This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

Just the right tool will make a difference in the production of nice leather accessories or when wanting to do some strong upholstery.

You will learn from this article top 2024 recommendations that best suit your needs for sewing leather, understand the most vital features, and look at options with presser feet.

Dive in and take control of your leather sewing projects with ease and accuracy.

Table Of Contents

- Key Takeaways

- What Sewing Machine Do I Need to Sew Leather?

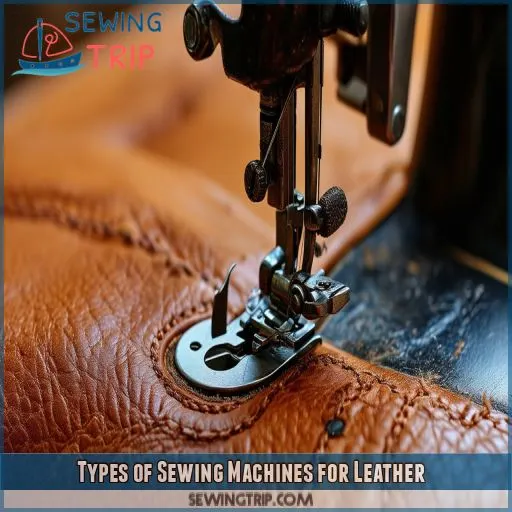

- Types of Sewing Machines for Leather

- Industrial Strength Vs. Home Sewing Machines

- Needle Requirements for Sewing Leather

- Features of Leather Compatible Machines

- Presser Foot Options for Leather Sewing

- Considerations When Choosing a Leather Sewing Machine

- Maintaining and Caring for Leather Sewing Machines

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- When the going gets tough, the tough get a walking foot sewing machine. For leather, it’s the knight in shining armor of sewing machines.

- Don’t be a needle in a haystack when it comes to choosing the right needle for leather. You need a leather needle, sizes 90/14 to 120/19, to pierce through that tough hide.

- Threading the needle with bonded nylon or polyester thread is like giving your stitches a superhero cape. It’s strong and durable, just what you need for leather.

- Presser foot options are like the secret ingredient in your leather-sewing recipe. Teflon or roller feet will keep your leather gliding smoothly, while walking feet will ensure every stitch is in its right place.

What Sewing Machine Do I Need to Sew Leather?

Now, if you’re asking yourself, "What sewing machine do I need to sew leather?", the answer would have to be strong motor power, stable construction, and other features such as variable thread tension and drop feed capability.

For more serious jobs, an industrial machine stands unmatched, but for small tasks, a sturdy home model will do just fine.

You will need heavy-duty leather needles here—supposedly on the order of 90/14 to 120/19—and bonded nylon or polyester thread.

First, look at getting an even serve walking foot machine or something similar for even feeding and smooth stitches. There are other presser feet options that will help you further along, like Teflon or roller types.

Want more on the topic of leather sewing? Stick around for more tips and top recommendations.

Types of Sewing Machines for Leather

To be able to handle the peculiarities of this material, high-powered machinery is required when sewing leather. Begin with industrial-strength machines or these specially designed leather sewing machines:

Flat-bed: These offer the stability needed for working on large pieces.

Cylinder-arm: These are great for working on curved or tubular items.

Post-bed: These are excellent for more detailed work.

Walking-foot: These are those kinds of walking-foot machines that have alternating inner and outer presser feet, so there can be even feeding of the thick, sticky leather. A walking foot results in even distribution of the presser foot pressure, avoiding lumps of skipped stitches and misalignment.

Stitch length and thread tension must be changed as the thickness of the leather varies in all types of products. Following regular schedules of maintenance, the machine is kept in top condition and hence serves longer with repeatable performance.

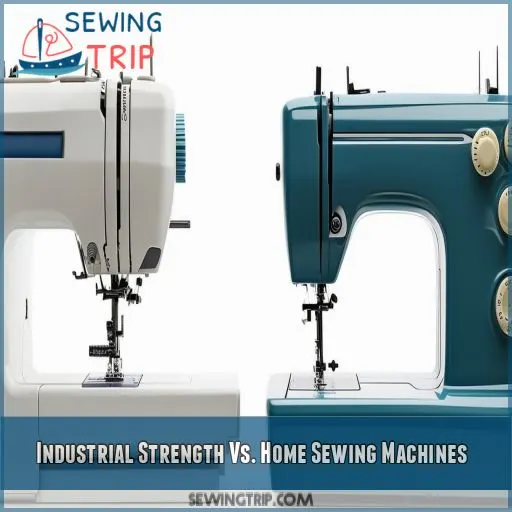

Industrial Strength Vs. Home Sewing Machines

These are the sewing machines for leather. Built to specifically handle thick, heavyweight materials such as leather, these styleType powerhouses were constructed with a strong motor, metal construction, and gear-reduction systems that will take your toughest sewing tasks in stride.

