This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

A tangled bobbin thread can derail your entire sewing session in seconds. You’re mid-project, momentum building, when suddenly your machine jams—and you’re fishing around inside the front compartment, trying to remember which way the thread loops through that tiny metal case.

Drop-in bobbin systems eliminate that frustration entirely. Instead of wrestling with a removable case tucked behind a front panel, you simply drop the bobbin into a clear compartment on top of your machine, snap the cover shut, and you’re ready to sew.

The best sewing machine drop-in bobbin models combine trouble-free loading with reliable stitching performance, giving you more time to create and less time troubleshooting. Whether you’re hemming curtains or piecing quilts, the right machine transforms your workflow from start to finish.

Table Of Contents

Key Takeaways

- Drop-in bobbin systems cut loading time by 35–50% compared to front-loading designs, eliminating the need to wrestle with removable cases while providing clear visibility to prevent threading errors and mid-seam thread runout.

- Heavy-duty models like the Singer 4423 deliver 1,100 stitches per minute with metal frame construction for thick fabrics, while lightweight options such as the Singer M1000 at 5.5 pounds prioritize portability for quick repairs and light materials.

- Drop-in bobbins require needle-plate removal every 2–3 bobbin changes for proper lint cleaning, and while factory-set tension simplifies operation, it offers less direct adjustment control than vertical bobbin systems with external tension screws.

- Match your machine choice to actual project demands—basic models with 23–32 stitches handle everyday sewing, while midrange options offering 600+ stitches and one-step buttonholes provide creative flexibility without sacrificing the convenience of top-loading bobbin access.

Top 6 Sewing Machines With Drop-in Bobbin

You’ve got plenty of options regarding drop-in bobbin machines, but not all of them deliver the same mix of features and reliability.

We’ve narrowed down the field to six models that stand out for home sewers who want straightforward bobbin access without sacrificing performance. Here’s what made the cut.

1. Portable Sewing Machine For Home

You’ll find the Brother XM2701 checks every box for home sewing tips and machine portability. At just 12.6 pounds, this portable sewing machine tucks into closets or slides between rooms without breaking a sweat.

The Quick-Set top drop-in bobbin system eliminates threading headaches, while 27 built-in stitches handle home decor projects and quick repairs.

Six included presser feet mean you won’t need separate purchases for sewing machine maintenance, and the 25-year warranty backs your investment. That’s control and freedom in a compact, storage-friendly package.

Best For: Home sewists who need a lightweight, beginner-friendly machine that’s easy to move between rooms and store in small spaces.

- Quick-Set drop-in bobbin system is jam-resistant and eliminates manual bobbin threading frustrations

- Includes 6 presser feet right out of the box, so you can tackle buttonholes, zippers, and hems without buying extras

- 25-year limited warranty provides long-term peace of mind for occasional home use

- At 12.6 pounds, it’s slightly heavier than some ultra-compact models like the SINGER at 10.41 lbs

- 27 built-in stitches may feel limiting compared to computerized machines with more programmable options

- Mechanical stitch selector means less precise speed and tension control than computerized competitors like the Janome C30

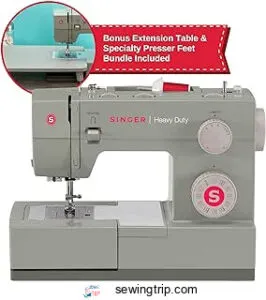

2. Heavy Duty Sewing Machine Singer

When you’re ready to power through denim or canvas, the Singer 4423 delivers 50% more muscle than standard machines. Its metal frame construction and 1,100-stitches-per-minute speed make heavy-duty sewing machines like this one unstoppable for thick fabrics.

The top drop-in bobbin with a clear cover keeps thread changes visible and fast, while automatic threading saves setup time.

At 14.6 pounds with 23 built-in stitches, you’ve got the sewing machine durability and high-speed stitching to tackle garments, home décor, and repairs without hesitation.

Best For: Sewers tackling thick fabrics like denim, canvas, and leather who need a fast, durable machine that can handle heavy-duty projects without slowing down.

- Powerful motor delivers 1,100 stitches per minute—significantly faster than most home machines—so you finish projects quickly.

- Metal frame construction provides stability and skip-free stitching, even when working through multiple layers of heavy fabric.

- Top drop-in bobbin with clear cover makes threading easy to see and change, cutting down on setup frustration.

- Struggles with stretchy knits, so it’s not ideal if you frequently sew activewear or jersey fabrics.

- LED work light is dim and may require additional lighting for detailed work in low-light conditions.

