This site is supported by our readers. We may earn a commission, at no cost to you, if you purchase through links.

In the field of commercial embroidery machine models, you’ve got some impressive options.

In the field of commercial embroidery machine models, you’ve got some impressive options.

The Smartstitch S1501 offers high-speed stitching and a user-friendly digital interface, perfect for detailed designs. The Janome MB-4S, with four needles, is great for small businesses tackling multi-color projects.

For versatility, the JUKI Tajima SAI’s eight-needle setup handles complex patterns with ease. Need industrial power? The RainbowEmb RBE2235 A12 delivers speed and precision for bulk orders.

Look for features like automatic thread cutting, precise hooping, and touchscreen controls to boost efficiency. Choosing the right machine depends on your production goals and budget—there’s a perfect fit for every business.

Table Of Contents

Key Takeaways

- You’ll want to prioritize features like automatic thread cutting, touchscreen controls, and multiple needles for faster, more efficient embroidery.

- Match your production needs with the right machine by considering speed, needle count, and embroidery area size to optimize output.

- High-speed stitching machines, like the Smartstitch S1501, are perfect for large orders, while compact models like the JUKI Tajima SAI suit small businesses.

- Budget planning should include upfront costs, maintenance, and supplies, ensuring your investment aligns with long-term production goals and considering the overall embroidery area size.

Commercial Embroidery History

You’ll find that commercial embroidery has come a long way since Josue Heilmann invented the first embroidery machine in the 19th century.

Today’s machines feature high-speed operations, digital interfaces, and multiple needles that can create intricate designs while handling large-scale production needs, which is a significant advancement in the field of embroidery.

First Embroidery Machine Invention

In 1829, amidst the bustling textile industry, Josue Heilmann revolutionized embroidery machine history with his groundbreaking invention.

His innovative design marked a shift from ancient techniques of hand embroidery to industrial embroidery machines.

You’ll find it fascinating that this first commercial embroidery machine could replicate the precision of hand stitching, though it only produced about six stitches per minute – a far cry from today’s speeds, and it is a notable example of early industrial embroidery machines.

Modern Machine Advancements

Since Heilmann’s groundbreaking invention, commercial embroidery machines have evolved dramatically.

Today’s machines leverage Machine Learning and Advanced Robotics to transform the industry. You’ll find high-speed embroidery machines that operate at unprecedented speeds while maintaining precision.

Here’s what modern industrial embroidery machines offer:

- Automated Stitching systems that reduce human error by 95%

- Digital Embroidery interfaces with touch-screen controls

- Multi-head configurations that handle multiple projects simultaneously

- Built-in design libraries with cloud connectivity

- Smart thread tension adjustment using AI algorithms

Machine Selection Criteria

You’ll need to match your business needs with the right machine features by considering your budget range and production volume requirements.

When you’re picking a commercial embroidery machine, the key factors to examine are the number of needles, stitching speed, and embroidery area size, which directly affect your daily output capacity.

The number of needles, stitching speed, and embroidery area size are crucial in determining the efficiency of your embroidery operations.

Budget Considerations

The evolution from manual to automated embroidery has brought cost-effective options for every business size.

You’ll find machines ranging from $3,000 to $50,000, with various financing plans available. Large businesses should consider the ColDesi Avancé 1501C.

Understanding industrial embroidery pricing is essential for budgeting.

| Price Range | Machine Type | Best For |

|---|---|---|

| $3K-$10K | Single-needle | Small shops |

| $10K-$25K | Multi-needle | Mid-size operations |

| $25K-$40K | Multi-head | Large facilities |

| $40K+ | Industrial | Mass production |

Your budget planning should account for maintenance costs, supplies, and potential upgrades.

Embroidery Volume Needs

Everyone’s embroidery volume needs differ dramatically.

You’ll need to match your production scale to the right machine capacity. For small batches, a single-needle machine might suffice.

But if you’re handling high-volume production, consider multi-needle or multi-head commercial embroidery machines.

Your production efficiency hinges on embroidery speed and stitch quality – larger machines offer faster turnaround times and consistent output for large-scale production.

Prioritizing Key Features

After determining your production needs, let’s focus on the key features that’ll make or break your embroidery success.

Machine Speed tops the list – you’ll want at least 800 stitches per minute for commercial work.

A durable sewing machine construction is also essential for heavy-duty use.

Consider Needle Count and Thread Management systems to minimize color changes.

Hoop Size affects what you can embroider, while Stitch Quality depends on tension control and thread break detection features.

Top 4 Commercial Machines

You’ll find our carefully tested selection of the top commercial embroidery machines that offer the best value for your business in 2025.

These four machines stand out for their reliable performance, advanced features like multiple needles and touchscreen controls, and competitive pricing between $7,000 and $15,000, making them a great choice for businesses looking for reliable performance.