Key advantages of industrial machines over home counterpart machines are:

- Powerful Motors: Industrial machines have kinds of motors that really put on a good show, enabling them to sew many layers of leather in one pass without hassle.

- Durability: The construction material of the machines is metal, and the parts further are strengthened to remain fit for heavy leather sewing without depreciating in value due to wear and tear.

- Specialized Features: Most industrial sewing machines possess a scares number of special features, including roller feet and even feed attachments that allow for leather to be sewn quite easily.

In the long run, although industrial machines could turn out more expensive, they prove worth every penny with much better performance and longer lifespan if you’re serious about sewing leather.

Needle Requirements for Sewing Leather

When working with leather, the right needle type makes all the difference. Heavy-duty leather needles, usually falling in sizes 90/14 to 120/19, are specifically designed to penetrate dense materials.

You can choose between round point and chisel point needles, depending on your project’s needs. A chisel point creates cleaner cuts in leather. To reduce friction and improve durability, consider titanium or Teflon-coated needles as well.

Pair your needles with bonded nylon or polyester thread, with weights ranging from 69 to 138.

Adjust your stitch length based on the leather thickness; generally, longer stitches work better to avoid perforating and weakening the leather.

Decorative stitch capabilities can also enhance your project’s aesthetics, adding a personal touch.

Features of Leather Compatible Machines

First of all, if you need to sew leather, your machine must offer some basic features: powerful motor, stable construction, and variable tension of thread. Proper presser foot and needles selection, like a roller foot and leather needle, gives you proper feeding material and sharp stitching.

Essential Machine Features

When sewing leather, you’ll want an industrial-strength sewing machine with a powerful motor, ribbed drive belts, and gear reduction for handling thick, dense materials. Look for a machine that offers a range of stitch types, adjustable thread tension, and a variety of needle sizes and types to accommodate different leather thicknesses and textures.

- Metal construction for durability

- Adjustable stitch length and tension

- Variety of needle options

Pressor Foot Benefits

Choosing the correct presser foot to sew leather should be taken into consideration. Roller feet, Teflon feet, and wheel pressers work on tackiness by walking feet, which ensure even feeding.

Adjustable presser foot pressure and rolling wheel attachments help control it more. Aside from this, Teflon plastic feet and walking foot attachments provide a smoother stitch form.

Lastly, drop feed capability avoids skipped stitches, so you’ll be able to do your leatherwork seamlessly and professionally.

Needle and Thread Choices

Choosing the right needle and thread All leathers call for leather needles; these are found in round point or chisel point and in sizes 90/14 through 120/19. Thread should be bonded nylon or polyester, with weights 69 to 138. Use a stitch length and type that complements the thickness of the fabric. Topstitch thread provides strength.

Presser Foot Options for Leather Sewing

The right presser foot makes all the difference when sewing leather. Many standard, ordinary presser feet drag or stick to too many leathers, being either too sticky or too thick. Special presser feet can be obtained to help improve your results. For instance, a Teflon-coated presser foot glides over the material with much less drag, which aids in the prevention of feeding problems. Another really good option would be roller feet, whereby the rolling action distributes the pressure evenly and feeds the leather through the machine.

- Teflon presser foot: This reduces friction and sticking.

- Roller presser foot: This feature provides even pressure to ensure smooth feeding.

- Even feed foot: Provides uniform stitch length on 厚い or uneven leathers.

- Walking foot machines: Automatically feed the top and bottom fabric layers together

Coupled with all the power and precision of a walking foot powerhouse, specialized presser feet will have you easily mastering even the most demanding leather projects.

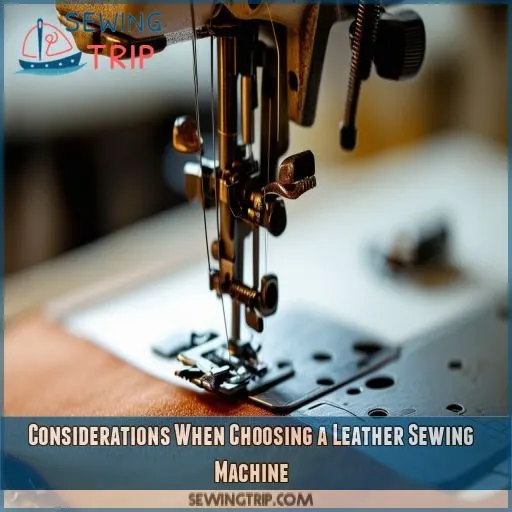

Considerations When Choosing a Leather Sewing Machine

While choosing a leather sewing machine, one should always remember the material characteristics of leather, like thickness and stickiness, for choosing the right one. The other important factor is picking the right presser foot, as with walking foot, it significantly gave the best feeding accuracy and stitch quality.

