This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

When your sewing machine thread keeps breaking at the needle, you’re likely facing one of several common culprits.

When your sewing machine thread keeps breaking at the needle, you’re likely facing one of several common culprits.

Check if you’ve threaded your machine correctly, with proper tension. A dull or bent needle won’t do you any favors—replace it regularly.

Verify your bobbin is wound evenly and inserted correctly. Like a car that needs regular maintenance, your machine requires cleaning—remove lint from the bobbin area and throat plate.

Quality matters too; cheap thread can snap faster than your patience. With these fixes in your sewing toolkit, you’ll be stitching smoothly again instead of wrestling with thread that breaks like clockwork. Your machine requires regular maintenance to ensure it runs smoothly, and using quality thread can make a significant difference.

Table Of Contents

Key Takeaways

- You’ll prevent most thread breaks by ensuring proper threading and tension settings on your machine, as incorrect tension is a major cause of breakage during sewing.

- Replace your needles regularly when they become dull or bent, and always match the needle size to your fabric weight—use smaller needles (8-11) for delicate fabrics and larger ones (14-18) for heavier materials.

- Don’t underestimate the importance of quality thread; cheap or old thread breaks more easily, so invest in reputable brands and store your thread properly to maintain its strength.

- Clean your machine every 8-10 hours of sewing by removing lint from the bobbin area and throat plate, and follow your manual’s recommendations for oiling to keep everything running smoothly.

Thread Breaking Causes

If your sewing machine thread keeps breaking, it’s often caused by simple, fixable issues like threading mistakes or tension problems.

Understanding the common causes can help you pinpoint the issue and keep your sewing projects on track.

Improper Threading

If your sewing machine thread is breaking, rethreading might solve it.

Improper threading disrupts the thread path, causing tangles or breaks. Check the spool placement and guide usage, ensuring the thread flows smoothly.

Avoid thread twists by following the threading path illustrated in your machine’s manual. A quick rethread often restores tension balance and prevents further frustration.

Inspecting the thread path for snags can also help prevent thread breaks. This step is crucial for maintaining a smooth sewing experience and is a key part of preventing frustration.

Incorrect Tension

Incorrect thread tension is a major cause of thread breaking. A balanced tension guarantees smooth sewing.

Follow these tips:

- Reduce top thread tension to avoid breakage.

- Check bobbin tension using subtle adjustments.

- Match thread weight with fabric and needle.

- Use tension balance tools to test sewing consistency.

- Always practice tension adjustment on scrap fabric first to ensure a smooth sewing experience and prevent thread breakage due to improper tension adjustment.

Needle and Bobbin Issues

If your thread keeps snapping, needle and bobbin issues might be the culprit.

Check for damaged needles or needle insertion errors—flat side back! Use the correct needle size and bobbin type specific to your project and machine.

Incorrect bobbins or bobbin problems, like poor winding, can wreak havoc. Different fabrics require specialized sewing needles.

Precision here keeps your sewing frustration-free!

Thread Quality Problems

Old or poor-quality thread causes unnecessary headaches.

Brittle fibers, uneven material types, or improper storage can compromise performance, leading to frequent thread breaking.

Watch out for these common culprits:

- Thread Age Factor: Old threads weaken over time, causing breakage.

- Thread Fiber Strength: Low-quality fibers fray easily during sewing.

- Thread Brand Differences: Opt for reputable brands to avoid poor-quality thread.

Machine Maintenance

Neglecting sewing machine maintenance often leads to frustration like thread breaking mid-project.

Keep lint buildup at bay by following a cleaning schedule. Oiling the machine guarantees smoother operation, while regular part replacement prevents needle issues.

Inspect parts like the needle plate for damage and maintain proper bobbins winding. Clear tension discs often, and you’ll see fewer thread tension problems.

Top 5 Thread Solutions

When thread keeps breaking at the needle, selecting the right tools can make all the difference. Here are five reliable solutions to keep your sewing projects running smoothly.

1. Schmetz Universal Sewing Needles Assorted

Schmetz Universal Sewing Needles Assorted are a solid choice for avoiding thread issues.