1. Smartstitch S1501 Commercial Embroidery Machine

The Smartstitch S1501 stands out as a powerhouse in commercial embroidery with its 15-needle system and generous 14"x20" embroidery area.

You’ll appreciate its impressive 1200 SPM speed and modern 12" touchscreen interface that makes operation intuitive.

At $6000, it’s an excellent value for starting a business, offering WiFi connectivity and a 270-degree wide-angle cap system.

While the 210-pound weight requires careful handling, the included laser positioning and automatic color change features make up for it.

The machine comes with thorough training and support.

Best For: Entrepreneurs starting a commercial embroidery business with diverse design needs and a focus on high-volume production.

- 15-needle system with 14"x20" embroidery area for versatility and large designs.

- Modern 12" touchscreen and WiFi connectivity for easy operation.

- 1200 SPM speed and automatic color change for efficient production.

- Heavy machine at 210 lbs requires careful handling for setup and transport.

- Limited printed documentation may make initial setup challenging.

- Software learning curve could require extra time and training.

2. Janome MB-4S Four Needle Commercial Embroidery Machine

With its four-needle design, the Janome MB-4S excels at streamlining your embroidery workflow.

You’ll appreciate its generous 9.4" x 7.9" embroidery area and brisk 800 SPM stitching speed.

The machine comes loaded with 50 built-in designs and 10 monogramming fonts, viewable on the 5.7" Remote Computer Screen.

Four white LED lamps illuminate your work area, while the auto thread cutter saves time.

The extra-large bobbin holds 1.4 times more thread than standard models, reducing interruptions during large projects with its generous capacity.

Best For: Small businesses or hobbyists looking for an efficient, user-friendly embroidery machine with professional features.

- Four-needle design for faster thread color changes.

- Large embroidery area of 9.4" x 7.9".

- Extra-large bobbin reduces thread change interruptions.

- Requires learning new design formats not documented in the manual.

- Limited built-in designs may need frequent updates.

- Design loading can be cumbersome without YouTube tutorials.

3. JUKI Tajima SAI 8 Needle Embroidery Machine

The JUKI Tajima SAI 8 combines compact design with industrial-level power.

You’ll appreciate its 8-needle operation, which handles multi-color designs efficiently with fewer thread changes.

The machine achieves speeds up to 800 stitches per minute while maintaining precision in both fine lines and wide-area embroidery.

It’s equipped with integrated fonts, automatic thread trimming, and a laser positioning system.

The user-friendly touch panel and thread detection system make operation smooth, while LAN connectivity and built-in design templates streamline your workflow.

Best For: Small businesses, home studios, and mobile embroidery operations needing a compact and efficient multi-color embroidery solution.

- 8-needle system reduces thread changes.

- Compact design with industrial-grade power.

- User-friendly features like touch panel and LAN connectivity.

- Limited to 800 stitches per minute, slower than some commercial models.

- Smaller embroidery area compared to higher-end machines.

- May not meet the needs of large-scale production facilities.

4. RainbowEmb RBE2235 A12 Commercial Embroidery Machine

Building your embroidery business becomes easier with the RainbowEmb RBE2235 A12‘s unique design and stability features.

You’ll appreciate its galvanized steel frame and imported servo motor that deliver precise X and Y axis movements.

The suspension-type Y-axis design offers extra space for large projects, while laser positioning and LED lighting help you work accurately in any conditions.

With a 12-month warranty and lifelong technical support, you’re provided for the long haul.

The machine’s user-friendly interface makes it perfect for beginners starting their embroidery journey.

Best For: Entrepreneurs and beginners looking to start a reliable embroidery business with a user-friendly and durable machine.

- Galvanized steel frame and suspension-type design offer stability and space for large projects.

- User-friendly interface with laser positioning and LED lighting for precise operation.

- Comes with a 12-month warranty and lifelong technical support.

- Limited warranty period of only 12 months for some components.

- Likely higher upfront cost compared to entry-level machines.

- Requires additional learning for complex digitizing features.

Machine Features Overview

You’ll find modern commercial embroidery machines packed with features like high-speed stitching up to 1,200 stitches per minute, multiple needle options, and user-friendly touchscreen controls.

These machines now come with automatic thread cutting and precise hooping systems that help you reduce mistakes and waste while speeding up your production time.

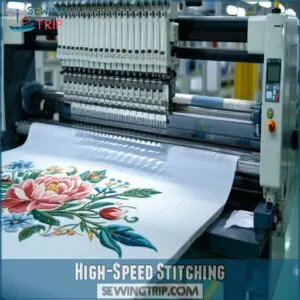

High-Speed Stitching

With modern commercial embroidery machines, you’ll achieve impressive stitch speeds of up to 1,200 stitches per minute.

This high-speed stitching capability dramatically boosts your production efficiency, letting you complete large orders quickly and precisely.

