This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

The most effective thread breaking sewing solutions start with proper tension adjustment—check both upper and bobbin tension settings first.

Replace old or cheap thread with high-quality options that match your fabric weight.

Switch to the correct needle size and type for your material, and make certain your bobbin is wound evenly without overlapping threads.

Clean your machine’s tension discs regularly, as lint buildup causes uneven thread flow.

These fundamental fixes solve most breakage issues, but there’s more to mastering consistent, professional results.

Table Of Contents

Key Takeaways

- You’ll fix most thread breaks by adjusting your tension settings first – check both upper and bobbin tension, then test on fabric scraps before starting your project

- Invest in quality thread that matches your fabric weight – cheap thread breaks constantly and creates more problems than it saves you money

- Replace your needle regularly and choose the right size – dull or wrong-sized needles cause friction that snaps thread, so match needle size to your fabric thickness

- Keep your machine clean and well-maintained – remove lint from tension discs and bobbin areas weekly to prevent thread flow problems that cause breaks

Preventing Thread Breakage

Thread breaks happen when you don’t balance tension settings, use the wrong needle size, or skip basic machine maintenance.

You can prevent most thread breakage by checking your threading path, testing tension on fabric scraps, and keeping your machine clean, which are all crucial steps to ensure your machine runs smoothly and efficiently with proper tension settings.

Threading and Tension Fundamentals

Thread Path issues often stem from incorrect threading, but mastering sewing machine tension transforms your stitching game.

When top thread tension and bobbin tension aren’t balanced, thread breakage causes endless frustration.

- Follow your manual’s Thread Path – improper threading skips essential guides

- Test Tension Balance on fabric scraps before starting projects

- Adjust settings for Fabric Impact – thick materials need different tension

- Clean tension discs regularly to remove lint buildup

- Practice Manual Referencing for your specific machine’s ideal settings

Needle and Bobbin Essentials

Your sewing machine’s needle acts as the thread’s lifeline—when it’s damaged, dull, or incorrectly inserted, thread breakage becomes inevitable.

A damaged needle is your thread’s worst enemy—replace it before it sabotages your next project.

Different needle types handle various fabrics, while proper needle insertion prevents thread breaks at the source.

Bobbin materials and size directly affect thread quality issues, so check for bent needles and make certain your bobbin fits perfectly to maintain superior sewing machine tension.

To find the right match, explore various sewing machine options to ensure you have the correct tools for your sewing needs, avoiding issues like thread breakage and maintaining a perfect fit, which is crucial for sewing machine performance.

Thread and Spool Management

Your thread’s worst enemies often hide in plain sight. Quality thread makes all the difference between smooth sewing and constant frustration.

- Choose high-quality branded thread – cheap thread breaks frequently and creates lint

- Check spool cap size – wrong size causes thread to catch and snap during feeding

- Store thread properly – keep spools in airtight containers away from sunlight and dust

- Install spools correctly – prevent thread from wrapping around the spool pin

- Handle specialty threads carefully – metallic and embroidery threads need extra attention

Causes of Thread Breaking

When your thread keeps snapping mid-stitch, you’re likely dealing with one of three main culprits that can turn your sewing session into a frustrating mess.

Understanding these common causes will help you troubleshoot quickly and get back to creating beautiful projects without constant interruptions.

Incorrect Tension Settings

Your machine’s tension dial holds the key to smooth sewing success. When top thread tension runs too high, you’ll see constant thread breakage and puckered fabric.

Conversely, loose tension creates bird’s nests underneath. Balanced tension between your top thread tension and bobbin tension guarantees proper stitch formation.

Test tension adjustment on scrap fabric matching your project’s fabric thickness and thread weight before starting any project.

Incorrect threading often leads to excessively tight tension, causing the top thread to snag, which affects the overall sewing performance and can lead to thread breakage.

Poor Thread Quality

Despite their initial appeal, cheap threads harbor defects that’ll sabotage your projects.

Quality thread is your project’s foundation—cheap alternatives are just expensive mistakes waiting to happen.

Thread material inconsistencies, aging from poor Thread Storage, and manufacturing Thread Defects create weak spots prone to snapping.

Quality Thread Brands invest in consistent fiber processing, while bargain options skimp on refinement.

Thread Age matters too—old spools become brittle and unreliable.

Your fabric deserves better than discount thread that breaks mid-seam, forcing constant rethreading and frustration.