Designed to handle both wovens and knits, these needles provide reliable performance and smooth stitching.

Their slightly rounded point guarantees compatibility with various fabrics. Each pack includes needles in assorted sizes, making them versatile for different projects.

Crafted to fit all household machines, Schmetz needles are loved for their durability and consistent quality. Whether you’re quilting, embroidery, or tackling home décor, these needles are a dependable, cost-effective option to keep your sewing frustration-free.

Best For: Beginner and experienced sewers looking for reliable, versatile needles for various fabric types.

- Requires frequent changes after long continuous use.

- Not ideal for specialized or heavy-duty sewing tasks.

- Limited to slightly rounded point needles only.

- Suitable for both knits and wovens with consistent performance.

- Compatible with all household sewing machine brands.

- Durable and cost-effective, great for quilting and embroidery.

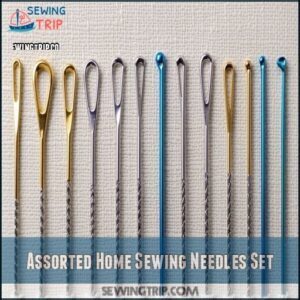

2. Home Sewing Machine Needles Assortment Kit

If you’re tired of thread breakage, a home sewing machine needles assortment kit could be your secret weapon.

They’re versatile, durable, and compatible with most machines.

Use smaller needles for delicate fabrics and larger ones for thicker materials like leather.

Remember thread weight selection for superior stitch quality.

Be sure to replace dull needles regularly—using a fresh needle keeps your stitches smooth and prevents frustrating snags or breaks mid-project.

Best For: Beginners and experienced sewers looking for a versatile, durable, and affordable needle assortment for various fabric types.

- Wide assortment for different fabric weights and projects.

- Compatible with most home sewing machines.

- Affordable price with long-lasting durability.

- May not include every specialized needle size or type needed.

- Packaging might not suit users who prefer plastic cases over foil.

- Not color-coded for instant identification of needle types.

3. Prewound Bobbins Size A Sewing Embroidery

Prewound bobbins, like the Size A Sewing Embroidery option, can save you time while improving thread consistency.

They’re compatible with many machine brands, including Brother, Bernina, and Janome, making them versatile for embroidery or sewing tasks.

Their recyclable core is a win for eco-conscious crafters, and proper tension and thread smoothness help avoid thread breaks.

These come preloaded with high-quality polyester thread, reducing bobbin changes during projects, and simply pop one in, and you’re ready to stitch without hassle, thanks to the improving thread consistency.

Best For: Embroidery and sewing enthusiasts who want reliable, prewound bobbins compatible with multiple machine brands.

- Occasional difficulty starting the thread on some bobbins.

- Limited to white matte polyester thread.

- Preference for filament thread by some users over polyester.

- Compatible with brands like Brother, Bernina, and Janome.

- Preloaded with high-quality polyester thread for fewer bobbin changes.

- Recyclable core promotes eco-friendly crafting.

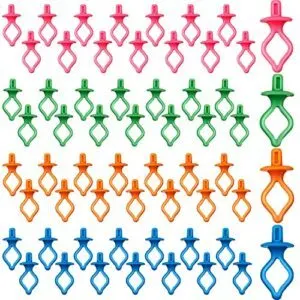

4. Bobbin Thread Spool Savers 20 Pack

Bobbin Thread Spool Savers are a game-changer for keeping your sewing threads and bobbins organized.

They’re flexible, colorful, and fit most spools, making them a practical tool for any sewing project.

Just squeeze, slide, and your bobbin stays matched to its thread, reducing tangles and waste, which is especially useful for quilting or travel.

These savers simplify storage and separate threads for specific projects, making them highly efficient.

However, they mightn’t work with pegged holders or very small spools, which is an important consideration for some users.

Affordable and practical, they’re highly recommended for sewing enthusiasts aiming to stay tidy and efficient.

Best For: Sewing enthusiasts, quilters, and crafters looking for an easy way to keep threads and bobbins organized and tangle-free.

- Not suitable for pegged thread holders.