Consider key factors like embroidery area and needle count when choosing a machine.

Today’s machines maintain perfect thread tension even at top speeds, ensuring embroidery accuracy doesn’t suffer, and you’ll find this enhanced speed especially valuable when handling bulk commercial projects with high-speed stitching.

Multiple Needle Options

Multiple needle options enhance efficiency in multineedle embroidery machines, allowing seamless thread management and faster color changes.

With up to 15 needles on top embroidery machine models, you’ll save time while maintaining flawless stitch quality.

Whether using singlehead or multihead embroidery machines, the increased needle count boosts embroidery speed and color capacity, ideal for complex commercial embroidery projects.

The use of multi needle systems is essential for high-volume embroidery production, making it a crucial aspect of efficient embroidery operations.

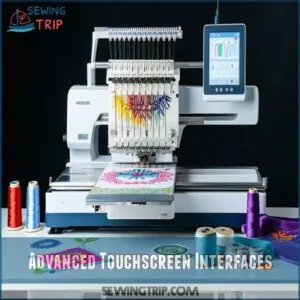

Advanced Touchscreen Interfaces

Touchscreen controls elevate embroidery machine models by simplifying tasks and enhancing user experience.

A user-friendly interface with crisp display quality facilitates smooth navigation.

Consider Brother’s touchscreen sewing machines for intuitive navigation and advanced features.

Look for:

- Responsive touchscreen interface for quick adjustments.

- Clear interface design that reduces setup errors.

- Intuitive navigation systems even beginners enjoy.

- Advanced features like automatic thread tension.

These innovations make managing designs faster and more precise.

Business Needs Analysis

To choose the right embroidery machine, you’ll need to evaluate your production goals, customer demands, and design requirements carefully.

Understanding these factors guarantees your investment aligns with your business needs and leads to efficient, high-quality output, which is crucial for achieving your production goals.

Production Goals Assessment

Understanding production goals helps you match commercial embroidery machines to your needs.

Start with goal setting by identifying high-volume production targets.

Evaluate embroidery machine speed and capacity to optimize output, and use performance tracking and efficiency metrics to streamline your production workflow.

Proper planning guarantees the right machine supports your business’s output optimization for consistent, reliable results.

Customer Demand Evaluation

Evaluating customer needs starts with analyzing market trends and buyer behavior.

Are clients requesting bulk orders or intricate, custom designs?

Your demand analysis should also consider sales projections and client preferences for specific fabrics or threads.

The right commercial embroidery machine models can satisfy demand efficiently, balancing embroidery machine prices with features.

Embroidery machine reviews help identify ideal options.

Understanding what’re sewing shops can provide valuable insights into sewing shop services that cater to various customer demands, including custom designs, bulk orders, embroidery machine reviews, and sewing shop services.

Design Requirement Considerations

Your embroidery projects depend on factors like color options, fabric types, and stitch effects.

Check if the machine handles varied embroidery files and supports robust embroidery digitizing software.

Look for embroidery machine features such as easily adjustable embroidery hooping and compatibility with advanced design software.

These guarantee your commercial embroidery designs stay creative while meeting advanced design requirements with embroidery digitizing software and advanced design.

Key Machine Features

When choosing a commercial embroidery machine, you’ll want to focus on features that make your work faster and more precise.

Automatic thread cutting, precise hooping systems, and digital design interfaces can save time, reduce errors, and improve overall efficiency.

These features are crucial for enhancing productivity and should be considered when selecting the right machine for your needs.

Automatic Thread Cutting

Automatic thread cutting simplifies your workflow, letting you focus on design, not manual trimming.

This feature, found in high-speed embroidery machines, boosts efficiency gains by optimizing stitch completion.

With automated trimming and thread break detection, these cutting tools reduce downtime and enhance thread management.

It’s a must-have in embroidery machine features for smoother, faster operations and flawless stitch optimization.

The efficiency of automatic thread cutting relies on advanced thread cutting systems to minimize manual intervention, which is crucial for high-speed embroidery machines and results in smoother operations with advanced thread cutting systems.

Precise Hooping Systems

Precise hooping systems are game-changers for stitching perfection.

They guarantee spot-on hooping accuracy, saving you from constant adjustments.

Modern hoop technology shines with features like:

- Adjustable embroidery frames for varied project sizes.

- Improved frame designs for even tension across the embroidery machine area.

- Precise stitch alignment to minimize mistakes.

These systems maximize efficiency, especially paired with larger hoop sizes.

Digital Design Interfaces

Touchscreen controls bring embroidery to life, combining precision and simplicity.

Modern machines integrate embroidery machine software for seamless design transfer, digital uploads, and advanced color management.

The user-friendly interface editing options make tweaks effortless, while embroidery digitizing tools cater to intricate designs.