- Plastic thread spool holder feels fragile and could break with rough handling or frequent use.

3. Singer Quantum Stylist Sewing Machine

When you need versatility beyond raw power, the Singer Quantum Stylist 9960 brings 600 built-in stitches and 13 one-step buttonholes to your workspace. This Singer sewing machine pairs automatic threading with a top drop-in bobbin system, giving you bobbin visibility through a transparent cover so you never run out mid-seam.

Free arm sewing manages sleeves and cuffs effortlessly, while sewing speed control up to 850 stitches per minute lets you match pace to fabric.

With stitch pattern variety spanning decorative, quilting, and alphanumeric options, you’ve got creative freedom.

Best For: Intermediate to advanced sewers who want extensive stitch variety and decorative options without giving up the convenience of a drop-in bobbin system.

- 600 built-in stitches with mirror-imaging and elongation functions give you nearly unlimited creative possibilities for garments, quilts, and home décor projects.

- Top drop-in bobbin with transparent cover lets you see exactly how much thread remains, preventing frustrating mid-project run-outs.

- Fast 850 stitches-per-minute speed with instant start/stop and adjustable control helps you power through large projects while maintaining precision on detailed work.

- The sheer number of features and stitch options can overwhelm beginners who just need basic straight and zigzag stitches.

- At 14.6 pounds it’s heavier than many domestic machines, making it less portable if you attend sewing classes or quilting groups.

- Some users report the automatic needle threader can be finicky and may require patience or manual threading as a backup.

4. Singer Heavy Duty Sewing Machine Bundle

The Singer Heavy Duty Sewing Machine Bundle delivers a powerful 1,100-stitch-per-minute motor and full-metal frame alongside curated accessory kits—walking feet, needles, and a hard case—at a discounted bundle pricing that beats piecemeal purchases.

You’ll tackle denim, canvas, and leather with confidence thanks to the machine’s durability and piercing power, while the top drop-in bobbin system keeps thread visible and loading fast.

With 32 stitches, a 25-year warranty, and accessories chosen to match the machine’s heavy-duty capability, you’re equipped for both everyday projects and demanding workloads.

Best For: Sewers who regularly work with heavy fabrics like denim, canvas, and leather and want a durable machine with essential accessories included at a better price than buying separately.

- Powerful 1,100-stitch-per-minute motor and full-metal frame handle thick materials with strong piercing power and long-term durability.

- Bundle saves money by including valuable accessories like walking feet, specialty needles, and a hard case matched to the machine’s heavy-duty capabilities.

- Top drop-in bobbin system with clear cover makes threading quick and lets you see remaining thread at a glance.

- Heavier weight makes the machine harder to move around or transport despite the included case.

- Some users report issues with thread jamming at the upright spool pin, requiring attention to setup and threading.

- Not ideal for industrial or continuous professional use—better suited to home and hobby workloads even with heavy fabrics.

5. Singer Heavy Duty Sewing Machine Kit

Accessory-packed Singer Sewing Machine Kits transform the Heavy Duty 4411 into a complete workstation for tackling canvas, denim, and layered projects right out of the box. You’ll get specialty feet—walking foot, non-stick foot—plus heavy-duty needles and a quilting guide, all chosen to match the Top Dropin Bobbin machine’s 1,100-stitch-per-minute speed and metal frame.

These Kit Bundle Options eliminate guesswork for beginners while giving experienced sewers the tools Heavy Duty Sewing Machines need for Sewing Machine Maintenance and Repair-free operation on thick fabrics.

Best For: Sewers who want to start heavy-duty projects like denim jackets or canvas bags immediately without hunting down specialty feet and needles separately.

- Includes walking foot, non-stick foot, and heavy-duty needles designed specifically for thick fabrics and multiple layers

- Bundles essential accessories at a lower combined price than buying the 4411, 4423, 4432, or 4452 machine and add-ons individually

- Covered by full Singer warranty with app support, so you get the same 1,100-stitch-per-minute motor strength and top drop-in bobbin convenience as standalone models

- The full metal frame adds weight, making the machine less portable than lighter domestic models

- Upright spool pin can cause thread to wrap and jam during high-speed sewing if not monitored

- Not ideal for advanced sewers who need computerized stitch editing or hundreds of decorative patterns beyond the 23–32 stitches offered

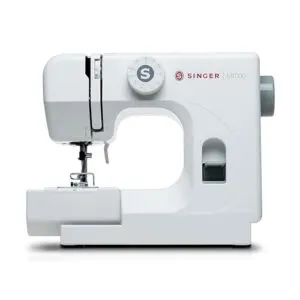

6. Singer M1000 Lightweight Mending Machine

At 5.5 pounds, the Singer M1000 shrinks your workspace demands while delivering 32 stitch applications through a Top Drop-in Bobbin with a transparent cover—perfect for mending techniques on light cotton and woven repairs. You’ll master thread management quickly thanks to printed threading guides, and the free arm lets you tackle cuffs and sleeves without fumbling.