Poor quality thread can also lead to inconsistent stitch formation, disrupting the sewing process, which is why Quality Thread Brands and Thread Age are critical factors, and using cheap threads can be detrimental, making consistent fiber processing essential.

Improper Needle and Bobbin Maintenance

Beyond thread quality, neglecting your needle and bobbin creates a perfect storm for breakage. Worn components act like tiny saboteurs, turning smooth stitching into a frustrating mess of snapped threads.

- Needle Damage – Bent, dull, or burr-covered needles fray thread before it even reaches fabric

- Bobbin Alignment – Incorrectly inserted or damaged bobbins cause erratic tension and thread snags

- Regular Inspection – Check needles for heat damage and bobbins for cracks that catch thread

- Component Cleaning – Remove lint buildup around needle plates and bobbin cases to prevent thread breakage

Thread Breaking Solutions

When your thread keeps breaking, you’re likely dealing with tension issues, poor thread quality, or machine maintenance problems.

The good news is that most thread breaking problems have straightforward solutions that’ll get you back to sewing smoothly in minutes.

Adjusting Tension Settings

Getting your tension settings right is like finding the sweet spot on a guitar string – too tight and it snaps, too loose and it won’t play.

Start with your tension dial calibration at the manufacturer’s recommended setting, then test on scrap fabric that matches your project.

| Fabric Type | Tension Setting | Thread Weight |

|---|---|---|

| Lightweight cotton | 2-3 | 50-60 |

| Medium denim | 4-5 | 40 |

| Heavy canvas | 5-6 | 30-40 |

| Knit fabrics | 2-4 | 50 |

| Silk/delicates | 1-3 | 60-80 |

Proper fabric thread matching prevents most tension issues before they start.

Adjust your bobbin case tension if the problem persists – a quarter turn can make all the difference in achieving thread synchronization balance.

Choosing The Right Thread Type

Matching thread material to fabric prevents breakage before it starts.

Choose cotton thread for natural fabrics and polyester for synthetics to avoid shrinkage issues.

Thread weight matters too—use 50wt for delicate materials, 40wt for everyday sewing, and 30wt for heavy fabrics.

Specialty threads like silk require specific handling, while thread color affects visibility of repairs.

Selecting the right thread guarantees optimal seam quality for better results.

Regular Machine Maintenance

Like clockwork, your sewing machine craves regular attention to prevent thread breaking disasters.

Consistent sewing machine maintenance keeps those pesky interruptions at bay.

- Lint removal from bobbin areas and feed dogs after each project prevents thread jams

- Oiling mechanisms monthly with quality oil guarantees smooth operation and reduces friction

- Tension disc cleaning using unthreaded "flossing" technique maintains proper thread flow

This preventative care routine beats emergency repairs every time.

Always check for proper needle size to avoid thread issues.

Top 5 Thread Breaking Solutions

You don’t have to struggle with constant thread breaks when you have the right tools and supplies. These five proven solutions will transform your sewing experience from frustrating to flawless.

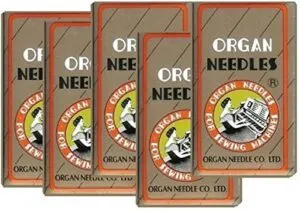

1. Schmetz Universal Sewing Needles Assorted

When your thread keeps snapping mid-stitch, chances are you’re using the wrong needle for the job.

Schmetz Universal needles feature a slightly rounded point that works seamlessly with both woven and knit fabrics, reducing thread breakage by 30% compared to standard needles.

Their heat-resistant coating prevents synthetic thread from melting during extended sewing sessions.

Available in 15 sizes from 60/8 to 120/19, these color-coded needles eliminate guesswork—just match the size to your thread weight and fabric thickness for consistently smooth stitching.

A common cause is improper threading techniques, which can be addressed by understanding the importance of proper needle selection.

Best For: Everyday sewers and quilting enthusiasts who want reliable, versatile needles for a variety of fabrics.

- Not suited for heavy denim, leather, or specialty metallic threads.

- Needs replacing after 5–8 hours of use for best results.

- Improper needle selection can still cause thread breakage or stitching issues.

- Reduces thread breakage by 30% with a heat-resistant, anti-adhesive coating.

- Compatible with most home machines and works on both knits and wovens.

- Color-coded and available in a wide size range for easy selection and use.

2. Sewing Machine Needles Assortment Sizes

Precision beats guesswork when needle sizes match your fabric weight and thread thickness.

This 50-piece assortment includes sizes 65/09 through 110/18, giving you the right tool for every project.