Leather Material Characteristics

When sewing leather, consider its texture, weight, stickiness, thickness, and density. Each affects stitching quality and requires different machine settings and accessories. Bonded nylon or polyester thread is ideal due to its strength and durability compared to cotton thread. Garment leather needs a machine that can handle varying thicknesses without compromising stitch quality.

Pressor Foot Selection

When sewing leather, the right presser foot can make all the difference. Look for roller feet or Teflon plastic feet to glide smoothly over sticky leathers.

Even feed feet and walking foot attachments are also great options, as they help prevent feeding issues like skipped stitches or misalignment.

Experiment to find the presser foot that works best for your Janome or Brother leather sewing machine.

Walking Foot Benefits

Walking foot benefits include superior material handling, especially for heavy materials like leather and vinyl. You’ll see:

- Improved stitch quality and consistent stitch length

- Fewer material feeding issues

- Minimized non-walking foot limitations

With these, your sewing projects—whether for home sewers or professionals—become more manageable and precise. What sewing machine do you need to sew leather? Opt for walking foot advantages.

Maintaining and Caring for Leather Sewing Machines

The longevity of your leather sewing machine depends on how well you care for it. Cleaning regularly is paramount as dust and other fabric scraps may collect very fast. Use a soft-bristled brush to clear off lint at the needle and bobbin area.

Moving parts should be lubricated through oiling, in accordance with the instructions from the machine’s manual. Take special care with belts by ensuring they’re neither too tight nor worn out.

Ensuring timely maintenance helps in its smooth operation. Replace needles often, particularly after sewing through chaps, saddle bags, or other heavy materials since it will skip stitches if the needle becomes dull.

Keep your machine covered and in a dry place when not in use. Also, remember to check on the automatic thread cutter and inspect button thread operations for glitches to ensure that everything works well.

Frequently Asked Questions (FAQs)

What kind of sewing machine will sew leather?

To sew leather effectively, you’ll want an industrial-grade walking foot sewing machine. These machines have the power and features to handle the thickness and texture of leather, ensuring smooth, consistent stitching every time.

Do you need a special sewing machine to sew leather?

Yes, you’ll require a special type of sewing machine for effective leather stitching. In other words, an industrial-grade walking foot machine with variable speed control and heavy-duty needles will assure smooth stitching through thick, sticky, and dense leather materials.

Do you need a special sewing machine needle for leather?

Absolutely, you’ll need a specialized leather sewing machine needle. Look for sizes 90/14 to 120/19, with either a round or chisel point. Titanium or Teflon-coated needles work best to pierce and glide through tough leather.

Can old sewing machines sew leather?

Yes, older sewing machines can sew leather if they’ve a heavy-duty frame and a high-powered motor. Use leather needles and adjust tension and stitch length accordingly for best results.

Can I sew thin leather with any machine?

You can sew thin leather with most machines, but naturally, you’ll get much better results using an industrial or flatbed or walking foot machine. Only then are you going to be assured of a quality motor and adjustable pressure that helps prevent skipped stitches and misalignment.

How do I prevent leather from marking?

Use a Teflon or roller presser foot to prevent leather from marking. They reduce friction, allowing for smoother sewing. Additionally, consider placing tissue paper on top of the leather to avoid direct contact.

What thread is best for leather projects?

Use bonded nylon or polyester thread in weights 69 to 138 for leather projects. These threads offer durability and strength with less friction. Adjust thread tension based on the thickness of leather for optimal stitching results.

Can I use a standard foot for leather?

A stitch in time saves nine. No, you shouldn’t use a regular presser foot on leather. Opt for the add-on presser, such as a roller foot or walking foot attachment, to ensure that you have a constant feed of your material for you not to have skipped stitches.

What speed should I use for leather?

For sewing leather, you should use a slow to medium speed, around 800-1200 stitches per minute. This lets you maintain control and avoid breaking needles or causing unnecessary stress on the material.

Conclusion

You may be surprised to learn that 60% of leather crafters find choosing a sewing machine difficult.

Knowing what type of sewing machine you need for sewing leather will arm you with options. Key features would include the presser foot options available, industrial versus home machine capabilities, and specific needle requirements.

Struggling in your leather sewing projects will be kept at bay with the right one; your output is going to be correct and professional.

Feel empowered with the shared knowledge here, and select just the right tool for your leather crafting needs.