- May not work well with very small spools or cones.

- Clips can protrude, interfering with some storage setups.

- Flexible, durable, and easy to use.

- Fits most thread spools and bobbins.

- Prevents tangles and wasted thread.

5. Bobbin Clips Thread Spool Holders

Keeping your bobbin and thread spool together has never been easier with bobbins clips. These flexible silicone holders securely snap bobbins onto matching thread spools, saving you time and frustration.

They prevent thread from unwinding, so you don’t need to dig through your stash searching for the right combination.

Lightweight and durable, they’re perfect for organizing polyester, cotton, or embroidery threads.

While longer pegs may slightly lift smaller spools off racks, their space-saving design makes them essential for sewing enthusiasts.

Best For: Seamstresses and sewing enthusiasts who want to organize their bobbins and thread spools efficiently.

- Compact and space-saving design.

- Durable and flexible silicone material.

- Keeps bobbins and spools securely together.

- Longer pegs may lift smaller spools off racks.

- Requires tucking loose bobbin threads for secure placement.

- No included storage case provided.

Preventing Thread Breaks

To prevent thread breaks, focus on setting the right tension, using quality thread, and maintaining your machine regularly.

Proper needle insertion and keeping lint buildup in check are also essential for smooth sewing.

Adjusting Tension Settings

Thread tension can make or break your sewing project, literally.

Thread tension is the heartbeat of your sewing project—get it right, and everything flows smoothly.

For balanced tension:

- Top Tension: Adjust to avoid tight or loose stitches.

- Bobbin Tension: Loosen or tighten the bobbin case screw slightly.

- Tension Testing: Test on a scrap fabric before starting.

- Manual Guidance: Follow your machine’s manual.

- Thread Tension: Verify compatibility between top and bobbin threads.

Fine-tuning prevents sewing machine thread breaking!

Using High-Quality Threads

Now that you’ve balanced your tension settings, let’s talk quality. Your thread choice matters more than you might think.

Using high-quality threads reduces breaking at the needle dramatically. Lower-quality threads often have uneven fibers and thickness that catch in your machine.

Using stronger thread options can further minimize breakage. Different thread fiber types perform differently – polyester offers strength while cotton provides a natural finish.

Remember that thread weight matters too – matching it to your fabric prevents those frustrating breaks mid-project.

Regular Machine Maintenance

High-quality threads aren’t enough if your machine is crying out for attention.

Regular maintenance prevents those frustrating thread breaks. Clean your machine every 8-10 hours of sewing to remove lint buildup that causes friction.

Oil the appropriate points according to your manual, and inspect parts for wear.

Professional servicing once yearly keeps everything running smoothly. Think of sewing machine maintenance as preventative medicine – a little cleaning now saves major headaches later, and it is essentially a form of preventative care that avoids major headaches.

Proper Needle Insertion

Proper needle insertion is often the unsung hero in preventing those frustrating thread breaks. When your needle isn’t seated correctly, thread breakage becomes inevitable.

Follow these three essential steps:

- Insert the needle with the flat side facing the back of your machine

- Push it completely up into the needle clamp before tightening

- Choose the correct needle size that’s compatible with your fabric weight

Consistent adjusting thread tension also plays a vital role in preventing thread breakage, making it a crucial step in the process to ensure smooth sewing and prevent thread breakage.

Avoiding Lint Buildup

How often do you clean your sewing machine? Lint buildup is a silent thread-breaking culprit.

You’ll need regular cleaning of the bobbin area every 8-10 hours of sewing. Use a small brush to sweep away fabric fuzz that collects under the needle plate.

Higher thread quality produces less lint. When not sewing, keep your machine covered to prevent dust accumulation that affects thread tension.

Common Thread Break Issues

You’ll encounter specific thread break scenarios depending on what you’re sewing, from metallic threads snapping during decorative work to persistent breaks when handling thick fleece.

Understanding these common issues will help you quickly identify and fix thread problems before they turn your creative project into a frustrating thread emergency.

Metallic Thread Breakage

Now that you know how to prevent thread breaks, let’s tackle those frustrating metallic thread issues.