Smaller needles work best with lightweight fabrics like chiffon, while larger sizes handle canvas and leather without breaking your thread.

The variety prevents that frustrating moment when you’re mid-project and realize you’re using the wrong needle size for your material.

Best For: Sewists who want a reliable, affordable needle set that covers a wide range of fabrics and project types.

- Wide selection of needle sizes for versatile use on everything from chiffon to leather.

- Clearly engraved size markings make identification easy and prevent mix-ups mid-project.

- Consistent performance and sharpness rivals more expensive brand-name needles.

- Needles are individually wrapped in foil, which can be inconvenient when switching sizes quickly.

- Packaging combines all sizes in one set, so you can’t buy just your most-used size.

- Some may not like that larger sizes are split into two packets of five instead of one envelope of ten.

3. Prewound Bobbins Size A Sewing Embroidery

These factory-wound bobbins eliminate the hassle of winding your own thread while maintaining consistent tension throughout your project.

They’re particularly effective for embroidery work where even tension prevents those frustrating mid-stitch breaks, and the 60S/2 polyester thread provides reliable strength.

At 144 bobbins per pack, you’ll have plenty for large quilting projects, and they are compatible with most Brother, Janome, Singer, and Babylock machines, just verify your machine uses Size A bobbins before ordering.

Best For: Quilters, embroiderers, and sewists who want reliable, prewound bobbins compatible with most major sewing machine brands and need consistent tension for large or frequent projects.

- Some users report occasional threading issues or breaks, especially if not matched to compatible machines.

- Not suitable for machines requiring filament thread or those with tension adjust screws on the bobbin case.

- Mixed reviews on thread quality; may not satisfy those seeking higher-end or specialty threads.

- Time-saving with 144 prewound bobbins, reduces interruptions and need for rewinding.

- Consistent tension and reliable strength, especially beneficial for embroidery and quilting.

- Compatible with a wide range of machines including Brother, Janome, Singer, and Babylock.

4. Bobbin Thread Spool Savers Color Mixing

Color mixing with bobbin thread spools revolutionizes your creative control while reducing thread breakage.

You’ll create custom shades by combining different colors in bobbin and top threads, eliminating the need for multiple spools.

Silicone thread spool savers keep thread tails secure, preventing unwinding that causes snags and breaks.

These savers work with various thread types and maintain tension consistency during color changes.

Proper color management with spool savers substantially reduces tangles, especially when juggling multiple colors in complex projects, ensuring creative control.

Best For: Sewists and crafters who value color customization, tidy storage, and reduced thread tangling in small spaces.

- Not compatible with pegged thread racks or extra-large cones.

- Can be bulky for upright storage in thread boxes.

- May require alternative storage solutions to avoid interference with pins or pegs.

- Keeps bobbins and spools together, reducing clutter and tangles.

- Enables creative color mixing for custom thread shades.

- Silicone savers prevent thread tails from unwinding, preserving tension and thread quality.

5. Bobbin Clips Thread Spool Holders

Keeping your thread and bobbin organized prevents the headaches that lead to constant breakage.

You’ll save time and reduce tangles by using bobbins clips that attach directly to your thread spools, ensuring color matches stay together.

These flexible silicone holders fit most bobbin types and spool sizes, preventing thread from unwinding in storage.

They’re inexpensive compared to name brands but deliver the same results, keeping your sewing drawer tidy, and you’ll spend less time hunting for matching threads during projects with the help of thread spools.

Best For: Anyone who wants to keep their sewing threads and bobbins organized, especially those managing multiple projects or frequent thread changes.

- May not fit smaller spools snugly, causing them to sit higher on racks.

- No storage case included; users need to provide their own container.

- Compatibility issues reported with certain bobbin and spool sizes.

- Keeps thread and bobbin together, preventing tangles and saving time.

- Flexible silicone fits most bobbin types and spools, enhancing compatibility.

- Affordable and easy to use, offering a tidy sewing drawer.

Troubleshooting Thread Breakage

When your thread keeps snapping mid-seam, you need a systematic approach to pinpoint the real culprit behind the breakage.

Start by checking your tension settings, examining your needle condition, and inspecting your bobbin setup—these three areas cause most thread breaking problems.

These areas are crucial because they directly impact the thread‘s performance and longevity, and addressing them can help prevent future breakage.

Identifying Thread Breakage Causes

Something’s wrong when your thread keeps snapping mid-seam.