This portable sewing machine suits quick fixes and fabric selection within its light-to-medium range, though sewing speed stays fixed and machine maintenance becomes critical when durability concerns surface in user reviews.

Best For: Beginners or occasional sewers who need a compact, lightweight machine for quick clothing repairs, hemming, and simple projects with light to medium-weight fabrics.

- Extremely portable at just 5.5 lbs with a compact design that’s easy to store and move around

- Simple operation with 32 preset stitch applications and easy top drop-in bobbin system that’s beginner-friendly

- Free arm functionality and built-in LED light make it easier to work on hems, cuffs, and sleeves with better visibility

- Not suitable for thick or heavy fabrics like denim or leather, limiting project variety

- Durability concerns reported by users, including bobbin malfunctions, thread bunching, and breakdowns after limited use

- Fixed sewing speed and reported issues with customer support and warranty service accessibility

Key Features of Drop-in Bobbin Systems

Drop-in bobbin systems have become a favorite among sewers because they’re easier to see, load, and adjust than older front-loading designs. You’ll notice the difference right away when you drop a bobbin into the clear window and skip the fumbling with a separate case.

Let’s look at the key features that make these systems so practical for everyday sewing.

Bobbin Holder Vs. Bobbin Case Differences

You’ll often see “bobbin holder” and “bobbin case” used interchangeably, but they’re not quite the same thing. The bobbin case is the component that grips your bobbin and controls thread tension through a spring and adjustment screw. Understanding this distinction helps you:

- Identify which part needs replacement when tension fails

- Choose between removable metal cases (adjustable) and inset plastic cases (factory-set)

- Match bobbin materials to your machine’s hook mechanism

- Troubleshoot thread nests and stitch imbalance

Drop-in bobbins simplify the entire bobbin system by keeping the case fixed in place. Proper maintenance of the bobbin case and bobbin is essential for preventing thread tension issues.

Improved Thread Visibility and Fewer Errors

That transparent window isn’t just for show—it’s your error-prevention tool. You’ll catch threading mistakes before they turn into bird’s nests, spot low thread before mid-seam runout, and confirm your bobbin sits correctly without second-guessing. This thread management advantage keeps beginners on track and experienced sewers moving forward. Top sewing machines often feature automatic needle systems that simplify the threading process.

| Visibility Feature | Error Reduction Benefit |

|---|---|

| Clear bobbin cover | Confirms correct bobbin seating instantly |

| Printed thread path | Guides threading direction at a glance |

| Color-matched spools | Prevents mismatched thread accidents |

| Visible hook race | Spots lint buildup before jams occur |

| Open bobbin window | Shows remaining thread during long seams |

Top drop-in bobbins paired with an automatic needle threader transform setup from guesswork into confidence. You’ll master thread tension adjustment faster when you can watch the bobbin feed, and sewing machine parts explanation becomes hands-on learning. Drop-in bobbins turn sewing efficiency from aspiration into daily reality—no fumbling, no frustration, just forward motion on your projects.

Faster Bobbin Changes and Enhanced Efficiency

Time savings stack up fast: you’ll swap a drop-in bobbin in 20–30 seconds versus 40–60 with front-loaders—a 35–50% efficiency gain per change. Bobbin access from the top means no wrestling with quilts or garment bulk, no machine tilting, and instant workflow optimization.

Drop-in bobbins cut swap time by 35–50%, eliminating bulk wrestling and machine tilting for instant workflow gains

Pair that bobbin system with an automatic needle threader, and you’ve unlocked sewing productivity that keeps pace with your ambition.

Built-in Tension Adjustment and Jam Resistance

Modern drop-in bobbin systems pair horizontal rotary hooks with automatic thread tension control to cut jam risk dramatically. You’ll find computerized machines that adjust tension in real time—keeping stitches balanced across thick and thin fabrics—while transparent covers let you monitor bobbin calibration at a glance.

That combination delivers machine reliability and sewing efficiency beginners and pros can trust.

Comparing Drop-in Vs. Vertical Bobbin Designs

Choosing between a drop-in and vertical bobbin system affects everything from how quickly you can load thread to how often you’ll need to clean lint buildup.