Metallic thread breakage happens primarily due to friction as this stiff material passes through your machine and fabric.

Try these quick fixes:

- Use a larger eye needle (90/14 topstitch or embroidery)

- Apply thread lubrication to reduce friction

- Loosen your tension settings and sew at slower speeds

Remember, the metallic foil separates easily from its nylon core when stressed, so handle with care!

Thread Breaks in Thick Materials

While metallic threads require gentle handling, thick materials present their own challenge.

When thread keeps breaking as you tackle denim, canvas, or leather, you’ll need to make specific adjustments.

Try increasing your needle size to 90/14 or larger, loosening thread tension slightly, and extending stitch length.

Heavy-duty thread types matched with the appropriate presser foot pressure can prevent those frustrating snaps that halt your sewing momentum, and using the right techniques can help you maintain your sewing momentum.

Stretch Thread Breakage

While thick fabrics challenge your machine, stretch threads present their own unique problems.

You’ll notice stretch thread breaking when tension’s too high or you’re using the wrong needle type. For better thread elasticity, switch to a ballpoint needle and reduce thread tension.

Maintain proper tension balance by testing on scrap fabric first. Adding a stabilizer and increasing stitch length can prevent undue stress on those specialty threads.

Don’t let thread breakage causes frustrate your stretchy fabric projects!

Free-Motion Quilting Thread Breaks

During free-motion quilting, thread breaks can derail your creative flow.

When your sewing machine thread keeps snapping at the needle, check these common culprits:

- Improper tension balancing act between top and bobbin threads

- Wrong quilting needle choice for your thread weight

- Batting fiber content creating excessive friction

- Darning foot usage at incorrect height

- Stitch regulation issues causing uneven thread feed

Slow down your quilting speed to reduce thread breaking – it’s not a race!

Fleece Thread Breaks

While free-motion quilting challenges your thread, fleece fabric presents its own set of problems.

Fleece’s dense pile can cause thread breaking when you’re using the wrong setup.

Choose a larger needle size (90/14 or 100/16) and quality thread that won’t get caught in fleece’s fibers.

Lengthen your stitch to 3.0-4.0mm, reduce thread tension slightly, and consider using a stabilizer underneath.

These adjustments will keep your thread intact while sewing through fleece’s thickness.

Troubleshooting Tips

You’ll need to systematically check common trouble spots when your thread keeps breaking at the needle.

Start with examining the needle condition, inspecting the bobbin case for debris, and verifying thread quality.

Before proceeding, cleaning the throat plate and adjusting the take-up lever spring are also necessary steps.

Checking Needle Condition

Worn or damaged needles are often the culprits behind frustrating thread breaks.

Examine your needle carefully for signs of bending, burrs, or dullness that might be snagging your thread.

A burred needle can shred thread faster than a cheese grater on parmesan.

Replace needles after 8 hours of sewing or when you notice skipped stitches.

Always use the correct needle type for your fabric to prevent thread breaking issues.

Inspecting Bobbin Case

While a dull needle can break thread, don’t overlook your bobbins! This tiny housing can harbor big problems.

Here’s how to inspect it properly:

- Remove the bobbin case and check for nicks or burrs

- Clean out lint using a small brush or compressed air

- Examine the tension spring for proper movement

- Verify your bobbin is compatible with your specific machine

Regular bobbins case maintenance prevents those frustrating thread breaks mid-project, which can be caused by a dull needle.

Thread Quality Check

Thread quality can make or break your sewing project.

Test thread fiber strength by giving it a sharp tug—if it snaps easily, it’s likely poor quality thread.

Check thread material type and thread weight impact on your specific project.

Thread age matters too; older spools become brittle.

Proper storage conditions prevent deterioration.

Don’t let cheap thread sabotage your hard work!

Cleaning Throat Plate

Like a detective searching for clues, inspect your throat plate regularly for signs of trouble.

Lint accumulation under the throat plate is a major culprit behind thread breaking issues.

Remove the plate and check for burrs, scratches, or thread debris that cause thread snagging.