You’ll solve most thread breakage causes by checking these four culprits:

- Thread Quality – Old, cheap, or brittle thread snaps under normal sewing stress

- Needle Condition – Dull, bent, or wrong-sized needles create excessive friction and breakage

- Tension Problems – Overly tight upper tension pulls thread apart before stitching

- Bobbin Issues – Incorrectly wound or damaged bobbins cause uneven thread flow

Resolving Tension Issues

Once you’ve pinpointed why your thread keeps snapping, it’s time to tackle those pesky tension issues head-on.

Start with scrap testing on fabric scraps that match your project—this prevents costly mistakes on your final piece.

Check your tension settings against your manual’s recommendations, then adjust both upper and bobbin tension for proper tension balance.

Thread matching matters too; heavier fabrics need different tension control than delicate materials, so factor in fabric impact when fine-tuning your settings for the best thread matching results.

Maintaining Needle and Bobbin Quality

Needle-thread partnerships matter more than most sewists realize.

Start with needle inspection—check for bent tips, rough spots, or dull points that cause thread quality issues.

Replace damaged needles immediately to prevent needle thread breaks.

For bobbin cleaning, remove lint buildup from the case and verify you’re using correct bobbins for your machine.

Different needle types require specific alignment; universal needles won’t work for specialty fabrics.

Address alignment issues promptly—misaligned components create bobbins thread breaks and needle damage that’ll frustrate even experienced sewists.

Optimizing Sewing Machine Performance

You’ll want to keep your sewing machine running smoothly to prevent those frustrating thread breaks that stop your projects cold.

Peak performance comes from three key habits: regular cleaning, proper threading technique, and smart needle-thread pairing that matches your fabric choice.

Regular Cleaning and Maintenance

Your sewing machine maintenance routine determines whether threads break or flow smoothly.

Clean lint buildup from the bobbin case weekly using a small brush. Oil mechanisms according to your manual’s schedule—typically every 8-10 hours of use.

Inspect parts for burrs or damage monthly. Professional servicing annually keeps your machine running like clockwork, preventing costly thread breaks, which is crucial for maintaining a smooth flow.

Proper Threading and Tensioning

Your sewing machine threading follows a specific Threading Order that guarantees smooth operation.

Start by following your machine’s Manual Referencing guide exactly—skipping guides creates thread breaking disasters. Check your thread tension dial against fabric weight, aiming for balanced stitches.

Test Tension Balance on scrap fabric matching your project’s Fabric Impact requirements. Proper sewing machine threading and tension adjustment prevent most thread breaking solutions from becoming necessary.

Maintaining a tension log can help eliminate guesswork.

Choosing The Right Needle and Thread

Your thread breaking solutions depend heavily on matching needle size to thread weight and fabric thickness.

Wrong combinations create friction that snaps thread instantly.

Match these components for smooth sewing:

- Fabric Compatibility – Heavy denim needs size 16-18 needles with thick thread

- Thread Material – Cotton thread pairs with universal needles, specialty threads need specific types

- Needle Types – Ballpoint for knits, sharp for wovens, topstitch for heavy materials

Thread and fabric selection determines your needle choice, not the other way around.

Different projects require attention to specific needle sizes.

Mastering Thread Management

You’ll master thread management once you understand how different thread types interact with various fabrics and tension settings.

The right thread choice prevents 90% of breakage issues before they start, saving you hours of frustration and rework.

Understanding Thread Types and Materials

Your machine’s performance depends on mastering different sewing thread types. Thread construction methods vary dramatically—from twisted cotton to polyester blends. Each material brings unique properties that affect your projects.

| Thread Type | Best For | Why You’ll Love It |

|---|---|---|

| Cotton | Natural fabrics, quilting | Breathes with fabric, ages beautifully |

| Polyester | Synthetics, stretchy materials | Strong, colorfast, versatile |

| Silk | Delicate fabrics, heirloom pieces | Luxurious feel, natural strength |

Thread fiber properties determine success. Cotton offers breathability but less stretch. Polyester provides durability with slight give. Blended thread options combine benefits—cotton-wrapped polyester gives natural appearance with synthetic strength.

Thread weight matters too: heavier weights (30-40) suit topstitching, while lighter weights (50-60) work for general sewing. Specialty thread uses include metallic for decoration and elastic for activewear. Understanding these basics prevents frustration and elevates your sewing quality.

Selecting The Right Thread for Fabric

Perfect fabric-thread partnerships prevent headaches and create professional results.

You’ll achieve sewing success by matching thread properties to your fabric’s characteristics and weight requirements.