Each design manages tension differently and demands its own maintenance routine.

Here’s what sets these two systems apart and how to decide which one fits your sewing style.

Technical Distinctions and Performance

Your choice between horizontal and vertical bobbin systems shapes everything from hook mechanics to speed optimization. Drop-in bobbins with rotary hooks deliver 800–1,100 stitches per minute—ideal for home projects—while vertical systems push past 2,000 on industrial floors.

Stitch formation stays balanced around a 60:40 thread ratio in both designs, but tension stability differs: vertical cases offer direct screw access for fine-tuning specialty threads, whereas top drop-in bobbin units rely on factory-set tension that’s harder to tweak.

Jam resistance improves with transparent drop-in covers, letting you spot tangles fast, though severe snags in horizontal mechanisms can hide dropped screws deep in the bed. Machine durability tilts toward all-metal vertical cases under continuous heavy use, while composite drop-in parts reduce noise but risk chipping.

Here’s how the core differences stack up:

| Feature | Drop-in (Horizontal) | Vertical (Front/Side-Load) |

|---|---|---|

| Hook type & speed | Rotary; 800–1,100 SPM typical | Oscillating or rotary; 2,000+ SPM industrial |

| Tension adjustment | Factory-set, indirect access | External screw, direct tuning |

| Jam visibility | High—clear cover shows tangles | Moderate—removable case aids extraction |

| Material & noise | Plastic/composite; quieter operation | All-metal; louder but more wear-resistant |

Both bobbin system architectures handle lightweight fabrics well at moderate speeds, but the bobbin mechanism you pick should match your throughput and the precision your projects demand.

Ease of Maintenance and Cleaning

Drop-in bobbins demand needle-plate removal every 2–3 bobbin changes to vacuum lint from feed dog grooves, while vertical cases pop out for quick brushing. Both systems need 1–2 drops of oil on metal-on-metal parts every 30 days, though drop-in mechanisms come pre-greased.

| Maintenance Task | Drop-in (Horizontal) | Vertical (Front-Load) |

|---|---|---|

| Bobbin area access | Requires stitch plate removal | Case lifts out—no tools needed |

| Lint removal frequency | Clean every 8–10 sewing hours | Brush after every 2–3 bobbin changes |

| Oil requirements | 1–2 drops on wick; pre-greased | Apply to case bottom monthly |

| Professional service interval | Every 12–18 months typical | Annual for heavy use |

Compacted lint knocks your bobbin case out of alignment, so vacuuming narrow crevices keeps stitches smooth.

Manufacturer Terminology Variations

Manufacturers scramble the bobbin case conversation with overlapping labels. Brother’s “quick-set drop-in” equals Singer’s “top-loading horizontal rotary hook,” yet both describe the same mechanism. You’ll see “jam-resistant” paired with “transparent cover” in retail copy, while technical specs mention “full rotary hook” separately—industry standards haven’t caught up to marketing language.

| Brand Term | Technical Equivalent | What It Really Means |

|---|---|---|

| Quick-set drop-in bobbin | Horizontal full rotary hook | Top-loading, 360° rotation |

| Front-loading machine | Vertical oscillating hook | Case inserts from front, arc motion |

| Easy-load top bobbin | Top drop-in system | Needle-plate insertion, no door |

User Experience and Satisfaction Insights

Real-world performance tells you more than specs ever could. Beginners want machines that won’t fight them during setup, while experienced sewers look for reliability that holds up project after project.

Let’s break down what actual users report about ease of use, common issues, and practical factors like portability and warranty support.

Beginner-friendly Operation and Setup

You’ll find easy threading and quick setup transform your first sewing session into a win instead of a wrestling match. Top drop-in bobbin machines simplify those early moments with features that guide you forward:

- Transparent covers let you monitor thread levels and catch mistakes before they happen.

- Printed diagrams right on the machine body eliminate constant manual flipping.

- Automatic needle threaders remove the squinting and fumbling for beginners.

- One-step buttonholes deliver professional results without multi-step guesswork.

- Preset stitch settings reduce trial-and-error, so you start sewing immediately.

These sewing machine accessories and beginner modes offer real user guidance—sewing for beginners becomes accessible, not intimidating.

Reliability and Common User Feedback

Overwhelmingly, drop-in bobbin models earn 4.45 out of 5 stars across thousands of sewing machine reviews, signaling strong machine longevity and error reduction in real homes. Top drop-in bobbin systems pair jam resistance with transparent covers, driving satisfaction when you compare sewing machine parts and weaving performance across brands.

You’ll notice user complaints cluster around tension and threading setup—not bobbin design failures—so mastering those basics unlocks sewing efficiency.