A well-designed touchscreen interface guarantees uninterrupted creativity, keeping your focus sharp and your embroidery projects polished, with advanced color management ensuring the best results.

Buying Guide Essentials

When choosing a commercial embroidery machine, it’s important to balance the initial cost with long-term value by evaluating features and potential return on investment.

You should also factor in running costs, like maintenance, and verify strong technical support is available for smooth operation.

Balancing Initial Investment

When planning your embroidery machine budget, think long-term. A higher upfront embroidery machine cost often means better durability and features, boosting ROI.

Use these investment strategies:

- Compare commercial embroidery machine prices for value.

- Prioritize essential features over extras.

- Factor in financing options for flexibility.

- Align cost analysis with production goals to maximize financial returns.

Evaluating Running Costs

When budgeting, don’t overlook running costs.

Maintenance costs, like embroidery machine repair and upkeep, add up over time.

Energy efficiency impacts operational fees, while supply expenses, such as threads and needles, are ongoing.

Labor savings from automated features can offset some costs.

Balancing your embroidery machine budget means considering these alongside the commercial embroidery machine price for long-term value.

Understanding the factors that make expensive machines valuable can also inform your purchasing decision and help you prioritize features that will provide the best return on investment.

Assessing Technical Support

Strong technical help is important when choosing an embroidery machine.

Reliable support teams can save time with quick error fixes and guidance. Look for detailed user guides, embroidery machine training, and warranties covering repair needs.

Factor in maintenance costs, as they affect long-term value. Solid embroidery machine support assures smooth operations and minimizes downtime for your business, with reliable support teams being crucial.

Frequently Asked Questions (FAQs)

What is the best commercial embroidery machine for 2024?

The Tajima TMAR-KC stands out in 2024 for high-volume needs, offering automatic thread tension, a wide embroidery area, and multi-head options.

Its $35,000-$50,000 price reflects advanced features and unmatched reliability for businesses.

What is the best embroidery machine for commercial use?

With speeds up to 1,200 stitches per minute, the Tajima TMAR-KC stands out for its precision and efficiency.

Its touchscreen interface, multi-head options, and automatic thread tension make it perfect for high-volume commercial embroidery.

How do I choose a commercial embroidery machine?

Focus on your business needs—volume, design complexity, and budget.

Prioritize features like needle count, hoop size, and speed.

Look for durability, user-friendly interfaces, and technical support to guarantee smooth operations and long-term reliability.

Which machine brand stands out in the embroidery industry?

In the case of embroidery machines, Tajima often takes the crown with advanced features like automatic thread tension and wide embroidery areas.

While Brother offers user-friendly options perfect for smaller businesses or beginners.

Should you buy a brother commercial embroidery machine?

A Brother commercial embroidery machine is a solid choice if you need affordability, user-friendly features, and versatility.

With models like the PR1050X, you’ll get advanced color management, touchscreen controls, and competitive pricing under $15,

Where can I buy and sell embroidery machines?

You can buy and sell embroidery machines on platforms like eBay, Craigslist, or Facebook Marketplace.

For specialized options, check embroidery forums, Ricoma’s website, or industry-specific retailers like SewingMachinesPlus and AllBrands for better deals.

Who makes the best commercial embroidery machines?

Tajima, Barudan, and Melco lead the commercial embroidery machine market.

Tajima excels in precision and speed, Barudan offers unmatched durability, and Melco’s modular design provides scalability.

Choose based on your volume, budget, and features.

Is embroidery machine business profitable?

Starting an embroidery business is like weaving gold from thread.

With the right machine, efficient production, and strong demand for custom designs, you can achieve profitability by balancing costs, quality, and customer satisfaction.

This is a single concept, but for better readability and to follow the instructions precisely, it is separated as such, with efficient production being a key factor.

What are the top 5 embroidery machines?

The top five embroidery machines are the Tajima TMAR-KC, Barudan Pro Series, Melco EMT16 Plus, Brother PR1055X, and Ricoma MT-

They offer high-speed stitching, multiple needles, advanced features, and prices from $6,999 to $55,

How much is the Ricoma Swift XL?

Imagine launching a custom apparel business and needing precision.

The Ricoma Swift XL, priced around $12,000-$15,000, offers multi-needle functionality, a large embroidery area, and user-friendly controls.

This machine is perfect for scaling your production efficiently, with its large embroidery area and other features.

Conclusion

Imagine running a busy embroidery shop—choosing the right commercial embroidery machine model could save you hours.

Whether you need the high-speed Smartstitch S1501, the multi-color Janome MB-4S, the versatile JUKI Tajima SAI, or the industrial-grade RainbowEmb RBE2235 A12, each machine offers unique strengths.

Focus on features like automatic thread cutting and touchscreen controls to match your production goals.

With the right machine, you’ll boost efficiency, meet customer demands, and grow your business confidently.