Clean with a small brush and wipe with a lint-free cloth.

If you spot damage, consider plate replacement to prevent needle issues.

Adjusting Take-Up Lever Spring

After cleaning your throat plate, don’t overlook the take-up lever spring. This tiny powerhouse regulates thread tension as your machine works. A bent or damaged spring can cause persistent thread breaking at the needle.

Check for these Spring Damage Symptoms:

- Thread repeatedly pops out during sewing

- Uneven stitch formation

- Thread tension inconsistencies

- Take-up lever not moving properly

- Thread breaking despite new needles

A bent spring can sometimes be reshaped for optimizing spring function. The take-up lever’s smooth operation is essential for even stitches. For severe issues, lever spring replacement might be necessary to ensure proper thread tension and prevent thread breaking.

Choosing Right Needles

You’ll need the right needle for your fabric to prevent thread breakage at the needle.

Using the correct needle size and type guarantees smooth stitching by reducing friction between the thread and needle eye.

Assorted Home Sewing Needles Set

Now that you’ve checked your machine, let’s talk about proper tools. An assorted home sewing needles set gives you options for every project.

You’ll need different sizes for various fabrics to prevent thread breaking. Most needle sets include sizes 9-18, with smaller numbers for finer fabrics.

A quality set guarantees you have various needle sizes for different projects.

Store your needles properly and remember their lifespan—replace them after 8 hours of sewing to maintain your sewing machine’s performance.

Leather Needle Size 18/110

When tackling leather projects where thread keeps breaking, a robust Leather Needle Size 18/110 is your secret weapon.

These specialized needles feature:

- Wedge-shaped point that pierces without tearing

- Extra-strong shaft to prevent needle flexing

- Larger eye to accommodate thicker thread types

- Reinforced design for handling multiple leather thickness

Adjust your tension settings and increase stitch length when using these powerhouse needles for the best results.

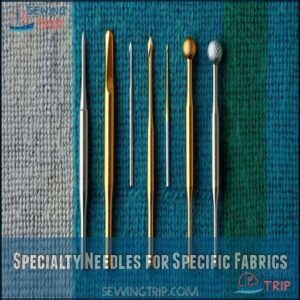

Specialty Needles for Specific Fabrics

While leather work requires heavy-duty 18/110 needles, other fabrics need their own specialty needles too.

While leather work demands heavy-duty 18/110 needles, other fabrics call for their own specialized tools for perfect stitching.

Ball point needles slide between knit fabric fibers without snagging. Microtex needles with slim points work wonders on silks and microfibers.

Denim needles have reinforced shanks to prevent breakage on thick seams. Jersey needles reduce skipped stitches on stretchy fabrics.

The right needle type for your fabric prevents frustrating thread breaks. Using the correct needle can make a significant difference in the quality of your work, and specialty needles are designed to handle specific types of fabric, such as knit fabric.

Needle Size and Type Selection

Beyond specialty needles, matching your needle size and type to your fabric is like finding the perfect dance partner.

Your needle’s point and size must complement both your fabric and thread weight. Check needle condition regularly—bent or dull needles break threads.

For ideal sewing machine performance, remember this simple rule: lighter fabrics need smaller needles (60/8-70/10), while heavier materials require larger sizes (90/14-110/18).

Needle and thread compatibility prevents frustrating breaks, and finding the perfect dance partner is crucial, as needle condition and ideal sewing machine performance are key to successful sewing.

Machine Maintenance Tips

You’ll prevent countless thread breaks by simply maintaining your machine with regular cleaning and proper oiling.

A well-maintained sewing machine lasts longer and also gives you consistent, trouble-free stitches that won’t leave you muttering under your breath at 2 AM when you’re rushing to finish that project, which is a trouble-free experience.

Regular Cleaning Schedule

With the right needles in hand, let’s talk about keeping your machine spotless.

You should establish a regular cleaning schedule for your sewing machine to prevent thread breaks. Remove lint after every 8 hours of sewing using a q-tip for the bobbin casing.

Fabric debris can accumulate quickly, causing tension issues.

