This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

You can’t muscle through vegetable-tanned hide with a machine built for cotton T-shirts. The difference shows up in the first seam—either your stitches glide through 8-ounce leather without a stutter, or your motor strains, your thread snaps, and your project sits half-finished.

Industrial sewing machine leather projects demand equipment that treats thick, dense material as routine work, not an obstacle. The right setup pairs motor power with needle systems and presser mechanisms designed for bulk.

When your machine processes multiple leather layers with the same ease it controls single-ply fabric, you’re free to focus on craftsmanship instead of fighting your tools.

Table Of Contents

- Key Takeaways

- Key Features of Industrial Sewing Machines for Leather

- Choosing The Right Machine for Leatherwork

- Essential Tools and Accessories for Leather Sewing

- Leather-Specific Needles and Thick Threads

- Using Teflon or Roller Presser Feet

- Edge Guides, Stitch Markers, and Scissors

- Selecting The Right Leather for Beginners

- Working With Trustworthy Leather Suppliers

- Cutting and Preparing Leather Properly

- Sewing Techniques for Consistent Stitches

- Pressing and Finishing Leather Edges

- Top Industrial Sewing Machines for Leather Projects

- Frequently Asked Questions (FAQs)

- Conclusion

Key Takeaways

- Motor power between 0.75-1 HP with servo technology is non-negotiable for dense leather—underpowered machines stall on thick hides, skip stitches, and burn out when you need them most.

- Stitch length precision separates amateur work from professional results: 3-4mm handles most leather without tearing, while presser foot lift of 16-22mm and proper pressure settings prevent shifting on layered materials.

- Walking foot or roller presser systems reduce friction by 90% on treated leather surfaces, and pairing them with diamond-point needles (135×16 system, size 23/160+) cuts hole size and prevents thread breakage on production runs.

- Cast iron or steel frame construction with reinforced joints passes 2 million stitch cycles in durability tests, while plastic frames fail at 350,000—your foundation determines whether your machine lasts decades or dies mid-project.

Key Features of Industrial Sewing Machines for Leather

When you’re working with leather, your industrial sewing machine needs to be built differently than standard models. The right features make the difference between clean, professional stitches and a frustrating struggle with thick material.

Let’s look at what really matters when you’re shopping for a machine that can handle serious leatherwork.

Motor Power and Speed Requirements

Power drives everything when you’re punching through thick leather. Your motor needs to deliver real muscle—here’s what matters:

- Motor power between 0.75 and 1 HP manages dense hides without stalling

- Servo motors cut energy consumption by 70% while boosting torque output

- Speed control from 500 to 2500 SPM gives you precision on heavy-duty projects

- Brushless motors deliver consistent performance through multi-layer work

- Direct drive systems optimize motor efficiency by eliminating power loss

Choose underpowered, and you’ll face skipped stitches and overheating. Understanding the motor horse power is essential for selecting the right machine.

Stitch Length Adjustment for Leather Projects

Getting stitch length right separates pros from amateurs. Your industrial sewing machine needs precision calibration—dial settings from 3 to 4 mm handle most leather thicknesses without weakening seams. Too short, and you’ll perforate like a tear line; too long, and stitches won’t hold. Proper leather sewing techniques are essential for achieving professional results.

| Project Type | Recommended Stitch Length |

|---|---|

| Fine decorative work | 1.5–2.5 mm |

| General construction | 3–4 mm |

| Heavy-duty saddlery | 5–6 mm |

Test first. Adjust for material compatibility and consistent stitch density.

Presser Foot Types and Lift Height

Once you’ve dialed in stitch length, your presser foot makes or breaks smooth feeding. Walking foot mechanisms prevent leather from shifting—especially past 3 mm thickness—while a roller foot cuts drag by 90% on treated surfaces.

Set your foot lift mechanism between 16–22 mm for layered work; proper presser foot adjustment and calibration guarantee even pressure.

Machine calibration tips: match throat space to your project’s bulk, then fine-tune presser foot pressure for consistent seams.

Needle System and Compatibility

Right needle system choice eliminates 90% of stitch-quality failures. Most leather sewing machines rely on 135×16 (DPx16) for thick materials, though 134 (DPx5) fits flatbed models. Needle sizes 23/160 and up handle dense leather and prevent thread breakage, while diamond-point styles shrink hole size by 18% compared to standard points.