Portability, Weight, and Warranty Considerations

Portability transforms drop-in bobbin sewing machines into travel-ready workhorses when you balance weight against durability. Lightweight materials in portable sewing machines—usually 10 to 15 pounds for full-function models—pair machine mobility with compact designs.

The Singer M1000 weighs 5.5 pounds, yet top drop-in bobbin heavy-duty sewing machines offer sturdier frames and longer warranties, often three years for home use versus one year for business applications.

How to Choose The Best Drop-in Bobbin Machine

Choosing the right drop-in bobbin machine means matching its capabilities to what you’ll actually sew. You’ll want to think beyond the bobbin system itself and consider how stitch variety, buttonhole options, and long-term support fit your projects and budget.

Here’s what to focus on as you narrow down your choice.

Matching Machine Features to Sewing Needs

Your choice hinges on what you’ll actually sew. Light cottons and repairs? A compact machine under 10 kg with 650–1,000 stitches per minute fits the bill.

Tackling upholstery or denim demands higher sewing speed, reinforced feed systems, and a sturdy frame.

Match fabric types and user skill to machine weight and stitch density—top drop-in bobbin models with smart sewing technology deliver control without complexity.

Evaluating Stitch Options and Buttonholes

Stitch variety separates basic from powerhouse machines. Entry-level drop-in bobbin models offer 8 to 32 stitches, while midrange options push 600 for sophisticated fabric compatibility.

Look for one-step automatic buttonholes if you value sewing efficiency; four-step systems demand manual control on each side. Computerized models store buttonhole styles in memory, ensuring consistent stitch quality across plackets.

Match thread tension adjustments to your fabrics for impeccable weaving results.

Considering Support, Price, and Long-term Value

Singer’s 25-year warranty on heavy duty sewing machine heads sounds impressive until you realize motors get just two years and adjustments only 90 days. Customer service reports reveal hour-long hold times and sluggish refund processing.

Factor in 15% annual depreciation and potential maintenance costs beyond the electronics window.

Balance upfront price comparison against long-term value—machines with accessible parts, responsive support, and solid warranty terms for drop-in bobbins deliver better return over decades of weaving projects.

Frequently Asked Questions (FAQs)

How often should I clean my drop-in bobbin?

Lint buildup silently sabotages stitch quality. Clean your drop-in bobbin after every 2–3 bobbin changes or each project to maintain sewing efficiency, prevent jamming, and extend machine longevity through proper bobbin maintenance and lint removal.

Can I use plastic bobbins in any machine?

No—bobbin material compatibility isn’t universal. Always check your machine’s manual for approved plastic or metal specifications.

Using the wrong bobbin material can trigger tension issues, thread jams, and even damage your bobbin case or hook mechanism.

What causes thread bunching under the fabric?

Incorrect thread tension is the main culprit—loose upper tension or tight bobbin tension creates loops underneath.

Threading errors, wrong bobbin insertion, forgetting to lower the presser foot, and dull needles also cause bunching in your bobbin case.

Do drop-in bobbins work with thick fabrics?

Yes, but they struggle with multiple denim layers. Heavy-duty machines like the Singer 4423 handle thick fabrics better, yet tension adjustment and slower speeds prevent bobbin thread catching issues when penetrating three-plus layers.

How do I fix incorrect bobbin tension?

Start by cleaning lint from your bobbin case—the top culprit behind tension adjustment headaches.

Then turn the tension screw clockwise in quarter-turn increments, test-stitching after each change to restore balanced thread visibility and eliminate looping issues.

Conclusion

Here’s the truth: you don’t need to tolerate bobbin headaches. The best sewing machine drop-in bobbin models prove that simplicity and performance can coexist—no fumbling with hidden cases, no guesswork about thread paths.

You load, you sew, you finish. Match your machine to your actual projects, prioritize clear tension adjustment, and choose a model that respects your time.

When your tools work with you instead of against you, your creativity flows without interruption.

- https://www.grandviewresearch.com/industry-analysis/sewing-machine-market-report

- https://www.marketresearch.com/Global-Industry-Analysts-v1039/Sewing-Machines-42588491/

- https://www.marketdataforecast.com/market-reports/sewing-machines-market

- https://www.prnewswire.com/news-releases/global-sewing-machines-strategicanalysis-report-2023-market-to-reach-5-2-billion-by-2030---rising-demand-for-advanced-and-feature-rich-sewing-machines-to-drive-healthy-long-term-gains-302011183.html

- https://insight.voc.ai/insight/sewing-machines