce friction and prolong tension assembly life.

Schedule professional service annually to catch wear before it becomes expensive downtime.

Frequently Asked Questions (FAQs)

What kind of sewing machine is best for leather?

You need a machine built to punch through thick hides without flinching—think heavy-duty motors, walking feet for smooth feeding, and all-metal construction that won’t buckle under pressure.

Do you need a special sewing machine to sew leather?

You don’t absolutely need a special leather sewing machine for thin hides, but thicker leather demands higher torque, reinforced feed systems, and heavy-duty construction that standard domestic machines just can’t deliver consistently.

Is it better to sew leather by hand or machine?

For delicate leather crafting and sewing, hand sewing techniques give you superior sewing precision on curves.

But when leather thickness climbs or you need consistent leather stitch quality across bigger projects, machine versatility wins every time.

Can a heavy duty sewing machine sew leather?

Yes, with the right needle selection and machine configuration, heavy-duty sewing machines handle medium-thickness leather beautifully. This is especially true when you pair them with proper stitch quality settings and a walking foot for smooth feeding.

What leather needle size should I use?

Most sewers overthink needle selection, but it’s simpler than you’d expect. For common 3–4 oz leather, a 90/14 works perfectly. Thicker hides demand 100/16 or 110/18 to guarantee proper stitch formation without skipping.

Can I sew suede on a leather machine?

Most leather machines handle suede beautifully with a walking foot and proper needle size. Adjust tension and stitch length, test on scraps first, and you’ll avoid nap damage while getting clean, professional seams every time.

How do I prevent leather sticking?

Ever fought sticky leather jamming mid-stitch? Swap to a Teflon Foot or Walking Foot, drop your presser pressure, and use Leather Needles with waxed thread. Light nonstick sprays on fabric help too.

Whats the best stitch length for leather?

For most leather sewing projects, aim for a stitch length between 5 and 0 mm. Thicker hides need shorter stitches around 0–5 mm for seam strength, while lighter leathers work well at 5 mm.

How often should I change my leather needle?

After every 1,000 stitches or when you notice skipped stitches and thread fraying, swap your needle.

Thicker hides demand more frequent changes to maintain stitch quality and protect your leather sewing machine.

Can I sew leather with a regular machine?

You can sew thin leather (under 5 mm) on a regular machine with proper needles and a walking foot, but thicker hides demand a heavy-duty or industrial leather sewing machine for reliable stitches.

Conclusion

Leather doesn’t lie—it’ll expose a weak machine faster than you can say “broken needle.” Now that you know what separates struggling domestic models from machines that actually handle thick hides, you’re ready to pick the best sewing machine for leather that matches your projects.

Whether you’re stitching belts, bags, or upholstery, the right equipment transforms frustration into clean, professional seams. Stop fighting your tools and start creating work you’re proud to show off.

- https://onlinepubs.trb.org/onlinepubs/nchrp/cd-22/manual/v1appendixb.pdf

- https://www.writingclearscience.com.au/category/writing-guides/writing-research-papers/page/2/

- https://academichelpexpress.blog/2024/08/please-use-the-bulleted-points-and-the-rubric-below-to-guide-your-work-your-pa/

- https://x.com/godofprompt/status/1990526288063324577

- https://www.linkedin.com/posts/bohdanlukianets_tasks-study-research-activity-7373377539521667072-UTEi