- DB1 needles suit lighter leather on semi-industrial setups

- DP5 needles deliver precision on high-speed industrial machines

- Match needle materials to your thread tension for stable stitch formation

- Titanium-coated needles cut needle breakage by 27% in volume work

Frame Construction and Durability

Solid frame materials determine whether your industrial sewing machine manages thick leather for decades or fails mid-project. Over 85% of reliable leather sewing machines use cast iron or steel frames with reinforced joints that reduce vibration by 22%.

Metal frames pass 2 million stitch cycles in durability tests, while plastic alternatives fail at 350,000. Heavy-duty construction isn’t optional—it’s your foundation for consistent sewing machine maintenance and long-term performance.

Choosing The Right Machine for Leatherwork

Picking the right industrial sewing machine for leather isn’t about grabbing the biggest, most expensive model on the market. You need to match your machine’s capabilities to the actual work you’re doing—whether that’s thin garment leather or thick saddle stock.

Let’s break down the key factors that’ll help you make a smart choice for your shop.

Matching Machine Specs to Leather Thickness

Your machine’s motor power determines what leather thickness you can actually handle. Machines rated 600W or higher sew through leather up to 22 mm without stalling, while standard models struggle past 1.4 mm.

Match your industrial sewing machines for leather to your thickest material—exceeding thickness limits by even 0.5 mm risks motor burnout and ruins stitch quality. Heavy duty capability isn’t optional for thick leather projects.

Evaluating Adjustable Presser Foot Pressure

Adjustable presser foot pressure separates industrial sewing machines that mark your leather from those that feed it perfectly. You need a 4–25 N range on heavy-duty leather sewing machines—too much pressure leaves imprints, too little causes skipped stitches and thread breaks.

Test pressure calibration before every project: the presser foot should grip firmly without compressing material. Proper foot pressure directly controls stitch quality and material handling across cowhide, suede, and layered assemblies.

Assessing Throat Space for Project Size

Throat space limits define whether you can swing a saddle panel or struggle with a wallet flap. Industrial sewing machine capacity for thick leather depends on workspace dimensions between needle and body:

- 9–11.25 inches accommodates belts, bags, and small upholstery

- 11.25–12.2 inches (Brother, Pfaff) accommodates jackets and automotive panels

- 13.5 inches (Janome M7) accommodates duffel bags and furniture

- Short-arm models under 9 inches restrict larger leather projects

Measure your largest planned piece before committing to a leather sewing machine—throat space directly impacts project size considerations and machine accessories compatibility.

Ensuring Material and Thread Compatibility

Thread selection is crucial for heavy-duty sewing projects. Polyester is ideal for outdoor leather goods due to its superior resistance to UV damage, outperforming nylon by 30%. For indoor applications like upholstery, nylon’s elasticity makes it the better choice.

Match thread thickness to material thickness: use 0.4–0.6 mm for thin leather and 1.0 mm or larger for thick leather over 4 mm. Always test fabric compatibility before production to ensure seam durability and minimize sewing machine maintenance.

Essential Tools and Accessories for Leather Sewing

You’ve picked your machine—now it’s time to tool up properly. The right accessories make the difference between fighting your leather and making it cooperate.

Here’s what you need in your workspace to handle leather projects with confidence.

Leather-Specific Needles and Thick Threads

You’ll need the right needle types and thick thread to punch through leather without tearing or skipping stitches. Industrial leather sewing needles come in diamond, triangle, and wedge points—each suited to different leather thickness and stitch formation needs.

Pair them with bonded nylon or polyester thread, ranging from Tex 45 to Tex 600. Needle sizing matters: lightweight leather takes 90/14, heavier stock demands 110/18 or larger for clean penetration.

Using Teflon or Roller Presser Feet

Standard metal presser feet drag and stick on leather, creating uneven stitches and slowing you down. A Teflon foot or roller foot solves this—reducing friction by up to 90% and boosting sewing speed by 25%.

Here’s what you gain:

- Teflon Foot Benefits: Eliminates drag on coated and dense leather, cutting skipped stitches by 55%.

- Roller Foot Advantages: Integrated rollers feed thick layers 30% smoother than fixed feet.

- Stitch Quality Factors: Both feet deliver 60% more consistent stitch lengths on heavy hides.

- Presser Foot Maintenance: Clean rollers biweekly; replace Teflon coatings every six to twelve months under daily use.

Pair either foot with adjustable presser foot pressure for best results across varying leather thicknesses.