Professional servicing twice yearly complements your routine maintenance, ensuring all parts work smoothly together, which is crucial for preventing thread breaks.

Oil Machine as Recommended

Once you’ve cleaned away the lint, don’t forget about lubrication! Regular oiling keeps your sewing machine running smoothly and prevents thread breaking issues.

Apply sewing machine oil only where your manual recommends—typically moving parts that create friction. Don’t overdo it; a drop or two is sufficient.

Proper machine maintenance through correct oiling frequency extends your machine’s longevity and keeps those threads intact during your sewing projects, ensuring smoothly running operations.

Replace Worn-Out Parts

Your sewing machine’s components wear out over time, leading to thread breaking issues.

Inspect and replace damaged Tension Discs, Bobbin Case, or Spool Caps that show signs of wear.

Even tiny nicks in these parts can wreak havoc on your thread.

Don’t forget to check for loose screws or worn gears that might affect thread tension and movement throughout your sewing machine.

Check Presser Foot and Needle Plate

After replacing worn parts, don’t forget to examine your presser foot and needle plate for issues that cause thread breakage.

These components directly contact your fabric and thread during sewing.

Check these four critical areas:

- Proper foot height adjustment for your material thickness

- Needle plate for scratches or nicks that can snag thread

- Rough edges or burrs on either component

- Secure attachment of presser foot to prevent wobbling

The goal is to ensure that your sewing machine is in good working condition to prevent thread breakage and achieve a smooth sewing experience with your needle plate.

Proper Bobbin Winding and Tension Settings

After inspecting your presser foot and needle plate, don’t overlook your bobbin—it’s often the hidden troublemaker.

Wind bobbins at a moderate speed for consistent bobbin fill. Avoid overwinding, especially with delicate threads.

Your bobbin thread type should match your top thread for balanced bobbin tension.

Perform tension consistency checks on scrap fabric before starting projects. Remember to adjust bobbin tension settings if you notice puckering or loose stitches.

Frequently Asked Questions (FAQs)

Why does the thread keep breaking at the needle on my sewing machine?

Your thread might be breaking due to tension issues, a worn needle, poor-quality thread, or improper threading.

Check these areas first, and don’t forget to clean lint from the bobbin area.

What is the solution to needle thread breakage?

To solve needle thread breakage, check and adjust tension settings, replace dull or bent needles, rethread correctly, and verify you’re using quality thread.

Regular machine maintenance will keep your stitches flowing smoothly.

When should I replace my sewing machine?

You should consider a new machine when repairs exceed replacement cost, parts aren’t available, or it can’t handle your projects. Most quality machines last 5-25 years with proper maintenance.

Will changing sewing speed affect thread breakage?

Yes, sewing too fast can definitely increase thread breakage.

You’ll get better results by lowering your speed, especially when working with delicate fabrics or specialty threads.

Steady pace means fewer breaks, and this is a key concept to remember, so a steady pace is crucial.

Can thread break due to temperature changes?

Like walking on thin ice, your thread can indeed break due to temperature changes.

Extreme heat or cold makes fibers brittle, while humidity fluctuations affect thread tension and strength.

Keep your sewing area climate-controlled to prevent these issues, as maintaining a stable environment is crucial for preserving thread strength.

How does fabric weight impact needle selection?

Heavier fabrics demand larger needles (sizes 14-18) to pierce through without breaking.

While delicate fabrics need smaller needles (sizes 8-11) to prevent damage.

Always match your needle size to fabric weight.

Why does thread twist while sewing?

You’d think thread wouldn’t dare twist, yet it does!

Your thread twists while sewing due to the rotational motion of the machine, improper thread path, or mismatched spool orientation.

Check your threading technique.

Conclusion

Remember when your sewing machine thread breaking at needle seemed like an unsolvable mystery?

Now you’re armed with solutions! By maintaining proper tension, using quality thread, keeping needles sharp, and giving your machine regular TLC, you’ll overcome this common frustration.

Don’t forget to check your bobbin setup and clean lint regularly.

With these simple fixes in your sewing arsenal, you’ll spend less time troubleshooting and more time creating beautiful projects.