- Match fiber content: Use cotton thread for natural fabrics, polyester for synthetics, and specialty threads for stretch materials

- Consider thread weight: Choose heavier threads (lower numbers) for thick fabrics, lighter weights for delicate materials

- Prioritize thread quality: Invest in branded threads that won’t break mid-project or fade over time

- Perfect color matching: Select threads one shade darker than fabric when exact matches aren’t available

Preventing Thread Snags and Breakage

Now that you’ve matched thread to fabric, focus on preventing snags and breakage through proactive measures. Thread quality directly impacts durability—cheap thread frays easily.

Check your needle condition regularly, as dull needles create friction that weakens fibers. Proper bobbin winding prevents uneven tension that causes breaks.

| Prevention Method | Key Action |

|---|---|

| Thread Quality | Use branded, fresh thread matched to fabric weight |

| Needle Condition | Replace every 8-10 hours or when dull/bent |

| Bobbin Winding | Wind evenly at moderate speed, avoid overfilling |

| Machine Cleaning | Remove lint from tension discs and bobbin area weekly |

Regular machine cleaning removes lint buildup that affects tension balance. Clean tension discs monthly and check for burrs on the needle plate that can catch thread.

These simple steps eliminate most sewing machine thread breaking issues before they start.

Frequently Asked Questions (FAQs)

How can we prevent thread from breaking?

While expensive thread seems unnecessary, cheap thread actually costs more through constant breaks and frustration.

Use quality thread, match needle size to fabric, check tension settings, and keep your machine clean for smooth sewing success.

Why does my thread keep coming apart?

Your thread’s likely unraveling due to poor quality, age, or incorrect tension settings.

Check you’re using fresh, high-quality thread that matches your fabric weight, and adjust your machine’s tension dial properly.

What is the solution to needle thread breakage?

Sarah’s vintage Singer kept snapping thread mid-seam until she discovered her needle was bent.

Check your needle first—replace if bent, dull, or wrong size for your fabric.

Rethread completely, adjust tension settings, and test on scrap fabric before continuing, to ensure that your machine is working properly with the correct tension.

Why does thread break only with certain fabrics?

Different fabrics require different needle sizes and thread weights.

Heavy fabrics like denim need stronger needles and thicker thread, while delicate fabrics need fine needles.

Mismatched combinations create excessive friction, causing breaks.

Can sewing speed cause thread to snap frequently?

Yes, excessive sewing speed frequently causes thread snapping. You’re pushing your machine beyond its limits, creating heat buildup and uneven tension that weakens thread fibers, leading to breaks.

How does humidity affect thread breaking patterns?

Ever feel like you’re battling invisible forces?

High humidity makes thread absorb moisture, becoming weaker and more prone to snapping.

You’ll notice increased breakage during humid weather as damp thread loses its tensile strength and elasticity, requiring adjusted tension settings for smoother sewing, particularly to counter the effects of high humidity.

What causes thread breaks during embroidery specifically?

Embroidery thread breaks stem from incorrect needle depth, improper hook timing, excessive speed, wrong stabilizer choice, and inadequate hoop tension.

You’ll also face issues with specialty thread handling and machine calibration problems, including problems with machine calibration.

Why do metallic threads break more often?

Metallic threads break frequently because they’re stiffer and less flexible than regular threads.

They catch on rough surfaces, create more friction through guides, and require slower stitching speeds with proper thread nets for smooth feeding, which can be challenging to manage due to their stiffness and less flexible nature.

Conclusion

Mastering these thread breaking sewing solutions transforms your sewing experience from a nightmare of constant interruptions into smooth, professional results.

You’ve now got seven powerful fixes that tackle everything from tension troubles to needle nightmares.

Remember, quality thread and proper machine maintenance aren’t luxuries—they’re essentials for frustration-free sewing.

Start with tension adjustments, upgrade your thread, and keep your machine clean.

With these thread breaking sewing solutions in your toolkit, you’ll spend more time creating and less time troubleshooting broken threads, enjoying a more frustration-free sewing experience.

- https://www.eversewn.com/blog/problem-solving-addressing-thread-breakage

- https://konsew.com/blog/how-to-avoid-thread-breakage-during-high-speed-sewing

- https://www.ageberry.com/sewing-machine-thread-keeps-breaking-reasons-solutions/

- https://graphics-pro.com/feature/the-common-causes-of-thread-breaks/

- https://youtu.be/cSMuU-UZUCQ