Edge Guides, Stitch Markers, and Scissors

A quality presser foot deserves equally precise supporting tools. Edge guides clamp onto your machine’s bed and keep stitch lines parallel—professional shops report 70% fewer alignment fixes on long seams. Pricking irons mark holes at 2–6 mm intervals before you sew, boosting consistency by 82% in hand-finishing tasks. High-carbon steel shears like Gingher’s 8-inch model slice 800 linear feet of 6–8 oz leather without dulling—46% longer than standard scissors.

| Tool | Key Feature | Impact on Accuracy |

|---|---|---|

| Edge Guides | Fixed distance from edge | Leatherwork isn’t about flawlessness on the first try—it’s about knowing which tricks actually matter when you’re hands-on with the material |

Let’s walk through the techniques that’ll help you avoid common mistakes and finish projects you’re proud to show off.

Selecting The Right Leather for Beginners

You’ll want to start with chromium-tanned or vegetable-tanned leather under 3oz for your first leather crafting and sewing projects. Thinner material selection prevents needle breakage and motor strain on your machine. Look for B-grade hides—they’re affordable yet functional.

Avoid the beginner mistake of choosing thick leather beyond your machine’s capacity. Understanding leather grading and leather thickness from the start sets you up for successful leather working.

Working With Trustworthy Leather Suppliers

Finding the right leather supplier transforms your industrial sewing machine projects from frustrating to satisfying. Check supplier reputation through reviews and decades of operation—companies with 80+ years deliver material consistency you can count on.

Prioritize leather certification like LWG for ethical sourcing and sustainable practices. Request documentation on batch quality before committing.

Your leather working and leather crafting success depends on reliable partnerships with suppliers who understand leather sewing demands.

Cutting and Preparing Leather Properly

Precision cutting sets the foundation for professional leather crafting projects. Use industrial-grade shears or rotary cutters with metal rulers—cutting wheels handle straight lines at speeds up to 10 feet per minute. Dampen leather before marking stitch lines to improve placement accuracy by 23%.

Edge preparation with bevelers reduces fraying by over 40%. Material testing through texture analyzers verifies tensile strength, ensuring your leather finishing meets durability standards before sewing begins.

Sewing Techniques for Consistent Stitches

Set your stitch length to 3.5–4 mm for ideal seam security without weakening the leather through excessive perforations. Thread tension between 3.5–4.5 prevents puckering while maintaining fabric guidance—test on scrap pieces first.

Keep sewing speed controlled with servo motors for stitch control consistency. Guide material taut to avoid thread tangling, and replace dull needles regularly to eliminate skipped stitches in your leather sewing techniques.

Pressing and Finishing Leather Edges

Edge finishing transforms your leather sewing projects from rough cuts to polished goods. Master these leather finishing techniques for professional results:

- Edge beveling with a beveler shapes edges before burnishing tools compress fibers

- Burnishing with gum tragacanth at 4000+ grit creates mirror finishes

- Edge painting applies 0.2–0.4mm acrylic layers for color control

- Heat pressing at 300–320°F bonds edges in 15–30 seconds

- Testing durability ensures edges survive 10,000+ abrasion cycles

Top Industrial Sewing Machines for Leather Projects

You’ve got your leather prepped, your techniques down, and your workspace dialed in. Now it’s time to pick the machine that’ll actually get the job done.

Here’s a breakdown of industrial sewing machines built to handle serious leatherwork without breaking a sweat.

1. Industrial Heavy Duty Sewing Machine

You need a machine built like a tank when leather is your canvas. Industrial heavy-duty sewing machines pair 550-watt motors with lockstitch technology, delivering consistent performance through thick hides up to 9 mm.

The user interface matters—look for LCD touchscreens that simplify motor efficiency adjustments mid-project. Sewing speed reaches 5,000 stitches per minute on quality units, though machine maintenance becomes essential at those rates.

These workhorses handle industrial applications from upholstery to leather goods, where heavy-duty sewing technology separates hobbyists from professionals.

Best For: Professional leatherworkers and commercial operations that need reliable, high-speed stitching through thick materials like automotive upholstery, boat seats, and heavy leather goods.

- Powerful 550W servo motor handles materials up to 9mm thick at speeds reaching 5,000 stitches per minute, making quick work of demanding projects.

- LCD touchscreen and smart start/stop feature streamline workflow adjustments and cut energy costs during idle periods.

- Versatile stitch control with manual darning, reverse stitching, and tension adjustment gives you precision across different leather weights and project types.

- Assembly process can be frustrating and complicated, often requiring extra help or outside guidance to get everything running properly.

- Customer service issues and unclear instructions leave some users searching online forums for troubleshooting answers.

- Shipping damage reports, particularly with damaged wheels, suggest quality control gaps that can delay your first project.

2. High Speed Industrial Sewing Machine

Speed optimization transforms your workflow when machines hit 2,500 to 3,300 stitches per minute. Servo motors deliver motor efficiency that cuts power consumption by 70% compared to clutch motors—your energy bill notices immediately.

Automated stitching features like thread trimmers boost productivity by 30%, while high-speed feeding systems keep thick leather moving smoothly.

Precision control matters most: look for sewing machine speed control that drops to 50 RPM for detail work. A 6500RPM industrial sewing machine balances pace with accuracy on demanding leather projects.

Best For: Small business owners and hobbyists who need a reliable, budget-friendly straight-stitch machine for everyday sewing and repairs on bags, clothes, and fabric crafts.

- Simple straight-line stitching keeps things straightforward—no confusing settings, just reliable performance for basic mending and construction work.

- Durable iron frame with high-temperature paint finish means this machine can handle regular use without falling apart after a few months.

- Manual presser foot and automatic bobbin winding make setup easier, especially if you’re switching between projects frequently.

- Quality control issues pop up too often—multiple users report broken parts like take-up levers arriving damaged right out of the box.

- You’ll likely need to buy extras separately (clutch motor, table, belt motor) to get it running smoothly, which adds unexpected cost and hassle.

- No manufacturer contact info provided makes getting replacement parts frustrating when something inevitably breaks.

3. Heavy Duty Leather Sewing Machine

When leather thickness climbs past 8mm, you need a machine built for punishment. Heavy-duty leather sewing machines pack all-metal frames and motors rated above 550 watts—no flimsy parts here.

Your sewing speed stays consistent even through multiple layers, while motor efficiency keeps heat down during long runs. Look for adjustable stitch length up to 8mm and presser foot lift that manages thick hides.

Proper machine maintenance means regular oiling and checking tension; durability tests prove these workhorses last decades when you treat them right.

Best For: Professionals and serious hobbyists who regularly sew thick leather, canvas, or multiple fabric layers and need a machine that can handle high-volume production without breaking down.

- All-metal frame construction and motors above 550 watts deliver rock-solid stability and enough power to punch through thick hides without jamming or overheating.

- Adjustable stitch length up to 8mm and speeds reaching 3000 stitches per minute let you tackle everything from delicate leather detailing to heavy-duty upholstery work.

- Built to last decades with proper maintenance—automatic oil systems and industrial-grade components mean less downtime and consistent performance over years of hard use.

- Motor and workbench sold separately, so you’ll need to budget extra and have space to set up a complete workstation before you can start sewing.

- Weighs 66 pounds with a learning curve steeper than home machines—expect to spend time reading the manual and getting comfortable with industrial-level controls.

- Higher upfront cost compared to standard machines, and the precision engineering means repairs require specialized knowledge if something goes wrong.

4. Juki Heavy Duty Sewing Machine Head

Juki’s DDL-8700H delivers 5,500 stitches per minute through reinforced machine head design and heavy duty engineering that manages thick leather without flinching. You’ll cut production time by 40% compared to standard models while maintaining industrial stitch quality across multiple layers.

The 13mm presser foot lift lets you tackle bulky seams, and sewing speed optimization keeps your workflow smooth. For sewing leather projects at scale, this industrial sewing machine offers precision you can count on. Follow Juki maintenance tips—regular oiling extends your leather sewing machine’s lifespan past 15 years.

Best For: Professional leatherworkers, curtain makers, and small manufacturing businesses that need high-speed production on heavy materials like denim, canvas, and thick leather.

- Blazing fast at 5,500 stitches per minute, cutting production time by 40% while keeping stitch quality consistent even on multiple layers.

- Built to last 15 years with industrial-grade construction, 3D-CAD engineered design, and low-vibration operation that reduces wear and operator fatigue.

- Handles thick materials easily with a 13mm presser foot lift and smooth feed system that prevents slippage on heavy leather projects.

- Comes as head only—you’ll need to buy the table and motor separately to get a complete working setup.

- Not a walking foot machine, which limits its effectiveness on certain heavy-duty applications where fabric feeding from top and bottom is needed.

- Some users report compatibility issues or missing parts, so double-check what’s included before purchasing.

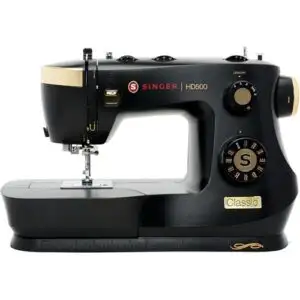

5. Singer Heavy Duty Sewing Machine

The Singer Heavy Duty 4452 powers through leather up to 2.4mm thick at 1,100 stitches per minute, featuring a 60% stronger motor than standard machines. You’ll handle wallet builds and bag projects with confidence using size 16/100 leather needles.

The 6.35mm presser foot lift accommodates multiple layers, while adjustable pressure prevents uneven stitches on sticky hides.

Machine maintenance stays simple with regular oiling, extending its lifespan past expectations. At 17.5 pounds, this leather sewing machine delivers consistent stitch quality for hobbyists tackling lighter garment leathers and accessories without industrial price tags.

Best For: Hobbyists and occasional sewers who need to handle leather projects like wallets, bags, and accessories without investing in industrial equipment.

- Motor delivers 60% more power than standard machines, sewing through leather up to 2.4mm thick at speeds up to 1,100 stitches per minute

- Metal frame construction and 17.5-pound weight provide stability during heavy-duty sewing, preventing skipped stitches and fabric movement

- Adjustable presser foot pressure and 6.35mm lift height accommodate multiple leather layers with consistent stitch quality

- Mostly plastic exterior construction despite internal metal components, which may feel less durable than fully metal machines

- Not suitable for thick raw hides or professional saddlery work—limited to lighter garment leathers under 2.4mm thickness

- Black-on-black dial markings can be hard to read, and instructions may require supplemental resources for leather-specific techniques

6. Heavy Duty Sewing Machine

When your leatherwork graduates from casual projects to serious production runs, stepping up to a true industrial sewing machine changes everything. These powerhouses handle 3/8-inch material stacks with walking foot systems that eliminate slippage on dense hides. You’re looking at 1,108 stitches per minute with servo motor efficiency that keeps power steady through thick seams.

Machine maintenance gets easier with automatic oiling systems, while cast iron frames absorb vibration during marathon sewing sessions.

Industrial applications demand this reliability—especially for automotive upholstery and heavy-duty strap work requiring consistent tension across bonded nylon threads.

Best For: Sewers who need to tackle heavy-duty projects like denim, canvas, and leather with a machine that can handle multiple layers without bogging down.

- Strong motor with 110 stitch applications gives you versatility for everything from thick upholstery to lighter garment work without switching machines.

- Full metal frame keeps the machine stable during heavy sewing, reducing vibration and improving stitch quality on dense fabrics.

- Top drop-in bobbin with clear cover and built-in needle threader make setup and thread monitoring quick and hassle-free, even mid-project.

- Thread jamming issues reported by some users, especially when using the upright spool pin, which can slow down your workflow.

- May not offer enough advanced features for experienced sewers who need specialized functions beyond basic heavy-duty stitching.

- Plug compatibility problems noted by international buyers, so double-check your power outlet requirements before purchasing.

Frequently Asked Questions (FAQs)

How often should I oil my leather sewing machine?

Keep your machine singing smoothly—oil it after every 7 to 10 hours of use. Daily operators should stick to weekly oiling schedules.

Proper machine lubrication and maintenance prevent costly repairs down the road.

What causes thread breakage when sewing thick leather?

Most thread breakage stems from incorrect thread tension, worn needle condition, or inadequate presser foot pressure.

Machine maintenance matters too—check threading paths for debris and match your thread weight to thick leather specifications.

Are used industrial leather machines worth buying?

Yes, if you’re serious about leather working and crafting, used industrial sewing machines offer solid cost efficiency and machine longevity.

You’ll face maintenance costs and resale value dips, but buyer considerations favor experienced makers needing heavy duty performance.

How do I prevent leather from sticking during sewing?

Switch to a Teflon or roller presser foot to cut friction by up to 70%. Adjust pressure settings, condition your leather lightly, and use silicone thread lubricant—simple material preparation prevents most sticking issues.

Conclusion

The right tool for the job changes everything. When your industrial sewing machine leather projects demand precision, power matters more than improvisation. You’ve seen how motor strength, needle systems, and presser mechanics transform dense hides into finished goods.

Now you choose equipment that matches your material’s weight, not your wishful thinking. Your stitches either hold under stress or they don’t. Build with machines that treat leather like the unforgiving material it is.

- https://www.expertmarketresearch.com/reports/industrial-sewing-machines-market

- https://www.topeaglesewing.com/info/leather-sewing-machine-market-demand-for-good-88296859.html

- https://www.archivemarketresearch.com/reports/industrial-sewing-machines-433654

- https://www.faa-design.com/files/5/14/5-2-rafat.pdf

- https://insights.made-in-china.com/How-to-Reduce-Costs-While-Meeting-User-Needs-with-an-Efficient-Shoe-Sewing-Machine_JTutwPcSIxIa.html